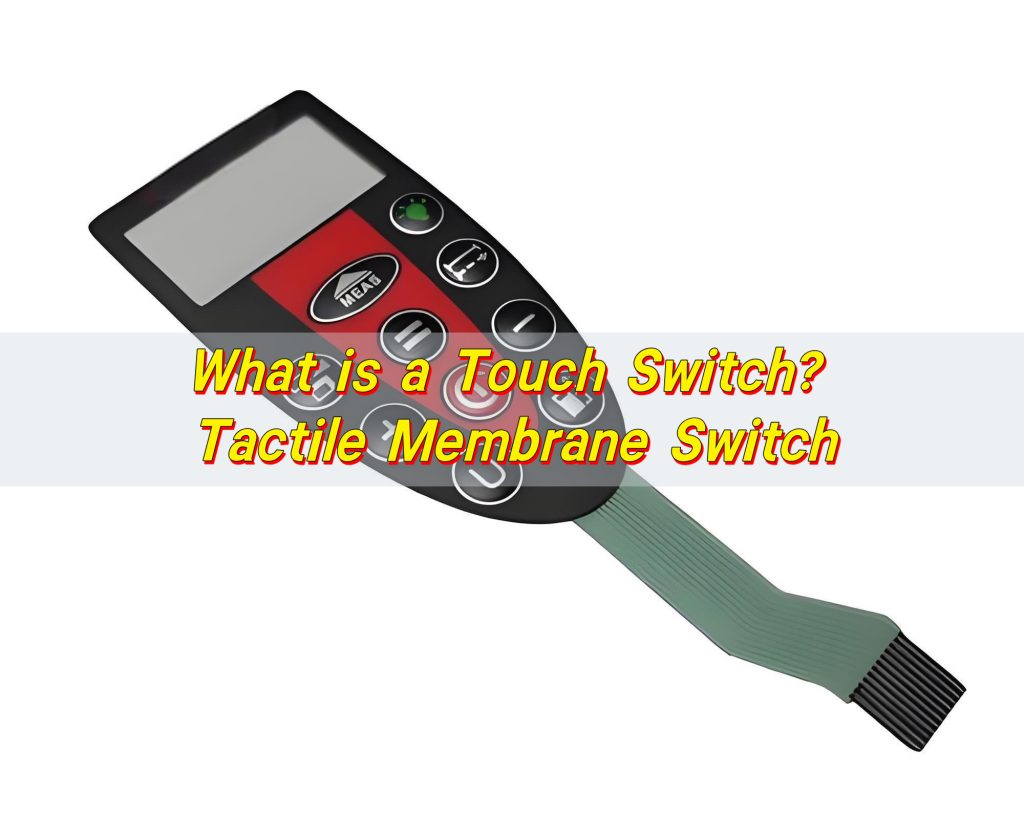

What is a Touch Switch? Tactile Membrane Switch

What is a Touch Switch? Tactile Membrane Switch

Touch switch is essentially a tactile membrane switch, a low-profile electronic interface that activates with a light press and provides a clear snap feedback to confirm operation. It consists of multiple layers, including a top graphic overlay and a metal or polyester dome beneath, allowing reliable actuation with high durability and minimal space usage.

What is a Touch Membrane Switch?

A touch membrane switch is a user interface that reacts to touch rather than mechanical movement. It consists of multiple layers, often including a graphic overlay, spacer, and circuit. When pressure or a touch signal activates the surface, the internal circuit closes, creating an electrical signal that triggers a function.

Compared to traditional buttons, a membrane switch panel is thin, flexible, and highly durable. Its surface can be printed with customized graphics, symbols, and text. It’s often sealed, preventing dust and moisture from entering the switch area.

In many cases, a membrane switch keyboard replaces mechanical keypads in medical, industrial, and consumer electronics. These keypads are easier to clean and maintain. They also improve user experience through aesthetic design and tactile or capacitive feedback.

Are Touch Switches Reliable?

Yes, touch switches are highly reliable. Their design removes moving parts that can wear out. With minimal mechanical stress, the lifespan of a touch switch often exceeds one million actuations.

The sealed construction plays a key role in reliability. The layers protect the internal circuitry from humidity, chemicals, and dust. That makes these switches suitable for harsh industrial and outdoor applications.

In terms of performance, tactile membrane switches maintain stable conductivity and sensitivity throughout their lifetime. Even under repetitive use, the contact resistance remains low and consistent.

The use of metal domes inside some tactile membrane designs increases both tactile feedback and durability. Each dome acts as a spring, returning the switch to its original state after being pressed.

Overall, touch switches are built to last. Whether for a medical diagnostic device or a consumer gadget, they deliver dependable control without frequent replacement.

