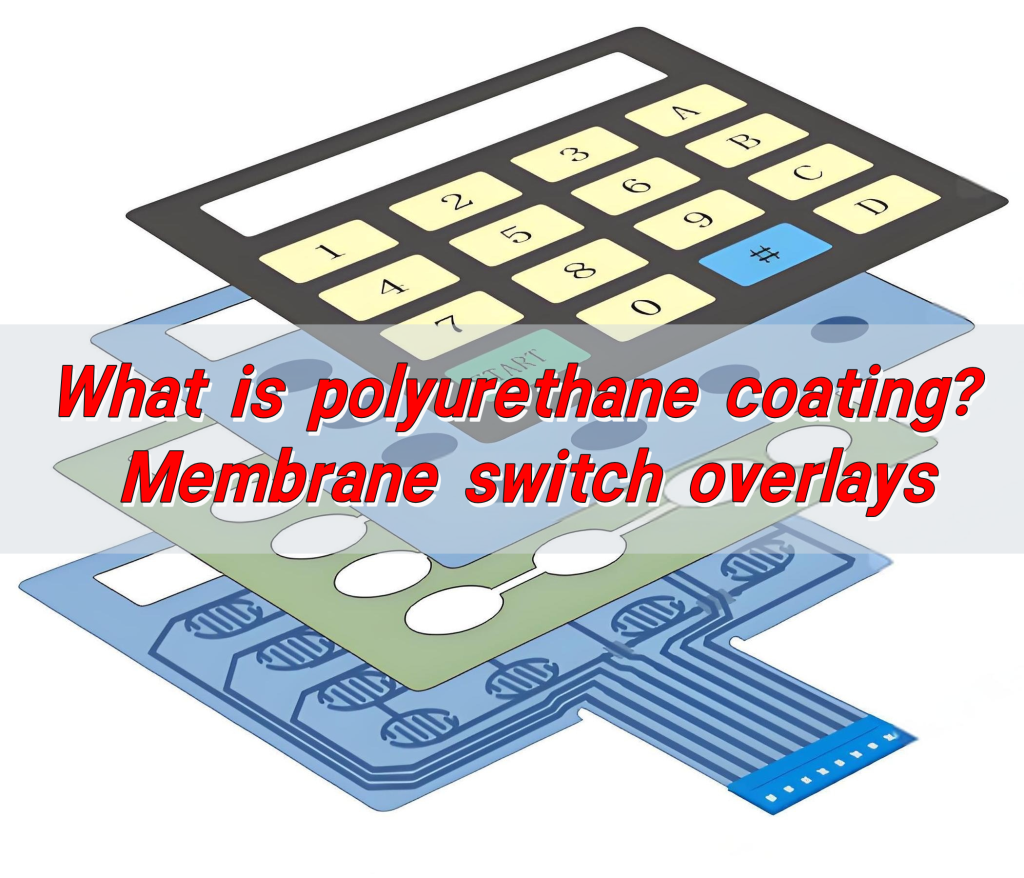

What is polyurethane coating? Membrane switch overlays

What is polyurethane coating? Membrane switch overlays

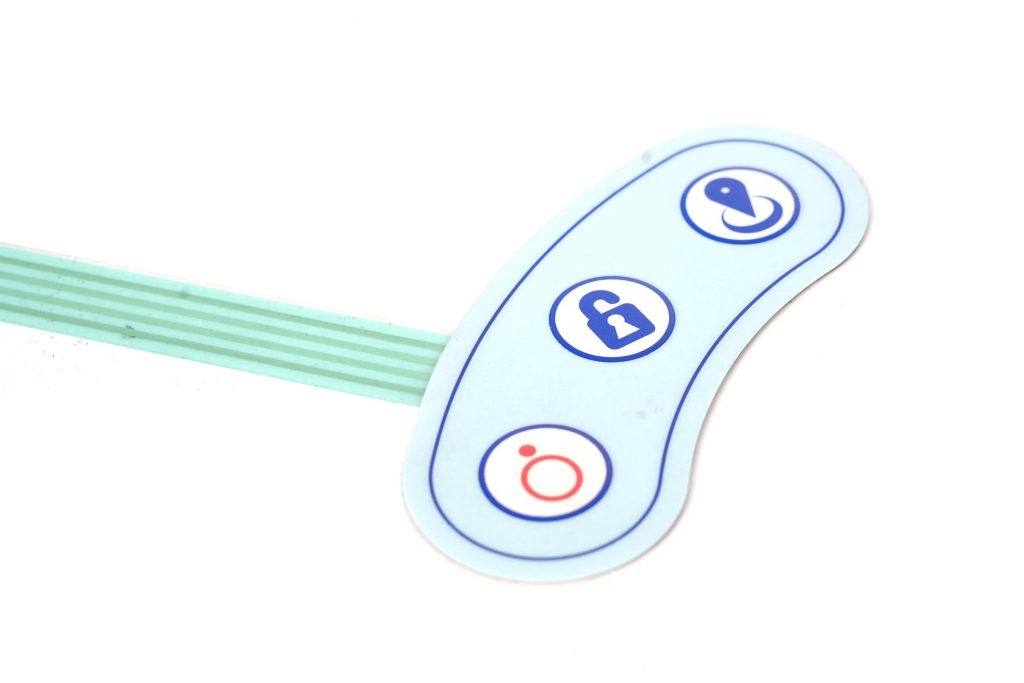

Polyurethane coating is an extremely thin elastic protective film that directly covers the surface of the membrane switch, isolating it from moisture, oil and scratches like invisible armor, while retaining a clear key touch. It allows the membrane switch to remain sensitive and durable in kitchen steam, industrial dust or outdoor exposure.

