What Are Waterproof Flexible Membrane Switches?

What Are Waterproof Flexible Membrane Switches?

Waterproof flexible membrane switches are thin, durable switches that register presses through flexible layers instead of moving parts. Their waterproof design protects circuits from spills, dust, and moisture.

They are widely used in medical devices, appliances, and industrial controls, offering reliable performance and satisfying tactile feedback.

What Is a Flexible Membrane Switch?

Flexible membrane switch is more than just a button. It is a thin, lightweight electronic switch that sits on a flexible surface. Unlike mechanical buttons, it doesn’t rely on heavy moving parts. Instead, it uses layers of conductive material to register a press.

The top layer usually carries graphics or labels. Beneath it, conductive traces connect to a circuit. When pressed, the layers make contact, completing the circuit and sending a signal. This design allows the switch to be both responsive and long-lasting.

These switches are called “flexible” because their base material can bend without breaking. They adapt to curved panels and confined spaces, making them ideal for modern devices where design matters as much as function.

Many call them flexible switches because they can be shaped, printed, and customized to meet specific design requirements. From small handheld controllers to full-scale industrial panels, their applications are endless.

How Do Membrane Switches Work?

The operation of membrane switches is simple yet efficient. At its core, it relies on pressure. Pressing the surface pushes conductive layers together. This completes the circuit and sends a signal to the device.

Unlike traditional mechanical switches, there are no springs or moving metal parts. This reduces wear and tear. It also ensures quieter operation, which is perfect for environments where noise is a concern.

Flexible layers can include tactile domes for feedback. These membrane buttons provide a click feeling, letting users know the command is registered. Some designs even include light indicators, making it easier to use in low-light conditions.

The beauty of switch type membrane design is its simplicity. Fewer parts mean fewer failures. It also allows designers to create complex panels with multiple buttons without increasing size.

Waterproof versions of these switches add another layer of protection. Sealed surfaces prevent water, dust, or oil from entering the circuitry, making them suitable for kitchens, factories, or outdoor devices.

Why Choose a Membrane Switch Panel?

Membrane switch panel offers more than just buttons. It is a complete interface solution. These panels can display graphics, labels, or icons alongside the switches. This makes them visually appealing and easy to operate.

Because the design is flat, cleaning is simple. There are no gaps where dirt or liquid can accumulate. This is particularly important in medical devices or food processing equipment. Hygiene becomes effortless without compromising functionality.

Another advantage is customization. Panels can be printed in any color, shape, or pattern. Designers can incorporate logos, symbols, or instructions directly onto the surface. This reduces the need for additional labeling and keeps the interface sleek.

Moreover, membrane switch panels can integrate multiple functions in a single surface. You can combine buttons, sliders, and indicators without adding bulk. This makes devices more intuitive and user-friendly.

Finally, these panels are cost-effective. Production is simpler than mechanical alternatives, especially for complex layouts. The result is a durable, attractive, and reliable interface that enhances the user experience.

Where Are Waterproof Flexible Membrane Switches Used?

Waterproof flexible membrane switches are everywhere, even if we don’t notice them. In kitchens, they control microwaves, ovens, and coffee machines. A simple spill won’t damage the buttons. In industrial settings, they operate machinery, tools, and control panels while resisting grease, dust, and water.

Medical devices rely heavily on these switches. Sterility and hygiene are critical. Sealed surfaces prevent contamination while allowing accurate input. Hospitals and labs benefit from these clean, responsive switches every day.

Even consumer electronics use them. Remote controls, gaming devices, and audio equipment often include flexible switches for their reliability and tactile feel. Outdoor devices, like garden tools or weather-resistant gadgets, benefit from their waterproof properties.

Essentially, any environment where exposure to liquid, dirt, or rough handling is a concern can use these switches. The adaptability, combined with a flexible membrane, ensures long-term performance and user satisfaction.

How Long Can Membrane Buttons Last?

