Nameplate

PET nameplate is made by polyethylene terephthalate material, and its manufacturing process is very simple that only coats some colors and legends on its surface. Compared with PC nameplate, its cost is 5 times higher than PC material. The features of PET materials are including:

1. Excellent adhesion to color ink, and the ink can be directly attached to the surface of the material.

2. Corrosion-resistant, heat-resistant

3. Long service life

4. Extreme suitable for embossing

5. Good mechanical properties

A TPU nameplate is made from thermoplastic polyurethane (TPU), an environmentally friendly material that can naturally degrade in the soil after 30years. This is a significant advantage not found in other materials. Nowadays, it was popular used in various medical equipment, such as the medical bottle when we see from the hospital room. Here are some advantages listing as below:

1. High tensile and tear strength ability that surpassing many synthetic and natural rubbers.

2. Excellent abrasion resistance.

3. TPU retains its elasticity and performance at low temperatures, making it suitable for use in cold environments.

4. TPU material is recyclable, contributing to environmental sustainability.

PC (polycarbonate), is a durable and versatile thermoplastic material. Polycarbonate is known for its high impact resistance, clarity, and excellent ability to corrosion color ink into the material because of its good adhesion. These qualities make it a popular choice for manufacturing durable and long-lasting nameplates. But it also has some drawbacks when put into use, such as:

Not resistant to corrosion and high temperature.

The material is easily to fracture after 30,000 to 50,000 clicks. So, it is suitable for use fingers for operation if you want to keep longer lifespan.

Thinner PC is easier to fold and damage.

Poor mechanical performance compared to PET material.

Its maximum hardness only can be achieved HB class.

A PMMA nameplate typically refers to a nameplate made from a type of plastic called polymethyl methacrylate, which is commonly known by its trade names, such as Plexiglas or Acrylite. PMMA is a transparent thermoplastic that is often used as a lightweight and shatter-resistant alternative to glass. It has excellent optical clarity and weather resistance, making it suitable for various applications, including signage and nameplates.

PMMA material has very good hardness and excellent scratch-resistant, so people always used it in high-end applications, such as military destroyer, security doorbell. Due to the good hardness of PMMA, it cannot make the emboss like other materials, and it always be used for adding thickness for the whole product.

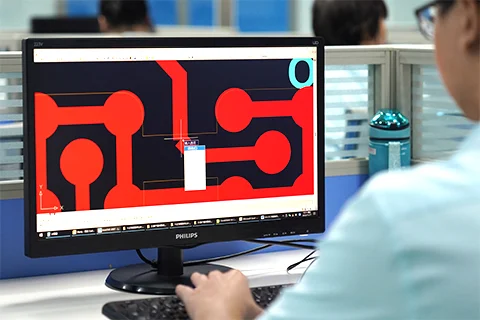

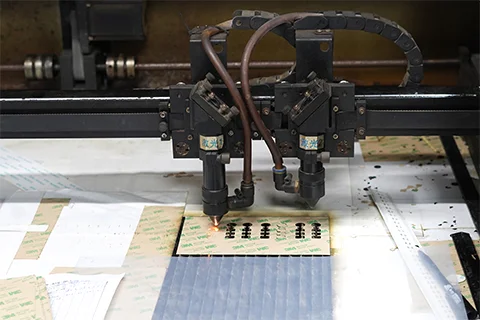

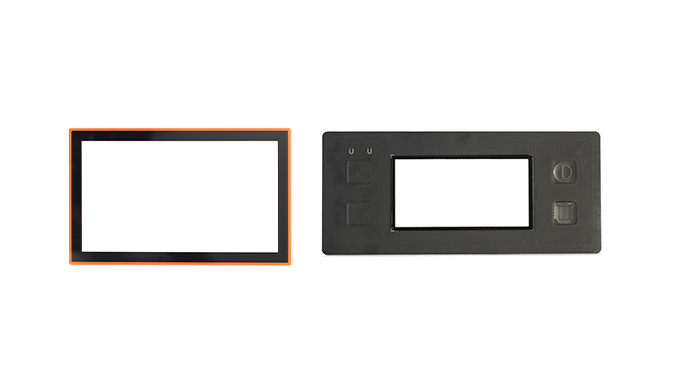

Nameplate Products Main Production Process

Choose the appropriate material for the nameplate based on the intended use and aesthetic requirements. Common materials used in Yu An include metals like aluminum or stainless steel.

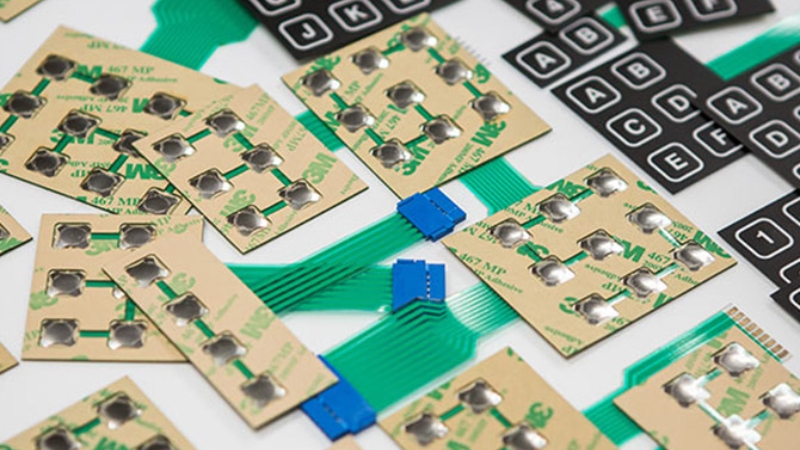

Our Advantages

| Comfort buttons | Water Proof | Chemical Resistant | Temperature Resistant |

Yu An Electronics is an experienced manufacturer that specializing in membrane switch, name plate, adhesive materials manufacturing. Contact us right now to get your first quotation.

