Top 10 Applications for Silicone Rubber Keypads in Modern Electronics

Top 10 Applications for Silicone Rubber Keypads in Modern Electronics

Silicone rubber keypads play a vital role in modern electronics, offering exceptional longevity and reliability across a wide range of applications.

- Consumer electronics, automotive controls, medical devices, industrial equipment, aerospace panels, telecommunications, remote controls, point-of-sale terminals, home appliances, and electronic toys all represent high use applications for silicone in electronics.

- The market continues to grow, driven by durability, tactile feedback, flexibility, and customisation.

- These applications benefit from silicone used in electronics for its water resistance, ease of cleaning, and design versatility.

- Silicone rubber keypad solutions also support longevity, making them ideal for both demanding and everyday uses.

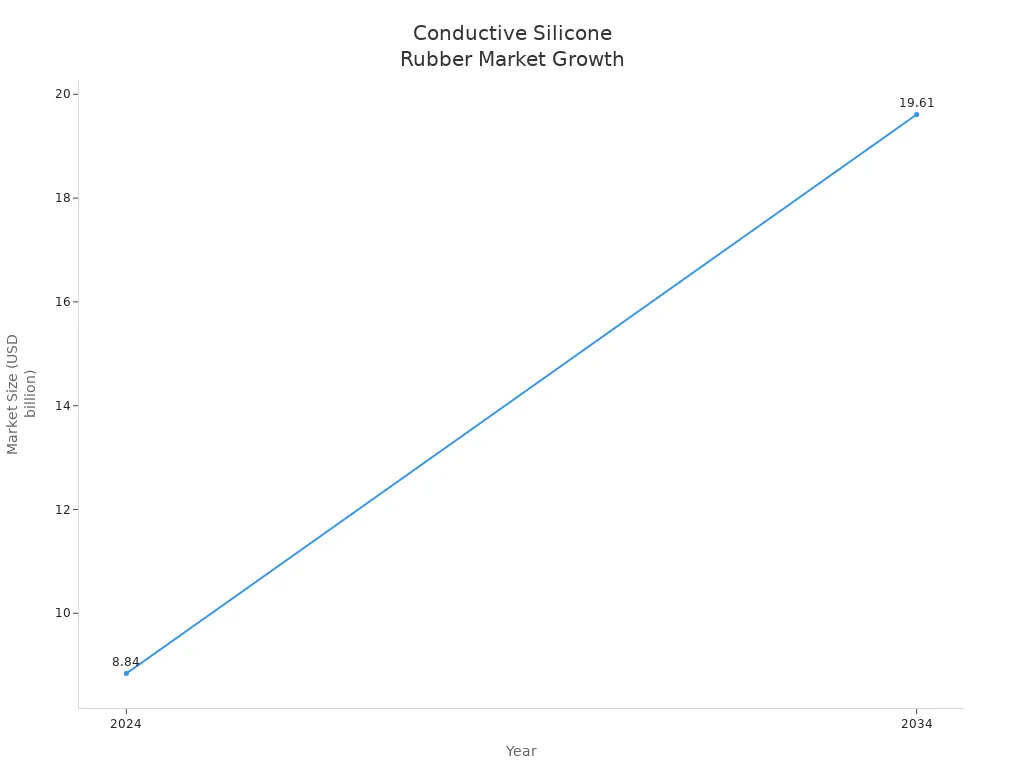

- The expanding market for silicone for electronics is illustrated by the projected growth in conductive silicone rubber and membrane keypads.

Key Takeaways

- Silicone rubber keypads offer durability, water resistance, and excellent tactile feedback, making them ideal for many electronic devices.

- These keypads support hygiene and safety in medical and consumer electronics through easy cleaning and antimicrobial properties.

- Customisation options allow designers to create keypads with various shapes, colours, and backlighting to enhance user experience.

- Silicone rubber keypads perform reliably in harsh environments like industrial, automotive, and military settings due to their chemical and temperature resistance.

