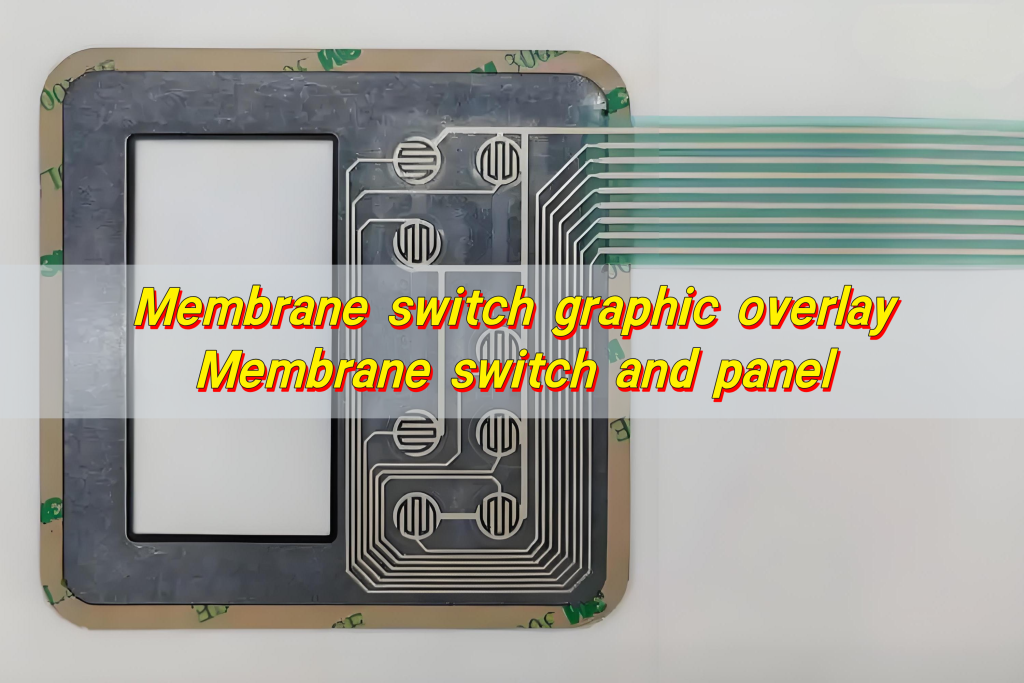

Membrane switch graphic overlay, Membrane switch and panel

Membrane switch graphic overlay, Membrane switch and panel

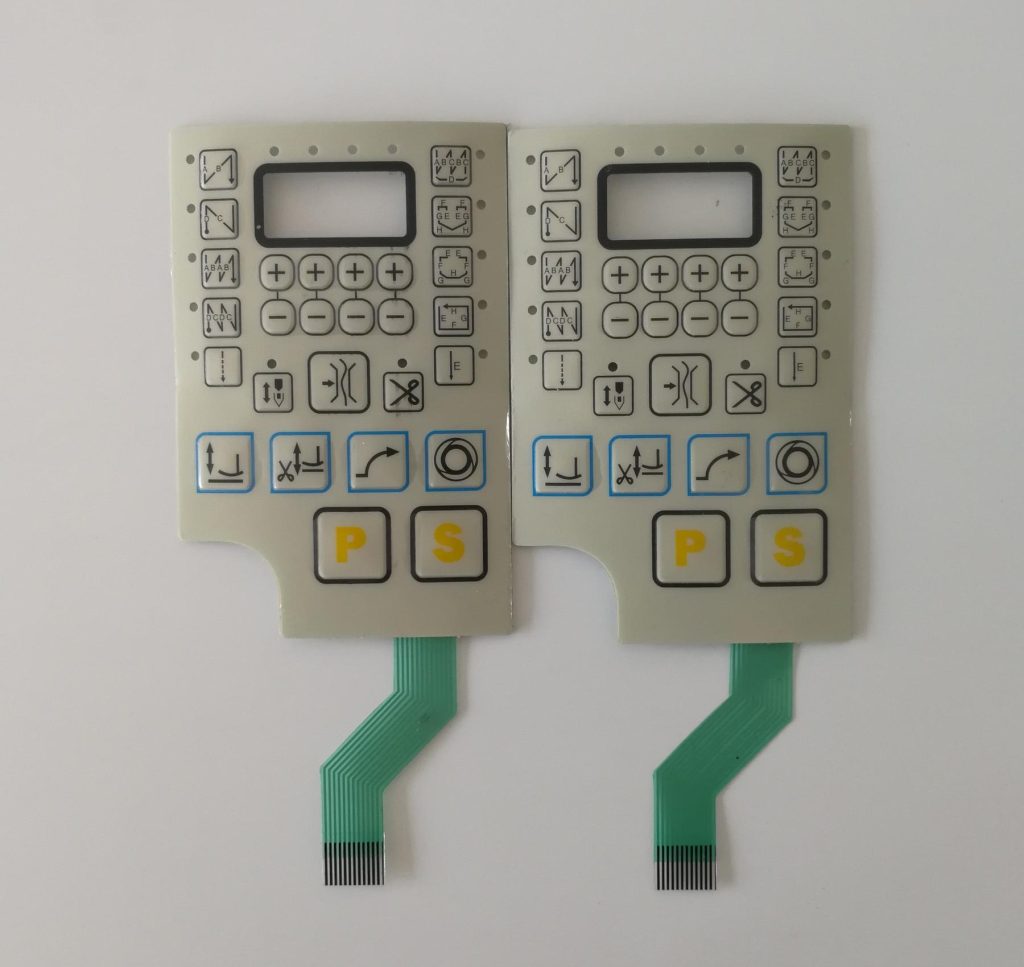

Membrane switch graphic overlay is an outer film printed with button logos and patterns, usually made of PET or PC, which protects the internal circuit and provides an operating interface. It is closely integrated with the membrane switch panel, which is a multi-layer film structure containing a conductive layer and an insulating layer to achieve circuit control.

What is a membrane switch overlay?

The membrane switch overlay is more than just the surface of your interface. It’s the visual and tactile layer that users interact with directly. Often printed with graphics, symbols, or labels, this overlay acts as the face of the entire membrane switch system. It guides users, and protects the internal layers underneath.

This top layer is typically made from a flexible material like polyester or polycarbonate. It’s chosen not only for its durability but also for its ability to display high-quality graphics and survive constant use.

Without a good overlay, a membrane switch may still function, but it won’t provide the clarity, usability, or branding presence your product deserves.

What materials are used in membrane overlays?

The success of a membrane switch often starts with material choice. The most common options are polyester and polycarbonate.

- Polyester (PET): Known for its toughness and resistance, polyester is a favorite in high-use environments. It offers excellent chemical resistance, which makes it ideal for medical, industrial, or outdoor applications. It also recovers well from repeated presses, keeping tactile feedback sharp and reliable over time.

- Polycarbonate (PC): This material shines in visual presentation. It’s easy to print on and creates crisp, vibrant graphics. However, it’s less durable under heavy wear. That’s why it’s usually recommended for applications where visual design is the top priority and usage is moderate.

