Technical Differences Between LED Membrane Overlays and Standard Membrane Switches

Technical Differences Between LED Membrane Overlays and Standard Membrane Switches

When you compare a standard membrane switch to a led membrane overlay, you notice clear technical differences. LED integration boosts visibility by providing illuminated buttons and labels, which makes operation easier in low-light environments. You benefit from high brightness, long lifespan, and a range of color options that support advanced user interface technologies. Proper light diffusion ensures even illumination and a polished look. Choosing the right technology impacts performance, cost, and durability in your application.

Key Takeaways

- LED membrane overlays improve visibility with illuminated buttons, making them ideal for low-light environments.

- Standard membrane switches are cost-effective and durable, suitable for a wide range of applications, including medical and industrial devices.

- Choosing the right membrane switch technology impacts performance, user experience, and long-term costs.

- LED overlays have a longer lifespan than EL panels, lasting over 100,000 hours compared to 3,000 to 8,000 hours for EL.

- Consider factors like tactile feedback, environmental protection, and user needs when selecting a membrane switch for your project.

Membrane Switches Overview

Definition

You encounter membrane switches in many electronic devices today. These switches use several thin, flexible layers to create a user interface. The top layer often displays printed graphics or icons. Underneath, you find a spacer and a circuit layer. When you press a button, the top layer pushes down, making contact with the circuit below. This action completes the electrical path and sends a signal to the device. Membrane switches offer a sealed, low-profile design that protects against dust and moisture. You benefit from their reliability and ease of cleaning. Manufacturers often choose membrane switches for their cost-effectiveness and versatility.

Applications

You see membrane switches in a wide range of industries and products. Their adaptability and durability make them a popular choice for many environments. Here are some common applications:

- Medical equipment, such as diagnostic machines and patient monitoring systems, rely on membrane switches for precise control.

- Industrial machinery uses membrane switches in control panels and automation systems, where reliability is critical.

- Consumer electronics, including smartphones, tablets, remote controls, and calculators, feature membrane switches for user input.

- The automotive industry integrates membrane switches into dashboard controls and infotainment systems.

- Healthcare devices, like ventilators and infusion pumps, use membrane switches for safe and hygienic operation.

- Aerospace applications, such as cockpit control systems, depend on membrane switches for dependable performance.

Tip: When you select membrane switches for your project, consider the specific requirements of your application. Their flexibility and protective features can enhance both performance and user experience.

Membrane switches continue to evolve, supporting advanced features like backlighting and tactile feedback. You can tailor them to meet the needs of almost any electronic interface.

Standard Membrane Switches

Construction

You interact with standard membrane switches every day in devices ranging from medical equipment to consumer electronics. Manufacturers build these switches using several thin layers, each serving a specific function. The graphic overlay forms the top layer, usually made from hard-coated polyester (PET) or polycarbonate. Polyester stands out for its robust nature and chemical resistance, supporting a lifespan of up to 5 million actuations. Underneath, you find a graphic adhesive that bonds the overlay to the dome retainer. The dome retainer holds metal domes or shorting pads, which provide tactile feedback. A spacer adhesive allows air flow during actuation, while the bottom circuit layer uses conductive inks printed on flexible PET. Rear adhesive secures the entire assembly to the device.

Note: The choice of polyester over polycarbonate can significantly extend the lifespan of your membrane switch, especially in demanding environments.

Operation

You activate a standard membrane switch by pressing a button on the overlay. This action collapses the top layer, bringing conductive traces into contact and completing the circuit. The switch remains inactive until you apply pressure, which closes the gap and sends an electrical signal to the device. The layers work together to ensure reliable input registration. You benefit from a sealed interface that resists dust and moisture, maintaining consistent performance throughout the switch’s lifespan.

Pros

| Advantage | Description |

|---|---|

| Durability and Reliability | You can rely on membrane switches to withstand harsh environments, including dust, moisture, chemicals, and extreme temperatures. This durability reduces maintenance and extends the lifespan of your equipment. |

| Cost-Effectiveness | You save on production and installation costs due to the lightweight, low-profile design. Manufacturers can produce these switches in large quantities, making them economical for many applications. |

- Membrane switches offer excellent resistance to environmental factors.

