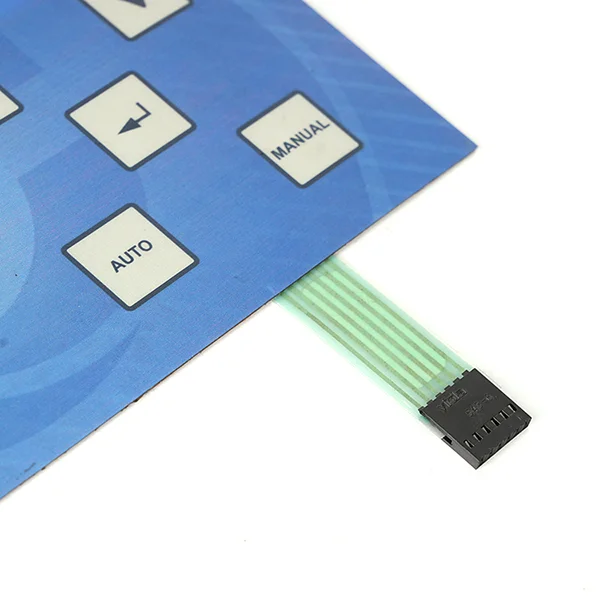

Human-machine Interface Tactile switch

A membrane switch, also referred to as a membrane keypad or membrane keypad switch, is a keypad type that employs a flexible membrane to regulate the flow of electricity. These keypads serve as interfaces for user equipment and tool devices, facilitating the transmission of commands between the user and the electronic device in use. Typically, a membrane switch comprises multiple layers, including a visible top overlay that users interact with, a spacer layer, and a circuit layer. The circuit layer contains the electrical contacts essential for the switch’s functionality. When the user presses on the top overlay, it transmits pressure on the circuit layer, completing the electrical circuit and triggering the switch.

-

Panel material:PVC, PC, PET

-

Insulation resistance:>=100VDC

-

Rebound time:<=6ms

-

Reliable life cycle:>100times

-

Trip force:160~450g

| Basic Parameters of Tactile Membrane Switch | |

| Max. Panel size | 600*800mm |

| Max. Panel size (with emboss) | 400*500mm |

| Paste | silver paste, carbon paste |

| Ink color | red, black, blue, white, yellow, green, purple, etc |

| Trace width | 0.15-0.20mm |

| LED spec. | 0402, 0603, 0805, 1210 |

| Wire length | Per customer requirements |

| Waterproof class | IP65 |

| Connector | female pin, male pin |

| Metal dome types | triangle, for-legs, circle |

| Trip force (metal dome) | 280g, 340g, 450g |

| Travel (metal dome) | 0.35-0.71 |

| Diameter (metal dome) | 8.4mm, 10mm, 12.2mm |

| Surface treatment (metal dome) | gold plating, nickle plating, stainless |

| Back adhesive | DSMS, 3M, SOKEN |

| Citcuit board option | FPC, PCB, Aluminum |

| Panel material | PET, PC, TPU, PMMA |

Why Choose Digital Printing Membrane Switches?

Digital printing membrane switch is a type of product that enable to using AI files to convert digital devices to print product patterns, this way is just like when we print a document using a printer. Compared to traditional screen printing overlays, the biggest benefit that we can get from this method is that it can print gradually changing color using the CYMK colors. Gradient colors always give the product a sense of premium, makes it more beautiful.

In additional, when produce the mass production, digital printing method has some price advantages, and it more cost-effective than screen printing way.

Customer Background:

Dyno Electronics is an integrated industry and trade company specializing in the manufacturing of microwave ovens. Their operational model involves procuring parts from various suppliers and assembling them into complete microwave oven products. In response to evolving aesthetic preferences in the market, Dyno aimed to design a control interface overlay featuring a gradient color scheme transitioning from dark blue to light blue. Despite inquiries with existing suppliers, none could execute the gradient color using traditional screen printing methods. Following a friend’s recommendation, Dyno approached our company for a solution.

Project Challenge:

The challenge lay in the fact that traditional screen printing methods couldn’t achieve the desired gradient color. Digital printing technology was identified as the only viable option, but many manufacturers faced difficulties in seamlessly blending colors.

Our Solutions:

Upon receiving Dyno’s request, our sales team engaged in detailed discussions to gather project specifics. Collaborating with our engineering team and conducting multiple tests, we discovered an effective method to achieve a flawless blend of the desired gradient color. Successful sample production ensued, and Dyno’s team expressed high satisfaction with the aesthetically pleasing colors on the control interface.

Customer Feedback:

Given the prototype nature of the order, we expedited the production, completing the product within 1.5 weeks and swiftly shipping it to Dyno. The Dyno team conducted incoming inspections and functionality tests promptly, confirming that all digital printed membrane switches featured consistent colors and adhered to the design specifications without any deviations. The positive outcome of this collaboration resulted in numerous subsequent orders from Dyno, with some sample orders transitioning into mass production.

Contact us online