- Their long lifespan and low maintenance needs make silicone rubber keypads a cost-effective and trusted choice for modern electronics.

Consumer Electronics

Silicone rubber keypads have become essential in consumer electronics, supporting a wide range of applications from mobile phones to gaming devices and music players. Manufacturers choose these keypads for their durability, tactile feedback, and customisation options. The use of silicone for electronics ensures reliable performance and meets the demands of modern users.

Silicone Rubber Keypad in Mobiles

Mobile phones rely on silicone rubber keypads for several reasons.

- These keypads offer excellent durability and withstand frequent use, resisting wear and tear over time.

- Waterproofing and antimicrobial coatings protect devices from moisture and germs, supporting hygiene for health-conscious consumers.

- The compact size and ease of installation make them ideal for slim smartphone designs.

- Users experience a satisfying tactile response, with a clear ‘snap’ or ‘click’ feel that confirms each press.

- Compared to alternatives such as capacitive touch screens, silicone rubber keypads provide superior mechanical resilience and allow for custom shapes and colours.

- The telecommunications sector continues to favour these keypads for their reliability and user satisfaction.

Note: Silicone rubber keypads also contribute to display protection, shielding sensitive components from dust and accidental spills.

Gaming Devices

Gaming devices benefit from silicone rubber keypads due to their rugged construction and responsive feedback.

- Players require precise input and quick reaction times, which these keypads deliver through their tactile design.

- Customisation options, including vibrant colours and unique textures, enhance the gaming experience and appeal to personal style preferences.

- The washable surface supports hygiene, especially in shared environments.

- Manufacturers adopt softer silicone materials for improved comfort during extended play sessions.

Music Players

Music players use silicone rubber keypads to provide reliable control and long-lasting operation.

- The membrane structure, consisting of two rubber layers separated by a plastic layer, ensures a good pressing feel and extended lifespan.

- These keypads are easier to clean than mechanical switches, maintaining hygiene for users on the go.

- Their affordability and low maintenance requirements make them a practical choice for portable electronics.

Consumer electronics continue to evolve, but the silicone rubber keypad remains a preferred solution for durability, tactile feedback, and customisation.

Medical Devices

Silicone rubber keypads have become indispensable in medical electronics, supporting critical applications such as diagnostic equipment and patient monitoring systems. Their design prioritises hygiene, reliability, and ease of cleaning, which are essential in healthcare environments.

Silicone Rubber Keypads in Medical Equipment

Medical equipment demands strict compliance with hygiene and safety standards. Manufacturers select silicone rubber keypads for their robust sealing and protection against contaminants. The following table outlines the key requirements these keypads must meet:

| Aspect | Requirement / Standard |

|---|---|

| Electrical Safety | IEC 60601-1 compliance for medical electrical equipment safety |

| Biocompatibility | ISO 10993 series for non-toxicity and non-sensitisation |

| Ingress Protection | IP65, IP67, IP68 ratings to prevent dust and liquid ingress |

| Material Grade | Medical-grade silicone, resistant to hospital disinfectants |

| Surface Design | Fully sealed, seamless, non-porous surfaces for thorough cleaning |

| Chemical Resistance | Withstands repeated exposure to bleach, alcohol, hydrogen peroxide |

| Regulatory Compliance | FDA 21 CFR 177.2600 for food contact where applicable |

| Cleaning Protocols | Use of EPA-registered disinfectants, proper wet contact time, avoidance of abrasives |

| Durability and Reliability | Robust construction for heavy use, long lifespan |

| Operational Suitability | Tactile feedback for gloved use, quiet operation, optional backlighting |

Medical electronics benefit from these features, ensuring devices remain safe and functional in demanding clinical settings. The smooth silicone surface allows thorough disinfection, supporting infection control protocols. Hospitals favour keypads with antimicrobial properties and dishwasher-safe designs, which enable rigorous cleaning without compromising performance.

Tip: Flat keys and seamless surfaces help prevent microbial ingress, reducing the risk of contamination in sensitive environments.