Adhesives also play a role. They’re used to bind the overlay to the switch layers beneath. High-performance adhesives like 3M acrylics offer strong bonds that resist moisture and temperature changes.

In some designs, hard coatings are added to enhance scratch resistance and UV protection. This helps maintain graphic clarity, especially in outdoor or demanding settings.

What are the types of membrane switch overlays?

Membrane overlays can be customized to fit a wide range of applications. Their variations usually depend on tactile feedback, finish, and functionality.

- Embossed Overlays: These overlays have raised areas—like buttons or icons—that offer a tactile response. They help users “feel” where to press, even without looking.

- Textured Overlays: Texture improves grip and touch sensitivity. It also minimizes glare and fingerprints. Matte finishes are popular in both industrial and consumer electronics for their anti-reflective properties.

- Transparent Windows: Often used to allow light or screens to show through. Think of medical monitors or handheld devices where LED indicators need to shine.

- Backlit Overlays: These use LED or fiber optics to illuminate the overlay from behind. It improves usability in dark conditions and adds an aesthetic edge.

- Custom Printed Overlays: Full-color printing allows branding, logos, instructions, or color-coded buttons to be integrated directly into the overlay.

Each of these types brings specific value. Choosing the right one depends on your product’s purpose and user needs.

Why is overlay design important?

The overlay is the first thing users see and touch. A well-designed overlay improves usability, enhances brand image, and ensures long-term reliability. Poor design, on the other hand, confuses users and leads to errors or frustration.

Good design translates to efficiency. Clear icons, tactile feedback, and smart layout help users operate devices without second-guessing.

Moreover, the overlay also protects what’s underneath. It guards the printed circuit layers from moisture, dust, and chemicals. This protective role means design isn’t just about looks—it’s about function and longevity.

