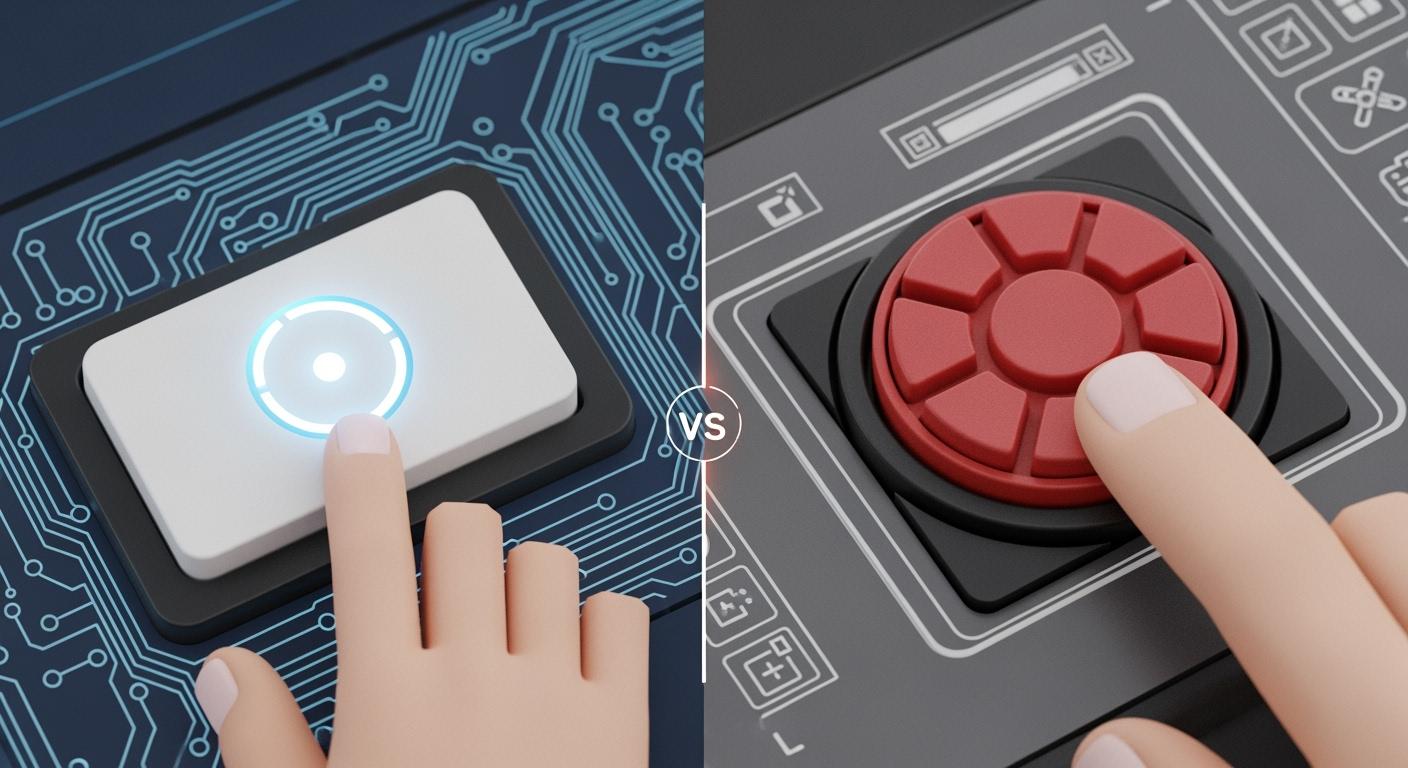

Capacitive Membrane Switches Versus Traditional Membrane Switches Key Differences

Capacitive Membrane Switches Versus Traditional Membrane Switches Key Differences

You need to understand exactly what sets a capacitive membrane switch apart from a traditional membrane switch. Your choice impacts how users interact with your equipment, how long the interface lasts, and how well it stands up to harsh environments. Industries demand different solutions; for example, agricultural and military applications require keypads that resist abrasion, chemicals, and temperature changes. The right switch ensures optimal performance and longevity, so you must consider user experience, reliability, and environmental resistance before making your decision.

Key Takeaways

- Capacitive membrane switches offer a modern, touch-sensitive interface that responds instantly without physical contact, making them ideal for sleek designs.