Accessibility Devices

Accessibility devices rely on silicone rubber keypads to improve usability for diverse users. These keypads withstand sterilisation processes and resist temperature and humidity fluctuations, ensuring consistent operation. Backlighting options, such as laser etching and LEDs, enhance visibility in low-light conditions, supporting users with impaired vision.

- Strong tactile feedback and customisable switch travel assist users with varying dexterity.

- Waterproof and dustproof designs guarantee long-term reliability.

- Personalised customisation adapts keypads to specific user requirements, improving accessibility.

Healthcare professionals value the reliability and flexibility of silicone rubber keypads in electronics, recognising their contribution to patient safety and device longevity. Their chemical resistance and robust construction ensure devices endure frequent cleaning and heavy use, making them ideal for medical applications.

Industrial Controls

Industrial environments demand components that can withstand harsh conditions while maintaining reliable performance. Silicone rubber keypads have become a preferred choice in electronics for machinery panels and automation interfaces due to their exceptional durability, longevity, and protection features.

Silicone Rubber Keypads for Control Panels

Control panels in factories and processing plants require robust input devices. A silicone rubber keypad provides chemical resistance to oils, solvents, and other aggressive substances often present in industrial settings. Its construction shields sensitive electronics from dust and moisture, ensuring consistent operation. Operators benefit from tactile feedback and ergonomic design, which reduce fatigue and improve input accuracy. These keypads meet strict industry certifications, including IP67 and IP68 ratings, UL recognition, and MIL-STD standards. Such compliance guarantees high reliability and a long operational life, often exceeding one million keystrokes. The abrasion resistant coating and non-porous surface make cleaning straightforward, supporting hygiene and reducing downtime.

Operators in demanding environments value the tactile response and reliability of silicone rubber keypads, which help protect circuit boards and maintain system integrity.

Factory Automation

Factory automation systems rely on user interfaces that must perform under extreme conditions. Silicone rubber keypads excel in these applications because of their environmental resistance and sealing properties. The following table highlights key benefits:

| Benefit/Feature | Explanation |

|---|---|

| Tactile feedback | Customisable force improves input accuracy and operator confidence. |

| Durability and reliability | Withstands high moisture, chemicals, and temperature extremes, ensuring longevity. |

| Sealing and insulation | Acts as a barrier, protecting internal components and providing electrical insulating properties. |

| Backlighting | Supports clear visibility in low-light or variable lighting conditions. |

| Abrasion resistant coating | Extends the life of printed key labels and maintains keypad appearance. |

Silicone rubber’s unique silicon-oxygen polymer structure gives it superior resistance to heat, UV, and chemical degradation compared to plastic alternatives. Its flexibility allows for quieter operation and greater design versatility. Although initial costs may be higher, the reduced need for maintenance and replacement offsets this investment over time. The abrasion resistant coating further enhances longevity, making these keypads a cost-effective solution for industrial electronics.

Automotive Electronics

Automotive electronics have evolved rapidly, demanding components that deliver reliability and responsive user interfaces. Silicone rubber keypads have become a preferred solution for dashboards and steering controls, meeting the industry’s stringent requirements for durability, safety, and integration.

Dashboards

Modern vehicle dashboards require intuitive controls that withstand harsh conditions. Manufacturers select silicone rubber keypads for their superior thermal stability and flame resistance, operating reliably from -40°C to 230°C. These keypads maintain performance even when exposed to moisture, dust, and vibration, ensuring consistent operation in diverse environments. Custom silicone formulations, colours, and finishes allow seamless integration with dashboard aesthetics. Features such as embedded LEDs and tactile feedback enhance user experience, enabling drivers to operate controls with minimal distraction.

Immediate tactile feedback helps drivers keep their eyes on the road, reducing input errors and improving safety.