Durability is a hallmark of membrane buttons. Many designs can withstand over one million presses. This longevity makes them ideal for frequently used devices. Unlike mechanical switches, there is no metal fatigue or spring failure.

The lifespan depends on materials and design. High-quality conductive inks and tactile domes improve performance. A well-sealed surface protects against moisture, dust, and oils. This ensures consistent functionality even under heavy use.

For designers and manufacturers, this durability translates to fewer replacements, lower maintenance costs, and better user satisfaction. End users benefit from a reliable, long-lasting interface that doesn’t wear out quickly.

In short, a flexible membrane ensures that pressing feels consistent and accurate from the first use to the last. This predictability builds trust in the device and brand.

What Makes Switch Type Membrane Designs Reliable?

Switch type membrane designs are inherently dependable. Their reliability comes from a few key factors:

- Simplicity – Fewer parts mean fewer failures. No springs, no complex moving metal pieces.

- Sealed Construction – Waterproof layers prevent dirt and liquids from causing short circuits.

- High-Quality Materials – Conductive inks, durable polyester films, and tactile domes extend lifespan.

- Precision Manufacturing – Modern production techniques ensure consistent performance for every switch.

Together, these factors make membrane switches a trusted choice in industries where reliability is critical. Unlike mechanical buttons, failures are rare, and maintenance is minimal.

Users feel confident pressing these switches, knowing each action will register correctly. The tactile feedback reinforces that confidence, creating a satisfying user experience every time.

How Does a Flexible Membrane Improve Durability?

Flexibility itself adds durability. Flexible membranes absorb stress and adapt to pressure without breaking. They bend, twist, and conform to different surfaces. This reduces mechanical strain on internal circuits.

The thin layers allow for smooth operation without fatigue. Even repeated pressing over long periods doesn’t damage the switch. Waterproof sealing further enhances protection, shielding the device from spills or moisture exposure.

Flexibility also benefits design. Curved panels, handheld devices, and tight spaces can all incorporate these switches without worrying about performance loss. In essence, flexible membrane switches combine strength, adaptability, and resilience.

What Affects the Tactile Feel of Membrane Buttons?

Tactile feedback is a key reason users prefer membrane buttons. The click, resistance, and response feel satisfying. Several factors influence this sensation:

- Dome Material – Metal or polyester domes provide different levels of feedback.

- Layer Thickness – Thicker layers give firmer resistance, while thinner layers feel softer.

- Spacer Design – Proper spacing ensures the circuit is only completed when pressed fully.

- Surface Coating – Textures or finishes can enhance the tactile feel.

Manufacturers can customize these factors to match user preferences. For example, medical devices may need soft, quiet presses, while industrial machinery may require firm, audible feedback. This flexibility ensures membrane switches feel natural and reliable in every application.

Conclusion:

Waterproof flexible membrane switches are a modern solution for a wide range of devices. They are durable, adaptable, and easy to maintain. With flexible membranes, sealed construction, and precise design, they provide long-lasting performance and a satisfying tactile experience.

Choosing a membrane switch panel guarantees both functionality and aesthetic appeal, while waterproof designs protect the device in challenging environments. If you want durable, responsive, and visually appealing interface solutions, waterproof flexible membrane switches are the smart choice.

For more information or to request a sample, contact sales@best-membraneswitch.com today.

