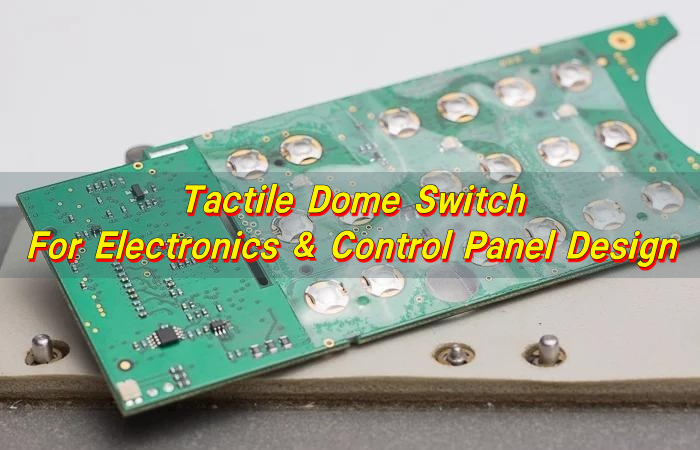

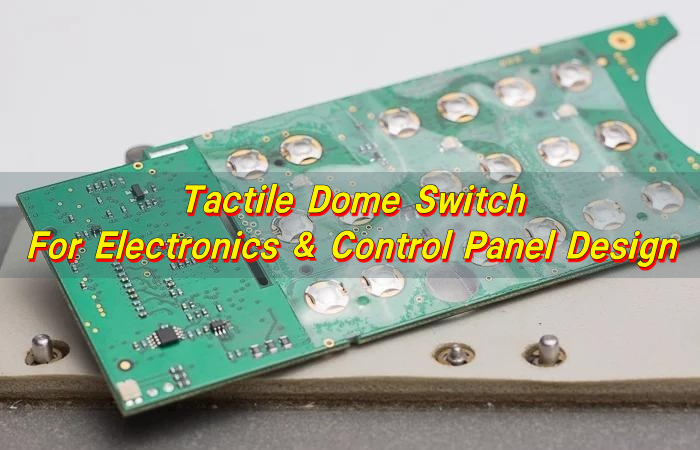

Tactile Dome Switch – For Electronics & Control Panel Design

Tactile Dome Switch – For Electronics & Control Panel Design

Our tactile dome switch delivers crisp tactile feedback and reliable precision actuation, with industrial-grade durability for small device control panels. Custom sizes available for your design needs.

What is a tactile dome switch?

A tactile dome switch is a compact switching component used in electronic interfaces where clear feedback matters. It delivers a sharp, physical response when pressed. Users can feel and often hear a click. This confirms that an input has been registered. That simple moment of feedback builds confidence and accuracy during operation.

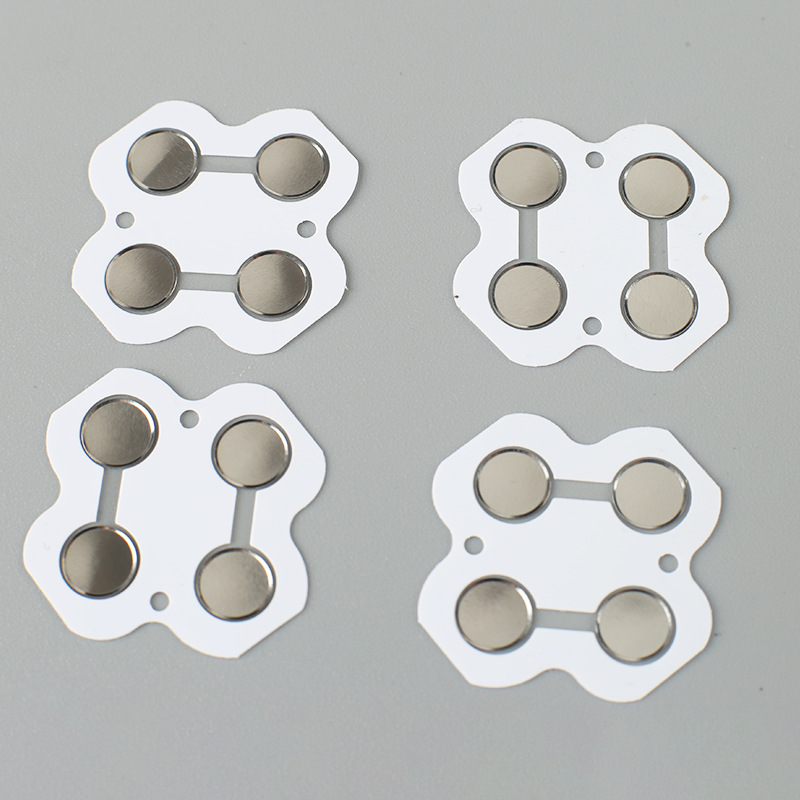

At its core, the switch relies on a formed metal or rubber dome. The dome sits between a circuit layer and a contact pad. When pressure is applied, the dome collapses and bridges the circuit. When pressure is released, the dome springs back to its original shape.