The following table highlights the essential features of silicone rubber keypads in dashboard applications:

| Feature | Description |

|---|---|

| Durability | Withstands extreme temperatures, humidity, and vibration without losing functionality. |

| Resistance to Environmental Factors | Resistant to water, dust, chemicals; does not corrode or rust, ensuring long-term reliability. |

| Tactile Feedback | Provides reliable touch response, enabling drivers to operate controls with minimal distraction. |

| Customisation Options | Can be tailored in colour, design, and integration with backlighting and conductive printing. |

| Safety Enhancement | Enables safer driving by allowing easy, distraction-free control operation. |

| Ergonomics and Aesthetics | Blends with modern dashboard designs, improving usability and visual appeal. |

Steering Controls

Steering wheel controls demand materials that offer both resilience and comfort. Silicone rubber keypads use compression moulding to create angled webbing, delivering uniform tactile feedback and rapid return to neutral position. This design ensures consistent user experience, even under frequent use. The natural shock and vibration resistance of silicone rubber enhances durability, while customisation for water and dust resistance makes these keypads suitable for rugged automotive environments.

- High-temperature resistance and chemical stability allow keypads to perform reliably in varied conditions.

- Automobile manufacturers favour silicone rubber for steering controls due to its proven reliability and compliance with strict safety standards.

- Ergonomic softness and vibration dampening improve driver comfort, especially during long journeys.

Automotive electronics continue to advance, and silicone rubber keypads remain essential for delivering safe, reliable, and responsive user interfaces.

Telecommunications

Silicone rubber keypads have become a standard feature in telecommunications equipment, offering robust performance and reliability. Their use in electronics such as landline phones and networking devices ensures long-term durability and user satisfaction.

Landline Phones

Landline phones require keypads that withstand frequent use and exposure to various environmental conditions. Silicone rubber keypads provide mechanical protection, waterproofing, and heat resistance, making them ideal for both domestic and commercial settings. Users benefit from safe operation, even with wet hands, which is especially important for children and elderly individuals. The following table highlights the main features and advantages:

| Feature | Explanation |

|---|---|

| Durability | Resistant to wear, extreme temperatures, chemicals, and UV radiation, extending device lifespan |

| Tactile Feedback | Soft, pliable material delivers comfortable, satisfying key presses, improving usability |

| Waterproof | Inherently resistant to water and liquids, protecting keypads in humid environments |

| Customisability | Can be moulded into various shapes, sizes, colours, and textures for tailored designs |

| Easy to Clean | Resistant to dirt and debris, can be wiped clean easily, maintaining hygiene and appearance |

Manufacturers favour silicone rubber keypads for their high sensitivity and greater durability compared to traditional switches. These keypads also prevent dust ingress, which manual switches cannot achieve. Their modern design fits well with contemporary device aesthetics, enhancing the overall appeal of telecommunications electronics.

Tip: Silicone rubber keypads offer easy and quick installation, with flexible warranty support for landline phone manufacturers.

Networking Devices

Networking devices, including routers and switches, demand reliable input solutions that maintain performance over time. Silicone rubber keypads excel in these applications due to their material quality and construction. High-grade moulded silicone rubber ensures durability under repeated use. Non-conductive keypads feature environmental sealing at the switch cavity, preventing contamination and improving reliability. The table below outlines key features relevant to networking devices:

| Feature Category | Description & Relevance to Reliability and User Experience |

|---|---|

| Material & Construction | High-grade silicone rubber provides longevity and stability. |

| Tactile Feedback | Force cone mechanism or metal snap dome switches deliver a clear snap feel, enhancing user confidence. |

| Environmental Sealing | Non-conductive keypads seal switch cavities, preventing dust and moisture ingress. |

| Keytop Stability | Thicker webs and higher durometer rubber reduce keytop wobble, ensuring precise input. |

| Durability & Resistance | Stable contact resistance and resistance to contamination maintain consistent performance. |

| Design Flexibility | Coatings, colours, and surface textures allow customisation without compromising reliability. |

Networking devices benefit from the scalability of silicone rubber keypads, allowing integration with smart remote-control centres and supporting manual, smartphone, or timer-based control. Their energy-saving properties and low power consumption contribute to efficient operation. Ongoing upgrades ensure stability and reliability, making these keypads a preferred choice in modern telecommunications electronics.