What Are the Disadvantages of Touch Switches?

While touch switches have many strengths, a few limitations exist. For instance, capacitive touch types can sometimes react to unintended touches, especially when the surface is wet or when gloves are used. In high-humidity environments, this sensitivity may require calibration.

Also, compared with mechanical buttons, touch switches don’t always provide the same level of tactile sensation. That’s why tactile membrane switches were developed—to bring back a responsive feeling through a subtle mechanical “snap.”

Another point to consider is customization cost. For small production runs, designing a custom membrane switch might be more expensive than using standard mechanical keys. However, for medium and large-scale manufacturing, the cost becomes highly reasonable due to printing efficiency and design flexibility.

Despite these minor drawbacks, the benefits far outweigh the limits. In most modern devices, touch membrane switches remain the preferred choice because of their long lifespan, design flexibility, and excellent hygiene performance.

How Does a Touch Membrane Switch Work?

The structure of a touch membrane switch usually contains four to six layers, each layer has a different purpose.

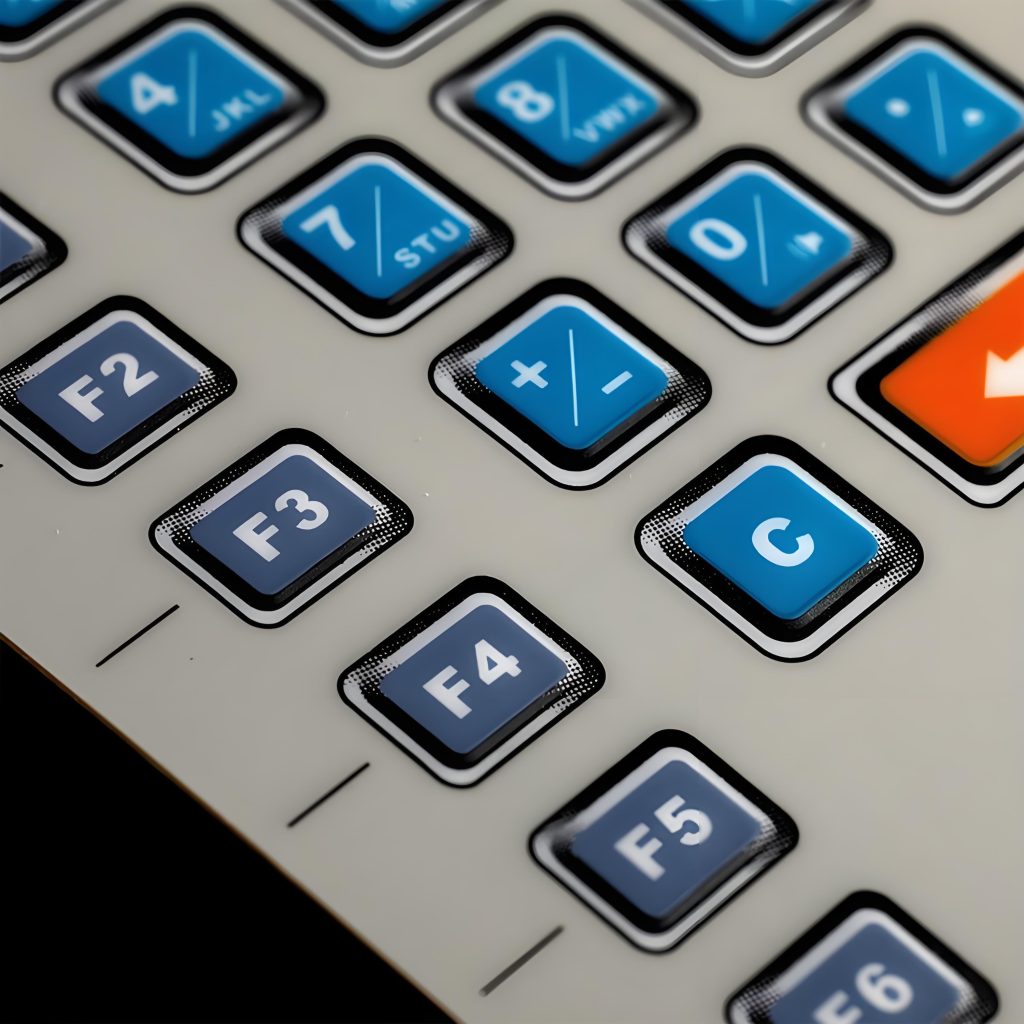

- Graphic Overlay: Polyester or polycarbonate is often used for its clarity and flexibility. It’s printed with icons, logos, or symbols to indicate each button function.

