Custom Membrane Switches Manufacturers, Membrane Switch Custom

Custom Membrane Switches Manufacturers, Membrane Switch Custom

What Are Custom Membrane Switches?

Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience.

These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the surface finish, print details, lighting, tactile response, and sensing method.

Custom membrane switch can be made into a keypad, a panel, or a full control surface. It can include embossed keys, LED backlighting, windows, protective coatings, and even special shapes. Because of this flexibility, it fits into devices with tight spaces where mechanical buttons may not work well.

How to Customize a Membrane Switch?

You can customize a membrane switch step by step. Yu An Electronics supports each stage to help clients build the switch they want without guesswork.

- 1. Define the Functional Needs

Start by listing what the switch must do. This includes the number of keys, the type of feedback you want, the layout, and any special features.

- 2. Choose the Graphic Overlay Material

The top layer shows the printed design. It also gives the first tactile impression. Materials like PET or PC are common because they resist wear. You can choose gloss, matte, textured, or anti-UV finishes depending on the environment.

- 3. Pick the Circuit Type

You can choose printed silver circuits or copper-etched circuits. Silver circuits are widely used because they are cost-effective and stable. Copper circuits work better for high-current devices.

- 4. Add Lighting Options

Custom LED placement gives better visibility and makes the interface more intuitive. You can use side-LEDs, backlighting, indicator LEDs, or even RGB lighting.

- 5. Decide the Tactile Feel

You can choose between metal domes, polydomes, or flat keys. Metal domes offer crisp feedback. Polydomes offer soft feedback. Flat keys offer silent control.

- 6. Specify Connectors and Tail Length

These define how the switch links to the PCB. A clear and stable connector ensures strong communication with the device.

- 7. Consider Environmental Conditions

If the device will be used outdoors or in harsh conditions, you can add coatings, waterproofing, and UV protection. Outdoor equipment, fitness machines, and medical devices often require more protection.

- 8. Approve Samples and Begin Production

After design and engineering review, samples are created. If all looks good, full production begins. Yu An Electronics ensures smooth communication at each stage.

Customization offers creative control and technical flexibility. It also lets brands create user experiences that feel aligned with their product purpose.

How Do Membrane Switches Work?

Membrane switches work through simple and reliable contact between two conductive layers. The design looks minimal from the outside, but each layer inside plays an important role. When you press a key, it pushes the top layer to meet the bottom layer. Once they touch, the circuit closes and sends a signal.

Layers Inside a Membrane Switch, A typical structure includes:

- Graphic overlay

- Adhesive layer

- Top circuit

- Spacer

- Bottom circuit

- Rear adhesive

Each layer uses thin materials that allow smooth operation. When someone presses on the overlay, the pressure travels through the layers and closes the circuit. Once released, the contact opens again.

If metal domes are used, they give a sharp click that helps the user feel the input. If polydomes or flat keys are used, the response is softer.

This simple contact method makes membrane switches dependable. They respond without mechanical springs or heavy parts.

Why Choose a Custom Membrane Switch Keypad?

Custom membrane switch keyboards can be designed freely. It combines appearance, functionality, and durability in one lightweight structure.

Here is why they stand out:

- Modern Look: Custom keypad gives a clean and organized interface.

- Better User Interaction: You can tune the tactile response, key spacing, lighting, and surface texture. These factors allow more controlled operation.

- Space-Saving and Slim: Custom membrane switches are extremely thin. They fit well in portable devices, compact tools, and lightweight products.

- Long Service Life: Even with frequent presses, custom keypads maintain their function. The stable structure and protected circuitry prevent early wear.

- Flexible Layout: Whether you need ten keys or one hundred keys, the layout is fully customizable.

- Branding Control: You can match the keypad design with your brand colors and visual style.

Good Performance in Tough Environments: Custom keypads withstand moisture, dust, and daily handling. They work well indoors and outdoors.

Custom membrane switch keypad is more than an input tool. It is a design asset that improves user trust and device appeal.

What Is a Custom Membrane Switch Panel Used For?

Custom membrane switch panel controls multiple functions in a single layout. It works as the face of many devices. These panels serve important uses across many industries:

- 1. Medical Equipment

Medical devices must be clean and easy to disinfect. Membrane switch panels offer smooth surfaces without gaps. They resist chemicals and help maintain hygiene.

- 2. Industrial Controls

Factory machines need rugged panels that can handle heavy use. Custom switch panels resist dust, oil, and vibration. Workers get reliable control every time.