- Their simple construction supports easy customization for specific needs.

- You benefit from sealed designs that prevent contamination and ensure long-term reliability.

Cons

- You may notice wear over time, especially with frequent use.

- Cleaning agents can degrade the surface, shortening the lifespan.

- Using the switch with gloves or wet hands can be challenging.

- Limited sealing may allow moisture to enter, causing hygiene issues.

- Fluid ingress can compromise performance in sensitive environments.

Tip: Regular inspection and proper cleaning can help you maximize the lifespan of your membrane switches, even in demanding settings.

LED Membrane Overlay Features

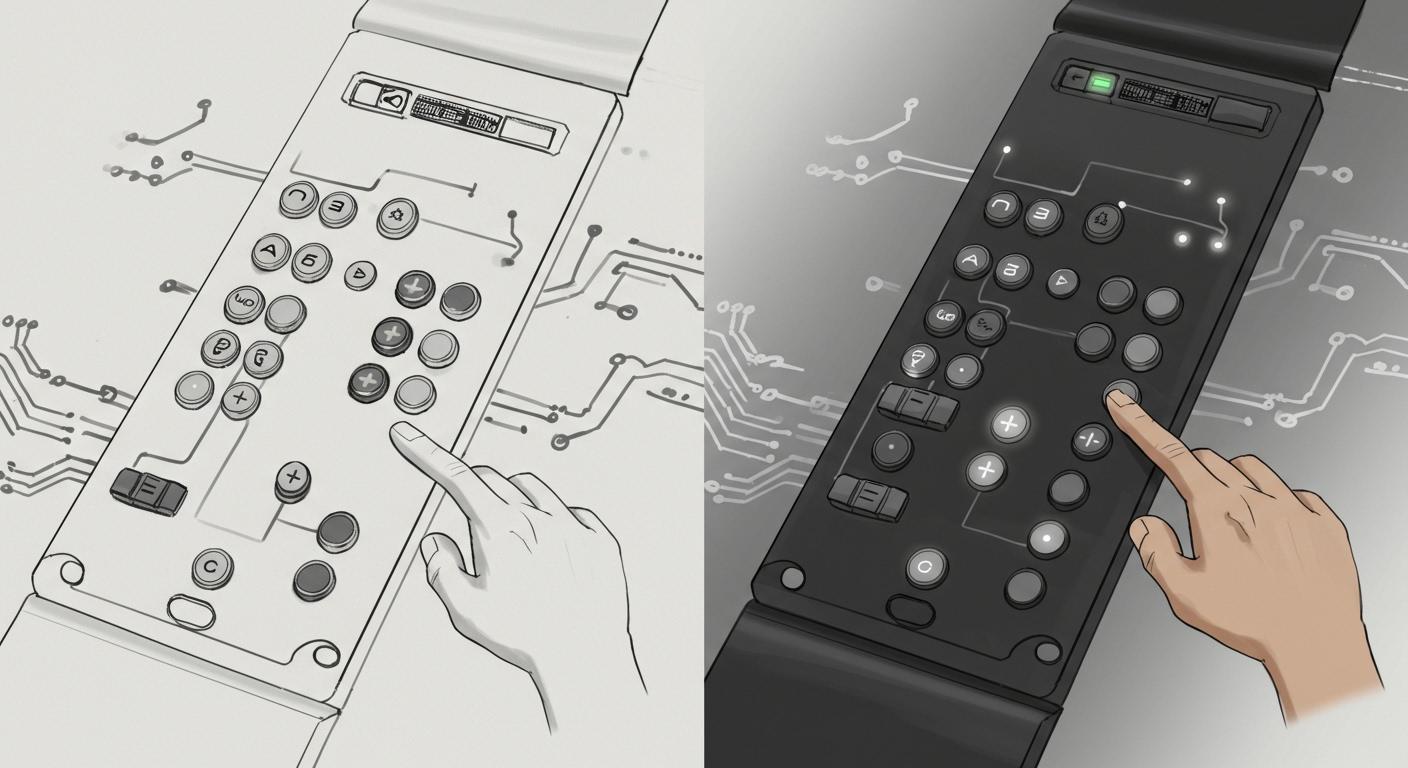

Light-Emitting Diode Integration

You gain a significant advantage when you choose a led membrane overlay for your device. Manufacturers integrate light-emitting diodes directly beneath the graphic overlay. This design allows you to illuminate specific icons, symbols, or entire button areas. You see improved reliability and longevity because leds have a long service life and low failure rates. The integration process requires careful placement of embedded leds to avoid uneven lighting and ensure consistent coverage. You benefit from a flexible design that adapts to different layouts and sizes.

| Backlighting Option | Advantages |

|---|---|

| Light-Emitting Diodes (LED) | Reliability, longevity, low cost; can light the entire surface of a graphic overlay. |

| Optical Fibers | Uniform brightness, longevity, low heat emissions; flexible backlighting layer. |

| Electroluminescence (EL) Lamps | Thin layer for uniform lighting; uses printable ink but lower quality illumination than others. |

| Light Guide Films (LGF) | Distributes light effectively, reduces number of LEDs needed, highlights text and symbols. |

Note: You should consider the placement and number of leds to achieve optimal performance and avoid bright spots.

Enhanced Visibility

You experience a dramatic improvement in visibility when you use a led membrane overlay. The targeted illumination from embedded leds helps you identify controls quickly, even in low-light or high-glare environments. You see illuminated icons and symbols that guide your actions, reducing errors and improving safety. The strategic use of leds ensures that each button stands out, making the user interface more intuitive and accessible. You notice that the led membrane overlay supports flexible layouts, allowing you to customize the lighting for different applications.

Tip: Enhanced visibility from leds increases usability and reduces the risk of mistakes, especially in critical settings like medical or industrial equipment.

Additional Components