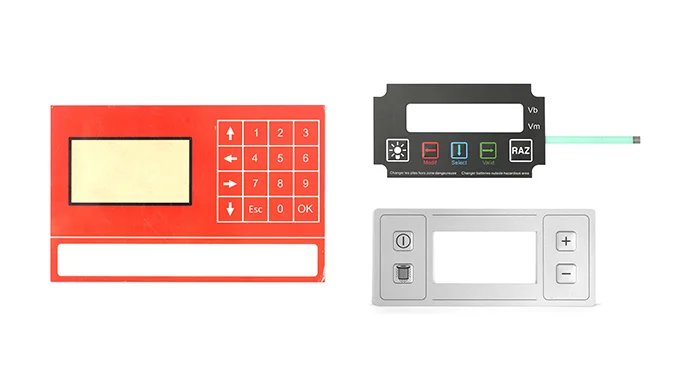

Nameplate Switch Is Used in Automation Machinery

A nameplate, also known as a name tag or label, can be referred to as a logo tag or logo nameplate. Therefore, we commonly use the term “Nameplate Logo” (trademark). Logo trademarks customized and produced using nameplates have become a highly popular material for creating logos in today’s context.

Nameplate Tactile Switch for Industrial Gas Meter

A nameplate, also known as a name tag or label, can be referred to as a logo tag or logo nameplate. Therefore, we commonly use the term “Nameplate Logo” (trademark). Logo trademarks customized and produced using nameplates have become a highly popular material for creating logos in today’s context.

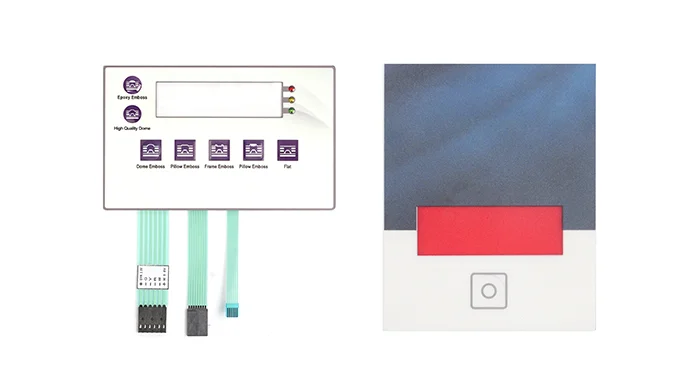

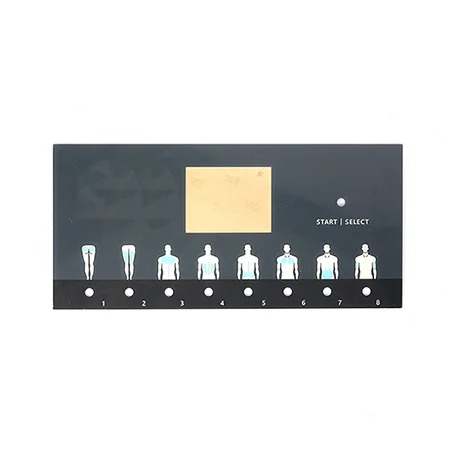

Body Massager Application Nameplate

A nameplate, also known as a name tag or label, can be referred to as a logo tag or logo nameplate. Therefore, we commonly use the term “Nameplate Logo” (trademark). Logo trademarks customized and produced using nameplates have become a highly popular material for creating logos in today’s context.

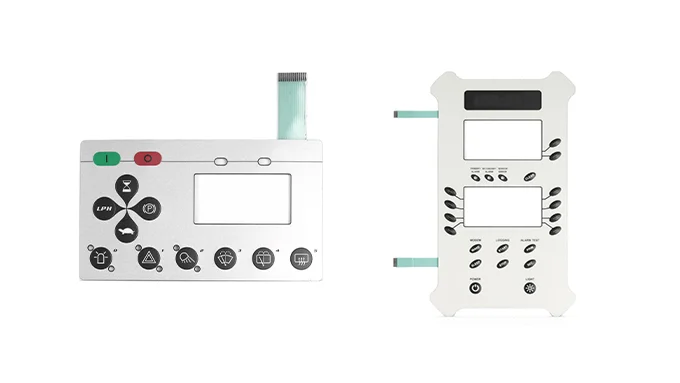

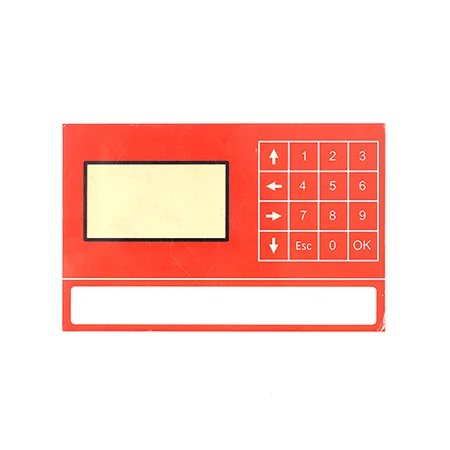

Customized Nameplate Products in Calculator

A nameplate, also known as a name tag or label, can be referred to as a logo tag or logo nameplate. Therefore, we commonly use the term “Nameplate Logo” (trademark). Logo trademarks customized and produced using nameplates have become a highly popular material for creating logos in today’s context.

Latest News

Contact us online