- 3. Consumer Electronics

Home devices like air purifiers, kitchen appliances, and fitness equipment use membrane switch panels. They give a clean look and simple control.

- 4. Communication Equipment

Two-way radios, control boxes, and handheld tools often use membrane panels because they require slim layouts and responsive keys.

- 5. Automotive Accessories

Keypads in car accessories, rear-seat systems, and control units benefit from the stable feel of membrane panels.

Custom panels help organize complex functions in a way users understand fast. They also create a refined look that enhances the overall device.

How Do Custom Membrane Switches Compare to Mechanical Keys?

Custom membrane switches offer a cleaner, slimmer, and more modern approach than mechanical keys.

- 1. Slim Profile

Custom membrane switches are lighter and thinner than mechanical keys. This makes them ideal for portable and compact products.

- 2. Simplified Design

Mechanical keys require springs, caps, housings, and moving parts. Membrane switches use layered technology that needs fewer components. The structure is easier to integrate.

- 3. Better Sealing

Custom membrane switches can be sealed against dirt and moisture. Mechanical buttons often allow particles to enter through gaps.

- 4. Flexible Layout

Membrane switches allow free-form shapes, printed icons, and unique zones. Mechanical keys have more limitations in shape and spacing.

- 5. Longer Graphic Life

Printed designs on membrane overlays last much longer than printed keycaps. They resist scratches and fading.

- 6. Smoother Cleaning

Flat surfaces are easier to clean. No crevices or gaps allow simpler maintenance.

- 7. Consistent Feedback

Metal domes give uniform tactile feedback with every press. Mechanical keys may vary over time.

Though mechanical buttons are useful in some rugged tasks, custom membrane switches offer a balanced mix of durability, simplicity, and elegance.

Where Are Custom Membrane Switches Used in Electronics?

Custom membrane switches are used almost everywhere in modern electronics. Their slim design, low profile, and stable performance make them suitable for countless devices. Here are some common examples:

- 1. Medical Devices

Hospital tools, diagnostic machines, and monitoring systems rely on membrane switches.

- 2. Industrial Automation

Control pads, factory devices, workshop tools, and measurement systems use custom keypads for reliable daily operation.

- 3. Consumer Products

Kitchen tools, fitness equipment, water purifiers, speakers, and home controls depend on membrane switches for sleek interfaces.

- 4. Communication Tools

Walkie-talkies, radios, satellite devices, and field communication tools use membrane keypads for clear input.

- 5. Automotive Electronics

Control panels, interior accessories, and navigation units often use membrane interfaces for smooth operation.

- 6. Test and Measurement Devices

Meters, gauges, handheld testers, and analyzers use custom keypads to provide clear and accurate control.

- 7. Security Devices

Access controls, monitoring systems, and alarm units rely on membrane switches for stable performance.

Custom membrane switches continue to grow in use because they adapt to new device designs with ease.

What Affects the Durability of a Custom Membrane Switch?

Many factors influence the durability of custom membrane switches.

- 1. Overlay Material

The top layer protects the switch from scratches and chemicals. PET and PC overlays offer strong resistance and help the keypad last longer.

- 2. Adhesive Quality

High-grade adhesives keep the structure stable. If the adhesive is reliable, the layers stay aligned for years.

- 3. Circuit Printing Quality

Accurate printing ensures clean signals. When circuits are printed with precision, the switch maintains excellent performance even after many presses.

- 4. Tactile Element Quality

Metal domes with strong stainless steel provide crisp feedback over long cycles. High-quality domes can reach millions of actuations.

- 5. Environmental Protection

UV-resistant, waterproof, and dust-resistant features improve durability. Devices used outdoors or in factories benefit greatly from these protections.

- 6. Proper Tail Routing

Good design prevents stress on the connector tail. This helps maintain communication between the switch and the PCB.

- 7. Operating Force

Choosing the right actuation force maximizes the life cycle. A well-balanced tactile feel improves the user experience and reduces stress on the circuit.

Every detail plays a role in how long the switch performs well. With proper design and materials, membrane switches operate reliably for a long time.

Yu An Electronics supports full customization and delivers stable, high-quality keypads and panels. If you need a dependable partner for custom membrane switches, we are ready to help.

