Top 10 Electronic Membrane Switches for Industrial Use

Top 10 Electronic Membrane Switches for Industrial Use

Here are the top 10 electronic membrane switches for industrial use. You need reliable membrane switches when working in harsh environments because single-sided designs often fail and reduce overall device quality. Leading manufacturers offer switches with excellent tactile feedback, long lifespan, and strong resistance to moisture or temperature changes. Consider the following selection criteria when choosing your switch:

| Selection Criteria | Description |

|---|---|

| Tactile Feedback and Lifespan | Consistent feel and long-term reliability |

| Environmental Conditions | Resistance to moisture and temperature |

| Budget vs. Performance Needs | Balancing cost with required performance |

| Supplier Support and Long-Term Fit | Reliable engineering support and delivery |

Key Takeaways

- Choose membrane switches with strong tactile feedback and long lifespan for reliable operation in industrial settings.

- Consider environmental factors like moisture and temperature when selecting a membrane switch to ensure durability.

- Balance cost and performance by investing in high-quality switches that reduce maintenance and improve efficiency.

- Consult with manufacturers early to customize membrane switches that meet your specific operational needs.

- Stay informed about new technologies and trends in membrane switches to enhance safety and functionality in your applications.

Top 10 Electronic Membrane Switches

C&K Components Membrane Switch

You can rely on C&K Components for a broad range of electronic membrane switch solutions. This manufacturer stands out among top membrane switch manufacturers due to its commitment to innovation and quality. C&K switches serve diverse industries, including safety, security, building automation, and factory automation. You benefit from their dust-tight, water-resistant, and ROHS3-compliant designs, which ensure long-term reliability in harsh environments.

| Key Features | Industrial Applications |

|---|---|

| Expansive product line | Safety & Security |

| Commitment to innovation and quality | Building Automation |

| Trusted by numerous OEMs | Factory Automation |

| Tailored to diverse industries | Energy & Utility |

| Feature | Description |

|---|---|

| Dust Tight | Yes |

| IP65 | Yes |

| Water Resistant | Yes |

| ROHS3 Compliant | Yes |

| Lead Free | Yes |

TE Connectivity Membrane Switch

TE Connectivity ranks among the top membrane switch manufacturers for advanced technology integration. You gain access to switches with capacitive touch layers, antimicrobial properties, and flexible substrates. These features make TE Connectivity ideal for healthcare, automotive, and industrial applications. Their switches support IoT integration, enabling real-time monitoring in packaging machinery and robotics.

| Feature/Use Case | Description |

|---|---|

| Capacitive Touch Layers | Integration of touch technology for enhanced user interaction |

| Antimicrobial Properties | Demand for switches in healthcare applications to prevent infection |

| Flexible Substrates | Use in wearable electronics for ultra-thin designs |

| IoT Integration | Embedded sensors for real-time monitoring in various applications |

| Automotive Applications | Control panels and infotainment systems in vehicles |

| Industrial Applications | Utilization in packaging machinery and robotics |

Honeywell Membrane Switch

Honeywell, a leader among membrane switch manufacturers, offers metal membrane switches with a low profile and extended durability. You experience clear tactile feedback, which improves safety and comfort in critical applications. Honeywell’s technology supports customization through additive manufacturing and precision laser etching. You can select features like backlighting and segmented actuation force, which enhance usability and meet strict safety standards.

Tip: Honeywell switches provide various overlay configurations, allowing you to tailor the interface for specific industrial needs.

Omron Membrane Switch

Omron stands out as one of the top membrane switch manufacturers for industrial reliability. You benefit from switches designed to withstand frequent use and harsh conditions. These membrane switches resist dust, oil, and chemicals, making them suitable for medical, laboratory, and factory environments. You can customize the size, layout, and functionality to match your requirements. The flat surface design makes cleaning easy, reducing maintenance time.