- Traditional membrane switches provide tactile feedback with each press, ensuring users feel a physical response, which can enhance user satisfaction.

- Consider the environment when choosing a switch; capacitive switches excel in harsh conditions due to their superior sealing against water and dust.

- Cost is a key factor; traditional membrane switches are generally more affordable, while capacitive switches offer advanced features at a higher price.

- Evaluate user preferences; if tactile feedback is important, traditional switches are preferable, but for a clean, buttonless look, capacitive switches are the way to go.

What Are Membrane Switches?

Basic Structure

You want a control interface that stands up to daily use and delivers a seamless experience. Membrane switches offer exactly that by combining several specialised layers, each with a unique function. When you examine a membrane switch, you notice how every layer contributes to its performance and durability. The table below breaks down the essential components you will find in a high-quality membrane switch:

| Layer Type | Description |

|---|---|

| Overlay | The top layer, often made of polycarbonate or polyester, protects against abrasion. |

| Conductive Layers | Essential for the functionality of the switch, allowing electrical signals to pass. |

| Adhesive | Used to bond the layers together, ensuring structural integrity. |

| Graphic Overlays | Provides visual elements and user interface design on the switch. |

| Thickness Control | Different layers vary in thickness, requiring precise cutting techniques. |

| Edge Quality | Clean edges are crucial for durability and user experience. |

You benefit from this multi-layered construction because it ensures reliability, tactile feedback, and a professional appearance. The precise engineering behind each layer means you can trust the switch to perform in demanding environments.

Common Uses

You encounter membrane switches in many devices you use every day. Their versatility and robust design make them the preferred choice across a wide range of industries:

- Medical: You find them in medical devices, where a user-friendly interface is critical for patient safety and efficiency.

- Industrial Automation: They appear in control panels, helping you manage machinery with confidence.

- Aerospace and Defence: These switches withstand extreme conditions, making them ideal for military equipment.

- Automotive: You interact with them in dashboards and infotainment systems, enjoying intuitive controls.

- Consumer Electronics: They power remote controls and gaming consoles, offering reliable performance.

- Telecommunications: You rely on them in phones and routers for consistent connectivity.

By choosing membrane switches, you ensure your equipment meets the highest standards for usability and durability. This decision positions your products ahead of the competition and guarantees satisfaction for your users.

Traditional Membrane Switch Overview

How They Work

You want a switch that responds reliably every time you press it. Traditional membrane switches use a simple yet effective mechanism. When you press a key, you push the top conductive layer down until it touches the bottom conductive layer. This contact completes an electrical circuit and sends a signal to your device. You feel a slight tactile response, which confirms your action.

Tip: You do not need much force to activate these switches. A gentle press is enough, making them ideal for frequent use.

This design keeps the switch thin and lightweight. You can integrate it into compact devices without sacrificing performance. The straightforward operation also means you can trust the switch to work consistently, even after thousands of presses.

Features

Traditional membrane switches offer several advantages that make them a popular choice for many industries. Here are the key features you should consider:

- Tactile Feedback: You get a physical response with each press, so you know the switch has registered your input.

- Customisable Graphics: You can design the overlay to match your brand or device requirements.

- Cost-Effective: You benefit from lower production costs, especially for high-volume orders.

- Simple Integration: You can easily fit these switches into existing panels or enclosures.

- Reliable Performance: You enjoy consistent operation in controlled environments.

| Feature | Benefit to You |

|---|---|

| Tactile Response | Confirms every press |

| Slim Profile | Saves space in your device |

| Easy to Clean | Maintains hygiene |

| Versatile Design | Matches your application needs |

If you want a dependable, budget-friendly solution for your equipment, traditional membrane switches deliver excellent value. Choose them when you need a proven technology that balances performance and affordability.

Capacitive Membrane Switch Overview

Capacitive Switch Operation

You want a control solution that feels modern and intuitive. A capacitive membrane switch gives you exactly that. Unlike traditional switches, a capacitive switch does not need you to press down or make physical contact to close a circuit. Instead, it senses the change in capacitance when your finger approaches the surface. This technology creates a touch-sensitive interface that responds instantly to your touch. You can even operate a capacitive membrane switch through glass or acrylic, which keeps the surface smooth and easy to clean. This means you get a seamless, hygienic, and reliable user experience every time.