For cooperation or inquiries, contact us at: sales@best-membraneswitch.com

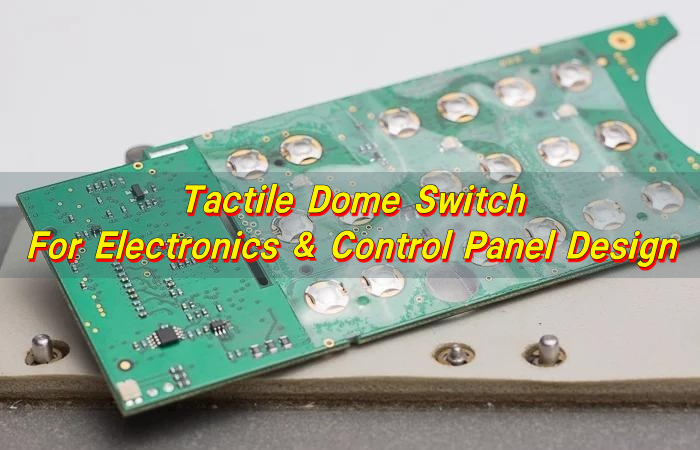

Tactile Dome Switch – For Electronics & Control Panel Design

Our tactile dome switch delivers crisp tactile feedback and reliable precision actuation, with industrial-grade durability for small device control panels. Custom sizes available for your design needs. What is a tactile dome switch? A tactile dome switch is a compact switching component used in electronic interfaces where clear feedback matters. It delivers a sharp, physical ...

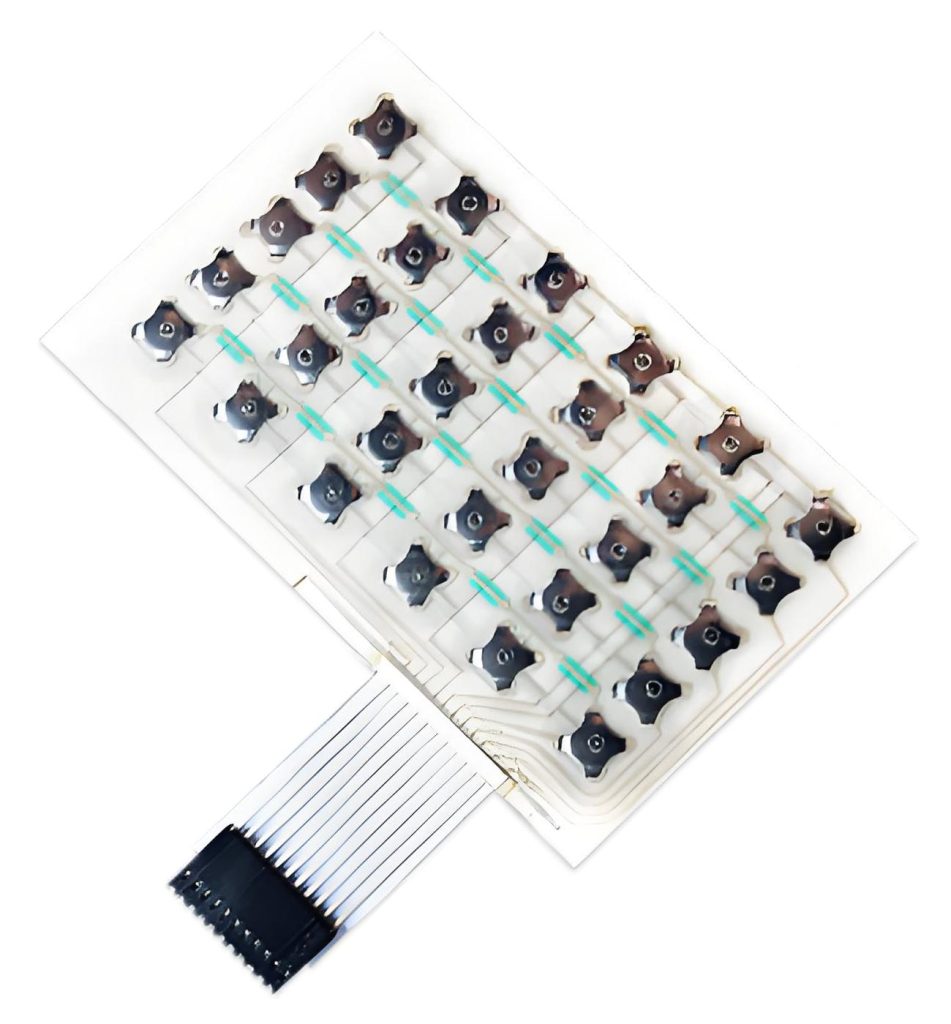

Custom Membrane Keypads – Industrial Grade Custom Design

Our custom membrane keypads are engineered with industrial-grade durability, waterproof & oil-resistant for control panels. Fully customizable sizes, layouts and symbols for your device needs. What is a custom membrane keypad? A custom membrane keypad is a low-profile input interface designed for a specific product, device, or operating environment. It combines printed circuits, tactile layers, ...

