Silicone rubber keypad manufacturer, Silicone rubber keypads suppliers

Silicone rubber keypad manufacturer, Silicone rubber keypads suppliers

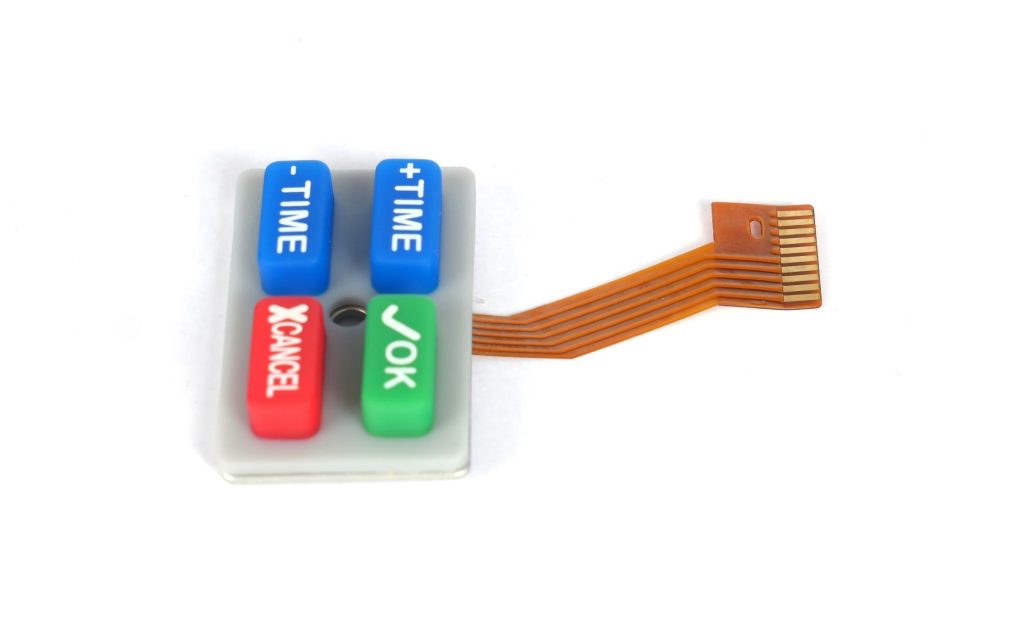

Silicone rubber keypad is a membrane switch made of silicone rubber material with good flexibility and insulation. It makes the conductive layer under the silicone rubber contact with the circuit by pressing, thus achieving the conduction of the circuit. This switch not only provides comfortable tactile feedback, but also has the characteristics of waterproof, dustproof and chemical corrosion resistance. It is widely used in home appliances, industrial equipment and electronic equipment.

Why use a custom silicone keypad?

Standard keypads work fine for general use. But when your device requires a specific look, feel, or function, a custom silicone keypad makes all the difference.

Custom keypad adapts to your product’s exact needs. Whether you want glow-in-the-dark buttons, waterproof coatings, or laser-etched legends that won’t fade, custom options let you design for performance and beauty.

In high-usage environments, customization also increases reliability. You can choose the right actuation force, tactile feedback, and materials that match your use case.

What are the advantages of custom rubber keypad designs?

Custom rubber keypad isn’t just about appearance—it’s about superior performance.

- 1. Enhanced Durability

Silicone rubber keypads can last millions of actuations. With the right design, your buttons resist wear, moisture, dust, and harsh chemicals.

- 2. Flexible Design Options

You can design buttons in any shape, thickness, or layout. Need embossed keys? Transparent areas for backlighting?

- 3. Better User Experience

A soft, responsive feel makes every press comfortable. Users appreciate the smooth, predictable response of silicone. It feels premium.

- 4. Cost-Effective Production

Once the mold is created, manufacturing becomes efficient. For high volumes, the cost per unit drops dramatically—without sacrificing quality.