In industrial electronics, medical equipment, and consumer devices, tactile feedback plays a critical role. Operators often work without looking directly at the panel. The physical response helps reduce errors. It also shortens reaction time.

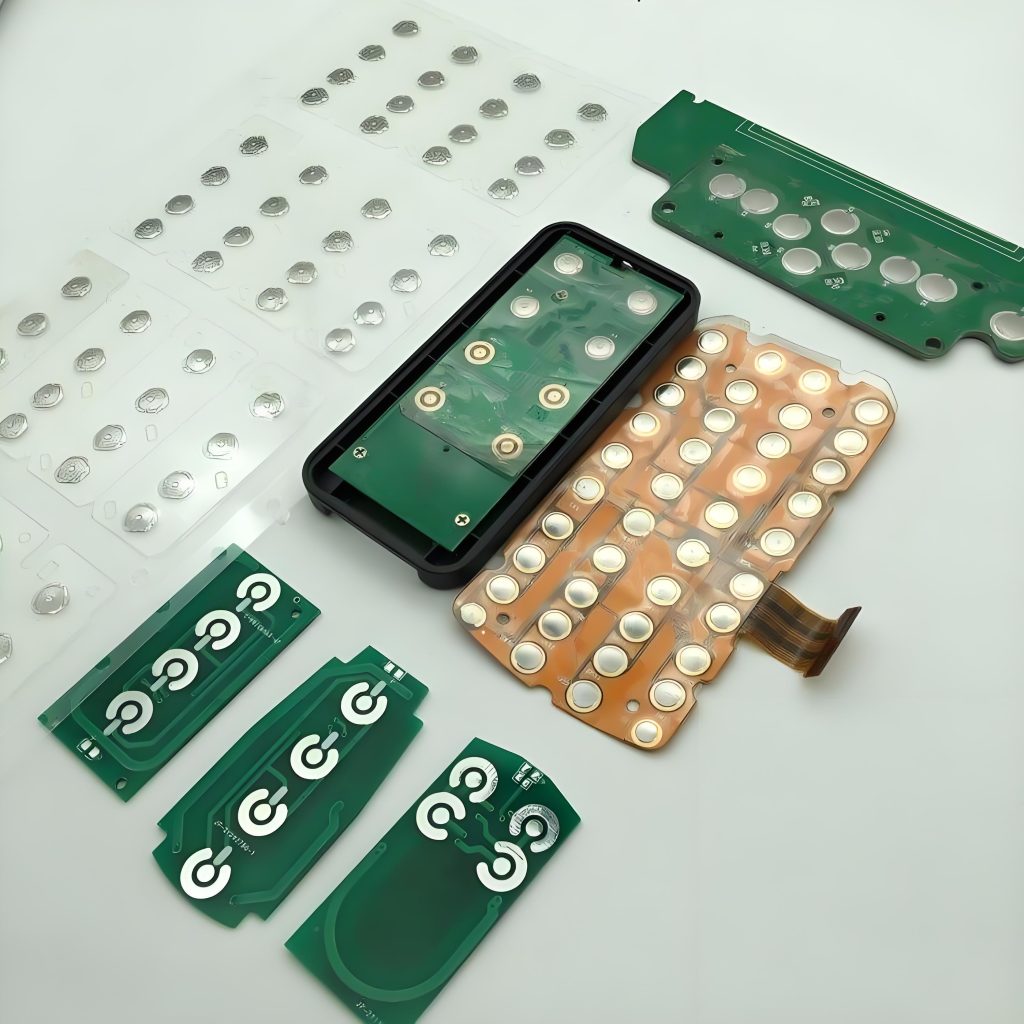

There are several dome-based switch forms used across industries. These include metal dome switch designs and rubber-based structures. Each type serves a different need. Metal domes provide a crisp snap. Rubber domes offer a softer press. Both can be integrated into modern PCB layouts and flexible circuits.

A dome switch button may look simple from the outside. Internally, it reflects careful engineering. Dome force, travel distance, and contact material all influence performance. Small changes can affect feel and lifespan.

