Comparing Membrane Panel Switches and Industrial Keyboards for Modern Factories

Comparing Membrane Panel Switches and Industrial Keyboards for Modern Factories

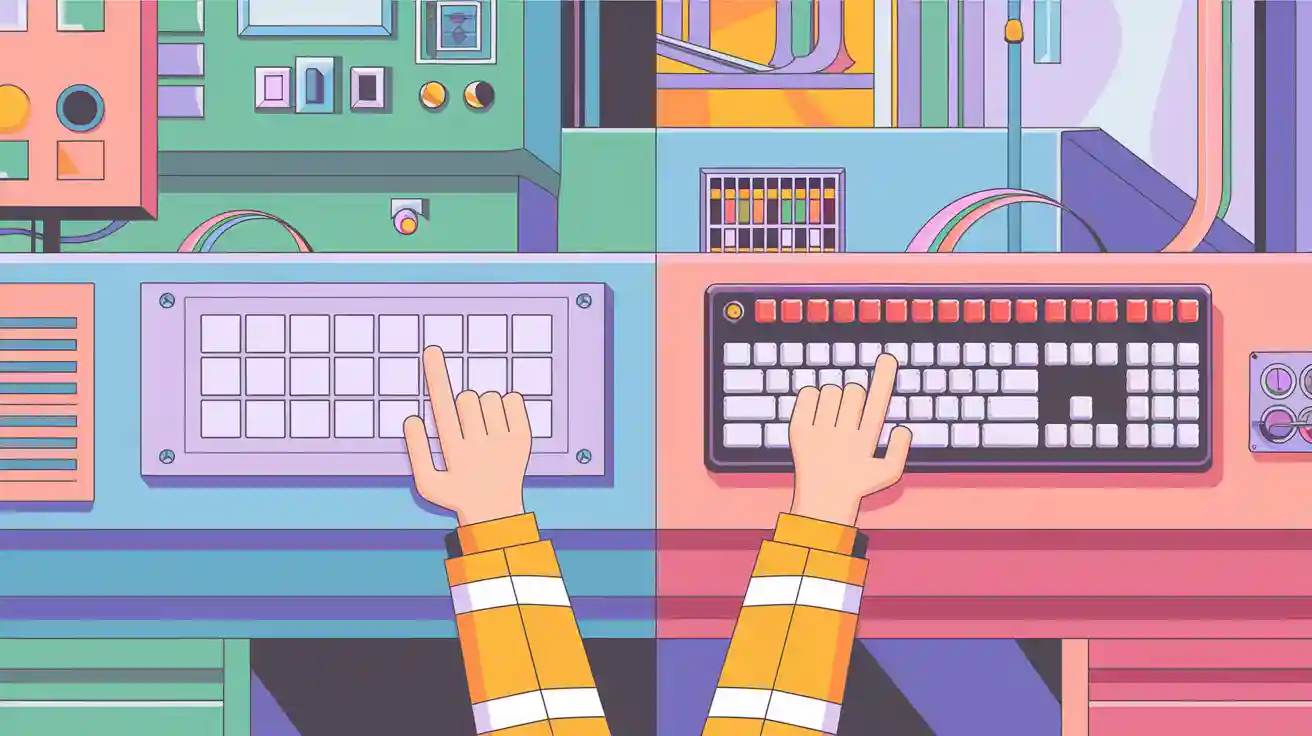

Factories need to pick a membrane panel switch or an industrial keyboard for control systems. Picture a worker with gloves in a dirty place. Which device is easier to use? People should think about strength, ease of use, price, fixing, and how each device works for the job. A membrane panel switch keeps out dust and water better. An industrial keyboard lets you feel the keys more. The best choice depends on what each factory needs.

Key Takeaways

- Membrane panel switches and industrial keyboards both keep out dust and water. You can use them with gloves. But they feel different when you use them.

- Membrane panel switches cost less money. They are simple to clean. They fit into small spaces. This makes them good for easy controls and hard places.

- Industrial keyboards give strong feedback when you press the keys. They are good for heavy use. They help workers make fewer mistakes. This is helpful in data entry and control rooms.

- Custom membrane panel switches let factories pick the size, look, and features they want. They can be made quickly.

- Picking the right device depends on space, money, and how tough it needs to be. It also depends on how workers will use it. This helps machines work well and stay safe.

