What is a Membrane Switch Overlay? Membrane Switch and Panel

What is a Membrane Switch Overlay? Membrane Switch and Panel

What Are Membrane Switch Overlays?

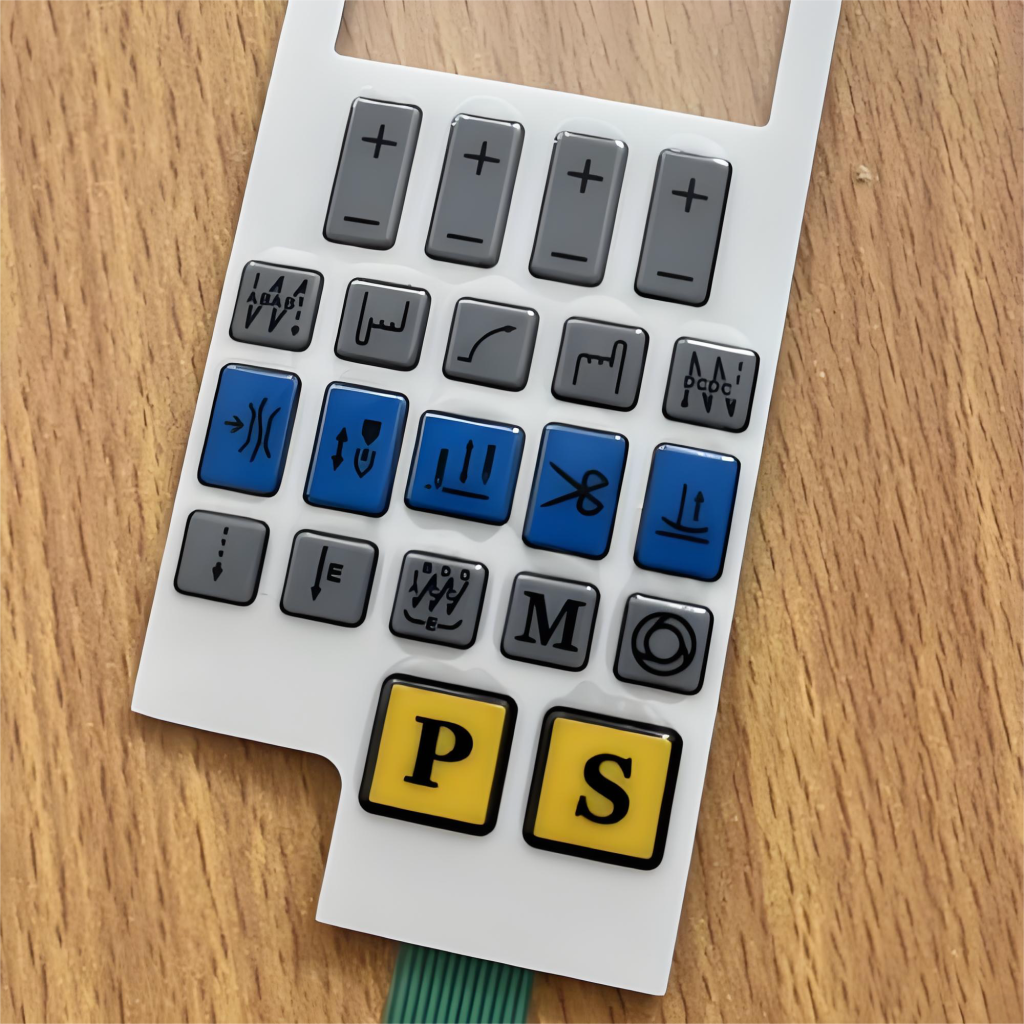

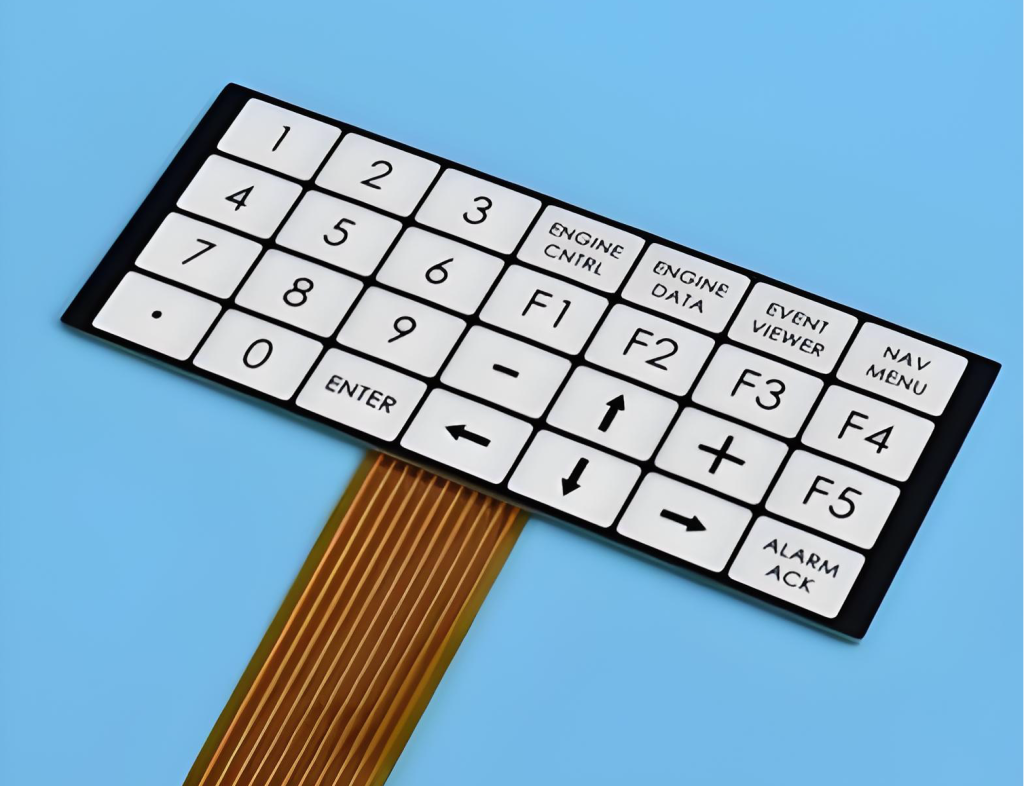

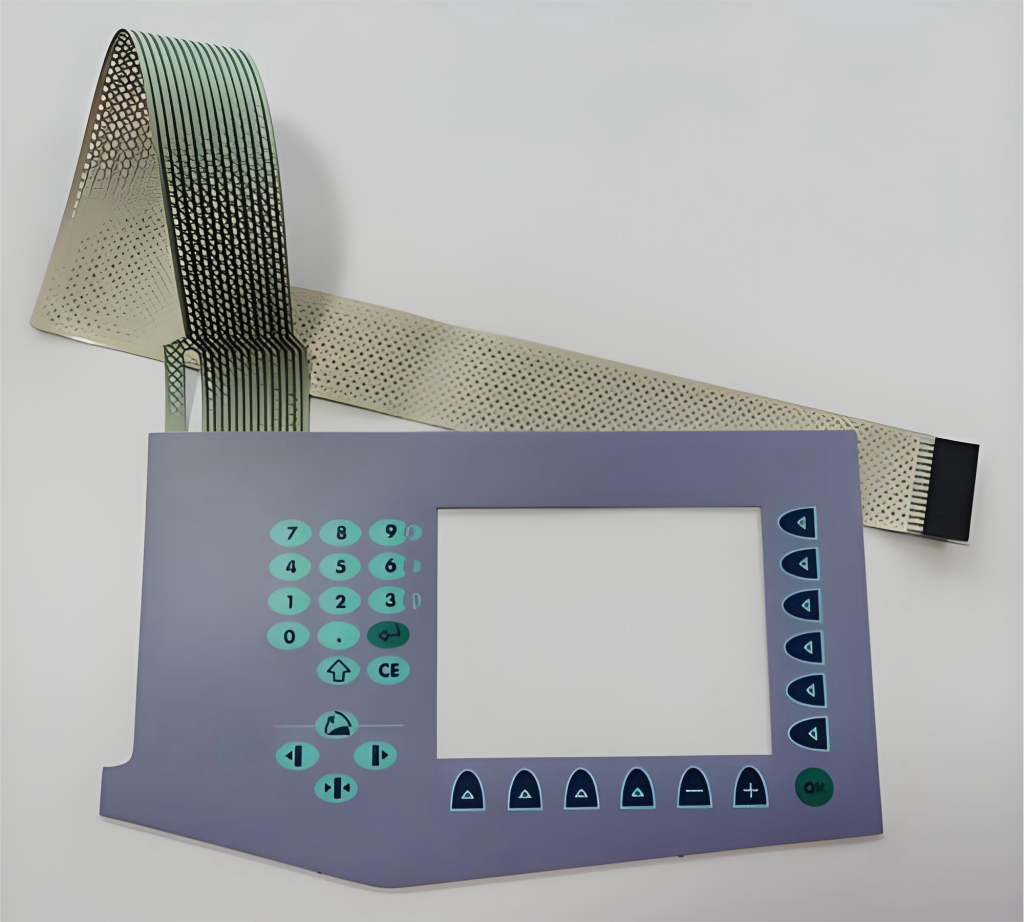

The membrane switch overlay is the outermost interface of the membrane switch assembly that the user actually contacts. When you press a button on a control panel, industrial equipment, or medical device, you’re interacting directly with this overlay.

This layer provides not only the visible interface but also protection and functionality. It displays the symbols, icons, and text that guide users. At the same time, it shields the internal circuits from dust, moisture, and wear.

Membrane switch overlays are typically made from polyester (PET) or polycarbonate (PC). These materials combine clarity, flexibility, and strong resistance to abrasion. They can endure repeated presses, exposure to cleaning agents, and environmental changes.

Overlays are printed using precise techniques, often silk-screen printing or digital printing, to ensure crisp colors, accurate alignment, and strong adhesion. The printing is usually done on the back side of the transparent film to protect the ink from scratches.

How Does a Membrane Switch Graphic Overlay Work?