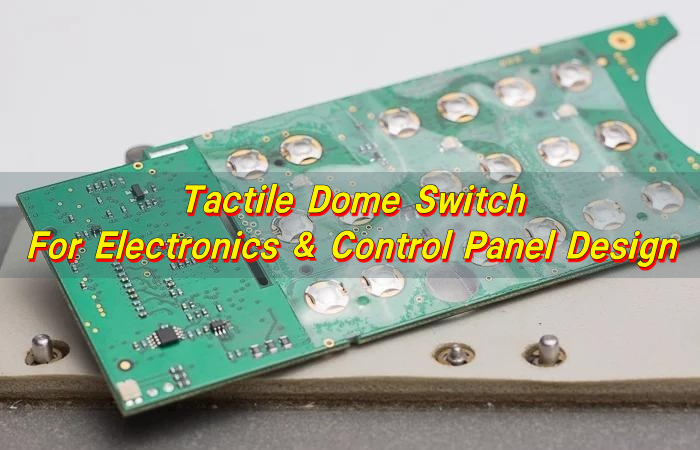

Tactile Dome Switch – For Electronics & Control Panel Design

Our tactile dome switch delivers crisp tactile feedback and reliable precision actuation, with industrial-grade durability for small device control panels. Custom sizes available for your design needs. What is a tactile dome switch? A tactile dome switch is a compact switching component used in electronic interfaces where clear feedback matters. It delivers a sharp, physical ...

