What is backlighting? Backlighting Membrane Switch

What is backlighting? Backlighting Membrane Switch

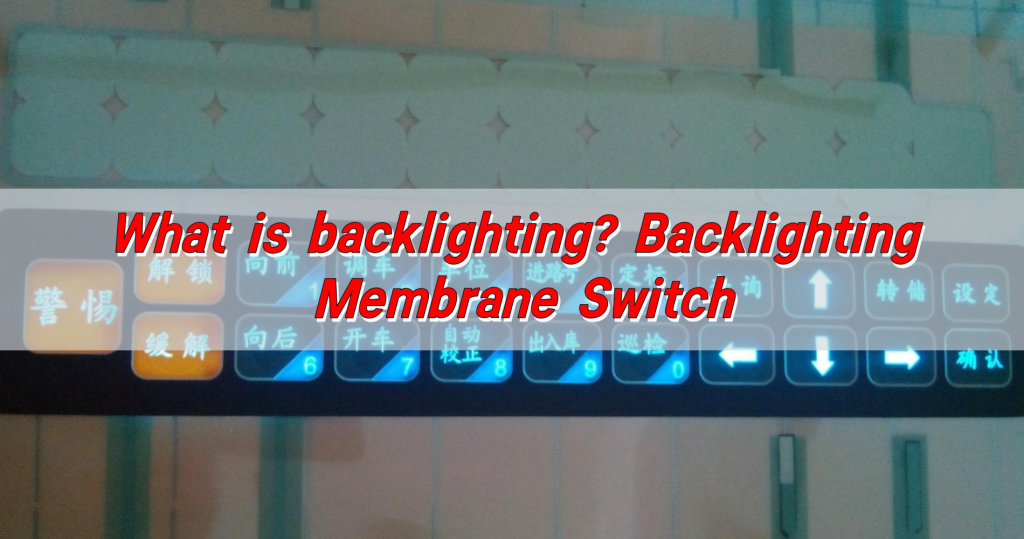

Backlight is a form of lighting used for LCD displays. By adding a light source to the switch surface, the buttons can still be clearly seen in low light environments. Backlight membrane switches combine membrane switches with backlight systems, which not only retains the advantages of membrane switches such as lightness, flexibility, and low cost, but also increases operability at night or in low light environments.

What is backlight switch?

Backlight switch is a switch with an integrated lighting feature that illuminates its surface or specific areas. This lighting allows users to locate and operate the switch even in dim environments. Backlit switches can be found in numerous applications, from household appliances to high-end industrial machines.

In membrane switches, backlighting is often embedded beneath the graphic overlay, illuminating key areas like symbols, text, or buttons. The light source is carefully placed to ensure uniform brightness without excessive power consumption. This type of switch improves both functionality and aesthetics, making it a preferred choice in industries that require precision and reliability.

What is led backlighting?

LED backlighting is one of the most popular methods used in membrane switch backlighting. It utilizes light-emitting diodes (LEDs) to produce illumination, offering bright, energy-efficient, and long-lasting light.

LEDs provide several advantages:

- High Brightness: They offer sharp and clear illumination.

- Energy Efficiency: LEDs consume minimal power, making them ideal for battery-powered devices.

- Longevity: They last thousands of hours, reducing maintenance costs.

- Customizability: Available in different colors and intensities, LEDs can be tailored to match branding or design needs.

LED backlighting in membrane switches is often used in critical applications such as medical instruments, aerospace controls, and automotive dashboards. The clear visibility they provide ensures precise operation in any environment.

How to make membrane switch have backlight?

Integrating backlighting into a membrane switch requires careful design and material selection. Several methods can be used, depending on the desired effect and application.

- LED Backlighting – Small LED lights are placed strategically beneath the switch layers. Light guides or diffusion films distribute illumination evenly across the surface.

- Electroluminescent (EL) Backlighting – A thin EL panel is embedded into the switch structure. It provides uniform lighting with low power consumption but has a shorter lifespan than LEDs.

- Fiber Optic Backlighting – Optical fibers transmit light from a single source to different parts of the switch, creating even and controlled lighting.

- Silicone Backlighting – In some designs, a silicone backlight membrane switch uses molded silicone keypads with embedded light paths, enhancing brightness and durability.

Each method has its own benefits. LED backlighting is the most common due to its efficiency, while fiber optics work best for highly flexible applications. The choice depends on the required brightness, lifespan, and environmental conditions.

Are membrane switches clicky?

Membrane switches do not naturally produce a click like mechanical switches. However, they can be designed to provide tactile feedback.

Tactile feedback is achieved by incorporating metal domes or polyester domes beneath the surface. These domes create a crisp, responsive feel when pressed. Metal domes are widely used because they offer a sharp, satisfying click and enhance durability.

For applications requiring silent operation, non-tactile membrane switches are preferred. These switches activate smoothly without an audible or physical response, making them ideal for medical and laboratory environments.

What material is a membrane switch made of?