Here’s how it works: when a user presses a button area on the overlay, the pressure deforms the top layer, pushing down onto a spacer layer and a circuit layer below it. This action connects conductive traces momentarily, completing an electrical circuit. Once the pressure is released, the flexible layers return to their original position, opening the circuit again.

This motion, though minimal, triggers an electrical signal recognized by the device’s system. The signal tells the device what command to execute—turn on, off, adjust, or activate a function.

The graphic overlay plays a vital role in this operation. It defines the button’s position, shape, and feel. Some overlays integrate metal domes or poly domes beneath the surface to give users a crisp tactile response. This tactile click assures them that the button press has been registered, enhancing the user experience.

Additionally, the overlay helps maintain the integrity of the inner layers. Since it forms a sealed surface, it prevents contaminants like water, oil, or dust from entering the switch assembly.

Lighting and visibility are also key. Often LED backlighting or fiber optics are integrated beneath the transparent portion of the cover. This helps in low-light environments and provides an aesthetic glow that improves usability.

Why Choose a Graphic Overlay Membrane Switch?

One of its most valued advantages is sealing capability. Unlike traditional mechanical switches, a membrane switch overlay provides a sealed barrier against fluids and dust. That makes it suitable for medical instruments, outdoor controls, and industrial environments.

Another major reason lies in customizability. The overlay can be printed with vivid graphics, company logos, or color-coded symbols. It can even include transparent windows for displays or backlighting zones for LED indicators.

The thin profile of the membrane switch overlay also saves space, making it perfect for compact electronics. Despite its slim design, it remains strong enough to handle thousands of actuations without losing sensitivity.

Energy efficiency is another plus. The low current requirements make it ideal for battery-powered devices. And with minimal moving parts, maintenance is rare.

In summary, a graphic overlay membrane switch is not just functional—it’s an enhancement to a product’s look and usability.

What Is the Role of a Membrane Overlay in UI Design?

In modern user interface (UI) design, the membrane overlay plays a key role in bridging human intention and electronic response. Every touch, symbol, and texture communicates something to the user.

A well-designed overlay uses contrast, color coding, and iconography to guide users intuitively. It helps users locate controls without confusion.

Textured finishes also influence perception. A matte finish reduces glare and provides a soft touch, while a glossy finish conveys modernity and precision. For medical and industrial devices, the overlay often uses antimicrobial coatings or UV-resistant layers to support long-term hygiene and durability.