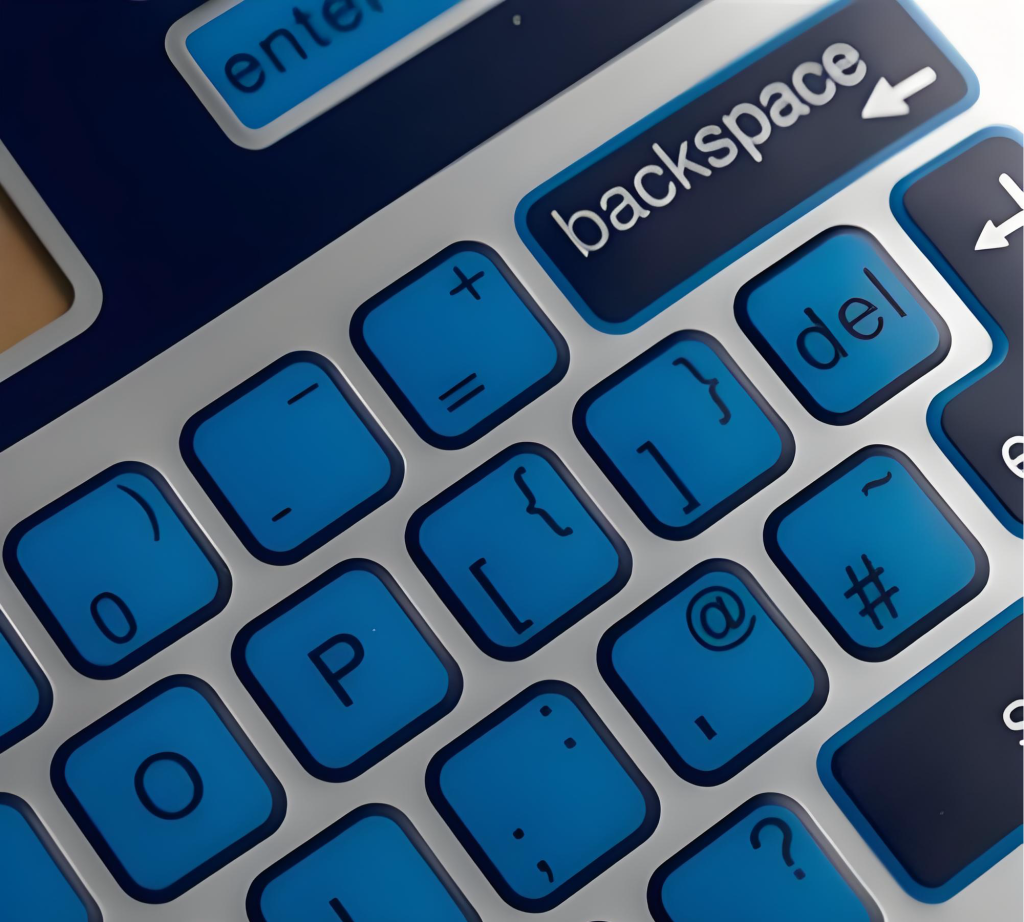

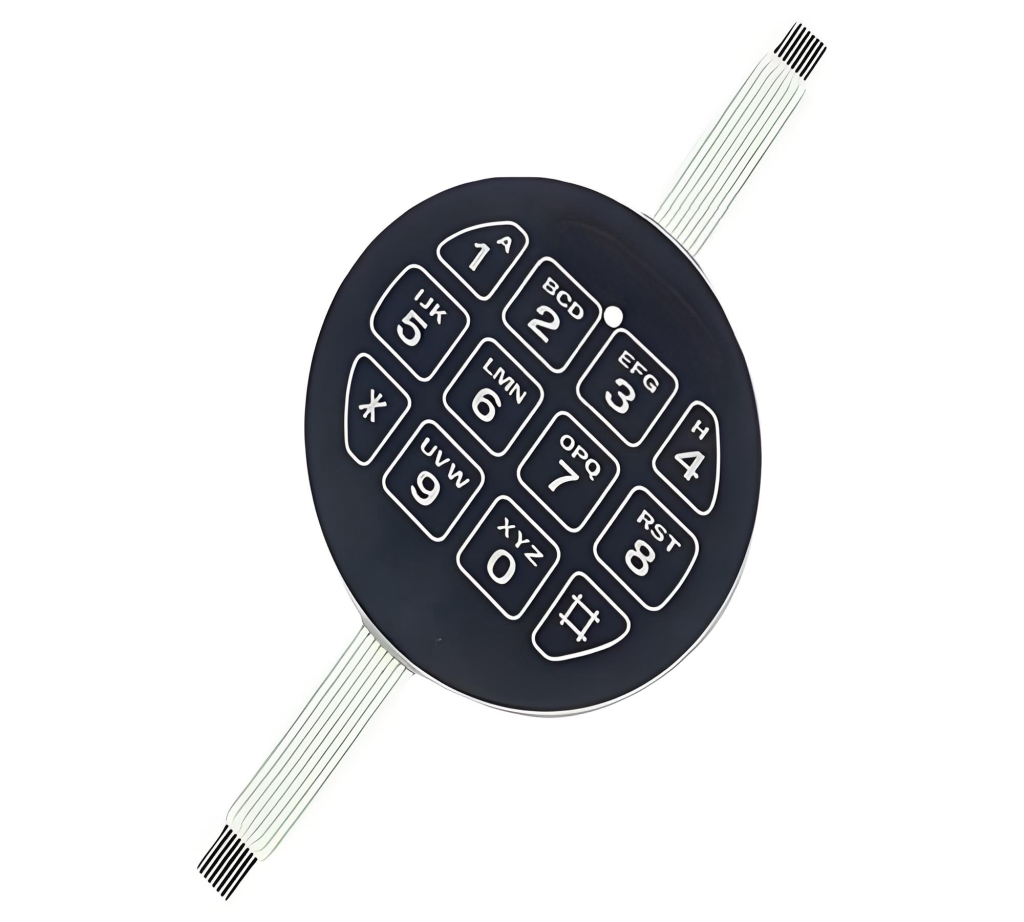

Custom Membrane Keypads – Industrial Grade Custom Design

Our custom membrane keypads are engineered with industrial-grade durability, waterproof & oil-resistant for control panels. Fully customizable sizes, layouts and symbols for your device needs. What is a custom membrane keypad? A custom membrane keypad is a low-profile input interface designed for a specific product, device, or operating environment. It combines printed circuits, tactile layers, ...