- Durability for frequent use

- Dust, oil, and waterproof protection

- Chemical resistance for medical and lab settings

- Sensitive operation for quick input

- Customizable design

- Easy-to-clean surfaces

Mitsubishi Electric Membrane Switch

Mitsubishi Electric delivers high-performance switches tailored for controllers and CNC milling machines. You can choose from basic dark gray or Pantone full-color options. The design resists vibration and shock, preventing mistaken touches. These membrane switches offer more than 100,000 operations and operate in temperatures from -25°C to +70°C. You receive IP67-rated waterproof and dustproof protection, along with CE and ROHS certification.

| Feature/Specification | Description |

|---|---|

| Design | Specially designed for MITSUBISHI controllers and CNC milling machines. |

| Color Options | Basic dark gray with options for Pantone full-color and gradient colors. |

| Customization | Graphics and text can be designed according to customer files (.jpg, .png, etc.). |

| Touch Sensation | Brisk touch feeling, resistant to vibration and shock, with mistaken touch prevention. |

| Mechanical Life | More than 100,000 operations (OMRON specification). |

| Operating Temperature | -25°C to +70°C. |

| Waterproof and Dustproof | IP67 rating, suitable for industrial environments. |

| Guarantee | One year under normal use. |

| Compliance | CE and ROHS certified (lead-free, environmentally friendly). |

| Custom Size | Sheet metal size can be customized according to needs. |

Panasonic Membrane Switch

Panasonic, recognized among top membrane switch manufacturers, supplies membrane switches for industrial control panels and automation systems. You can expect reliable tactile feedback and robust construction. Panasonic switches support custom graphics and layouts, which help you optimize machine interfaces for operator efficiency. Their switches perform well in environments with high vibration and temperature fluctuations.

Note: Panasonic’s engineering team provides support for custom membrane switches, ensuring you receive solutions tailored to your specific industrial requirements.

Yu’an Touchscreens Membrane Switch

Yu’an Touchscreens specializes in membrane switches for harsh environments. You benefit from waterproof and durable designs that minimize maintenance and maximize uptime. These switches suit outdoor kiosks, heavy machinery, and industrial control panels. You can request custom layouts and graphics to match your branding and operational needs.

| Feature | Description |

|---|---|

| Waterproof | Suitable for use in harsh environments |

| Durability | Ensures long-lasting performance and minimal maintenance |

UTC Membrane Switch

UTC, a trusted name among membrane switch manufacturers, offers rugged and durable membrane switches for industrial use. You can rely on their robust construction to withstand dust, moisture, and extreme temperatures. UTC switches provide precise control and intuitive interfaces, which help you optimize production processes. Their lightweight and space-saving design makes integration easy.

| Feature/Application | Description |

|---|---|

| Ruggedness | Membrane switches are designed to withstand harsh environments, including dust, moisture, and extreme temperatures. |

| Durability | Their robust construction reduces the need for frequent replacements, saving time and maintenance costs. |

| Precise Control | Allows operators to accurately adjust machinery settings, optimizing production processes. |

| Simple Control Interfaces | Provides intuitive control panels that enhance operator efficiency and reduce errors. |

| Customizability | Can be tailored with different colors, graphics, and tactile feedback for specific applications. |

| Lightweight and Space-Saving | Ideal for compact control panels, facilitating easy integration into existing systems. |

| Energy Efficiency | Low power consumption reduces operating costs. |

- Custom membrane switches from UTC offer versatility and durability, which are essential for industrial productivity.

- Their user-friendly design and adaptability ensure reliable operation in various environments.

