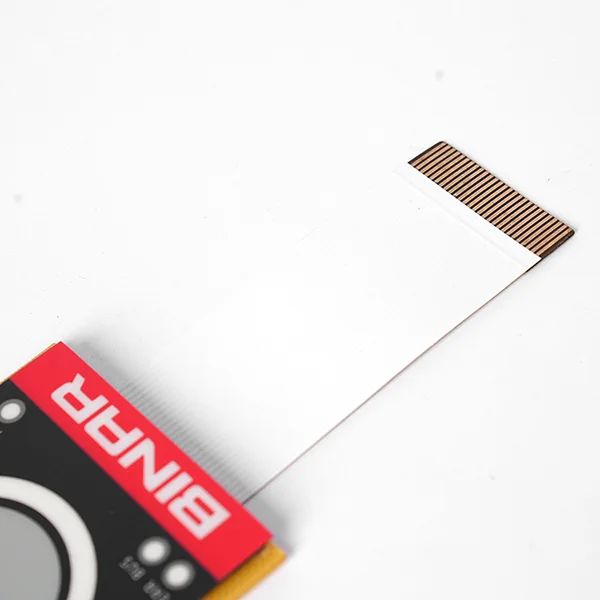

Fitness tracker controls use silicone tactile switch

The use of silicone membrane switches in the design of fitness tracker controls provides a technologically advanced solution that enhances the user experience and functionality of these health and activity monitoring devices.

-

Electrical characteristics:35V (DC), 100mA, 1W

-

Contact resistance:10Ω-500Ω (varies according to the lead wire and the material use, generally<200Ω)

-

Insulation impedance:≥ 100MΩ 100V

-

Dielectric strength:250V Rms (50-60HZ, 1min)

-

Contact jitter time:≤ 5ms

| Basic Parameters of Tactile Membrane Switch | |

| Max. Panel size | 600*800mm |

| Max. Panel size (with emboss) | 400*500mm |

| Paste | silver paste, carbon paste |

| Ink color | red, black, blue, white, yellow, green, purple, etc |

| Trace width | 0.15-0.20mm |

| LED spec. | 0402, 0603, 0805, 1210 |

| Wire length | per customer requirements |

Tactile membrane switches offer tactile feedback in response to being activated by finger or actuator. This tactile feedback improves the user experience in scenarios where other types of feedback are limited or where it’s critical to confirm that the switch has been pressed.Tactile membrane switches offer tactile feedback in response to being activated by finger or actuator. This tactile feedback improves the user experience in scenarios where other types of feedback are limited or where it’s critical to confirm that the switch has been pressed.

Client Profile:

TCD Technologies is a leading manufacturer of state-of-the-art fitness tracker controls. They specialize in producing advanced patient monitoring systems used in fitness industries.

Project Challenges:

TCD Technologies was in the process of developing a new generation of suitable tracker devices. The challenge they faced was to design a user interface that could withstand frequent use, ensure easy cleaning to meet stringent hygiene standards in various environments, and provide a seamless and intuitive experience for end users.

Our Solutions:

When received this inquiry, our sales team suggested to use silicone material as the base material, since this material has long lifecycle, good mechanical properties and very suitable to make emboss. Emboss can provide a good instruction for peoples when they are inconvenient. Combined with this suggestion, TCD engineering team updated and optimized the design files, then sent to us for evaluation. Our engineers prepared the sample drawings quickly and got the approval from customers. Then we made the samples within 2 weeks and shipped them out immediately.

Customer’s Feedback:

TCD team proceeded the incoming inspection immediately when received the samples and install to their monitor devices for verifying the function. And finally, all the testing were passed successfully and no problems happened until now. They gave a big thumbs up to us and promised that they will give us the large quantity order to us if this kind of monitor put into the market.

Contact us online