You find that led membrane overlays often include extra electronic components to boost functionality. These additions work together to improve performance and reliability.

- LEDs

- Resistors

- Capacitors

You may also encounter other backlighting options, such as embedded led, fiber optic, or electroluminescent (EL) backlighting. These components help regulate current, protect the leds, and support advanced features like dimming or color changes. You benefit from a flexible design that adapts to your specific needs, whether you require simple illumination or complex lighting effects.

Pros

You gain several advantages when you select a led membrane overlay for your project. The combination of embedded leds and durable materials delivers outstanding performance.

| Durability Feature | Description |

|---|---|

| Resistance to Dust and Liquids | LED membrane switches are designed to resist environmental factors like moisture and chemicals. |

| Long Service Life | They typically have a lifespan exceeding 100,000 hours, ensuring longevity. |

| Ability to Withstand Extreme Conditions | Constructed to endure harsh environments and repeated use, making them reliable for demanding applications. |

- Constructed from flexible materials like polyester and polycarbonate.

- Built to withstand repeated use in harsh conditions.

- Long lifespan, typically over 100,000 hours.

You also benefit from energy efficiency. Leds consume less power and generate minimal heat, making them cost-effective for long-term use.

| Technology Type | Power Consumption | Heat Generation |

|---|---|---|

| LED Membrane Switch | Minimal | Low |

| Standard Membrane Switch | Higher | Moderate |

| Incandescent Bulbs | High | High |

- LEDs consume less power, making them cost-effective for long-term use.

- They generate minimal heat, ensuring comfort during prolonged use.

You see improved performance, lower maintenance needs, and greater flexibility in design.

Cons

You should consider some drawbacks before choosing a led membrane overlay. The initial cost is higher than standard membrane switches or EL panels. You may encounter uneven lighting if you do not place the leds carefully. Maintenance can be more complex due to the additional components.

| Drawback | Description |

|---|---|

| Higher Initial Cost | LEDs cost more upfront than EL, which can be a hurdle for tight budgets. |

| Uneven Lighting Risk | If not placed carefully, you might get bright spots instead of smooth coverage. |

You need to balance the benefits of enhanced functionality and performance against these limitations. Careful design and quality control help you minimize risks and maximize the value of your investment.

Alert: You should work with experienced manufacturers to ensure proper integration of leds and avoid common pitfalls like uneven lighting or premature failure.