Schurter Membrane Switch

Schurter ranks among the top membrane switch manufacturers for industrial-grade solutions. You can select switches with momentary action, gold or silver contacts, and a lifetime exceeding one million actuations. Schurter membrane switches operate in temperatures from -25°C to 60°C and feature IP65 protection. They meet industry standards such as IATF 16949 for automotive and ISO 13485 for medical technology.

| Feature | Details |

|---|---|

| Momentary Action Switch | Available in square or round |

| Contact Material | High-quality gold and silver |

| Switching Voltage | 5 VDC to 48 VDC |

| Maximum Switching Current | 125 mA |

| Lifetime | Over 1 million actuations |

| Actuating Force | 3 ± 1 N |

| Actuating Travel | 0.5 ± 0.1 mm |

| Operating Temperature | -25 °C to 60 °C |

| IP Protection | IP65 |

| Industrial Suitability | Designed for industrial environments with approvals from testing bodies according to standards. |

| Certification/Standard | Industry/Application |

|---|---|

| IATF 16949 | Automotive |

| ISO 13485 | Medical Technology |

| Customer-specific agreements | Aerospace |

- Schurter membrane switches comply with national and international standards and are approved by independent testing bodies.

Custom Waterproof Membrane Switch

Custom waterproof membrane switches deliver reliable performance in extreme industrial environments. You can specify graphics, layout, and size to match your application. These switches feature IP67 and NEMA 4X waterproof ratings, operate in temperatures from -40°C to +80°C, and withstand over one million touches. Their quick response time and robust construction make them ideal for oil and gas, outdoor kiosks, and heavy vehicles.

| Feature | Description |

|---|---|

| Waterproof Rating | IP67, NEMA 4X |

| Customization Options | Graphics, Layout, Size |

| Operating Temperature Range | -40°C to +80°C |

| Lifespan | 1 million+ touches |

| Quick Response Time | <5ms |

| Durability | Designed for harsh industrial environments |

Custom membrane switches are engineered to resist chemicals, moisture, and vibration. You can trust their performance in settings with sandstorms or frequent chemical exposure. These high-performance switches help you maintain safety and reliability in demanding industrial applications.

What Is a Membrane Switch?

Definition

You encounter membrane switches in many industrial devices. A membrane switch is a user interface component that allows you to control machines or systems with a simple press. You see these switches on control panels, medical equipment, and factory automation systems. Researchers such as Rao et al. (2019) describe membrane switches as thin, flexible layers that respond to touch, making them ideal for environments where durability and reliability matter.

Tip: You can improve safety and efficiency by choosing membrane switches for applications that require frequent operation and minimal maintenance.

Structure and Materials

You find that membrane switches use several layers to create a responsive interface. The typical structure includes:

- Graphic overlay: Displays symbols, text, or colors for easy identification.

- Spacer: Separates the top and bottom layers, preventing accidental activation.

- Circuit layer: Contains conductive traces that complete the electrical circuit when pressed.

- Backer: Provides support and stability.

Manufacturers use materials such as polyester, polycarbonate, and silver ink for these layers. You benefit from these choices because they resist moisture, chemicals, and extreme temperatures. The table below summarizes common materials and their advantages:

| Layer | Material | Benefit |

|---|---|---|

| Graphic Overlay | Polyester | High durability |

| Spacer | Polycarbonate | Flexibility |

| Circuit Layer | Silver Ink | Reliable conductivity |

| Backer | Adhesive | Secure attachment |

How It Works

You activate a membrane switch by pressing the graphic overlay. This action pushes the top layer down, causing the circuit layer to touch and close the electrical circuit. The device then registers your input and performs the desired function. You experience fast response times and consistent tactile feedback. Engineers design these switches to minimize wear and maximize lifespan, even in demanding industrial settings.

Note: You can request custom tactile feedback or illumination features to enhance usability for your specific application.

Membrane Switches in Industrial Applications

Benefits for Industrial Machines

You gain significant advantages when you choose membrane switches for industrial machinery. These switches offer you a reliable interface for controlling complex systems. You see them in control panels and human-machine interfaces (HMIs), where they help you streamline automation and process control. Recent industry reports highlight several benefits:

- Membrane switches are durable and reliable.

- You can use them in harsh environments without worrying about frequent failures.

- They support automation, which increases efficiency in industrial devices.

- You find them ideal for Industry 4.0 applications due to their consistent product quality.

You notice that membrane switch manufacturers focus on innovative solutions to meet the growing demand for automation. High quality suppliers design electronic membrane switches to deliver reliable products that improve safety and functionality in industrial applications.

