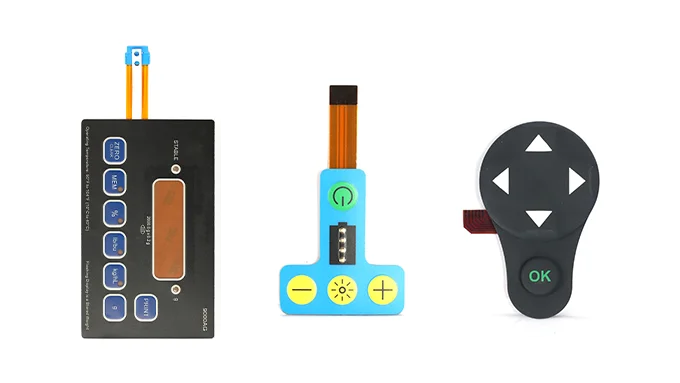

FPC Circuit Structure Membrane Switch

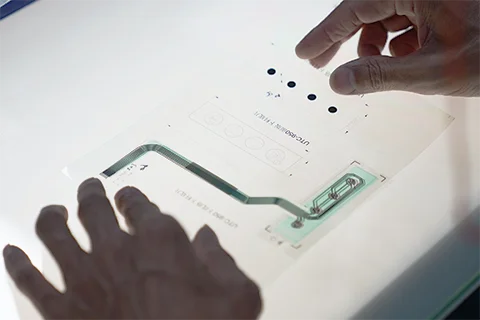

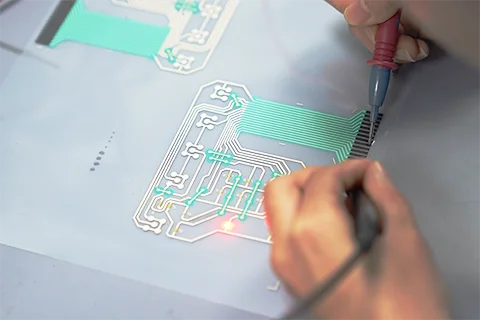

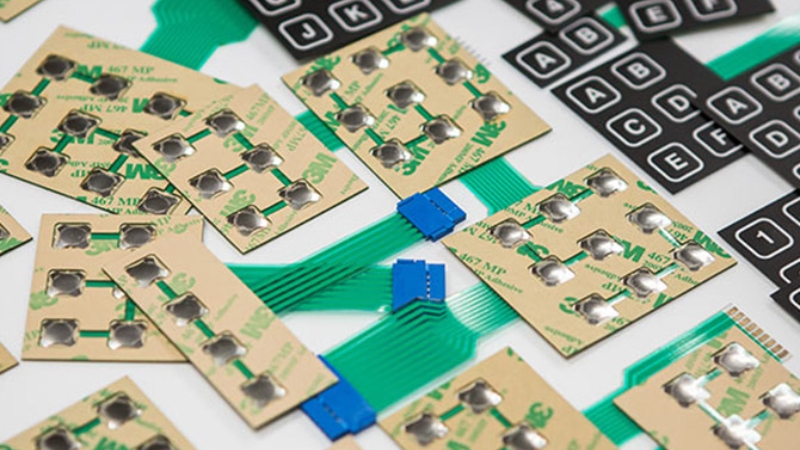

A Flexible Printed Circuit (FPC) membrane switch is a type of user interface that utilizes flexible printed circuits as the key component. Compared with traditional membrane switches by using the silver paste printed flex as the circuit layer, the FPC membrane switch is made from Polyimide copper etched FPC circuits. Copper Flex Membrane Keypads, also known as Copper Flex Printed Circuit Membrane Switches, are essential input devices in the electronics industry. They are designed to offer a user-friendly interface for a wide range of applications, from consumer electronics to industrial machinery. Because FPC circuit structure membrane switch is made by flex circuit board, it has high precision, low resistance value and more stable circuit function.

FPC membrane switches offer several advantages, making them a popular choice for various applications. Here are some of the key benefits of using FPC membrane switches:

•Lower electrical resistance and higher conductivity

•Achieve a much finer trace width

•Endure High-temperature

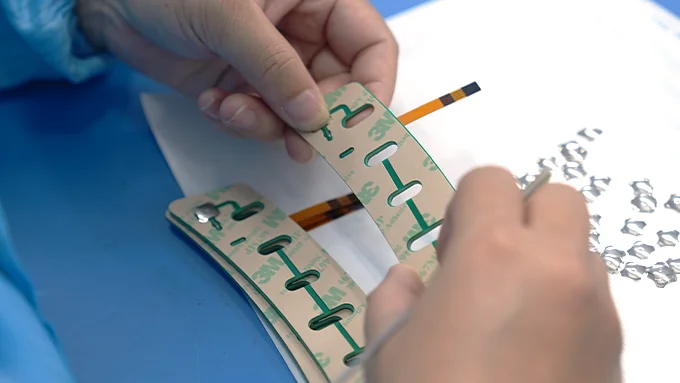

•Ability to withstand bending, creasing, and vibration

•SMT technology & smaller designs

•Reliability

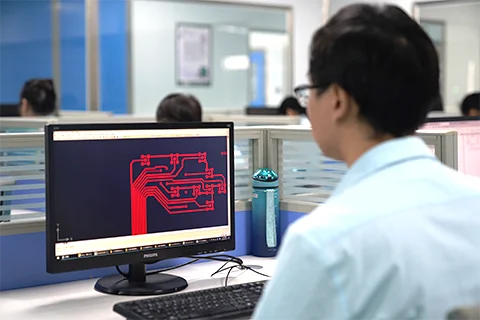

Considerations in FPC membrane tactile switch design

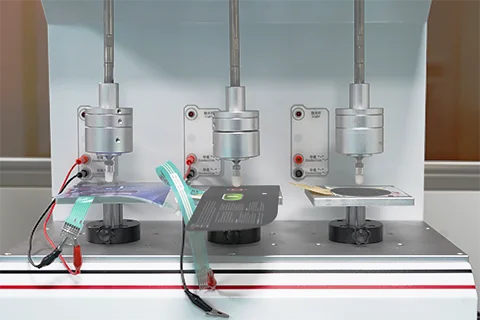

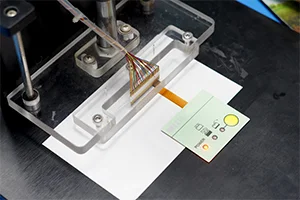

Designing FPC (Flexible Printed Circuit) membrane switches requires careful consideration to ensure they meet the intended functionality and durability requirements. Here are some key considerations in FPC membrane switch design:

Design Guides about Membrane Switches

| Comfort buttons | Water Proof | Chemical Resistant | Temperature Resistant |

By thoughtfully examining these elements in the design of a flexible printed circuit (FPC) membrane switch, one can craft a product tailored to meet precise application requirements, ensuring both a favorable user experience and enduring reliability. Deliberate consideration of these factors is paramount in achieving optimal performance and longevity.

The meticulous evaluation of FPC membrane switch design elements allows for the creation of a product that not only aligns with specific application demands but also enhances user satisfaction and guarantees sustained dependability over the long term.

The synthesis of these considerations is pivotal in achieving a seamless balance between functionality, user interaction, and product durability. Consequently, by methodically addressing these aspects in FPC membrane switch design, the result is a finely tuned product that not only fulfills the unique needs of its intended application but also cultivates a positive and lasting impression on users while upholding a high standard of reliability.

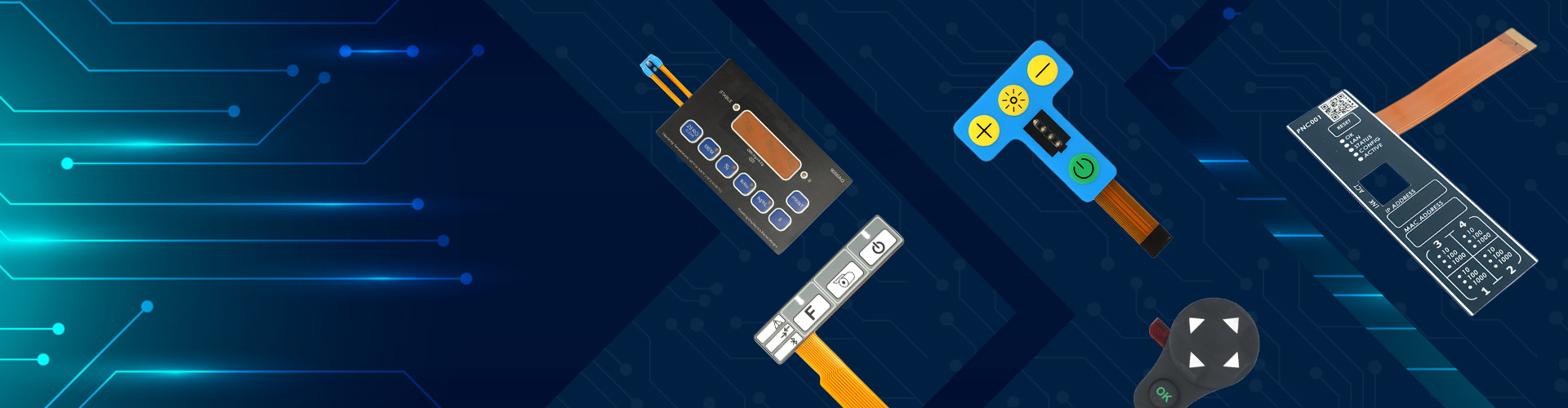

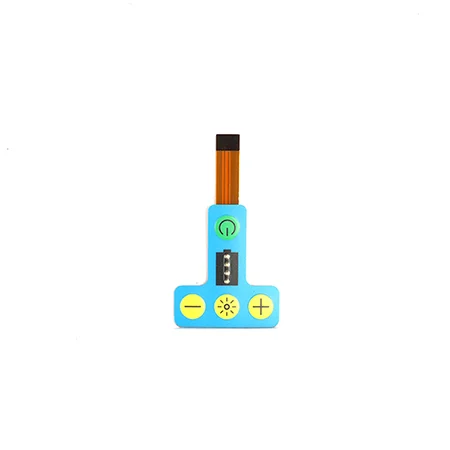

Application of FPC Membrane Switch in Lighting Facility

FPC membrane switches are commonly used in applications where a compact and reliable user interface is required. They are often found in electronic devices such as remote controls, medical equipment, industrial control panels, and various consumer electronics. The flexibility of the FPC allows for versatile design options, and the membrane switch design contributes to a ...

FPC Membrane Switch applied to Analytical instrument

FPC membrane switches are widely used in analytical instruments as integrated components that facilitate user interaction and control within these devices.

FPC membrane switch in healthy industry

FPC membrane switches find extensive applications in analytical instruments, serving as integrated components that enhance user interaction and device control.

FPC membrane switch for printers

FPC membrane switches is a type of user interface that combines the benefits of flexible circuit. It is a thin, lightweight, and flexible electronic component used to create a user interface in various electronic devices, such as keyboards, control panels, and appliances.

Latest News

Contact us online