Conductive Panel Switches Made Simple Features You Need

Conductive Panel Switches Made Simple Features You Need

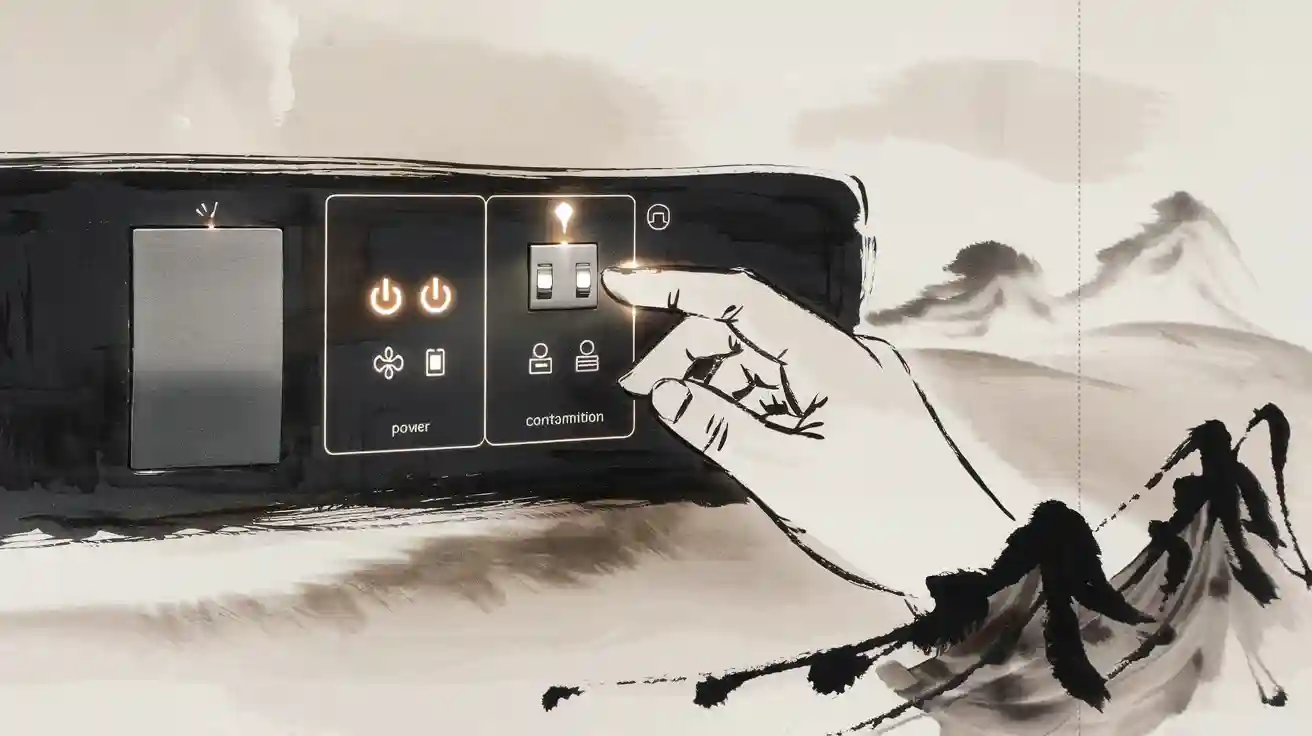

Imagine you need to control the liquid level in a storage tank with precision. You must choose a switch that responds quickly and works reliably, even in harsh environments. When you select Conductive Panel Switches, pay attention to features like durability, sensitivity, and safety. These attributes help you avoid costly downtime and ensure your equipment performs as expected.

Key Takeaways

- Choose conductive panel switches with high touch sensitivity for precise control. This feature allows detection through protective surfaces, enhancing usability.

- Look for durability ratings like IP54 to ensure switches withstand harsh environments. This protects against dust and water, reducing maintenance needs.

- Select switches with fast response times to enhance safety. Quick detection can prevent accidents and equipment damage in critical applications.