Other Membrane Switch Technologies

EL Panels

You may consider EL panels as one of the most energy-efficient backlighting options for your custom membrane switch assemblies. EL panels use electroluminescent material to spread light evenly across the surface, which eliminates dark spots and bright patches. This uniform illumination supports high brightness in compact devices. The thin and lightweight design fits well in applications where space is limited. EL panels also allow you to print custom patterns, making them ideal for custom backlighting solutions. However, you should note that EL panels have a shorter lifespan, typically between 3,000 and 8,000 hours, so they may not suit devices that require constant backlighting and status indication.

| Feature | Description |

|---|---|

| Uniform Illumination | EL spreads light evenly, eliminating dark spots or bright patches. |

| Thin and Lightweight | The design is super slim, ideal for compact devices. |

| Low Power Consumption | EL consumes relatively little power, making it suitable for battery-powered gadgets. |

| Cost-Effectiveness | Generally lower price point compared to other lighting options. |

| Printable Patterns | Can be printed in various patterns for integration under displays. |

| Short Lifespan | Typical half-life of 3K to 8K hours, making it less suitable for constant use. |

Tip: EL panels work best when you need a slim profile and even light, but you should plan for replacement if your application runs continuously.

Fiber Optics

Fiber optic membrane switches give you excellent light diffusion and design flexibility. You can use fiber optics to achieve uniform brightness over large areas, which is essential for displays that require consistent illumination. The design allows you to create flexible mounting configurations, adapting to unique shapes and layouts. Fiber optics also support custom backlighting solutions, letting you highlight specific features or symbols. You benefit from the efficiency of fiber optics, as they distribute light with minimal energy loss. This technology fits well in applications where you need both innovative design and reliable performance.

Capacitive Switches

Capacitive switches offer a modern alternative to traditional tactile membrane switches. You interact with these switches through touch, not pressure. The design enables feature-rich capacitive user interfaces, giving you a sleek and intuitive experience. Unlike mechanical switches, capacitive switches do not provide a physical click or snap. Instead, you get a smooth, touch-based response. This difference impacts user experience and tactile feedback.

| Feature | Capacitive Switches | Tactile Membrane Switches |

|---|---|---|

| Feedback | No click; uses touch screen | Click or snap you can feel |

| User Experience | Sleek and modern touch | Clear feeling when you press |

You can use capacitive switches in applications that demand advanced features, such as touch sensitivity and smart controls. The design supports customization and integration with other technologies, making it suitable for devices that require a high level of interaction.

Note: Capacitive switches excel in environments where you want a modern look and advanced features, but you may miss the tactile feedback of traditional switches.

Comparison Table

When you evaluate membrane switch technologies, you need a clear side-by-side comparison. This section helps you understand how LED membrane overlays, standard membrane switches, EL panels, fiber optics, and capacitive switches perform in real-world applications.

Performance

You want reliable performance from your user interface. LED membrane overlays deliver high visibility and precise control, especially in low-light settings. You can illuminate specific icons or entire panels, which improves accuracy and reduces errors. Standard membrane switches provide consistent actuation and tactile feedback, making them suitable for most environments. EL panels offer even light distribution but may not match the brightness of LEDs. Fiber optics give you uniform illumination across large surfaces, which is ideal for custom layouts. Capacitive switches stand out for their advanced touch response. You interact with these switches using only your finger or a conductive object, which enables sleek, modern designs. Capacitive technology supports multi-touch, gesture recognition, and programmable sensitivity. You gain a smooth user experience, but you lose the physical feedback of a click or snap.

| Technology | Visibility | Tactile Feedback | Touch Sensitivity | Customization | Multi-Touch Support |

|---|---|---|---|---|---|

| LED Membrane Overlay | Excellent | Yes | No | High | No |

| Standard Membrane | Good | Yes | No | High | No |

| EL Panel | Good | Yes | No | Medium | No |

| Fiber Optic | Good | Yes | No | High | No |

| Capacitive | Variable | No | Yes | High | Yes |

Tip: If you need advanced touch features, capacitive switches give you the best results. For high visibility and tactile feedback, LED membrane overlays work best.

