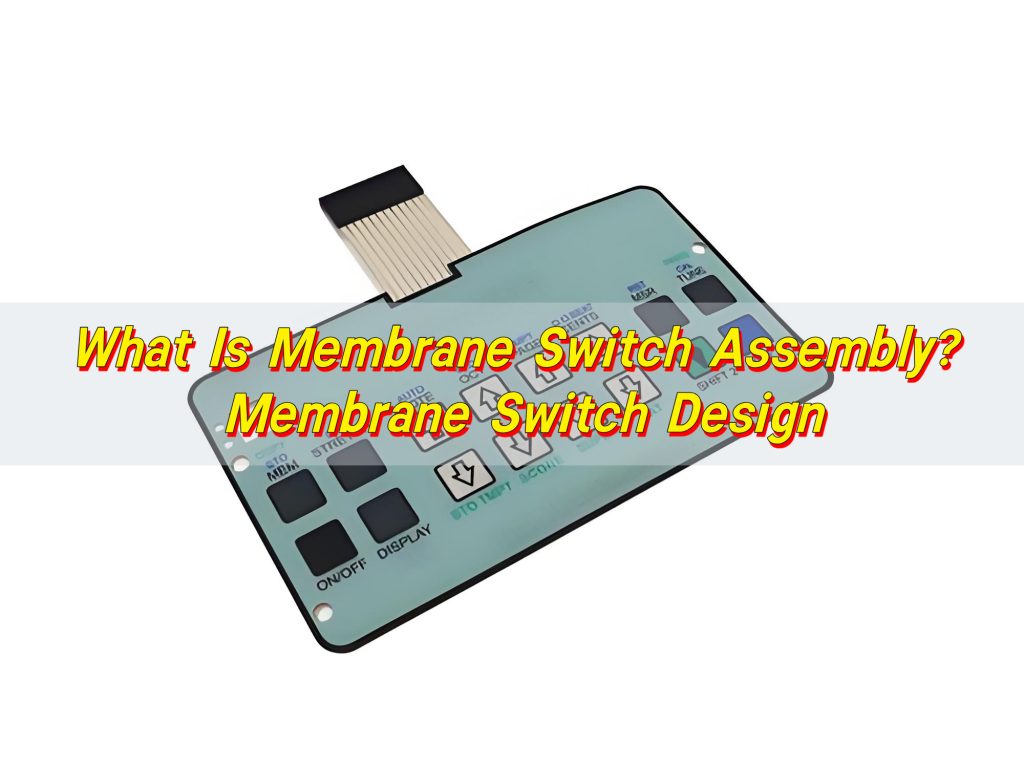

What Is Membrane Switch Assembly? Membrane Switch Design

What Is Membrane Switch Assembly? Membrane Switch Design

Membrane switch assembly is the process of layering materials—like graphic overlays, spacers, and circuits—to form a responsive control panel. When pressed, the top layer flexes to complete an electrical circuit, sending a signal to the device.

What Is a Membrane Switch?

Membrane switch is an electrical switch for turning a circuit on and off. It is usually a thin, flexible structure made from multiple layers of printed circuits, adhesives, and graphic overlays. When you press the surface, it activates the underlying circuit, completing an electrical connection.

Unlike mechanical switches, membrane switches have no moving metal parts. Instead, they rely on pressure-sensitive layers and conductive ink circuits. This makes them compact, lightweight, and ideal for products that need flat, sealed interfaces.

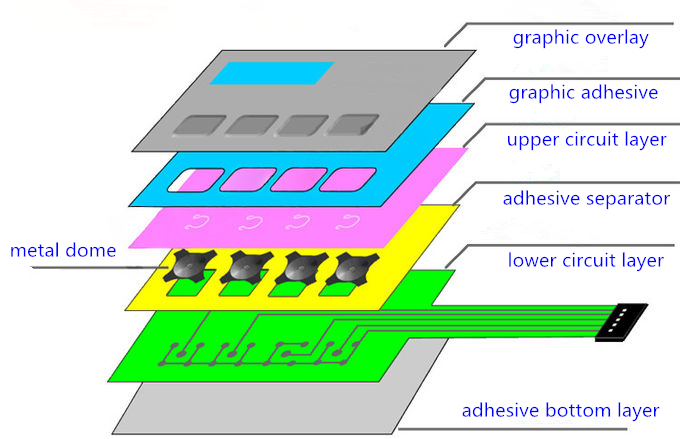

What Is the Construction of a Membrane Switch?

A membrane switch assembly is built layer by layer. Each layer performs a special function to ensure smooth electrical performance and tactile feedback.

- 1. Graphic Overlay

This is the top layer that users touch. It often carries symbols, logos, or icons. The material is usually polyester or polycarbonate, printed with UV inks. It provides durability and protects against scratches, chemicals, and moisture.

- 2. Spacer Layer

Below the overlay lies the spacer. It separates the top and bottom circuits and defines the “travel” distance when pressed. The spacer has openings aligned with the contact points, allowing the switch to close the circuit when pressed.