How to Improve Tactile Feel with Membrane Switch Overlays?

The tactile feel gives users confidence that a command has been recognized. Without it, a button can feel lifeless or uncertain.

One way to enhance tactile feel is through the integration of metal domes or poly domes beneath the overlay. Metal domes provide a sharp, clicky response, ideal for equipment that requires precision feedback. Poly domes, on the other hand, create a softer touch, suitable for consumer electronics.

The thickness and flexibility of the overlay material also play a role. Thinner films respond faster to pressure, while thicker ones offer a more cushioned feel.

Embossing—whether pillow, rim, or dome style—raises certain areas of the overlay, helping users locate buttons by touch alone.

Adhesives matter too. Using the right pressure-sensitive adhesive (PSA) ensures consistent actuation and long-term stability. Poor adhesive choices can reduce tactile sharpness or cause uneven button feel over time.

Lastly, maintaining uniform dome alignment and proper layer spacing prevents inconsistent feedback across the panel.

What Factors Affect Membrane Switch Design?

Designing a membrane switch involves balancing visual appeal, functionality, and manufacturability.

- The first factor is material selection. Polyester and polycarbonate are most common, but their properties differ. Polyester offers better fatigue resistance, while polycarbonate provides better formability.

- The environmental conditions also play a big role. If the switch will be used outdoors or in chemical-rich surroundings, UV-resistant or chemical-resistant coatings may be needed.

- Electrical design determines responsiveness. The type of circuit—silver ink, carbon ink, or copper flex—affects conductivity and signal reliability. Some designs even use printed LEDs or flexible circuits for enhanced performance.

- Then there’s appearance. The color scheme, typography, and graphics should match the device’s branding. Backlighting options like EL or LED lighting can highlight important zones and improve night visibility.

- Another important factor is interface compatibility. The switch must fit the device’s mechanical design perfectly, aligning holes, windows, and connectors accurately.

A well-planned membrane switch design takes all these factors into account, ensuring that the end product performs reliably and feels intuitive.

What Impacts Membrane Switch Overlay Lifespan?

Durability is a top concern for every membrane switch overlay. Several elements influence the lifespan.

- The base material quality is fundamental. Polyester films, with higher flex endurance, typically last longer than polycarbonate ones. The ink type and printing process also matter. Using UV-cured or epoxy inks improves resistance to abrasion and fading.

- Environmental exposure is another factor. UV radiation, moisture, or chemicals can slowly degrade overlays. That’s why protective coatings, hardcoats, or laminated finishes are often applied to extend life.

- Mechanical design contributes as well. Consistent actuation pressure, balanced dome design, and proper spacer thickness reduce stress points. Overly stiff layers can cause cracks, while weak adhesives may lead to delamination.

- Routine cleaning or harsh chemicals can impact longevity. Choosing overlays with chemical-resistant coatings helps maintain clarity and flexibility even after years of cleaning.

In general, a high-quality membrane switch overlay can withstand over a million actuations if designed and maintained properly. Attention to materials, coatings, and precise assembly ensures consistent performance throughout its operational life.

How to Customize a Membrane Switch and Panel Solution?

Every application has its unique requirements, which is why custom membrane switch and panel solutions are so popular.

The process begins with understanding the application. Is it for medical equipment, industrial controls, or consumer devices? Each environment demands different specifications.

Next comes graphic design. You can incorporate brand colors, company logos, and distinct symbols to match the product’s identity.

Customization also extends to tactile feedback. You can choose between flat or embossed buttons, adjust dome force, and select textures that feel right for your users. Backlighting, transparency, and LED integration can further enhance the user experience.

Interface integration is another key. The overlay can be bonded with PCB assemblies, rigid backplates, or housings using high-adhesion tapes or adhesives.

Finally, thorough testing verifies actuation life, color accuracy, and adhesion performance.

Conclusion:

Membrane switch overlays represent the “face,” “feel,” and “function” of modern electronic interfaces. They blend aesthetics with performance, guiding users through precise and intuitive interactions.

By selecting the right materials, surface finishes, and tactile designs, you extend the lifespan and reliability of your devices.

For expert guidance on membrane switch design, contact sales@best-membraneswitch.com today.

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online