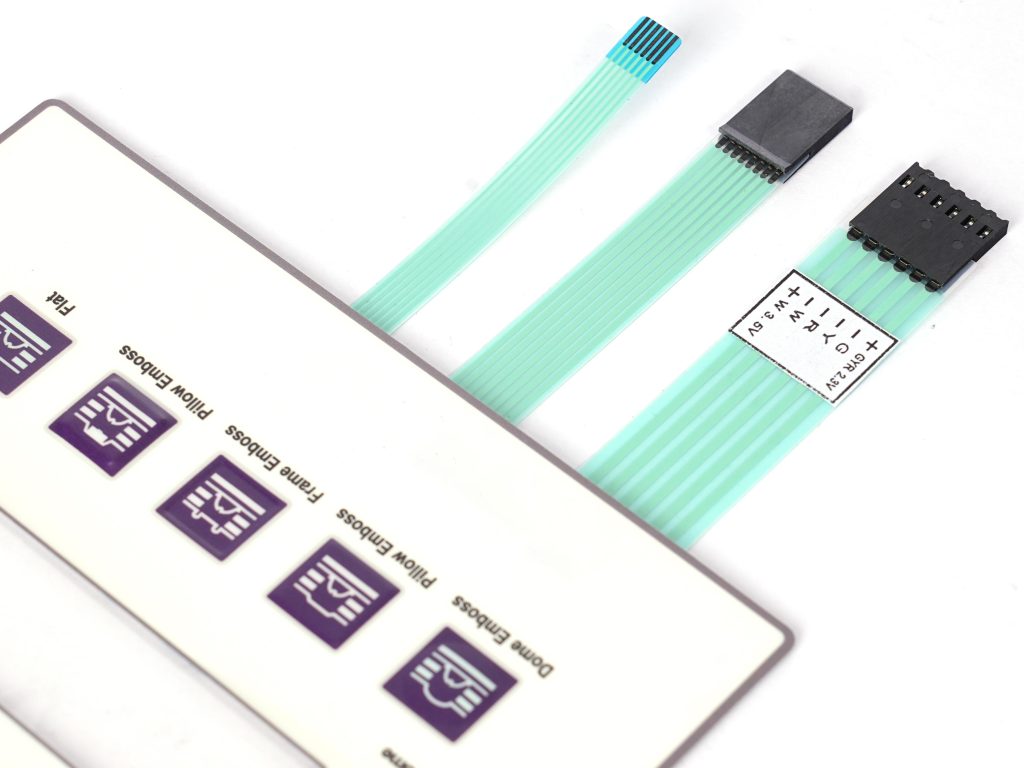

Membrane switches are constructed from multiple layers of specialized materials:

Graphic Overlay: The top layer, made of polyester or polycarbonate, provides durability and customization options.

- Adhesive Layers: These hold the switch components together, ensuring strong bonding.

- Circuit Layer: Usually made from flexible copper, silver ink, or printed conductive materials.

- Spacer Layer: This prevents accidental contact between circuits when the switch is not in use.

- Back Panel: Sometimes included for additional support and rigidity.

The materials used determine the switch’s resilience to environmental conditions such as moisture, chemicals, and extreme temperatures. Industrial and medical applications demand high-quality materials for long-lasting performance.

What are the advantages of backlight membrane switches?

Backlighting enhances membrane switches in several ways:

- Improved Visibility: Essential for nighttime or low-light environments.

- Enhanced Aesthetics: A sleek, modern look that adds sophistication.

- User-Friendly Experience: Ensures easy operation, even in critical applications.

- Customizable Lighting: Different colors and intensities can be tailored for specific needs.

- Energy Efficiency: LED-based backlighting consumes minimal power.

- Long Lifespan: Quality backlit switches can last for years without significant wear.

These benefits make backlit membrane switches indispensable in industries where precision, durability, and ease of use are priorities.

What does a membrane switch do?

A membrane switch acts as an interface between users and electronic devices. When pressed, it activates an electrical connection that sends a signal to the device, executing a function.

Unlike traditional mechanical switches, membrane switches offer:

- Sealed Protection: Resistant to dust, moisture, and contaminants.

- Flat, Compact Design: Takes up less space, making devices slimmer and more efficient.

- Durability: Can withstand millions of actuations without degradation.

These features make them essential for industries requiring reliable and long-lasting input solutions.

Where are membrane switches used?

Membrane switches are widely used in various industries, including:

- Medical Equipment: Used in diagnostic devices, ventilators, and hospital equipment.

- Industrial Controls: Found in machinery, automation systems, and control panels.

- Aerospace & Military: Applied in cockpit controls, communication devices, and defense systems.

- Consumer Electronics: Used in remote controls, household appliances, and fitness devices.

- Automotive: Integrated into dashboards, climate controls, and infotainment systems.

Their reliability and resistance to harsh conditions make them the preferred choice for demanding applications.

How long do backlight membrane switches last?

The lifespan of a backlight membrane switch depends on its components and usage.

- LED Backlighting: Typically lasts 50,000 to 100,000 hours before dimming.

- Electroluminescent Backlighting: Has a shorter lifespan, around 3,000 to 10,000 hours.

- Overall Switch Lifespan: Can exceed 5 million actuations, depending on material quality.

Proper design and material selection ensure that backlit membrane switches function effectively for years, minimizing replacements and maintenance costs.

Conclusion:

Backlighting in membrane switches enhances visibility, functionality, and design. Whether using LED backlighting, fiber optics, or EL panels, these switches provide a reliable and energy-efficient solution for various industries.

For high-quality backlit membrane switch panels with superior performance, contact us at sales@best-membraneswitch.com

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online