Remote Controls

Silicone Rubber Keypads for TV Remotes

Silicone rubber keypads have become the standard in TV remote controls, offering a blend of durability, comfort, and design flexibility. Manufacturers select these keypads for their ability to withstand repeated presses without deformation, ensuring long-term reliability in everyday electronics. The tactile feedback provided by the snap ratio and actuation force delivers a satisfying response, reducing finger fatigue during extended use.

Key design considerations for TV remote keypads include precise legend printing, durable silicone-compatible inks, and multi-layer colour application. The process involves careful stencil preparation, oven curing for ink bonding, and rigorous quality control. This approach guarantees clear, long-lasting symbols that remain legible throughout the keypad’s lifespan.

- Silicone rubber remains safe, hypoallergenic, and odourless, making it suitable for all users.

- The material resists both high and low temperatures, maintaining stable performance in various home environments.

- Customisation options in colour and texture enhance the visual appeal and brand identity of remote controls.

Tip: Conductive elements, such as carbon pills, ensure reliable electrical contact with the circuit board, improving overall device performance.

Hi-Fi and Video Units

Hi-Fi and video unit remote controls demand components that combine resilience with a premium user experience. Silicone rubber keypads excel in these applications due to their exceptional thermal stability, functioning reliably from -100°C to 250°C. The material resists chemicals, UV light, and moisture, protecting sensitive electronics from environmental hazards.

The following table summarises the main benefits of silicone rubber keypads in Hi-Fi and video unit remotes:

| Benefit Category | Description |

|---|---|

| Environmental Resistance | Maintains performance in extreme temperatures, humidity, and exposure to chemicals or UV light. |

| Tactile Feedback | Provides a soft, responsive feel, improving input accuracy and user satisfaction. |

| Hygiene and Safety | Hypoallergenic, non-toxic, and easy to clean, supporting safe use in shared environments. |

| Design Flexibility | Allows for custom shapes, colours, and textures, supporting branding and ergonomic needs. |

| Durability | Withstands frequent use, reducing the need for replacements and lowering maintenance costs. |

Silicone rubber’s smooth surface prevents microbial growth and simplifies cleaning, which is essential for devices handled by multiple users. The keypad’s design flexibility supports the integration of backlighting, enhancing visibility in low-light conditions and further improving the user experience.

Point-of-Sale Terminals

Silicone rubber keypads have become the industry standard in point-of-sale (POS) terminals. Retailers, banks, and hospitality providers rely on these components for secure and efficient transactions. The unique properties of silicone rubber make it ideal for high-traffic environments, where reliability and hygiene are essential.

Payment Keypads

Payment keypads must deliver both security and a positive user experience. Silicone rubber keypads offer several advantages:

- Firm tactility and customisable surface structures enable reliable operation, even when users wear gloves.

- Tactile feedback reduces input errors and increases user confidence, which is vital for secure payment systems.

- Environmental resistance to chemicals, abrasion, and temperature protects the keypad and underlying electronics, preventing tampering and damage.

- Sealing capabilities guard against moisture, dust, and UV exposure, enhancing security by protecting internal components.

- Customisable features such as laser-etched high-contrast legends and backlighting improve visibility and usability.

- Advanced manufacturing allows for 3D designs with varied button heights and contours, improving intuitive navigation and reducing mistakes.

- Durable materials ensure longevity and consistent performance, which is essential for secure and reliable payment environments.

Studies show that solid tactile feedback in silicone keypads can increase user satisfaction by up to 30% and reduce input errors by 40%. The material’s resistance to temperatures from -60°C to 300°C and its chemical stability ensure durability in harsh conditions, reducing the risk of keypad failure and security breaches.

Note: Enhanced tactile feedback and robust sealing help prevent fraud and accidental input, supporting compliance with industry standards.

