9 Things You Must Know When Designing A Membrane Switch

9 Things You Must Know When Designing A Membrane Switch

Designing a custom membrane switch keypad for your business requires careful consideration. To ensure a successful project, here are 10 key factors to keep in mind.

Clarify Your objectives As Soon As Possible

All things are difficult before they are easy, especially you don’t know what you are looking for. Whether you want something customized, or you have a completed design in your mind, or simply want a prototype to replace, it is needed to clarify your objectives to your engineers at the first beginning. They are expertise in this aspect and they know how to optimize your design to maximize space and enhance user experience or make your idea come true.

Your thoughts on your Human-Machine Interface (HMI) solutions

Before engineer or manufacturer gets involved, you are the one person who knows your HMI best. You know where should be changed and which element should be updated. Think about as many of these things as you can, and share your thoughts with your engineer. Meanwhile, provide feedback on what aspects you wish to retain or improve in the new membrane switch keypad. For example, traces/circuits, texts, or shapes you want to keep, let engineers know and this will be much useful when drawing membrane switch schematic.

How Your Keypads Will Be Operated?

Membrane switch keypads can be separated into tactile membrane switch and non-tactile membrane switch. The first one is we can touch the key buttons and press them to connect the circuit. Non-tactile membrane keypad means we can’t touch the buttons on the surface and it is a touch screen like the mobile phone. Specify how you will used the keypads and who will use it. Engineer needs this to know which material to use and how to design it, including sizes, thickness, adhesive types, metal dome types and other design considerations.

What Applications It Will Be Used?

For some experienced engineers, knowing their applications or end-application will help to save much time in design evaluation. They can provide the professional suggestions according to their experience and help to avoid potential risks during manufacturing. You must know, closely communicate with your engineers is the best way to improve the efficiency and make sure the high-quality of membrane switch, so make sure share more and more information with your engineers.

What Standard You want to Follow?

In the manufacturing industry, follow standard is very important. Determine any industry standards or regulations that your keypad must meet, such as UL94 for flammability or IP ratings for sealing. It’s crucial to understand which regulations are applicable to your situation, whether for traceability purposes or for ensuring compliance with sanitization and disinfection requirements.

What is Your Budget?

For any companies, it is very important to evaluate a new project budget in advance for the operation of company. Provide a clear budgetary framework to guide the design and manufacturing process. Balancing cost-effectiveness with quality ensures that the final product meets your financial objectives.

Would You Want to Have a Sample?

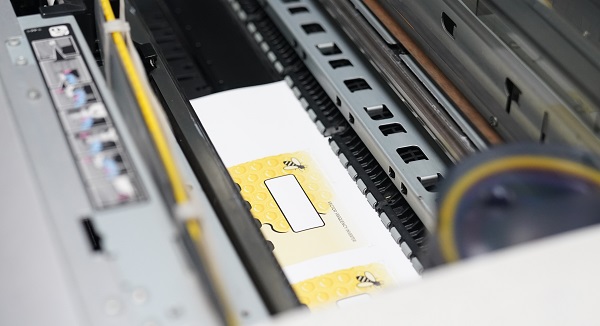

Consider creating prototypes or 3D models to evaluate the design before full-scale production. Prototyping allows for early identification and resolution of any design issues or modifications. Best team always make samples for customer before mass production.

Do You Possess a Design File?

It’s important to have all CAD, 3D, and vector files properly organized and easily accessible for order processing. Manufacturers might provide support for file conversion or modeling services if necessary.

What is your projected timeline?

Different with PCB manufacturing, membrane keypads fabrication involves design, evaluation, samples making, and mass production. So, clearly communicate with your supplier about your expected delivery time and require a timely process update is necessary.

You must know, from design and decide to manufacture is not an easy thing, there are many factors to considered during this period. Therefore, choose an experienced supplier is the best way to save time and money. If you want to elevate your products with the most dependable membrane switches available, your search ends here!! Our engineer team is very happy to work with you to find the best solution for your projects.

Know the Difference between Tactile and Non-Tactile Membrane Switching

When selecting the appropriate interface for a product, it can be wise to understand the differences between tactile and non-tactile membrane switches so that the engineer and the purchaser make a better decision. They are both very common in medical equipment, domestic appliances, and industrial equipment, though they do not present the same user experience. ...

Step-by-Step Guide to Selecting the Right Membrane Switch for Your Product

It is not easy to choose the appropriate interface for an electronic device with the number of various types of membrane switches. This is a basic, stepwise analysis to help product designers and manufacturers select the optimal choice. Step 1: Determine your Application Requirements Begin by making a list of locations where switches are used, ...

Top Membrane Switches for Home Electronics Projects in 2025

You can elevate your home electronic membrane switch project in 2025 with standout models such as the 4×4 Matrix 12 Keys Keypad from SOUSHINE, the rgb-enabled strip switches from Molex, and custom graphic switches by Panasonic. These switches offer slim profiles and reliable performance, making them easy to integrate into your DIY setup. You gain ...

Contact us online