Durability and Reliability

You expect membrane switches to last through millions of cycles. Well-designed tactile membrane switches can exceed 1 million actuations, and some reach up to 5 million. Fully sealed switches achieve a cycle life of over 1 million cycles, which means you spend less time on maintenance and replacements. Manufacturers use attention to quality control and advanced materials to ensure durability. You benefit from this reliability, especially when you operate industrial machinery in challenging conditions.

Note: You can trust membrane switch manufacturers to provide custom solutions that match your specific needs. Their focus on product quality and reliability helps you maintain high standards in your operations.

Versatility and Integration

You experience versatility when you integrate membrane switches into various industrial devices. Manufacturers offer custom designs, allowing you to select graphics, layouts, and tactile feedback that suit your requirements. You can easily combine membrane switches with other components for seamless industrial automation. Their adaptability supports a wide range of industrial applications, from factory automation to specialized equipment.

| Integration Feature | Benefit for You |

|---|---|

| Custom graphics/layouts | Enhanced user experience |

| Flexible design | Fits diverse machinery |

| Easy integration | Streamlines installation |

| Reliable functionality | Consistent performance |

You see that membrane switch manufacturers deliver innovative solutions that improve the functionality and efficiency of your industrial devices. Their commitment to quality ensures you receive reliable products from high quality suppliers.

Types of Membrane Switches

Conductive Panel Switches

You encounter conductive panel switches in many industrial control systems. These switches use a conductive layer to complete an electrical circuit when pressed. Manufacturers design these switches for environments that demand high reliability and fast response. You benefit from their simple structure and low profile, which make them easy to integrate into compact devices. Researchers such as Wang et al. (2021) highlight the efficiency of conductive panel switches in automated production lines. You often see these switches in medical equipment and laboratory devices.

Tip: You can request custom conductive panel switches from membrane switch manufacturers to match your specific application needs.