How to choose a tactile dome switch?

Choosing the right tactile dome switch starts with understanding the user and the environment. A switch does not operate in isolation. It responds to fingers, gloves, tools, and repeated actions. Each factor shapes the final choice.

The first consideration is tactile force. This defines how much pressure is needed to activate the dome. Light-force domes suit handheld electronics. Higher-force domes fit industrial panels where accidental presses must be avoided.

Travel distance also matters. Short travel delivers fast response. Longer travel gives clearer feedback. The right balance depends on the application and user habits.

Material selection is another key point. A tactile metal dome switch offers sharp feedback and long life. It performs well in high-cycle environments. A rubber dome switch provides softer feedback and can integrate sealing features. This helps in moisture-prone conditions.

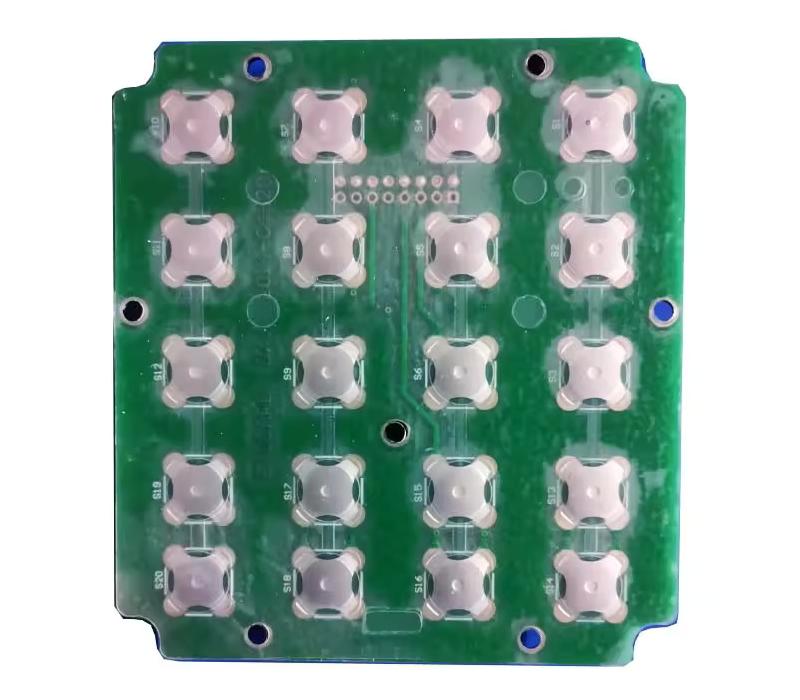

Circuit integration must be considered early. A dome switch PCB layout affects reliability. Pad geometry, spacing, and surface finish all influence contact quality. Poor alignment leads to inconsistent feel and early failure.

Environmental factors often drive the final decision. Temperature range, humidity, vibration, and exposure to dust all affect dome behavior. Metal domes resist fatigue well. Rubber domes handle sealing better. Matching the switch to the environment extends service life.

How does a dome switch work?

The working principle of a dome switch is straightforward, yet refined. It relies on elastic deformation and electrical contact.

Inside the switch, the dome rests above conductive pads. In its natural state, the dome does not complete the circuit. When pressed, the dome collapses. Its center makes contact with the pad. The circuit closes. The signal is sent.

Once pressure is removed, the dome snaps back. The circuit opens again. This snap action creates the tactile response users feel. It also ensures clean signal switching with minimal bounce.

In a tactile metal dome switch, the dome is stamped from stainless steel or similar alloys. The metal stores elastic energy. This produces a crisp click. The shape and thickness of the dome control force and travel.

Rubber domes work slightly differently. They rely on molded elasticity. Conductive pills under the dome bridge the circuit when pressed. The feedback is softer, but still clear.

Contact surface design also plays a role. Gold, carbon, or silver coatings improve conductivity. They reduce wear and oxidation. This keeps resistance stable over time.

Signal consistency matters in modern electronics. A clean on-off transition prevents false triggers. Dome switches achieve this through controlled collapse and rebound.

Why use a tactile dome switch for devices?

A tactile dome switch enhances interaction by making every press clear and intentional. This matters in industrial control, medical operation, and mobile electronics.

Dome switches fit flat or curved panels. They integrate with PCBs and flexible circuits. They support compact layouts without sacrificing feedback.

Durability is another reason. Many dome designs handle repeated use without loss of feel. This suits devices with long service life. Maintenance needs remain low.