With a capacitive membrane switch, you enjoy effortless activation and a sleek, buttonless design that stands out in any environment.

Key Characteristics

You gain several advantages when you choose a capacitive membrane switch for your application. Manufacturers design these switches to deliver high performance, flexibility, and durability. The table below highlights the defining features you can expect:

| Characteristic | Description |

|---|---|

| Functionality | Keys can be latching/toggle or momentary, giving you control over how each key behaves. |

| Design Features | You can add sliders and rotary wheels for analogue functions, expanding your interface options. |

| Power Efficiency | Low supply current and low current indicators make a capacitive switch ideal for battery-powered devices. |

| Durability | Thicker window materials and toughened glass boost impact resistance and longevity. |

| Interface | SPI interface or direct logic output lets you connect easily to your host processor. |

| Calibration | Auto calibration ensures stable performance over time, so you avoid drift or false triggers. |

| Sealing | Sealed front panels and reverse mounting options protect your device from dust and moisture. |

You can see that a capacitive membrane switch offers more than just touch activation. You get a robust, energy-efficient, and highly customisable solution. If you want your product to stand out with a premium look and feel, a capacitive switch is the smart choice.

Key Differences Explained

Activation Method

You want a switch that matches your application’s needs. The activation method is the first area where you see clear differences between capacitive and traditional membrane switches. Capacitive switches use advanced sensing technology. When your finger touches the surface, the switch detects a change in capacitance. You do not need to press down. The switch responds instantly to your touch, even through glass or acrylic.

Traditional membrane switches require a physical press. You push the top layer until it contacts the bottom layer, closing the circuit. This action gives you a familiar, mechanical feel. The table below highlights how each switch type activates:

| Feature | Capacitive Switches | Mechanical Switches |

|---|---|---|

| Activation Method | Uses a capacitive sensor to detect changes in capacitance when touched. | Requires physical contact between two conductive traces to close the circuit. |

| Circuit Closure | Completes the circuit based on capacitance drop caused by a finger touch. | Closes the circuit when the upper trace contacts the lower trace upon pressing. |

| Reset Mechanism | Automatically resets when the finger is removed, restoring capacitance. | Bounces back to the open state when the button is released. |

You gain speed and convenience with capacitive switches. You get a classic, tactile response with traditional membrane switches. Your choice depends on how you want users to interact with your device.

User Experience

You care about how your users feel when they operate your equipment. Traditional membrane switches give you tactile feedback. When you press a button, you feel a physical response. This feedback confirms your action and makes operation more satisfying. Many users prefer this sensation, especially in environments where you need to know a command has registered.

Capacitive membrane switches offer a different experience. You do not feel a physical click. Instead, you rely on visual or auditory cues to know the switch has activated. Some users enjoy the smooth, modern feel. Others may miss the reassurance of tactile feedback.

- Tactile membrane switches provide a physical response when pressed, enhancing user experience by confirming the action taken.

- Non-tactile membrane switches lack physical feedback, often relying on auditory or visual signals to indicate activation, which may lead to a less satisfying user experience.

If you want users to feel every press, choose traditional membrane switches. If you want a sleek, touch-based interface, capacitive switches deliver a modern experience.

Design and Appearance

You want your product to stand out. Both switch types offer customisable graphics and overlays. You can match your brand and create a unique look. Capacitive membrane switches give you more design freedom. You can use resin doming for a premium finish. You can also create seamless, buttonless surfaces that look clean and futuristic.

Traditional membrane switches allow embossing and custom overlays. However, they do not support resin doming. Their appearance feels more conventional. Durability also differs. Capacitive switches use tougher materials, so they last longer and resist wear better.

Here is a quick comparison:

| Feature | Capacitive Membrane Switches | Traditional Membrane Switches |

|---|---|---|

| Embossing | Yes | Yes |

| Resin Doming | Yes | No |

| Tactile Feedback | Limited | Yes |

| Graphic Overlays | Customisable | Customisable |

| Durability | High | Moderate |

You can create a high-end, durable interface with capacitive switches. You get a reliable, familiar look with traditional membrane switches. Your design choice shapes how users see and feel your product.

Performance and Reliability

Durability

You want your equipment to last. Capacitive membrane switches give you outstanding durability. Manufacturers design these switches to withstand millions of touches without losing sensitivity. You do not need to worry about wear and tear from repeated use. The toughened glass or acrylic surface resists scratches and impacts. You get a switch that keeps working even in harsh conditions.