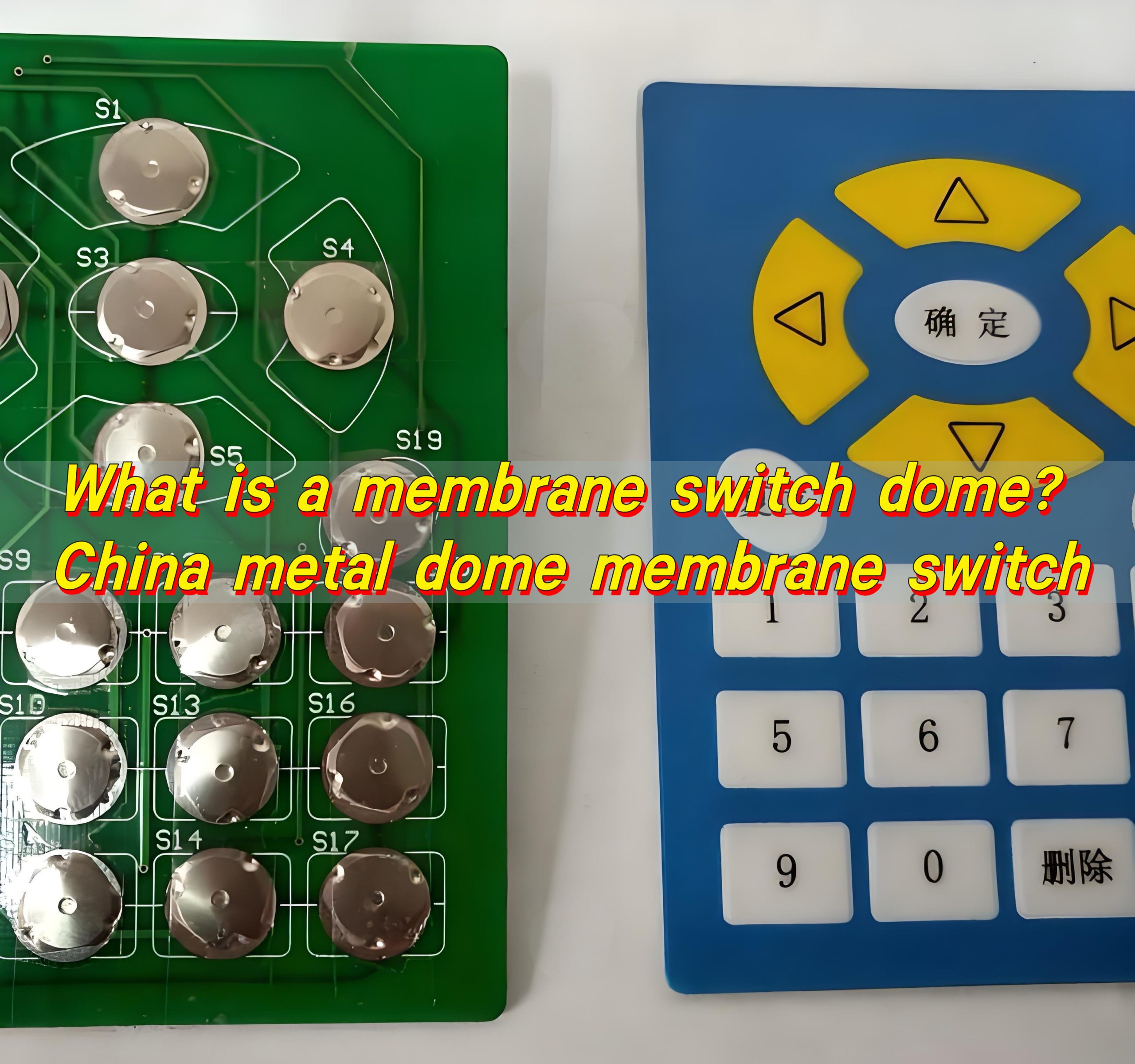

What is a membrane switch dome? China metal dome membrane switch

A membrane switch dome is a small but powerful part of many modern input devices. You see it in factory control panels, medical tools, handheld devices, POS systems, and more. It looks simple, yet it shapes how a product feels, responds, and lasts over time. What Is a Dome Switch Membrane Keyboard? A dome switch ...

Contact us online