Durability

You expect your interface to last. Standard membrane switches typically withstand 5 to 10 million keystrokes. This means you can use them for several years, even with daily operation. Their sealed construction protects against dust and moisture, which reduces the risk of mechanical failure. LED membrane overlays use the same robust materials, so you get similar durability, plus the added benefit of long-lasting LEDs. EL panels have a shorter lifespan, usually between 3,000 and 8,000 hours, so you may need to replace them more often. Fiber optic solutions resist wear and environmental damage, but the light source may require maintenance. Capacitive switches have no moving parts, so you avoid mechanical wear. However, you must protect the surface from scratches and contaminants to maintain touch accuracy.

- Standard membrane switches and LED overlays last 3–7 years with regular use.

- Sealed construction and robust overlays improve resistance to harsh environments.

- Capacitive switches excel in environments where you want minimal wear and tear.

Note: For outdoor or high-humidity applications, you should use hard-coated polyester overlays, perimeter gaskets, and the right adhesive. Marine electronics and automotive controls benefit from these features, ensuring reliable operation in wet or dirty conditions.

Cost

You need to balance performance with your budget. Standard membrane switches offer the lowest cost, which makes them ideal for high-volume production. LED membrane overlays cost more upfront because of the added components and integration steps. However, you save on maintenance and energy costs over time. EL panels provide a cost-effective backlighting solution, but you may face higher replacement costs due to their shorter lifespan. Fiber optic systems require a higher initial investment, especially for custom designs. Capacitive switches have the highest upfront cost because of the advanced electronics and programming required. You also need to consider the cost of integrating capacitive touch controllers and ensuring compatibility with your device.

| Technology | Initial Cost | Maintenance Cost | Replacement Frequency |

|---|---|---|---|

| LED Membrane Overlay | High | Low | Low |

| Standard Membrane | Low | Low | Low |

| EL Panel | Low | Medium | High |

| Fiber Optic | High | Low | Low |

| Capacitive | Highest | Low | Low |

Alert: If you need advanced touch or multi-touch features, capacitive switches justify the higher cost with their unique capabilities.

Application Suitability

You must choose the right technology for your environment and user needs. LED membrane overlays excel in medical devices, industrial controls, and any application where you need illuminated buttons and clear visibility. Standard membrane switches fit most general-purpose devices, including office equipment and consumer electronics. EL panels work well in slim, portable devices where even light is more important than brightness. Fiber optic solutions suit large control panels and custom layouts that require uniform backlighting. Capacitive switches dominate in modern consumer electronics, smart appliances, and interactive kiosks. You benefit from touch-based control, gesture support, and a seamless interface. Capacitive switches also work well in environments where you want to minimize mechanical wear and maximize design flexibility.

- Marine and automotive applications require sealed membrane switches or overlays with hard-coated polyester and perimeter gaskets.

- Capacitive switches provide the best user experience for smartphones, tablets, and touch-enabled displays.

- Industrial and medical devices benefit from LED overlays for enhanced visibility and tactile feedback.

- EL panels and fiber optics serve best in custom or space-constrained designs.

Tip: Always match your switch technology to your application’s environment, user expectations, and required features. Capacitive touch interfaces offer unmatched flexibility, but you may need tactile feedback for safety-critical controls.

Choosing the Right Membrane Switch

Key Factors

When you select a membrane switch for your project, you need to focus on several important factors. Each factor affects the performance, durability, and user experience of your device.

- Tactile Feedback: You want a switch that gives a clear, distinct feel when pressed. This feedback helps users know when they have activated a control.

- Lifespan: Choose a switch that can handle millions of press cycles. This ensures long-term reliability.

- Strength & Rigidity: Some applications require extra support. Make sure your switch provides enough structural strength.

- Environmental Protection: Your switch should resist moisture, chemicals, and temperature extremes. This is vital for outdoor or industrial use.

- Adhesion Strength: Layers must bond securely but allow for easy removal if needed.

- Temperature Resistance: The switch must work within your device’s temperature range.

- Ergonomics: Place switches where users can reach them easily. Good button size and spacing improve comfort and reduce errors.

