Little Knowledge About Membrane Switch Panel Layer

Little Knowledge About Membrane Switch Panel Layer

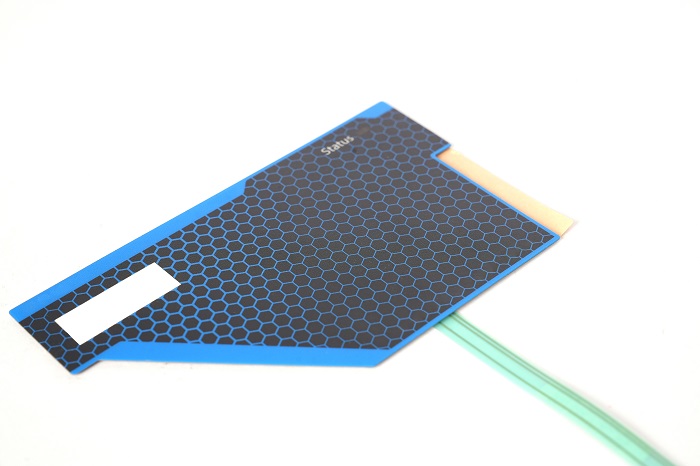

Thin film panels are very common in the field of household appliances and various industrial products, and have both decorative and functional control panel trademarks.

The membrane switch plays an important role as a tactile switch between the user and the instrument. Membrane buttons have a better feel and longer life, which can indirectly improve the production efficiency of various types of switches using conductive films. The contacts on the membrane button are located on the conductive parts of the PCB. When the button is pressed by external force, the center point of the contact is concave and contacts the circuit on the PCB, thereby forming a loop, allowing current to pass through, and the entire product can work normally.

Membrane switch panels can be printed on plastics such as PVC, PC, PET, PMMA, etc. through digital printing technology to customize graphics, text, and color requirements according to customer needs. Double-sided tape can be pasted on the back to produce logos, control panels, and protection. of plastic products.

How to choose the thickness of membrane switch panel?

Regardless of whether it is PC, PVC or PET, as the panel layer of the membrane switch, due to its resilience, lifespan and other factors, the thickness is usually 0.175MM, which is relatively moderate. Users can adjust it within the appropriate range according to the characteristics of the product. However, it should be noted that: if the panel layer is too thin, the three-dimensional molding will not be obvious enough, and it is difficult to keep it flat in a larger area; if the panel layer is too thick, the feel will be dull and the operation strength will increase.

What is the use of membrane switch button bulge?

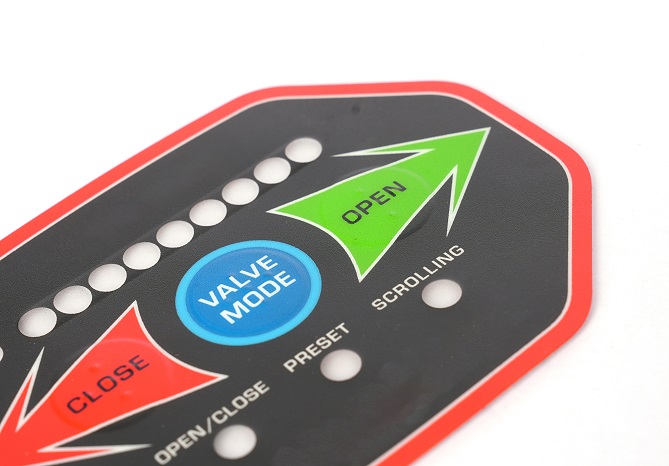

There will be a raised bulge in the membrane switch, so what does this bulge do?

The buttons on the membrane switch are designed as bulges, which can better allow the operator to quickly determine the position of the buttons, make the buttons feel better, and also make the product more designed and three-dimensional. The conventional diameter size of the button protrusion is 8-15MM, and the height is usually between 0.3-1.2MM. Other values can be customized according to customer needs.

4 advantages of membrane switch bumps:

1. Enhanced the decorative effect of the appearance of the membrane switch panel

2. Improve the operator’s feel

3. Accurately give the key range

4. Improve key recognition speed

The panel layer of the membrane switch provides users with an operating feel and visual beauty, so it is also a very important link in the design of the membrane switch. Membrane buttons occupy most of the market due to their low cost, simple process and good feel. Membrane buttons also have the characteristics of thin, soft and good protective performance. Combined with the application of customer products, Yu An Electronics provides customers with the most suitable membrane switch solutions and solves customers’ difficulties. This is our service tenet! If you want to know about membrane switches, you can send us an email: sales@best-membraneswitch.com.

Difference between mechanical and membrane keyboards

What is a membrane keyboard? Membrane keyboard is a type of keypad that uses a flexible printed circuit to register key presses. Unlike traditional keyboards with individual mechanical parts under each button, membrane keypads rely on pressure to push conductive layers together. This pressure causes an electrical contact that sends the signal. This type of ...

What is silicone rubber shore hardness?

The Shore hardness of silicone rubber is usually between 10-80 A, and 30-60 A is mostly used for daily membrane switches and buttons: it is soft enough to ensure a rebound feel, and is wear-resistant enough. What is the shore value of silicone? Shore hardness is a measure of how soft or hard a material ...

Silicone rubber properties, Silicone rubber membrane switch

Silicone rubber is a modern material that has completely transformed the way industries think about flexibility, durability, and adaptability. Whether in electronics, medical devices, or automotive systems, the demand for reliable, long-lasting, and high-performing materials is greater than ever. What are the properties of silicon rubber? Silicone rubber is not like ordinary rubber. It’s built ...

Contact us online