Checkout Systems

Checkout systems demand components that withstand constant use and exposure to various environmental factors. Silicone rubber keypads meet these requirements through their robust construction and adaptability. The following table outlines key performance metrics for these keypads in checkout systems:

| Performance Metric | Details |

|---|---|

| Lifespan | More than 1 million cycles |

| Operating Temperature | -40℃ to +250℃ |

| Durability | High |

| Material | Silicone Rubber |

| LED Backlighting | Optional |

| Thickness | Customisable |

| Shape | Customisable |

| Logo | Customisable |

| Certifications | ROHS, SGS, ISO |

| Application Environment | Industrial, Commercial, Household |

| Tactile Feedback | Important for user experience |

Retailers benefit from keypads that maintain performance over time, even in demanding settings. Customisation options allow for branding and ergonomic improvements, while certifications ensure compliance with safety and environmental standards. The result is a reliable, user-friendly interface that supports efficient transactions and customer satisfaction.

Military & Aerospace

Silicone rubber keypads have become essential in military and aerospace electronics, where reliability and resilience are paramount. These environments demand components that perform under extreme conditions, ensuring mission-critical systems remain operational.

Field Communication

Field communication devices used by military personnel must withstand harsh environments and unpredictable conditions. Manufacturers select silicone rubber keypads for their robust construction and advanced features. The following table highlights key attributes that ensure reliability in the field:

| Feature | Description and Relevance to Military Reliability |

|---|---|

| Liquid-injection moulded Santoprene | Resists chemical warfare agents, ensuring keypad survival during exposure. |

| 100% environmentally sealed keypad | Prevents moisture and contaminants from entering, maintaining functionality in all weather. |

| Metal dome switches with LED indicators | Delivers tactile feedback and visual cues, supporting usability in stressful situations. |

| Copper flex circuit | Enhances durability of electrical connections, reducing failure risk. |

| Stainless steel backer | Provides rigidity and protection against physical shocks during field use. |

Designers often integrate EMI shielding mesh to protect against electromagnetic interference, which is vital for secure and uninterrupted communication. Keypads feature superior insulating properties, precise dimensional accuracy, and customisable actuation forces. These qualities guarantee consistent performance and user confidence, even in the most demanding military applications.

Note: Fully sealed assemblies and rubber wrapping around PCBs prevent environmental damage, while backlit keys with laser-etched symbols improve visibility during night operations.

Cockpit Panels

Aerospace cockpit panels require keypads that deliver both safety and operational reliability. Silicone rubber keypads excel due to their vibration resistance and tactile differentiation, which help pilots operate controls accurately. These keypads comply with strict aerospace standards such as DO-160G and feature EMI/RFI shielding for avionics. They operate reliably across temperature extremes from -40°C to +150°C and use flame-retardant materials certified to UL94 V-0, enhancing cockpit safety.

Manufacturers test these keypads for altitude, temperature cycling, and mechanical shock to ensure durability. Precision engineering in cleanroom environments guarantees high quality and consistency. The long actuation life, often exceeding one million cycles, supports the rigorous demands of aerospace operations. Custom shapes, surface finishes, and pressure-sensitive adhesive installation allow seamless integration into advanced cockpit designs, while effective sealing protects against dust, moisture, and chemicals.

Home Appliances

Microwave Ovens

Microwave ovens rely on silicone rubber keypads to deliver reliable and user-friendly interfaces. Manufacturers choose silicone rubber for its durability and flexibility, which allows repeated pressing without loss of tactile feedback. The material resists heat, making it suitable for appliances exposed to high temperatures during cooking cycles. Users benefit from waterproof keypads that prevent moisture ingress, protecting sensitive electronics and extending the lifespan of the device.

Silicone rubber keypads enhance the user experience by providing increased switch travel and tactile feedback. The diaphragm design controls actuation force and return force, resulting in a smooth and consistent response. Customisable surface finishes and discrete key appearances improve the aesthetics of microwave oven panels. Integration of backlighting and electronic components is possible, supporting usability in low-light kitchens.