- 3. Circuit Layers

Circuit layers are printed with conductive silver or carbon ink. These traces form the electrical path between components. Some assemblies use flexible printed circuits (FPC) or copper flex circuits for better performance.

- 4. Metal Dome or Tactile Layer

Many membrane switch assemblies include a metal dome beneath the overlay. When pressed, the dome collapses and snaps back, giving a tactile “click.”

- 5. Backer or Rear Adhesive Layer

The final layer bonds the entire switch to the control panel or product housing. It ensures stability and protects internal components from dust or moisture.

Each of these layers is carefully designed and assembled. Their combination defines how the membrane switch panel feels, performs, and lasts.

How to Assemble a Membrane Switch?

Assembling a membrane switch requires precision and cleanliness. Even tiny dust particles can affect performance. The process involves multiple controlled steps:

- 1. Circuit Printing

Conductive inks are screen-printed onto polyester sheets. The layout follows the electrical design, forming paths and contacts. The printed sheets are then cured at specific temperatures for strong adhesion and conductivity.

- 2. Dome Placement

Metal domes are positioned over the contact points. High-speed machines or manual alignment tools ensure exact placement. In high-volume production, Tape & Reel packaging can speed up this process, improving accuracy and efficiency.

- 3. Layer Lamination

Adhesive layers bond the circuit, spacer, and overlay together. Each layer must align perfectly. Lamination occurs under controlled temperature and pressure to prevent bubbles or wrinkles.

- 4. Connector Installation

A tail or connector is added to the switch. This flexible tail plugs into the main circuit board or controller. It transmits signals when the switch is pressed.

- 5. Testing and Inspection

Every membrane switch assembly undergoes strict electrical and tactile testing. Engineers check for continuity, actuation force, and response consistency.

How Does a Membrane Switch Assembly Work?

The working principle of a membrane switch assembly is simple yet effective. When a user presses a specific area, the top circuit layer or metal dome collapses onto the bottom circuit. This contact completes the circuit, sending a signal to the device’s control unit. Once the pressure is released, the layers separate again, and the circuit opens.

This on-off behavior repeats thousands or even millions of times. Because the layers are sealed, the switch remains protected from dirt, liquids, and environmental stress. That’s why membrane switches are ideal for outdoor or industrial use.

When a metal dome is used, users feel a satisfying tactile response. This instant feedback helps confirm the operation, reducing errors and improving user confidence. Some designs also include backlighting or embossing for better visibility and appearance.

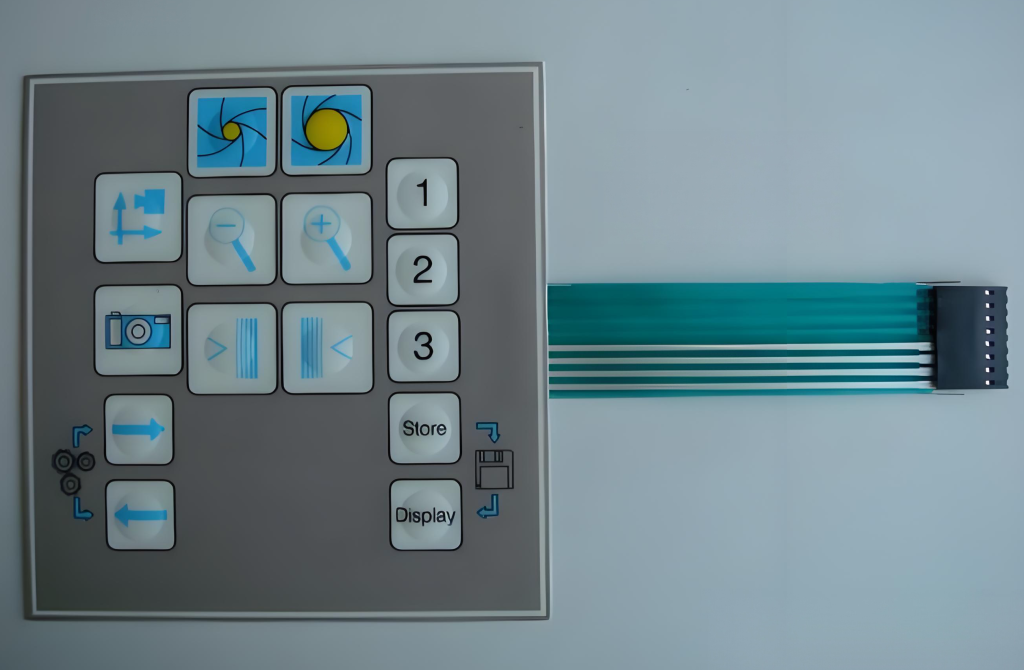

How Is a Membrane Switch Panel Designed?

Designing a membrane switch panel requires a balance between function, aesthetics, and durability. It’s not just about where to place the buttons—it’s about how the interface feels and performs.

