Membrane Switch Durability

Membrane Switch Durability

A membrane switch gives a visually pleasing human-machine interface that is easy to use, low profile, and electronically stable. They are well known to stand up to harsh conditions. Flex circuitry is resilient and can be used in many different environments. Once you know what the end use will be for the flex circuit, the appropriate overlay material can be selected for the part.

Polycarbonate and polyester are the two most used materials for membrane switches. The overlay starts out as a clear material and then is printed on the back side. This protects the graphics and increases durability.

Adhesive Layers

A membrane keypad is made of about 6 layers and each layer serves a unique function. The Graphic Overlay is on top and provides the actual interface buttons and controls. It is mounted to the rest of the keypad with pressure sensitive adhesive.

The PSA (adhesive) forms a strong body when pressure is applied. It doesn’t need any heat or other solvents to activate. This is also sometimes called cold laminating.

These adhesives will give a certain amount of sealing properties to the rest of the membrane switch. Small amounts of liquid and dust are kept out of the switch by the membrane construction. However, this durability is not good enough for severe settings.

The membrane switch may have problems if dropped into water or other liquids and is submerged for any length of time. The edges of a keypad, which protect the circuitry for most normal day to day operation environments, will be insufficient to keep water out if submerged.

Other Contaminants

- Certain abrasive and corroding cleaners may degrade the quality of an Overlay over time.

- Dust can be a problem with outdoor use.

- High humidity.

- Very high or low temperatures.

- High altitudes.

Can You Put Mechanical Switches on a Membrane Keyboard?

No, you can’t. Mechanical switches and membrane keyboards use completely different structures. Membrane boards rely on pressure pads, while mechanical ones use physical switch mechanisms. They’re not compatible. But there are still ways to improve the feel and sound of a membrane keyboard without full mechanical parts. What are membrane switches keyboard? Membrane switch keyboards ...

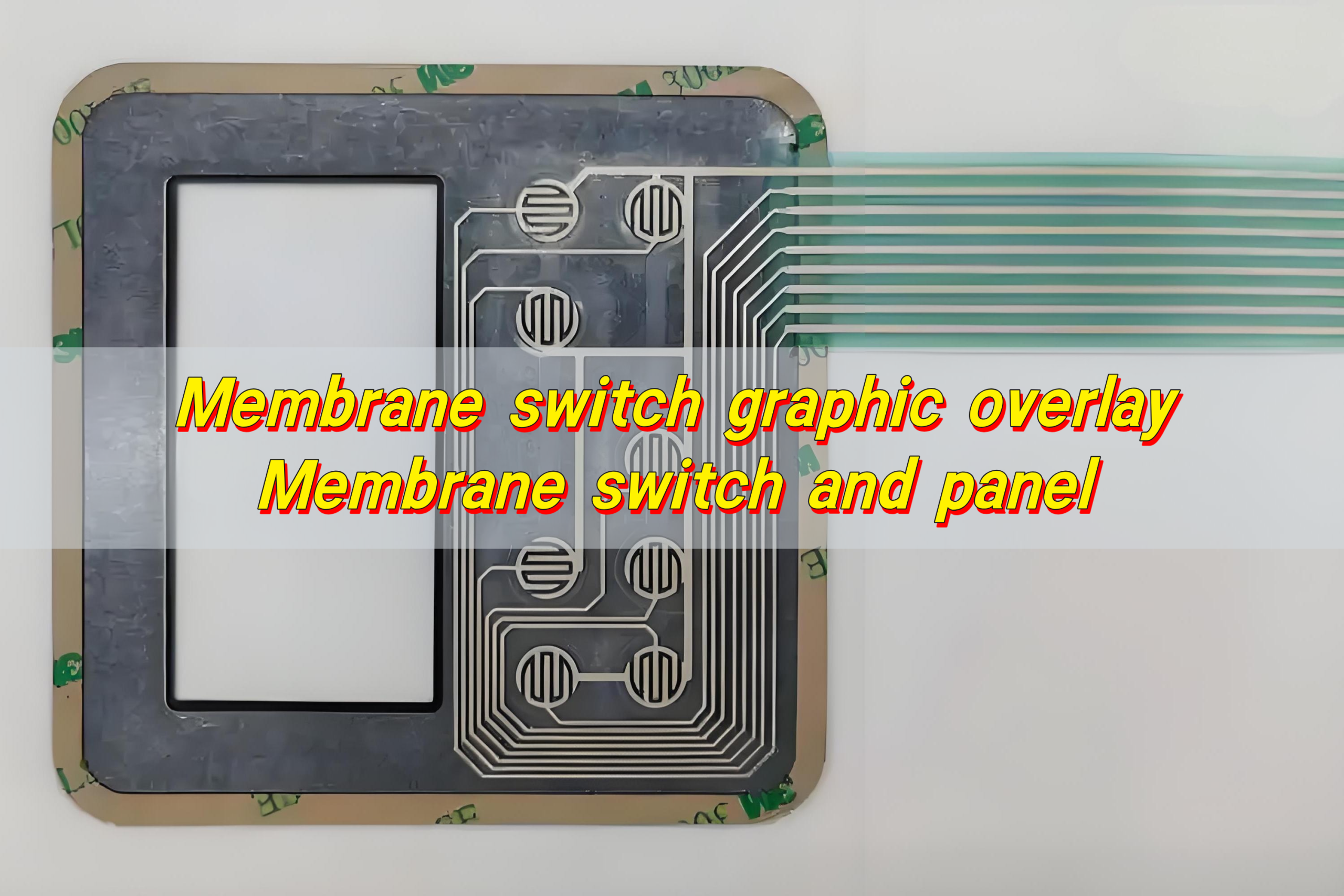

Membrane switch graphic overlay, Membrane switch and panel

Membrane switch graphic overlay is an outer film printed with button logos and patterns, usually made of PET or PC, which protects the internal circuit and provides an operating interface. It is closely integrated with the membrane switch panel, which is a multi-layer film structure containing a conductive layer and an insulating layer to achieve ...

What are membrane switches? Membrane switch design guide

Membrane switches are thin, flexible interfaces that activate a circuit when pressed. Built from multiple flat layers, they offer a clean look, strong durability, and precise control. Commonly used in medical devices, industrial panels, and consumer electronics, they’re known for being reliable, customizable, and space-saving. What is membrane switch design? Membrane switch design is the ...

Contact us online