What are polyurethane coatings used for?

Polyurethane coatings are used to enhance surface durability, resist moisture, and protect against harsh conditions. Their most common use in electronics is for membrane switch overlays. These coatings keep the printed surface safe from scratches, UV light, and aggressive chemicals.

They’re also widely used in other industries. You’ll find them on wood, metal, plastic, and fabrics. But in membrane switches, polyurethane serves a more critical purpose. It keeps overlays clear, flexible, and tough, even when exposed to repeated touch and environmental stress.

Because it’s thin and transparent, polyurethane does not interfere with the function of the switch. It preserves the sharpness of the graphics and enhances tactile feedback. That’s why it’s a trusted choice across industries, from medical devices to control systems.

Is polyurethane coat waterproof?

Yes, polyurethane coating is waterproof. Once applied, it forms a continuous seal across the surface. Water, humidity, and steam cannot pass through. This makes it perfect for membrane switch coatings, especially in outdoor or high-humidity environments like kitchens, hospitals, and factories.

In waterproof testing, polyurethane coatings consistently outperform other surface treatments. They resist not just water but also oil, dust, and corrosive vapors. This waterproof nature ensures the switch continues to function without short circuits or corrosion.

Does polyurethane coating wear off?

Polyurethane coating is designed to last. It resists wear better than most alternatives. However, over time and with constant exposure to heavy abrasion or strong chemicals, minor surface wear can occur. But compared to other coatings, polyurethane holds up much longer.

In membrane switch overlays, the coating is expected to handle thousands or even millions of touches. It maintains its gloss, flexibility, and clarity. Most products using polyurethane coating show minimal signs of aging, even after extended use.

The key lies in quality. A properly formulated and applied polyurethane layer doesn’t peel, crack, or discolor easily. Even in high-contact environments, it stays strong.

What are the disadvantages of using polyurethane?

Every material has limits. Polyurethane is no exception, though its downsides are minimal.

One potential issue is curing time. Some polyurethane coatings may take longer to cure, especially if applied in thicker layers.

Another concern is slight yellowing. Under constant sunlight, older or low-quality polyurethane coatings may develop a faint yellow hue. However, modern UV-resistant formulas have mostly solved this.

Cost is another factor. Polyurethane may be slightly more expensive than basic coatings. But in most cases, the added durability and lifespan justify the investment.

Overall, these disadvantages are minor. With proper handling and high-grade materials, they’re easily avoided.

How long does polyurethane coating last?

Polyurethane coatings are built to last. Their average lifespan ranges from 5 to 10 years, depending on the application and environment.

In membrane switches, longevity is even more critical. These switches are part of machines and devices that operate daily. The coating must protect the interface from damage for the product’s entire service life.

When tested in high-touch applications, polyurethane-coated overlays have shown remarkable durability. They resist cracking, fading, and peeling even after 1 million actuations.

Why choose polyurethane coating for membrane switch overlays?

Membrane switches face tough environments. From heavy daily use to exposure to cleaning agents, they need robust protection.

First, it enhances clarity. The graphics under the overlay remain bright, sharp, and easy to read. This matters in critical applications like medical equipment, control panels, and industrial machines.

Second, it improves tactile feedback. The coating is flexible and soft to the touch, making every press feel responsive and comfortable.

Third, polyurethane resists chemicals. Disinfectants, oils, and cleaning sprays don’t break it down.

Fourth, it stands up to abrasion. The overlay stays clean and free of scratches.

Finally, polyurethane is customizable. It can be applied in different gloss levels, textures, and thicknesses. Whether you need a matte look or a glossy finish, the coating can adapt to your design.

Can polyurethane coating improve membrane switch longevity?

Absolutely. Polyurethane coating dramatically increases the life of membrane switches.

When people press the keys, wipe down the surface, or expose it to moisture, the coating takes the hit—not the underlying graphic or circuitry.

By stopping physical wear, chemical corrosion, and environmental damage, polyurethane extends the product’s lifespan by years. It keeps switches functional and visually appealing long after cheaper coatings would have failed.

Longer life means fewer complaints. Less maintenance. And lower costs for replacements or repairs.

Conclusion:

Polyurethane coating is not just a surface treatment—it’s a performance upgrade. Its unmatched durability, waterproof barrier, and soft-touch feel make it perfect for membrane switch overlays. While it may cost slightly more upfront, the long-term savings and improved performance are undeniable.

By choosing polyurethane, you ensure that your membrane switches remain strong, reliable, and beautiful—no matter the environment. You get fewer failures, better feedback, and a stronger customer impression.

Don’t let your overlays fall short. Choose polyurethane for the protection and polish your products deserve.

For custom polyurethane-coated membrane switches, contact us today at sales@best-membraneswitch.com. We’re here to help your products last longer and perform better.

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

What is rubber dome keyboard? Rubber keyboard

Rubber keyboard is known for its soft feel, quiet operation, and reliable everyday performance. A rubber dome keyboard is a keyboard that uses a flexible rubber dome under each key to register input. When a key is pressed, the dome collapses and makes contact with the circuit below, sending a signal, then springs back when ...

Contact us online