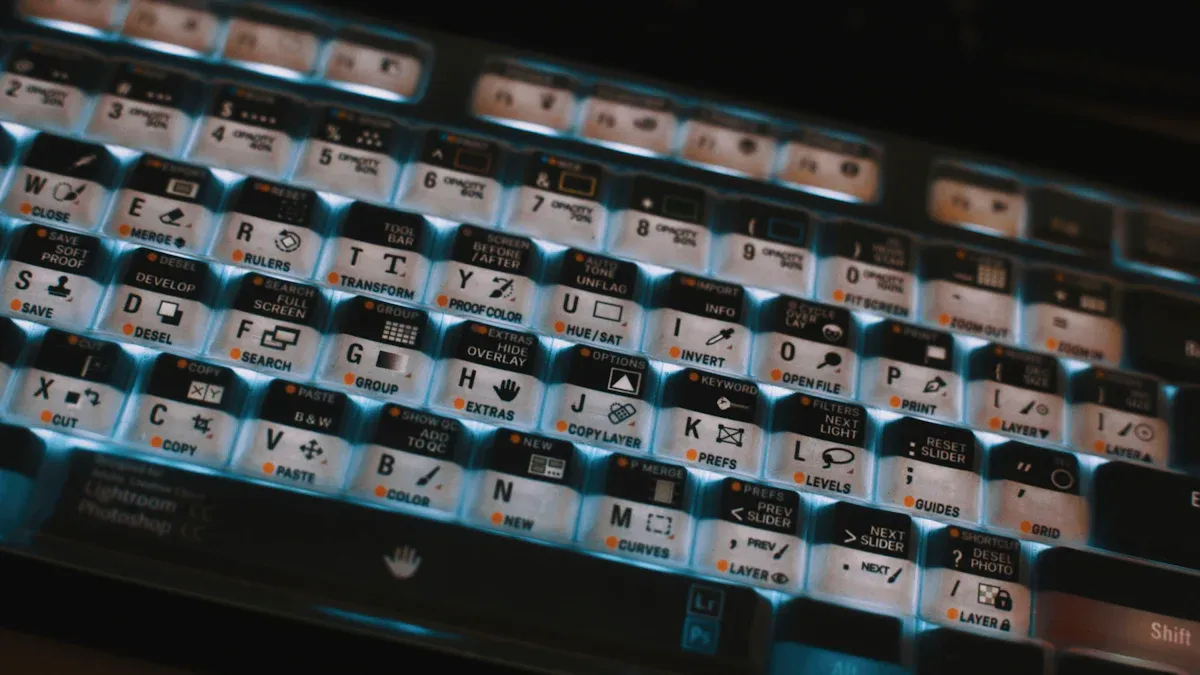

Hybrid Keypad Switches

Hybrid keypad switches combine the advantages of mechanical and membrane switches. You gain tactile feedback and durability, which improve user experience in industrial settings. Manufacturers use advanced membrane switches technology to create hybrid designs that withstand heavy use. You find these switches in machinery that requires precise control and frequent operation. Hybrid keypads offer flexible layouts and support custom graphics, which help you optimize your interface.

- Enhanced tactile response

- Long lifespan

- Customizable layouts

Illuminated Keyboard Switches

Illuminated keyboard switches provide visibility in low-light environments. You rely on these switches for control panels in factories, outdoor kiosks, and transportation systems. Manufacturers integrate LED backlighting into the membrane switch layers, which ensures clear identification of each button. You can select custom colors and brightness levels to suit your operational requirements. Academic studies, such as those by Müller et al. (2020), confirm that illuminated switches improve safety and reduce operator errors.

| Feature | Benefit |

|---|---|

| LED Backlighting | Improved visibility |

| Custom Colors | Enhanced usability |

| Energy Efficient | Lower power usage |

Tactile Button Switches

Tactile button switches deliver a distinct physical response when pressed. You feel a noticeable click, which confirms successful activation. Manufacturers design these switches for applications that require fast and accurate input. You often use tactile button switches in industrial machinery, medical devices, and automotive controls. You can request custom tactile feedback to match your preferences. These switches support advanced membrane switches features, such as waterproofing and chemical resistance.

Note: You improve operator confidence and reduce errors by choosing tactile button switches for critical industrial tasks.

Comparison of Top Membrane Switches

Performance

You need membrane switches that deliver consistent performance in demanding environments. Manufacturers design these switches to respond quickly and accurately to user input. You notice that high quality suppliers focus on tactile feedback and fast actuation, which improves operator efficiency. For example, custom membrane switches often feature LED illumination and segmented actuation force, making them ideal for industrial automation. You benefit from slim profiles and easy-to-clean surfaces, especially in medical and food processing applications. Academic studies, such as Müller et al. (2020), confirm that illuminated switches reduce operator errors and enhance safety.

Durability

You rely on membrane switches that withstand repeated use and exposure to harsh conditions. Manufacturers use materials like polyester and polycarbonate to ensure long product life and fewer replacements. You see switches tested for high humidity resistance up to 95% and reliable operation from -30°C to +80°C. These features protect against moisture, dust, and chemicals, which is essential for industrial settings. The table below highlights durability features across popular membrane switch types:

| Membrane Switch Type | Durability Features | Environmental Resistance |

|---|---|---|

| Memtron | Slim, durable, easy-to-clean | Moisture, dust, chemicals |

| Polyester | Long product life, fewer replacements | High humidity resistance |

| Polycarbonate | Balance of durability and cost | Operates reliably in harsh environments |

You can choose custom designs to match your specific durability needs, ensuring reliability in your operations.

Application Suitability

You select membrane switches based on the requirements of your industry. Manufacturers offer solutions tailored for medical devices, automotive systems, food processing, and industrial controls. You find hygiene and reliability critical in medical settings, while automotive applications demand ergonomic and moisture-resistant interfaces. Food processing equipment requires switches that are durable and easy to clean. Industrial automation benefits from rugged, spill-resistant designs. The table below summarizes application suitability:

| Industry | Application Examples | Key Features |

|---|---|---|

| Medical Devices | Diagnostic equipment, hospital bed controls | Hygiene, reliability, durability |

| Automotive | Dashboard controls, infotainment systems | Ergonomic, reliable, moisture-resistant |

| Food Processing | Processing equipment | Hygiene, durability, ease of cleaning |

| Industrial Controls | Factory automation, robotics | Rugged, spill-resistant, demanding environments |

- You improve quality and efficiency by choosing membrane switches from high quality suppliers that match your application needs.