Compared with alternatives, dome switches offer a strong balance of performance and cost. They do not require complex mechanical parts. Assembly is efficient. Replacement is rare when designed correctly.

In environments where gloves are worn, tactile feedback becomes essential. The snap response cuts through reduced sensitivity.

Key benefits often include:

- Clear tactile response for accurate input

- Compact structure for dense layouts

- Long operational life with stable performance

- Flexible integration with different circuits

A snap dome tactile switch also improves accessibility. Users with limited vision rely on touch. Consistent feedback helps them interact safely.

Which tactile dome switch fits your panel?

Every control panel tells a story about how it will be used. The right tactile dome switch fits that story. It matches function, environment, and user behavior.

Panel size sets initial limits. Compact panels favor low-profile domes. Large panels allow greater travel and force variation.

User interaction patterns matter. Frequent presses demand high-cycle domes. Occasional inputs allow broader options. Emergency controls often use higher force to prevent mistakes.

The dome switch PCB layout defines alignment needs. Precise pad placement ensures consistent actuation.

Panel material also plays a role. Plastic overlays transmit force differently than metal. Graphic layers affect tactile feel. Designers must consider the full stack-up.

For panels exposed to dust or moisture, sealing becomes critical. Rubber domes often support integrated sealing. Metal domes may require additional layers.

Here are common panel scenarios and matching dome traits:

- Industrial panels: higher force, metal domes, long life

- Consumer devices: moderate force, slim profile

- Medical equipment: consistent feel, clean surfaces

- Automotive controls: vibration resistance, temperature stability

Tactile mech dome switches are sometimes used where a hybrid feel is desired. They combine elements of mechanical feedback with dome simplicity.

What makes a durable tactile dome switch?

Durability begins with material quality. A tactile metal dome switch depends on consistent alloy composition.

Forming precision follows material choice. Dome height, radius, and thickness must stay within tight limits.

Surface treatment protects contact points. Coatings reduce wear and corrosion. This keeps electrical performance stable.

Assembly accuracy also matters. Misaligned domes wear unevenly. Proper fixation keeps the dome centered over the pad.

Environmental resistance extends durability. Domes designed for temperature extremes maintain performance where others fail.

Testing validates durability claims. Cycle testing, force measurement, and environmental exposure reveal weaknesses early.

Durable design often includes:

- High-quality stainless steel or elastomer

- Precise forming and inspection

- Protective contact coatings

- Verified cycle life through testing

A durable switch does more than last long. It maintains consistent feel over time. Users notice when feedback changes. Consistency builds trust.

How to test a tactile dome switch?

Testing confirms that a tactile dome switch meets design expectations. It also reveals potential issues before mass production.

Force testing measures actuation pressure. This ensures consistency across samples. Variations affect user perception.

Travel testing checks displacement. The snap point should occur at the intended depth. This confirms tactile quality.

Electrical testing verifies contact resistance. Stable resistance ensures reliable signal transmission.

Cycle testing simulates long-term use. Repeated presses reveal fatigue behavior. High-quality domes maintain performance through extended cycles.

Environmental testing exposes the switch to heat, cold, and humidity. Performance stability under stress indicates robustness.

Common test steps include:

- Measure actuation force and return force

- Verify electrical continuity

- Perform repeated actuation cycles

- Inspect for deformation or wear

Yu An Electronics conducts these tests during development and production. Customers may also request custom test reports. This transparency builds confidence.

What is the purpose of a tactile switch?

The purpose of a tactile switch is simple yet essential. It provides physical confirmation of an input..

In electronic systems, feedback closes the loop between user and device. Without it, interaction feels uncertain.

A tactile keypad dome switch supports fast operation. Users develop muscle memory. They rely on feel rather than sight.

In safety-critical systems, this purpose becomes even more important. Operators need assurance that commands are received.

Beyond function, tactile switches shape perception. A solid click suggests quality. A vague response suggests weakness.

Summary:

A tactile dome switch remains a trusted solution for electronics and control panel design. It offers clear feedback, compact structure, and reliable performance. From material choice to testing, every detail matters.

For technical support or project inquiries, contact sales@best-membraneswitch.com

Custom Membrane Keypads – Industrial Grade Custom Design

Our custom membrane keypads are engineered with industrial-grade durability, waterproof & oil-resistant for control panels. Fully customizable sizes, layouts and symbols for your device needs. What is a custom membrane keypad? A custom membrane keypad is a low-profile input interface designed for a specific product, device, or operating environment. It combines printed circuits, tactile layers, ...