- Certifications and Quality: Work with manufacturers who have industry experience, certifications, and strong quality testing.

Tip: Always match the switch technology to your application’s environment and user needs. For medical or industrial devices, consider resistance to cleaning agents and custom layouts that fit user workflows.

Use Cases

You see different membrane switch technologies excel in specific real-world scenarios. The right choice depends on your application’s demands.

| Use Case | Advantages |

|---|---|

| Medical Equipment | Enhanced visibility in low-light settings, tactile feedback, and resistance to cleaning agents. |

| Industrial Automation | Clear visibility in harsh environments, strong durability, and improved operator safety. |

| Consumer Electronics | Better usability in dim rooms, modern look, and higher customer satisfaction. |

| Transportation & Automotive | Safer operation at night, reduced driver distraction, and robust environmental protection. |

| Home Appliances | Easy interaction in dark spaces, sleek design, and reliable performance. |

You benefit from LED membrane overlays in environments where visibility and safety matter most. Standard membrane switches work well for general-purpose devices that need tactile feedback and cost efficiency. Capacitive switches fit best in modern touch-based products, while EL panels and fiber optics serve unique design needs.

Note: Consider your users’ needs, the environment, and the required features before making your final decision. The right membrane switch technology can improve both performance and user satisfaction.

You see clear technical differences between LED membrane overlays, standard membrane switches, and alternative technologies. LED integration boosts visibility and user satisfaction, with surveys showing high approval and improved outcomes. When you select a membrane switch, consider these expert guidelines:

- Focus on intuitive design and tactile feedback for better user experience.

- Set a realistic budget and compare materials for long-term savings.

- Test thoroughly and maintain quality standards throughout production.

Choosing the right technology ensures your project meets both performance and user needs.

FAQ

What is the main advantage of LED membrane overlays?

You gain improved visibility and user experience with LED membrane overlays. The integrated LEDs light up buttons and symbols, making controls easy to see in low-light or high-glare environments. This feature helps you reduce errors and operate devices safely.

Can you customize the color and brightness of LED membrane overlays?

Yes, you can select different LED colors and adjust brightness levels. This flexibility lets you match your device’s design or highlight specific functions. You can also create dynamic lighting effects for advanced user interfaces.

How do LED membrane overlays compare to EL panels in lifespan?

LED membrane overlays last much longer than EL panels. You can expect LEDs to operate for over 100,000 hours, while EL panels usually last between 3,000 and 8,000 hours. This difference makes LEDs a better choice for long-term applications.

Are LED membrane overlays suitable for outdoor or harsh environments?

You can use LED membrane overlays in outdoor or industrial settings. The sealed construction resists dust, moisture, and chemicals. For extreme conditions, choose overlays with hard-coated polyester and perimeter gaskets for extra protection.

How do you choose the right membrane switch technology for your project?

You should consider your application’s environment, required features, and user needs. Evaluate factors like tactile feedback, visibility, durability, and cost. If you need help, contact a membrane switch specialist for expert advice.

Backlit Membrane Switches – High-Quality Backlit Keypads

We provide reliable backlit membrane switches with long service life, stable backlight, and customizable design to fit your device control panel. What are backlit membrane switches? Backlit membrane switches are low-profile control interfaces that combine printed circuitry with integrated lighting. They allow users to see and operate equipment in low-light or dark environments. A backlit ...

Membrane Switch with LED, Customized LED Membrane Switches

Our LED membrane switches provide bright, even backlighting, long lifespan and reliable performance for control panels in dark environments. What are LED membrane switches? LED membrane switches are advanced user interface panels that combine a flexible membrane circuit with integrated light sources. The structure looks simple from the outside. Inside, it is a layered system ...

Click Touch Membrane Switch, Premium Membrane Switch with Tactile Click Response

Our click touch membrane switch provides clear tactile click response, stable performance and long service life, ideal for control panels requiring obvious touch feedback. What is a click touch membrane switch? A click touch membrane switch is a pressure-activated interface designed to deliver a clear, physical response each time a key is pressed. Unlike flat ...

Contact us online