- Custom options allow you to optimize interfaces for automation and specialized equipment.

Choosing a Membrane Switch for Industrial Use

Assessing Requirements

You need to start by identifying the specific needs of your industrial machinery. Consider the type of equipment, the number of actuations required, and the level of tactile feedback you expect. Manufacturers often provide tailor-made solutions that match your operational demands. You should also evaluate the interface layout and decide if you need custom graphics or illumination. When you define your requirements clearly, you help manufacturers deliver membrane switches that improve both reliability and quality in your production environment.

Tip: Consult with manufacturers early in your project. Their expertise can guide you toward the best membrane switch design for your application.

Environmental Factors

You must account for the environment where the membrane switch will operate. Temperature, humidity, and exposure to chemicals all affect performance. The choice of material plays a key role in ensuring long-term reliability. For example, polyimide and silicone work well in high-temperature settings, while polyester and polycarbonate suit moderate conditions. PVC offers strong moisture resistance, making it effective in humid environments. Sometimes, you need additional sealing layers to protect against water or dust.

| Material Type | Environmental Resistance | Notes |

|---|---|---|

| Polyimide | High temperature | Suitable for extreme heat |

| Polyester | Moderate conditions | Good for general use |

| PVC | Moisture resistance | Effective in humid environments |

| Silicone | High temperature | Flexible and durable |

| Polycarbonate | Moderate conditions | Good impact resistance |

- Consider the temperature extremes your membrane switches will face.

- Use polyimide or silicone for high heat.

- Choose polyester or polycarbonate for moderate environments.

Cost vs. Performance

You want to balance cost with performance when selecting a membrane switch. Custom features, such as backlighting or advanced sealing, may increase the price but also enhance durability and usability. Manufacturers can help you compare options and find the right fit for your budget. Always weigh the initial investment against the long-term benefits, such as reduced maintenance and improved reliability. High-quality membrane switches often deliver better value over time, especially in demanding industrial settings.

Note: Investing in quality and custom solutions can reduce downtime and extend the lifespan of your equipment.

You have explored the top electronic membrane switch options for industrial use. Matching the right membrane switch to your application ensures safety and efficiency. Consult manufacturers for guidance and consider custom membrane switches for unique requirements. Stay informed about new technologies and market trends. You can improve your operations by choosing a custom solution that fits your needs. For more insights, review recent academic research or contact us with your questions.

FAQ

What is the main advantage of using a membrane switch in industrial equipment?

You gain reliable operation and long lifespan with a membrane switch. Researchers like Rao et al. (2019) confirm its durability and resistance to moisture, dust, and chemicals. This switch helps you maintain safety and efficiency in demanding environments.

How do you clean and maintain membrane switches?

You should use a soft, damp cloth to wipe the surface. Avoid harsh chemicals or abrasive materials. Regular cleaning prevents buildup and ensures consistent performance. Always follow manufacturer guidelines for best results.

Can you customize the design and layout of membrane switches?

You can request custom graphics, colors, and button layouts. Manufacturers offer tailored solutions to match your branding and operational needs. Customization improves usability and supports specific machine functions.

Are membrane switches suitable for outdoor applications?

You benefit from waterproof and UV-resistant options designed for outdoor use. These switches withstand temperature changes, rain, and direct sunlight. Always choose models with appropriate IP ratings for your environment.

What certifications should you look for when selecting membrane switches?

You should check for certifications like CE, ROHS, and ISO 13485. These standards ensure product safety, environmental compliance, and suitability for medical or industrial use. Certified switches meet strict quality requirements.

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online