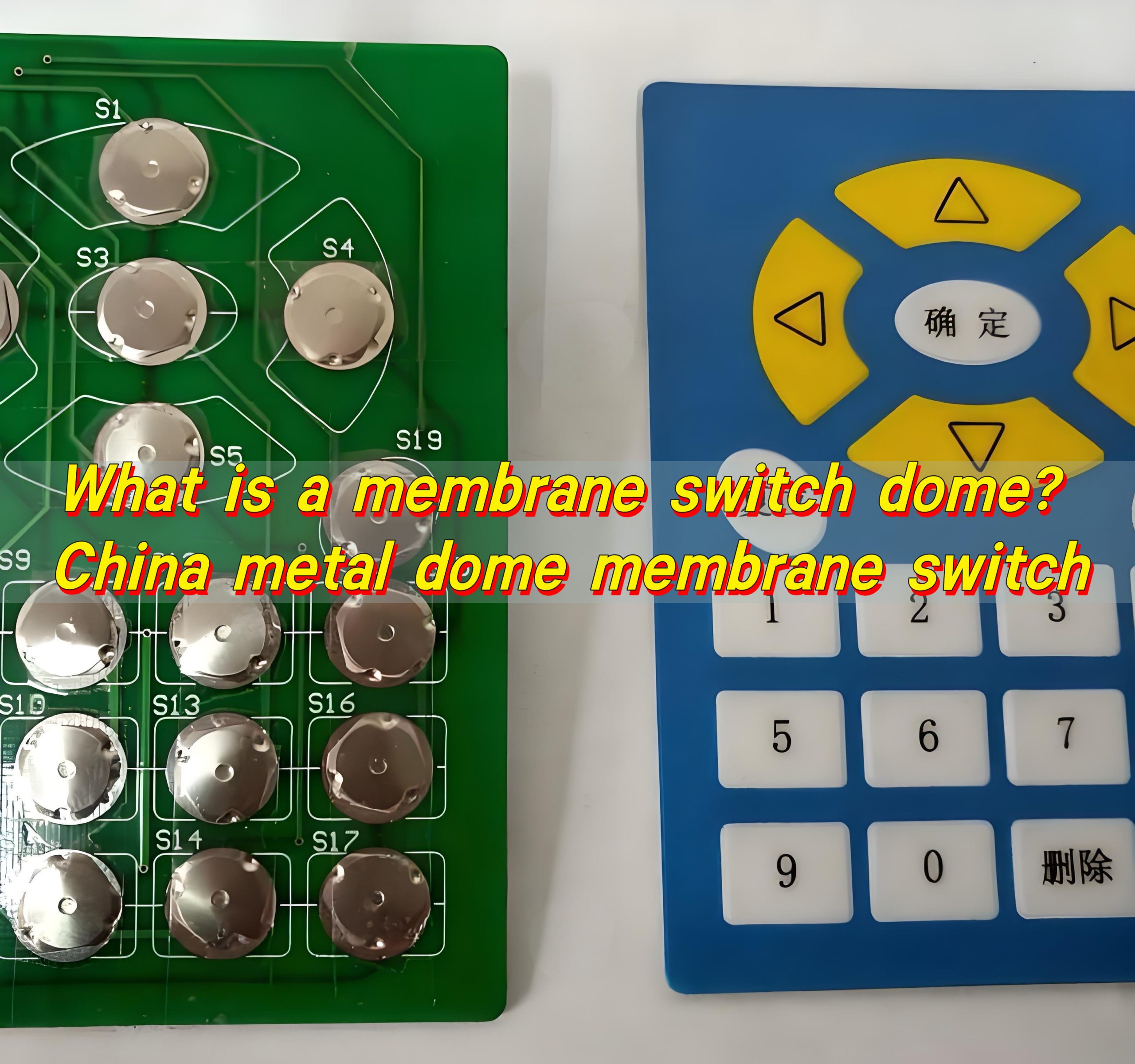

What is a membrane switch dome? China metal dome membrane switch

A membrane switch dome is a small but powerful part of many modern input devices. You see it in factory control panels, medical tools, handheld devices, POS systems, and more. It looks simple, yet it shapes how a product feels, responds, and lasts over time. What Is a Dome Switch Membrane Keyboard? A dome switch ...

Membrane Switch Button Touch Control Panels – Crucial Benefits You Must Learn

The application of membrane switch touch control panels spreads across various industries. They are used for a wide range of purposes. These products feature an efficient interface, providing outstanding user-friendliness. Moreover, they exhibit remarkable durability. You can expect many advantages when relying on the finest membrane touch control panels. The performance and utility are two ...

Contact us online