Traditional membrane switches also offer impressive longevity. You can expect them to endure millions of actuations. The tactile feedback remains consistent over time. However, the surface may show signs of abrasion or fading if exposed to rough handling or chemicals. You may need to replace overlays or clean the surface more often.

Consider the following comparison:

| Feature | Capacitive Membrane Switch | Traditional Membrane Switch |

|---|---|---|

| Lifespan | Millions of touches | Millions of actuations |

| Surface Resistance | High (glass/acrylic) | Moderate (polyester/polycarbonate) |

| Maintenance Needs | Minimal | Occasional cleaning/replacement |

| Sensitivity | Superior | Good, but less precise |

You get a longer-lasting, low-maintenance solution with capacitive membrane switches. You save time and money on repairs and replacements.

Sealing and Environmental Resistance

You need a switch that stands up to water, dust, and chemicals. Capacitive membrane switches offer complete sealing. The front panel forms a barrier against moisture and contaminants. You can install these switches in outdoor or industrial environments without worrying about damage. The sealed design prevents liquid ingress, so you avoid costly downtime.

Traditional membrane switches provide basic protection. The overlay shields the internal layers from dust and splashes. However, the edges and seams may allow water or chemicals to seep in over time. You may face issues with corrosion or malfunction if you use these switches in wet or hazardous locations.

Here are the key benefits of capacitive membrane switches:

- 🛡️ Waterproof and chemical-resistant surface

- 🧼 Easy to clean and disinfect

- 🌡️ Stable performance in extreme temperatures

Choose capacitive membrane switches if you want maximum reliability in challenging environments. You protect your investment and ensure your equipment works when you need it most.

You see the difference in performance and reliability. Capacitive membrane switches deliver superior sealing, durability, and sensitivity. You reduce maintenance and extend the lifespan of your devices. If you value long-term performance and minimal upkeep, capacitive technology is the clear winner.

Application Suitability

Best Uses for Traditional Switches

You want a switch that delivers reliability and value. Traditional membrane switches excel in environments where cost-effectiveness and proven durability matter most. You can trust these switches in healthcare, industrial, and OEM settings. They withstand frequent use and resist water and chemicals, making them a smart choice for demanding workplaces.

Here is a quick overview of where traditional membrane switches shine:

| Application Environment | Key Advantages of Membrane Switches |

|---|---|

| Healthcare | Meets exacting requirements for water and chemical resistance |

| Industrial | Extremely durable, suitable for harsh working conditions |

| OEMs | Hard-wearing quality beneficial for regular use in demanding environments |

You benefit from tactile feedback, which helps users confirm every press. You also enjoy easy integration into existing panels. If you need a dependable solution for medical devices, factory controls, or equipment used daily, traditional membrane switches give you peace of mind.

Choose traditional membrane switches when you want a cost-effective, robust interface that stands up to tough conditions.

Best Uses for Capacitive Switches

You seek innovation and a premium user experience. Capacitive membrane switches offer advanced features that set your product apart. These switches work perfectly in modern electronic devices, especially where touch sensitivity and sleek design matter. You can use them in human-machine interfaces (HMIs) for extreme environments, as they remain responsive and durable.

Consider these common applications for capacitive membrane switches:

| Use Case | Description |

|---|---|

| Human-Machine Interfaces (HMIs) | Ideal for HMIs in extreme environments due to durability and responsiveness |

| Multi-Touch Support | Supports multi-touch, enhancing user interaction in modern devices |

| Rugged Applications | No need for physical contact, making them suitable for rugged environments |

| Operation with Gloves | Can be operated while wearing gloves, providing versatility in various conditions |

You gain the ability to create seamless, buttonless surfaces that look modern and are easy to clean. Capacitive switches also support operation with gloves, which is essential in medical, food processing, or outdoor settings. If you want your device to offer intuitive touch control and stand out in the market, capacitive membrane switches are the right choice.

Select capacitive membrane switches when you demand cutting-edge performance, versatility, and a superior user experience.

Pros and Cons

Traditional Membrane Switch

You want a switch that delivers reliability and value. Traditional membrane switches offer several advantages, but you should also consider their limitations.