- 5. Custom Backlighting and Legends

Use laser etching, printing, or coating to create legends that won’t fade. Add LED-compatible sections to make night use a breeze.

- 6. Environmental Resistance

Custom silicone keypads can be sealed to achieve IP67 ratings. That means no worries about water or dust ingress.

Whether for aesthetics, durability, or precision control, customized rubber keypad designs deliver far more than off-the-shelf options.

How are rubber keypads made?

Once the silicone is ready, it’s molded using compression molding. This involves placing the silicone into a heated cavity and compressing it with high pressure to form the keypad shape.

Next comes curing, where the molded part is heated again to stabilize the shape and remove any moisture. After curing, the keypad may go through a coating or printing stage. This is where legends, icons, or colored areas are added using screen printing or laser etching.

For illuminated keypads, clear silicone or light windows are incorporated during molding. Metal domes or carbon pills can be added for electrical conductivity and feedback.

Finally, each keypad goes through strict quality control, where every button’s force, feel, and visual details are inspected.

How do silicone rubber buttons perform?

Silicone rubber buttons aren’t just soft. They deliver tactile feedback that feels precise. With every press, the button responds with a clean snap or smooth touch, depending on the design. This helps prevent accidental presses while improving speed and control.

The elastic memory of silicone ensures each button returns to its original position. Even after thousands of uses, the button feels the same as the first press.

And since silicone resists heat, UV, moisture, and chemicals, the performance holds up in extreme environments. Whether on a dusty factory floor or a wet kitchen countertop, silicone buttons stay reliable.

Plus, they’re quiet. Unlike plastic keys or mechanical switches, silicone absorbs noise, making them perfect for low-noise environments like hospitals or office settings.

What is silicone rubber keypad used for?

Silicone rubber keypads are everywhere. They power industrial control panels, where workers need a tactile yet durable interface. In the automotive sector, they’re used in dashboard controls, key fobs, and GPS units. In medical devices, they provide safe, cleanable interfaces.

Consumer electronics like remote controls, handheld devices, and calculators rely on silicone keypads for smooth user interaction.

These keypads are also favored in telecom, marine, military, and aerospace applications, thanks to their resistance to weather, chemicals, and mechanical stress.

What’s the difference between rubber keypads and silicone keypads?

All silicone keypads are technically rubber keypads—but not all rubber keypads are silicone.

“Rubber keypad” is a broader term. It can refer to natural rubber, neoprene, or silicone. Among them, silicone is the most used and preferred due to its superior performance.

Silicone offers better flexibility, durability, and weather resistance. It also resists yellowing, retains its softness, and can be made food-grade or medical-grade for sensitive applications.

Other rubbers may be cheaper, but they don’t last as long or feel as smooth. Silicone rubber wins in nearly every category.

Where are rubber buttons for electronics used?

Rubber buttons—especially those made of silicone. They’re used in remote controls, allowing fast, quiet channel switching. In portable electronics, such as calculators and barcode scanners, they offer excellent wear resistance and a good feel.

Fitness devices and smartwatches use them for their flexible shapes and smooth surface. These buttons are lightweight, comfortable to press, and easy to seal against sweat or water.

In medical tools, they create sterile, soft-touch interfaces. In point-of-sale terminals, they stand up to high-frequency use without failure.

Conclusion:

Silicone offers outstanding performance, customization, and durability. It handles tough conditions with ease and delivers a premium feel that lasts.

Whether you’re building medical equipment, smart devices, or industrial controls, choosing the right design and the right silicone rubber keypad manufacturer makes all the difference.

Ready to explore high-performance silicone keypads for your next product? Contact us at sales@best-membraneswitch.com

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

What is rubber dome keyboard? Rubber keyboard

Rubber keyboard is known for its soft feel, quiet operation, and reliable everyday performance. A rubber dome keyboard is a keyboard that uses a flexible rubber dome under each key to register input. When a key is pressed, the dome collapses and makes contact with the circuit below, sending a signal, then springs back when ...

Contact us online