- 1. Define User Needs

The design starts with understanding user interaction. How often will the switch be pressed? Will it be used in a cleanroom, hospital, or outdoor environment? These questions decide material choice and structure.

- 2. Choose Materials

Graphic overlays must resist chemicals or sunlight. Circuits may need conductive inks or flexible copper. Adhesives should handle humidity and temperature.

- 3. Layout and Graphics

Button shapes, symbols, and colors enhance usability. Embossing or tactile domes help guide fingers naturally to key areas.

- 4. Electrical Design

The layout minimizes resistance and ensures stable signal transfer. Good electrical design avoids signal interference and contact wear.

- 5. Backlighting and Indicators

Many membrane switch panels include LED backlights or light guides. This feature improves visibility in dark environments and adds a professional look.

- 6. Prototype and Test

Before mass production, prototypes are built and tested. This stage ensures tactile feel, lighting balance, and circuit accuracy meet the design goals.

Good membrane switch design blends aesthetics with function. Every detail—from dome height to key spacing—affects user comfort and device reliability.

What Matters Most in Membrane Switch Design?

When developing a membrane switch, several factors decide its success. These include tactile response, durability, resistance, and usability.

- 1. Tactile Feedback

A clear tactile response improves user satisfaction. The right metal dome or embossing shape ensures comfortable feedback. The click should be crisp but not harsh.

- 2. Material Quality

Use high-quality films, inks, and adhesives. Good materials resist humidity, UV, and wear. This extends switch life and reduces maintenance.

- 3. Actuation Force

The actuation force must match the product’s purpose. For medical devices, a soft touch works best. For industrial panels, a stronger force prevents accidental activation.

- 4. Circuit Design

Precise circuit design avoids false triggering. Contact spacing and conductive paths should ensure consistent signal transmission.

- 5. Environmental Protection

A sealed structure prevents water, dust, and oil from entering. It helps the membrane switch panel work even in rough conditions.

- 6. Aesthetic and Branding

An attractive overlay enhances product appeal. Use vibrant colors and clear legends to create a professional look that reflects the brand.

When all these elements are balanced, a membrane switch assembly not only performs well but also strengthens the product’s overall user experience.

What Are Membrane Switches Used For?

Membrane switches are everywhere. Their versatility allows them to be used across industries:

- Medical Equipment: Flat, easy-to-clean surfaces prevent bacterial buildup.

- Industrial Control Panels: Durable and resistant to oil, moisture, and vibration.

- Consumer Electronics: Sleek and lightweight for remote controls, microwaves, or printers.

- Automotive Systems: Used for dashboard controls and interior lighting.

- Communication Devices: Reliable input for handheld radios and transmitters.

- Home Appliances: Simple and cost-effective interface for washing machines or ovens.

Their compact design and customizable appearance make them suitable for almost any electronic interface.

How Does Membrane Switch vs Mechanical Keyboard Differ?

Many people compare membrane switches vs mechanical keyboards, but their construction and performance are quite different.

- 1. Structure

A mechanical keyboard uses individual mechanical switches under each key. Each switch has a spring and metal contact.

A membrane keyboard, on the other hand, uses pressure-sensitive layers or domes. There are no separate moving parts.

- 2. Tactile Feel

Mechanical keyboards offer a strong, clicky response. Membrane switches deliver a softer, quieter touch.

- 3. Durability

Both types can last long, but membrane switches offer better protection against moisture and dust. With proper materials, they can last over one million actuations.

- 4. Design Flexibility

Membrane switches are thinner and can integrate lighting, graphics, and sealing—all in one compact panel. Mechanical switches are bulkier and limited in shape.

- 5. Cost and Application

Membrane switch assemblies are cost-effective and perfect for devices needing sealed, flat surfaces. Mechanical switches are often used for high-end keyboards or gaming gear.

In short, the membrane switch keyboard focuses on practicality, flexibility, and reliability, while mechanical ones emphasize tactile performance and modularity.

What Affects Membrane Switch and Panel Performance?

Performance depends on both materials and manufacturing precision. Here are the main influences:

- Material Consistency: Inconsistent films or adhesives cause uneven key feel.

- Dome Quality: Metal domes must have consistent actuation force and rebound.

- Circuit Printing Accuracy: Even minor misalignment in printed circuits leads to signal loss.

- Environmental Factors: Humidity, UV exposure, or temperature extremes affect adhesives and overlays.

- Assembly Conditions: A dust-free environment is essential during lamination.

- Testing Procedures: Routine testing ensures quality consistency.

With these factors controlled, membrane switches can perform reliably for years—even under heavy daily use.

Conclusion:

From the flexible circuit layer to the haptic feedback plate, every component in the membrane switch assembly plays a crucial role in the feel and performance of the switch.

Whether used in medical equipment or industrial control, they deliver dependable performance and modern aesthetics.

If you are looking for reliable, high-quality membrane switch components, please contact us today: sales@best-membraneswitch.com

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online