Pros:

- Tactile Feedback: You feel a physical response with every press. This feedback helps you confirm each action.

- Cost-Effective: You save money, especially on large production runs. Traditional switches keep your project within budget.

- Customisable Graphics: You can match the switch to your brand or device. The overlay supports detailed designs.

- Simple Integration: You install these switches easily into most panels or enclosures.

- Proven Durability: You trust them in controlled environments for years of consistent use.

Cons:

- Limited Sealing: You may face issues with water or chemical ingress in harsh environments.

- Surface Wear: You notice abrasion or fading over time, especially with heavy use.

- Less Modern Appearance: You get a more conventional look, which may not suit high-end products.

Tip: Choose traditional membrane switches when you need a dependable, budget-friendly solution for standard applications.

Capacitive Membrane Switch

You want innovation and a premium user experience. Capacitive membrane switches bring advanced features, but you should weigh their drawbacks.

Pros:

- Touch Activation: You enjoy effortless, instant response without pressing down.

- Superior Sealing: You benefit from complete protection against water, dust, and chemicals.

- Modern Design: You create sleek, buttonless surfaces that impress users.

- Long Lifespan: You rely on tough materials that resist scratches and impacts.

- Easy Cleaning: You wipe the surface clean, maintaining hygiene in demanding settings.

Cons:

- Higher Cost: You invest more upfront, especially for custom designs.

- No Tactile Feedback: You may miss the physical click, relying on visual or audio cues.

- Complex Integration: You need careful calibration and sometimes extra electronics.

If you want your product to stand out with advanced features and durability, capacitive membrane switches give you a clear advantage.

Choosing the Right Switch

Key Considerations

You want to make the best choice for your project. Start by thinking about the environment where you will use the switch. If you expect exposure to water, dust, or chemicals, you need a solution that offers strong sealing and resistance. Capacitive membrane switches provide excellent protection in harsh settings. You also need to consider user experience. If your users prefer tactile feedback, traditional membrane switches deliver a satisfying click with every press. For a modern, touch-based interface, capacitive switches create a sleek and intuitive feel.

Cost matters as well. Traditional membrane switches usually cost less, especially for large orders. Capacitive switches require a higher investment, but you gain advanced features and longer lifespan. Think about your budget and the value you want to deliver.

Industry experts recommend you pay attention to these technical factors for harsh environments:

- 🛡️ Electrostatic Discharge (ESD): Leave enough space around the active area and use ESD shielding layers.

- 💧 Seal Integrity: Choose high-quality adhesives and ensure proper gasketing to block moisture and chemicals.

- 🔗 Tail Fracture: Reinforce tail exits and plan cable routes to reduce stress.

- 🧲 Delamination: Use shear-resistant adhesives and secure the tail connection.

- 🧪 Material Compatibility: Pick materials designed for your specific conditions and chemical exposure.

- 🧷 Adhesive Match: Test all materials and select adhesives made for your environment.

You protect your investment and boost reliability when you address these factors early in your design.

You see clear distinctions between capacitive and traditional membrane switches. Capacitive switches deliver modern design and superior sealing, while traditional switches offer tactile feedback and cost savings. In industrial settings, you face challenges such as contamination and sanitation:

| Challenge | Description |

|---|---|

| Contamination | Frequent cleaning can damage interfaces with seams or gaps. |

| Sanitation | Sensors must avoid false triggers from water or debris. |

Choose the switch that matches your environment, reliability needs, and user expectations. Make your decision with confidence.

FAQ

What makes capacitive membrane switches better for harsh environments?

You gain superior protection with capacitive membrane switches. The sealed surface blocks water, dust, and chemicals. You avoid costly downtime and repairs. Choose capacitive technology if you want your equipment to last in extreme conditions.

Can you use capacitive switches with gloves?

Yes, you can operate capacitive membrane switches while wearing gloves. This feature makes them ideal for medical, industrial, and outdoor settings. You maintain hygiene and safety without sacrificing performance.

Do traditional membrane switches offer tactile feedback?

You experience a satisfying click with traditional membrane switches. This tactile feedback confirms every press. If you want users to feel each action, traditional switches deliver the response you need.

Are capacitive membrane switches difficult to clean?

No, you clean capacitive membrane switches easily. The smooth, seamless surface resists dirt and bacteria. You wipe them down quickly, making them perfect for environments where hygiene matters.

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online