What is FPC Circuit Structure Membrane Switch?

What is FPC Circuit Structure Membrane Switch?

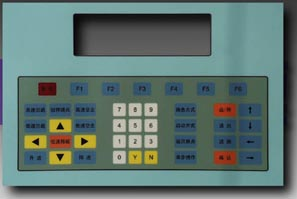

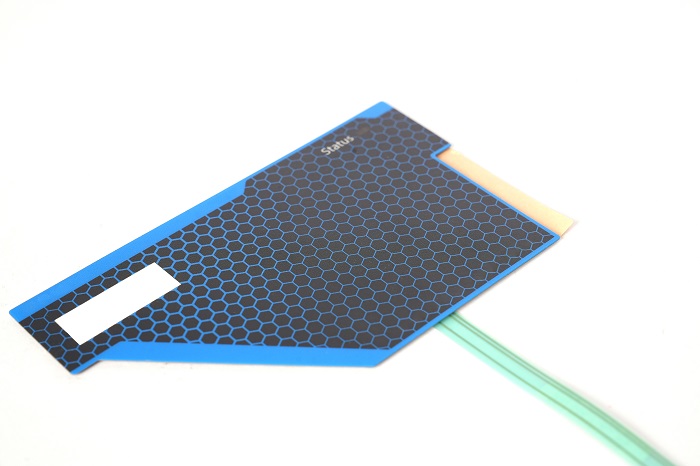

Compared with traditional membrane switches by using the silver paste printed flex as the circuit layer, the FPC membrane switch is made from Polyimide copper etched FPC circuits. Copper Flex Membrane Keypads, also known as Copper Flex Printed Circuit (FPC) Membrane Switches, are essential input devices in the electronics industry. They are designed to offer a user-friendly interface for a wide range of applications, from consumer electronics to industrial machinery. Because FPC circuit structure membrane switch is made by flex circuit board, it has high precision, low resistance value and more stable circuit function.

Advantages of Flex Circuit Membrane Switch

FPC (Flexible Printed Circuit) membrane switches offer several advantages, making them a popular choice for various applications. Here are some of the key benefits of using FPC membrane switches:

- Lower electrical resistance and higher conductivity

FPC Membrane Keypad Copper traces have far lower resistance, only 20% of the silver circuit. - Achieve a much finer trace width

With the PET silver circuit, the minimum pitch is 1mm, however, the minimum trace width for copper flex is 0.3mm and the pitch is 0.5mm. - Endure High-temperature

The temperature resistance of the flexible printed circuit is better than silver circuitry. FPC can resist high temperatures up to 280 degrees. - Ability to withstand bending, creasing, and vibration

FPC can be bent and folded, which improves the efficiency of the configuration and is able to last for a long period of time. - SMT technology & smaller designs

When dealing with smaller package sizes, footprints, and rugged environment applications, the Copper Flex circuit can fit more components in a smaller area and can accommodate unique functionality and characteristics in the membrane switch. It is ideal for smaller designs where dense circuit patterns or trace routing limitations exist. - Reliability

Polyimide circuits use a soldered connection that can be up to three times as strong as the conductive glue. Electronics components soldered on FPC are more reliable than those glued on silver circuitry.

Considerations in FPC membrane tactile switch design

Designing FPC (Flexible Printed Circuit) membrane switches requires careful consideration to ensure they meet the intended functionality and durability requirements. Here are some key considerations in FPC membrane switch design:

- User Interface

Button Layout: Determine the arrangement of buttons or keys and their size and spacing to provide a user-friendly interface.

Legend/Graphics: Decide on the graphics, labels, or symbols to be printed on the switch surface for clear user guidance.

Tactile Feedback: Design the switch to provide the desired tactile feedback, whether it’s a click, snap, or soft touch, based on user preferences.

- Material Selection

Substrate Material: Choose the appropriate flexible material for the FPC, considering factors like flexibility, resistance to environmental conditions, and electrical properties.

Overlay Material: Select a durable and chemically resistant material for the top graphic overlay to ensure longevity and ease of cleaning.

- Environmental Conditions

Circuit Design: Design the circuit layout to meet the electrical requirements of the application, including the number of circuits, traces, and connections.

Contact Design: Choose between different contact types (such as dome switches, metal domes, or printed silver contacts) based on electrical performance and tactile feedback needs.

- Backlighting

If backlighting is required, plan for the integration of LEDs or fiber optic elements into the membrane switch design to provide illumination. - Actuation Force and Travel

Determine the actuation force (the amount of pressure required to activate the switch) and the travel distance for each button. These factors affect user experience and must align with the application’s requirements. - EMI/RFI Shielding

Consider electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding to prevent signal interference in electronic equipment. - Durability and Lifecycle

Estimate the expected lifecycle of the membrane switch and design it to withstand the anticipated number of actuations and environmental stress. - Cost Considerations:

Keep an eye on manufacturing costs, as different design choices can impact production expenses. Balancing performance and cost is important. In addition, different tooling and manufacturing processes have different cost. But whether it’s screen printing, etching, or digital printing, and choose a reliable manufacturing partner.

By carefully considering these factors in FPC membrane switch design, you can create a product that meets your specific application needs while providing a positive user experience and long-term reliability.

Tags:

Smart Device Interface Operating System-Membrane Switch

With the needs of the market, the design of membrane switches has become more and more user-friendly. Nowadays, membrane switches are commonly used in intelligent consumer electronics products, general durable household appliances and even industrial machinery applications. The typical structure of a membrane switch is a multi-layer structure, planar self-locking key switch composed of a ...

Little Knowledge About Membrane Switch Panel Layer

Thin film panels are very common in the field of household appliances and various industrial products, and have both decorative and functional control panel trademarks. The membrane switch plays an important role as a tactile switch between the user and the instrument. Membrane buttons have a better feel and longer life, which can indirectly improve ...

Do You Understand the Working Principle of Membrane Switches?

What is a membrane switch? The membrane switch mainly integrates button functions, appearance display, and instrument panel to form a precise electronic component control system. With its rigorous structural design, beautiful appearance, good sealing performance and excellent durability (such as moisture-proof, long life), membrane switches have been widely used in electronic communication equipment, electronic measuring ...

Contact us online