- Spacer Layer: Beneath the overlay, a spacer separates the top and bottom circuits. When you press a button, the spacer compresses, allowing the upper and lower contacts to meet.

- Circuit Layer: This layer contains conductive traces printed using silver ink, carbon, or copper. It acts as the electrical path for signals.

- Adhesive and Backing: These layers bond the membrane switch to the device surface, ensuring stability and resistance to peeling.

- Dome or Contact Element: In tactile membrane switches, metal domes are added to create a click response. When pressed, they deform and complete the circuit. Once released, they return to their dome shape, breaking the contact instantly.

Some switches use capacitive sensing instead of physical contact. Here, the change in capacitance caused by a finger’s touch triggers the electronic response. This allows a completely flat and smooth interface—ideal for waterproof designs.

How to Test a Touch Switch?

Testing of touch switches is used to check their responsiveness, accuracy and durability.

- Visual Inspection: Start with the surface. Inspect for scratches, misaligned graphics, or contamination.

- Continuity Test: Using a multimeter, technicians verify that pressing a key closes the circuit.

- Tactile Force Test: In tactile membrane switches, the actuation force is measured to ensure consistent feedback. The typical range lies between 100 and 350 grams.

- Life Cycle Testing: Switches are pressed repeatedly—sometimes over a million cycles—to test endurance.

- Environmental Testing: Tests simulate heat, humidity, and vibration.

- Electrical Reliability: Resistance, insulation, and conductivity are measured.

Regular testing ensures that each touch membrane switch meets performance standards before being integrated into a final product.

How Does a Tactile Membrane Switch Provide Feedback?

Feedback is one of the defining features of a tactile membrane switch. It tells users that their input has been received.

Inside, a metal dome or poly dome is placed above the circuit contact. When pressed, it collapses and touches the lower circuit layer. This physical movement creates both tactile and audible feedback.

The metal dome type offers a crisp, sharp click—ideal for precision devices. The poly dome type, on the other hand, provides a softer feel suitable for devices that need quieter operation.

Some designs combine tactile feedback with LED indicators or sound cues. The combination creates a multisensory experience—visual, auditory, and tactile all at once.

What is a Capacitive Touch Switch?

A capacitive touch switch senses the electrical properties of a finger instead of physical pressure. It uses conductive layers that form a small capacitor. When your finger approaches, it alters the capacitance, which the circuit detects as an input.

Because there’s no mechanical contact, capacitive switches last longer and are fully sealed. That makes them ideal for environments where cleanliness or waterproofing is vital.

Capacitive switches are commonly used in kitchen appliances, medical devices, and high-end consumer electronics because they are aesthetically pleasing and flexible. Backlighting, transparency, and custom icons can be easily integrated.

What is the Difference Between Inductive and Capacitive Switches?

While both detect touch, the working principles differ.

- Capacitive Switches: Rely on the change in capacitance when a conductive object (like a finger) touches the surface. They work best with direct contact and are widely used in touch panels and smartphones.

- Inductive Switches: Detect changes in magnetic fields or inductance caused by a nearby metallic object. They can work even when a non-conductive layer separates the surface from the user.

In simple terms, capacitive switches react to the electrical field of a human finger, while inductive switches respond to magnetic or metallic interaction. Capacitive ones are smoother and more sensitive, while inductive types are more robust for industrial conditions.

Both offer different advantages depending on the design goals. For example, medical instruments often prefer capacitive types for hygiene reasons, while heavy machinery may use inductive ones to withstand gloves and debris.

What Industries Use Membrane Switch Panels the Most?

Membrane switch panels are used across a wide range of industries because of their adaptability and reliability.

- Medical Equipment: Touch membrane switches are easy to disinfect, making them perfect for hospital devices, diagnostic tools, and monitoring systems.

- Industrial Control Systems: A sealed membrane switch withstands harsh environments while providing precise input for machinery.

- Consumer Electronics: From microwave ovens to air purifiers, touch membrane panels enhance design aesthetics and user convenience.

- Aerospace and Defense: Lightweight, durable, and resistant to vibration, these switches perform flawlessly even under extreme conditions.

- Automotive Applications: Dashboard interfaces, control panels, and seat adjustment modules use tactile membrane switches for their thin structure and reliability.

- Fitness Equipment: Exercise machines often use membrane switch keyboards for speed, mode, and resistance controls. The tactile feedback improves usability even during motion.

If you’re searching for high-quality custom membrane switches for your products, our engineering team can help you design, prototype, and manufacture exactly what you need. Contact us today at sales@best-membraneswitch.com to discuss your project or get a free quote.

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

Contact us online