- Customize your switches to fit specific needs. Options for shape, materials, and features improve functionality and user experience.

- Always verify voltage and current ratings before installation. Proper alignment with your circuit prevents electrical hazards and ensures reliable operation.

Key Features

Touch Sensitivity

You need reliable touch sensitivity when working with Conductive Panel Switches. High-quality switches detect even the lightest touch, which is essential for precise control. Sensitivity depends on the sensor type and the materials used in the panel. For example, some sensors can detect a finger through several millimeters of glass or polycarbonate. This capability allows you to install the switch behind protective surfaces without sacrificing performance.

| Sensor Type | Sensitivity Range |

|---|---|

| TTP223 Capacitive Sensor | Detects a finger from 5mm away |

| CG211AJ0GS Panel Switch | 6 mm Glass or 4 mm Polycarbonate |

This range ensures you can select a switch that matches your installation needs, whether you require a flush surface or a more robust protective layer.

Durability

Durability stands as a critical factor in choosing Conductive Panel Switches. You want a switch that withstands dust, water, and harsh environments. Manufacturers often rate these switches using the IP (Ingress Protection) system, which tells you how well the device resists external elements. For example, an IP54 rating means the switch offers protection against dust and water splashes, making it suitable for semi-industrial and outdoor settings.

| IP Code | Description |

|---|---|

| IP54 | Protection against dust and water ingress, suitable for semi-industrial environments. |

| IEC 60529 | International standard defining the IP rating system. |

- IP54: Commonly used for electrical cabinets and outdoor equipment, providing a specific level of protection against dust and water.

You can trust these ratings to guide your selection, ensuring long-term reliability and reduced maintenance.

Response Time

Fast response time is vital, especially in safety-critical environments. Conductive Panel Switches with rapid response can detect and react to changes in milliseconds. This speed helps prevent accidents and equipment damage. For instance, some advanced systems can detect hazardous electrical arcs in less than one millisecond, reducing the risk of fire or explosion.

- Rapid response minimizes the energy released during faults.

- Quick detection and action protect both equipment and personnel.

- Essential for applications where every millisecond counts.

You benefit from enhanced safety and operational efficiency when you choose switches with superior response times.

Customization

Customization options let you tailor Conductive Panel Switches to your specific needs. You can select from various shapes, rim options, dome types, and circuit materials. These choices help you match the switch to your panel design and application requirements. You also have options for connectors, backlighting, and shielding, which improve both functionality and user experience.

| Customization Aspect | Options |

|---|---|

| Shape | Round or rectangular keys |

| Rim Option | Perimeter raised with recommended dimensions |

| Dome Types | Various materials and sizes, including metal for durability |

| Circuit Materials | Silver, copper flex, rigid printed circuit boards |

| Connector Options | Bare Tail, Latching Female, Latching Male, Plain Male, Plain Female |

| Backlighting Options | Fiber Optic, LED, Electroluminescent lamps |

| Shielding Types | Connector, Conductive adhesive, Tab; three types of shielding |

| Tactile/Non-Tactile | Option to create either tactile or non-tactile switches |

Tip: Embedded LED indicators and tactile feedback can greatly enhance the user experience. Tactile metal domes provide a crisp, responsive feel, ensuring you know when the switch activates. Visual feedback from LEDs gives immediate confirmation, reducing errors and improving accuracy.

- Tactile feedback improves the accuracy of user inputs.

- LED indicators offer clear visual confirmation of switch status.

- Both features make operation intuitive and reliable.

When you customize your switch, you create a solution that fits your workflow and environment perfectly.

Specifications

Voltage Rating

You must select Conductive Panel Switches with a voltage rating that matches or exceeds your circuit requirements. The voltage rating determines how much electrical potential the switch can safely handle. If you choose a switch with a rating too low for your application, you risk electrical hazards and device failure. Manufacturers design these switches to meet strict safety standards, so you can trust the rating to guide your selection. Always check the specifications before installation to ensure compatibility and prevent costly downtime.