Overview

samsung range membrane switch panelSimilarities

Lots of factories use both membrane panel switches and industrial keyboards. These devices help workers run machines and systems. Both keep out dust and water very well. Workers can clean both without trouble. Each device fits into many control panels. Some models have backlighting for dark places.

Tip: Both types work with gloves, but they feel different. Workers should try both to see which feels best.

Here is a quick comparison:

| Feature | Membrane Panel Switch | Industrial Keyboard |

|---|---|---|

| Dust/Water Resistance | High | High |

| Cleaning Ease | Easy | Easy |

| Backlighting | Available | Available |

| Glove Usability | Good | Good |

Samsung Membrane Switch Panel Replacement

Factories sometimes must change a membrane panel switch. This job is usually easy to do. Workers take out the old panel and put in a new one. They do not need special tools. Many sellers have panels that match the old design. Some companies make custom membrane switch panels for special needs.

Note: Checking panels often helps find worn ones early. Fast replacement keeps machines working well.

Membrane Switch and Panel Inc

Membrane switch and panel companies make these panels for many jobs. They use strong stuff that stands up to chemicals and water. Some companies make custom panels for special machines. These panels last a long time and need little care. Many factories pick these panels because they work well and cost less.

Membrane Switch Panel Manufacturer

Membrane panel switch manufacturers make products for tough places. These switches use a thin film. There are no moving parts inside. This makes them slim and light. The flat surface blocks dust, water, and chemicals. Many factories pick these switches. They last long and need little care.

Industrial keyboards look different from membrane panel switches. They have keys that move when pressed. Most use mechanical or metal dome switches. These keyboards work well in rough places. They often have waterproof and dustproof cases. Workers feel each key press. This helps lower mistakes.

Both membrane panel switches and industrial keyboards work with gloves. Factory workers wear gloves to stay safe. Membrane panel switches respond to light touches. This works even with gloves on. Industrial keyboards need more pressure. They give clear feedback. Noise is different for each type. Membrane panel switches are quiet. Industrial keyboards make more sound when used. Cleaning both types is easy. The flat surface of a membrane panel switch wipes clean fast. Industrial keyboards take more time to clean between keys.

Membrane Switch Panel Repair

Factories sometimes need to fix a membrane panel switch. Most repairs mean changing the thin film or fixing the connector. Many manufacturers help with repairs quickly. Workers can swap out a broken panel. No special tools are needed. This keeps machines running with little delay. Regular checks help find problems early.

Tip: Keeping spare panels ready helps fix problems fast. This stops long machine breaks.

Marine Membrane Switch Panel

Marine places need special control panels. Saltwater, humidity, and shaking can hurt regular switches. A membrane panel switch works well on ships and boats. The sealed surface blocks water and salt. Some marine panels have a waterproof rating up to IP67. This means they handle splashes and short dips in water. Marine membrane switch panels often have backlighting. This helps at night or in dark places.

Custom Membrane Switch Panel

Custom membrane switch panels help factories with special needs. Manufacturers offer many ways to change the design:

- Size can fit any space or machine.

- Color schemes match the factory’s look.

- Surface finish can be matte or glossy.

- Connector types can be chosen, like a 1.0 mm pitch black connector.

- Waterproof ratings go up to IP67 for tough places.

- Used in many industries: machinery, automotive dashboards, medical equipment, and home appliances.

- Factories can order one piece or many.

- Certified with ISO9001:2015 for quality.

- Full technical support for design and setup.

Custom panels give factories more control over machines. They fit tight spaces and match other equipment. Many companies pick custom panels for new machines or upgrades.

Manufacturers work fast to make custom membrane panel switches. Sample production takes 1 to 7 days. Large orders need 1 to 3 weeks. Complex designs may take an extra week. Shipping usually takes 3 to 7 days.

| Item | Lead Time |

|---|---|

| Sample Production Time | 1-7 days |

| Quantity Order Time | 1-3 weeks |

| Additional Time for Complex Products | +1 week |

| Shipping Time | 3-7 days |

Note: Custom membrane panel switches help factories get the right fit. Fast lead times mean less waiting for new parts.