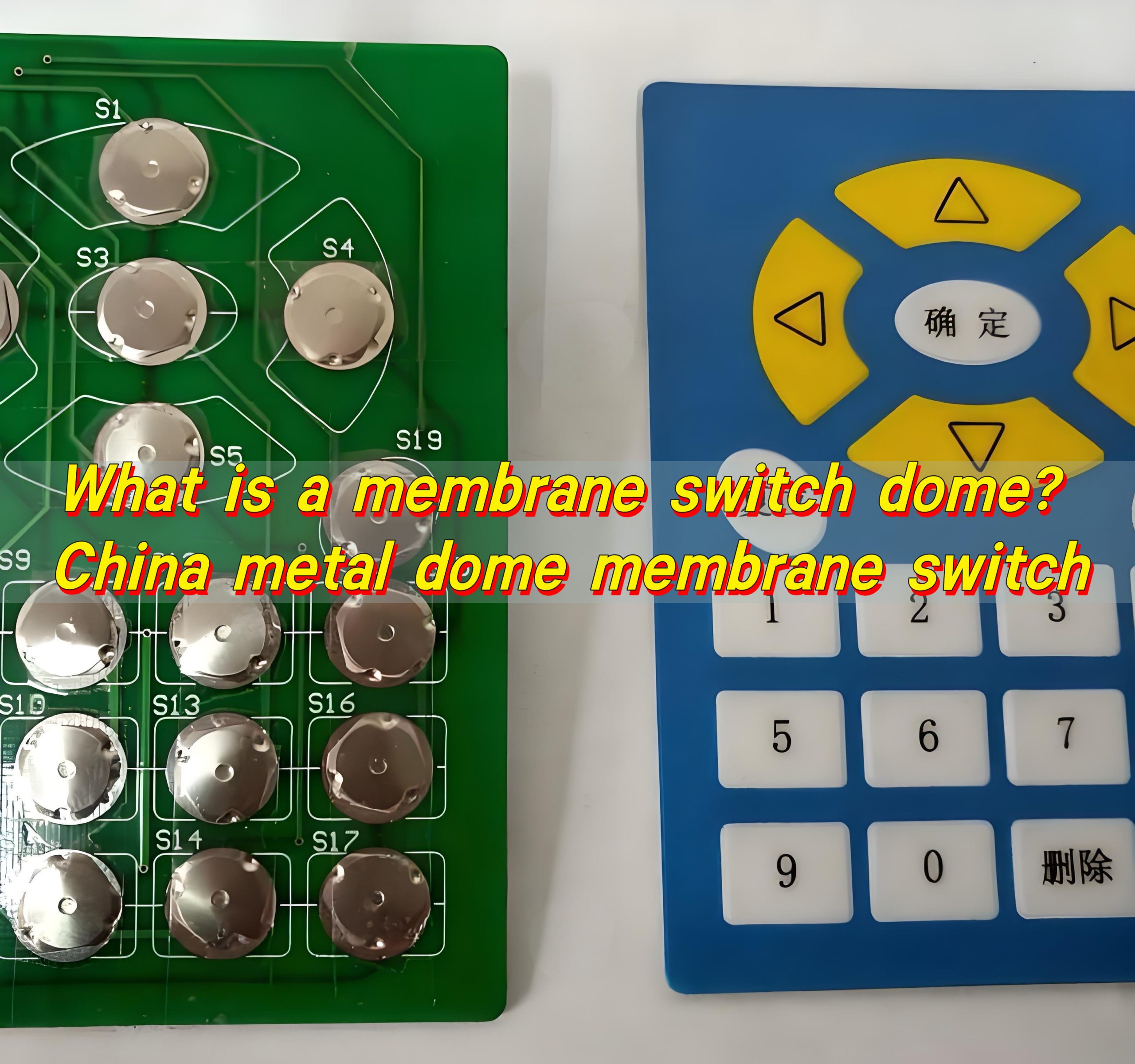

What is a membrane switch dome? China metal dome membrane switch

A membrane switch dome is a small but powerful part of many modern input devices. You see it in factory control panels, medical tools, handheld devices, POS systems, and more. It looks simple, yet it shapes how a product feels, responds, and lasts over time. What Is a Dome Switch Membrane Keyboard? A dome switch ...

Contact us online