Tip: Proper voltage alignment protects your equipment and personnel from electrical faults.

Current Capacity

Current capacity defines the maximum continuous current a switch can handle without overheating. You need to match the current rating to your application’s demands, especially in high-power environments. Overloading a switch leads to excessive heat and potential failure. Reliable Conductive Panel Switches offer a range of current capacities, allowing you to choose the right model for your needs.

| Switch Rating | Maximum Current Capacity |

|---|---|

| 1 A @ 60 or 120 Vac/Vdc | 1 A |

| 5 A @ 240 Vac | 5 A |

| 10 A, 1/3 hp @ 120/240 Vac | 10 A |

Selecting the correct current rating ensures safe operation and extends the lifespan of your switch. You also protect your system from overcurrent damage by choosing a switch with proper capacity.

Material Composition

Material composition plays a vital role in the durability and reliability of Conductive Panel Switches. Manufacturers use advanced materials to create switches that withstand frequent use and harsh conditions. The graphic overlay often consists of polyester or polycarbonate, providing strength and customization options. Circuit layers use conductive inks, such as silver or copper, to facilitate efficient electricity flow. Flexible film substrates allow for precise etching and robust performance.

| Material Type | Description |

|---|---|

| Polyester | Commonly used for the graphic overlay, providing durability and customization. |

| Polycarbonate | Known for its strength and clarity, ideal for overlays. |

| Conductive Inks | Silver or copper, used in circuit layers for reliable conductivity. |

| Flexible Film Substrates | Base layer for etching conductive traces, ensuring flexibility and strength. |

The choice of materials directly affects the switch’s longevity. Carbon black and graphite resist oxidation and wear, allowing the switch to endure millions of activations. Silicone overlays add flexibility and comfort, while adhesives maintain structural integrity under stress.

- Polyester and polycarbonate overlays resist temperature and chemical exposure.

- Adhesives provide tear-resistance and flexibility.

- Conductive elements like graphite and carbon black ensure stable performance.

Environmental Resistance

Environmental resistance ensures that Conductive Panel Switches perform reliably in challenging conditions. You must consider ratings such as IP (Ingress Protection) and NEMA when selecting a switch for your application. These ratings indicate how well the switch resists dust, water, and other environmental hazards.

| IP Rating | Protection Level | Description |

|---|---|---|

| 0 | None | No protection against dust |

| 5 | Dust protected | Dust does not easily enter the body |

| 6 | Dust tight | No dust enters the body |

| NEMA Rating | Description |

|---|---|

| NEMA 1 | Indoor use, basic protection against contact |

| NEMA 3R | Indoor/outdoor, protects against rain, sleet, snow, and dirt |

| NEMA 4X | Water splashes and corrosion resistance |

Manufacturers engineer these switches to withstand moisture, chemicals, vibration, and temperature extremes. Multiple adhesive and conductive layers, rugged overlays, and hermetically sealed structures provide durability. You can rely on these switches for consistent performance in industrial, outdoor, and high-humidity environments.

- Membrane switches resist moisture, UV, chemicals, and vibration.

- Advanced coatings and adhesives enhance durability.

- Switches maintain performance in extreme temperatures and humidity.

Note: Specifications like voltage rating, current capacity, material composition, and environmental resistance directly impact the reliability and longevity of Conductive Panel Switches. Always review these details to ensure your switch meets the demands of your application.

Conductive Panel Switches Applications

Liquid Level Control

You rely on Conductive Panel Switches for accurate liquid level monitoring in tanks and reservoirs. These switches detect the presence or absence of conductive liquids, such as water or chemicals, at specific points. You can use them for single-level service, differential service, or multi-point control. Their compact size and solid-state reliability make them ideal for environments where space and durability matter. You benefit from cost-effective solutions that minimize wiring and maintenance.