Cost

Initial Investment

Factories look at how much each device costs at first. Membrane panel switches are cheaper to buy. They use thin layers and have a simple build. Industrial keyboards have more parts and need tough cases. This makes them cost more money. Some factories want custom membrane switch panels for special jobs. Custom panels can be pricier, but they fit the job well.

| Device Type | Typical Initial Cost | Customization Cost |

|---|---|---|

| Membrane Panel Switch | Low | Medium |

| Industrial Keyboard | Medium-High | High |

Tip: Factories should get prices from different sellers. This helps them find the best deal for what they need.

Maintenance Costs

Membrane panel switches do not need much care. Their flat top keeps out dust and water. Workers can clean them with a quick wipe. Repairs are simple and fast. Most times, workers just change the panel. Industrial keyboards need more cleaning. Dirt can get stuck between the keys. Fixing them takes longer and may need special tools. Over time, fixing or cleaning industrial keyboards can cost more.

- Membrane panel switches: Easy to care for, fast to fix.

- Industrial keyboards: Need more cleaning, take longer to repair.

Checking devices often helps find problems early. This keeps machines working and saves money.

System Integration

Factories must connect these devices to their systems. Membrane panel switches work with many machines. They use simple connectors and fit in small spaces. Custom membrane switch panels can match special wires or layouts. Industrial keyboards need more space. They might use USB or other ports. Some systems need extra software to use all keyboard features.

| Integration Factor | Membrane Panel Switch | Industrial Keyboard |

|---|---|---|

| Space Needed | Small | Large |

| Connector Types | Many options | USB, PS/2 |

| Setup Time | Fast | Medium |

Picking the right device makes setup faster. It also helps stop mistakes.

Application Fit

Membrane Panel Switch Use Cases

Factories use membrane panel switches in lots of places. These switches work well in control panels. Workers press them many times every day. The switches last long and do not need much care. Medical devices also use membrane panel switches. Doctors and nurses trust them for quick and safe input. Cars use them for dashboard controls and lights. Communication equipment uses them for fast commands.

Membrane panel switches have many good points:

- They are reliable and can handle many presses.

- Tactile feedback helps workers know when they press a button.

- The small and light design fits in tight spaces.

- Factories can order custom membrane switch panels for special needs. These panels can change size, shape, or how hard you press.

Factories pick membrane panel switches for simple and cheap controls. Backlighting helps workers see buttons in the dark.

Industrial Keyboard Use Cases

Industrial keyboards are for factories that need strong input devices. Workers use them in tough places. These keyboards can take rough use and lots of pressing. Important jobs, like machine work or typing data, need clear key presses. Industrial keyboards work well where mistakes must be low and speed is important.

Factories choose industrial keyboards for:

- Control rooms with lots of people and long hours.

- Data entry spots that need fast and correct typing.

- Places with dust, water, or chemicals, where tough design matters.

- Jobs where workers wear gloves and still need to feel keys.

Industrial keyboards give strong feedback. This helps workers make fewer mistakes and stay focused.

Selection Checklist

Factories need to pick the right device for their needs. The checklist below helps managers choose:

| Factor | Membrane Panel Switch | Industrial Keyboard |

|---|---|---|

| Space Available | Small, fits tight areas | Needs more room |

| Budget | Lower cost | Higher cost |

| Durability | High, few moving parts | Very high, rugged build |

| Maintenance | Easy, quick to clean | Needs more cleaning |

| Tactile Feedback | Light, soft touch | Strong, clear key press |

| Customization | Many options, easy to adapt | Limited, mostly layout changes |

| Backlighting | Available | Available |

| Glove Usability | Good | Good |

| Application Fit | Simple controls, panels | Heavy use, data entry |

Managers should look at their space, use, and budget before picking. The right choice makes work safer and faster.

Factory managers know that metal dome membrane switches and industrial keyboards are both tough and work well. Metal dome switches are good for small control panels. They give a clear feel when pressed. Industrial keyboards are best for hard jobs. They let workers type easily, even with gloves on. Custom membrane switch panels help factories with special needs. Each device is right for different tasks. Managers should think about their workplace, how they will use the device, and how much money they have before choosing.

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

What is rubber dome keyboard? Rubber keyboard

Rubber keyboard is known for its soft feel, quiet operation, and reliable everyday performance. A rubber dome keyboard is a keyboard that uses a flexible rubber dome under each key to register input. When a key is pressed, the dome collapses and makes contact with the circuit below, sending a signal, then springs back when ...

Contact us online