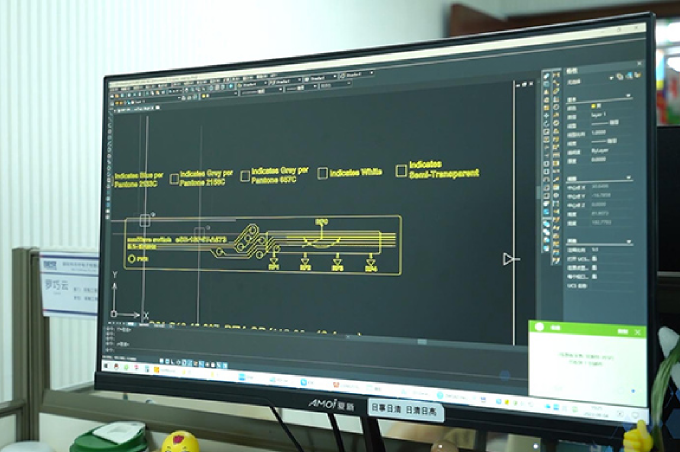

Graphic Overlay

This layer is the visual layer, typically utilizes high-toughness polyester or polycarbonate transparent colorless sheets with a thickness of 0.25mm or less. Patterns, text and icons are printed on them, serving the primary purpose of providing identification and key functions. Embossed domes may be designed under the icons to look like what we say “button”.