Tip: Silicone rubber keypads offer strong electrical insulation, safeguarding internal circuits from accidental spills and steam.

The robust nature of silicone rubber ensures resistance to chemicals, oils, and cleaning agents commonly found in household environments. This abrasion resistance helps keypads withstand frequent use, maintaining performance and appearance over time. Appliance designers value the three-dimensional look and tactile feel, which provide a premium touch compared to flat membrane switches.

Washing Machines

Washing machines demand keypads that perform reliably in wet and humid conditions. Silicone rubber keypads excel due to their high water resistance and flexibility. The material’s thermal stability allows operation across a wide temperature range, from cold washes to hot cycles. Users experience consistent tactile feedback, which improves control and reduces input errors.

Manufacturers favour silicone rubber for its excellent dielectric properties, ensuring electrical safety even in damp environments. The keypads resist corrosion and contamination, reducing maintenance and extending the service life of electronic components. Silicone’s protective qualities enable the development of advanced smart washing machines with compact, efficient control systems.

- Silicone rubber withstands exposure to detergents, solvents, and cleaning agents.

- The abrasion-resistant surface maintains clarity of printed legends and symbols.

- Customisable shapes and thicknesses support ergonomic designs for improved usability.

Washing machines equipped with silicone rubber keypads offer reliable, long-lasting performance. These keypads contribute to the safety, convenience, and durability expected in modern home appliances, supporting the needs of UK households and the electronics manufacturing sector.

Electronic Toys & Measuring Devices

Silicone rubber keypads have become a staple in the design of electronic toys, games, and measuring instruments. These keypads deliver resilience, flexibility, and precise input, making them ideal for products that experience a high number of daily actuations. Manufacturers in the UK market value these features, especially when designing for demanding environments or for users who require reliable performance.

Toys & Games

Children’s toys and handheld gaming devices often face rough handling and frequent use. Silicone rubber keypads provide a soft, responsive touch that enhances the play experience. The material absorbs shocks and resists tearing, which helps toys last longer even in active hands. Designers can create colourful, engaging keypads that attract young users and support branding.

- Keypads with an abrasion resistant coating maintain their appearance and function despite repeated pressing and exposure to dirt.

- The flexibility of silicone rubber allows for creative shapes and interactive features, such as illuminated buttons or textured surfaces.

- Parents appreciate the easy-to-clean surface, which supports hygiene in shared play environments.

Note: Silicone rubber keypads also improve safety by eliminating sharp edges and reducing the risk of small parts breaking off.

Measuring Devices

Precision instruments, such as digital thermometers, multimeters, and kitchen scales, rely on silicone rubber keypads for accurate and reliable input. These devices often require users to operate them with gloves or in challenging conditions. Silicone rubber keypads respond well to light touches and provide clear tactile feedback, which reduces input errors.

A table below highlights the key benefits for measuring devices:

| Feature | Benefit |

|---|---|

| Flexibility | Adapts to various device shapes |

| Water Resistance | Protects internal electronics |

| Precise Input | Ensures accurate readings |

| Durability | Withstands daily actuations |

Engineers choose silicone rubber keypads for measuring devices because they support consistent performance and long service life. The material’s resistance to chemicals and moisture makes it suitable for laboratory and industrial settings.

Silicone rubber keypads serve a wide range of modern electronics, from consumer devices to industrial controls. Their versatility supports applications in automotive, medical, and home appliances.

- Engineers value the durability and tactile feedback these keypads provide.

- Designers appreciate customisation options and seamless integration with Flex PCB technology.

- Entrepreneurs recognise the longevity and reliability that benefit product development.

Silicone rubber keypads remain a smart choice for future electronic designs in the UK market.

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

What is rubber dome keyboard? Rubber keyboard

Rubber keyboard is known for its soft feel, quiet operation, and reliable everyday performance. A rubber dome keyboard is a keyboard that uses a flexible rubber dome under each key to register input. When a key is pressed, the dome collapses and makes contact with the circuit below, sending a signal, then springs back when ...

Contact us online