How to design an effective membrane switch overlay?

Creating an effective overlay is a careful balance of appearance, usability, and durability.

- Understand Users: Know who will use the product and under what conditions. Will they wear gloves? Will the environment be dark, wet, or dirty?

- Choose the Right Material: Polyester for rugged use. Polycarbonate for visual impact. Sometimes a hybrid works best.

- Keep It Simple: Simplicity wins. Too many buttons or too much text slows down users. Use intuitive icons and clear labeling.

- Add Tactile Feedback: Embossing or metal domes under the overlay provide satisfying, responsive feedback. This helps prevent accidental presses and improves user confidence.

- Consider Light and Color: Use high-contrast colors for readability. Backlighting can boost visibility in dark settings.

- Test Before Finalizing: Before mass production, prototype the design. Let users interact with it. Test how it feels, looks, and performs under real conditions.

Overlay design is not just art or engineering. It’s both. A good design speaks clearly. A great one inspires trust.

What are the advantages of membrane switches?

Membrane switches offer clear benefits compared to mechanical switches or touchscreens.

- Compact and Lightweight: Their slim profile makes them perfect for handheld or portable devices.

- Sealed and Durable: They resist water, dust, and chemicals, especially when sealed correctly.

- Cost-Effective: Their construction is simpler and more affordable than many mechanical systems, especially in large volumes.

- Customizable: From colors to shapes to logos—nearly every element can be tailored to fit your brand or need.

- Tactile Options: Depending on the dome choice and embossing, you can fine-tune feedback for a precise user feel.

- Ease of Cleaning: Their flat surface is easy to wipe down, crucial in medical and food environments.

- Long Life Cycle: When designed well, these switches can handle over a million actuations without failure.

How do membrane switches work?

Membrane switch functions through layered interaction. Beneath the overlay, there are circuit layers, a spacer, and often metal or polyester domes. Here’s how it works:

When a user presses a graphic key on the overlay, the pressure compresses the layers beneath. This closes a circuit and sends a signal. Once released, the layers return to their original state.

Metal domes can be inserted for better tactile feedback. Some switches include LEDs for lighted feedback or resistors for added functionality.

There are no open gaps like mechanical keyboards, which reduces the chance of failure from dust or moisture.

What does a membrane switch do?

Membrane switch allows users to interact with an electronic device. It converts physical input into digital commands. Whether it’s turning on a machine, adjusting settings, or triggering an emergency stop, it bridges human action to machine response.

And it does it while protecting internal electronics from wear, damage, and contaminants. So when you press a button on a medical device, vending machine, or industrial control panel—that’s often a membrane switch at work. Quiet, precise, and reliable.

Conclusion:

Membrane switch overlays combine interface, protection and user guidance in one. Choosing the right materials like polyester or polycarbonate, designing for function and clarity, and understanding user environments can turn a basic switch into a durable, high-performance component.

With benefits like slim design, long life, customization, and resistance to harsh conditions, membrane switches outperform many alternatives in industrial and consumer devices.

If you’re ready to upgrade your device with high-performance membrane switch overlays or need help with membrane switch and panel design, we’re here to assist. Contact us anytime at sales@best-membraneswitch.com

Top Membrane Switches for Home Electronics Projects in 2025

You can elevate your home electronic membrane switch project in 2025 with standout models such as the 4×4 Matrix 12 Keys Keypad from SOUSHINE, the rgb-enabled strip switches from Molex, and custom graphic switches by Panasonic. These switches offer slim profiles and reliable performance, making them easy to integrate into your DIY setup. You gain ...

Top tips for fixing PS4 controller conductive film keypads

Are you frustrated because your PS4 controller buttons have stopped working? You are not alone. Many gamers experience issues with the conductive film keypad for ps4. Button failures often happen because of dirt, debris, or rough handling. Take a look at the most common causes: Cause Description Dirt and debris Accumulation in button crevices can ...

Top Membrane Switch Companies Leading the Industry in 2025

You see a dynamic market shaping the future of membrane switch technology. Leading companies like Molex, SOUSHINE, YU AN Electronics, TE Connectivity, Honeywell, Omron, Mitsubishi Electric, Panasonic, Industrial Print Technologies, SCHURTER, XYMOX, Douglas Corp, Dyna-Graphics, ELO Touchscreens, UTC, LUNFENG Technology, and Fujikura drive growth with innovation and global reach. Choosing the right membrane switch company ...

Contact us online