Tip: Choose switches with adjustable time delays for applications that require precise control over filling and draining cycles.

| Application Type | Description |

|---|---|

| General Purpose Controls | Compact size, various time delays, solid state reliability; used in single-level service, point level, valve control, differential service, alarms, and pump controls. |

| Low Water Cut-Off Controls | Designed for low-water cutoff protection, meeting CSD1 requirements, with options for time delays and test features. |

| Liquid Level Relays | Boost sensor load handling ability in non-hazardous locations with solid-state control advantages. |

Overflow Protection

You prevent costly spills and equipment damage by installing Conductive Panel Switches for overflow protection. These switches activate alarms or shut down pumps when liquid reaches a critical level. You can set up multiple detection points to monitor different stages in the tank. This approach helps you comply with safety regulations and avoid environmental hazards. You also reduce the risk of downtime and expensive repairs.

- Install switches at overflow points for immediate response.

- Use solid-state relays to enhance reliability in hazardous locations.

- Select models with test features for routine safety checks.

Pump Control

You optimize pump operation by integrating Conductive Panel Switches into your control system. These switches start or stop pumps based on liquid levels, ensuring efficient use of resources. You can automate filling and draining processes, reducing manual intervention. Multi-point control allows you to manage several pumps or valves from a single panel. This setup improves system performance and extends equipment life.

Note: Brands offer models tailored for pump control, but always match the switch specifications to your application needs.

You gain flexibility and reliability when you choose Conductive Panel Switches for these applications. Their versatility supports a wide range of industrial and commercial uses, from water treatment plants to food processing facilities.

User Benefits

Easy Installation

You can install panel switches quickly, even if you have limited technical experience. Manufacturers design these switches with clear wiring diagrams and standardized mounting options. You often receive pre-assembled units that fit directly into control panels. You save time during setup because you do not need specialized tools or extensive training. Many models include plug-and-play connectors, which reduce the risk of wiring errors. You benefit from simplified installation, especially in industrial environments where downtime costs money.

Tip: Always review the installation manual before starting. This step helps you avoid mistakes and ensures proper operation.

Low Maintenance

You want equipment that requires minimal upkeep. Panel switches need regular inspection because they come into direct contact with liquids. Over time, exposure to water or chemicals can cause wear or failure. You may need to clean or replace components more often than with non-contact sensors. Non-contact sensors, such as ultrasonic or radar types, do not touch the liquid. These alternatives offer lower maintenance needs, especially in tanks with corrosive or sticky substances.

- Direct contact with liquids increases maintenance frequency.

- Non-contact sensors reduce cleaning and replacement tasks.

- Regular checks help you catch problems early.

You should weigh the maintenance requirements against your application. If you operate in a harsh environment, consider how often you can service your equipment.

Safety

You protect your team and assets by choosing switches with built-in safety features. Many panel switches include insulation barriers and fail-safe designs. You find models with visual indicators, such as LEDs, that show operational status at a glance. These features help you respond quickly to faults or abnormal conditions. Some switches offer lockout mechanisms to prevent accidental activation. You reduce the risk of electrical hazards and improve compliance with safety standards.

| Safety Feature | Benefit |

|---|---|

| Insulation Barriers | Prevents accidental electrical contact |

| LED Indicators | Provides immediate status feedback |

| Lockout Mechanisms | Stops unintended operation |

Note: Safety features not only protect people but also extend the life of your equipment.

Choosing Conductive Panel Switches

Match to Application

You need to match the features of conductive panel switches to your specific industrial application. Start by identifying the type of operation required, such as momentary or maintained pushbutton. Consider the contact configuration, including the number and type of contacts, to ensure compatibility with your control logic. Evaluate the current and voltage ratings to confirm the switch can handle your circuit’s requirements. Environmental ratings, like resistance to temperature, humidity, dust, and water, play a key role in harsh settings. Physical size and mounting style must fit your panel layout. Material and build quality, such as stainless steel or durable plastics, increase reliability in tough environments. Actuation force prevents accidental activation and improves safety. Color coding and clear labeling help operators use the switch correctly. Illumination enhances visibility in low-light conditions. Safety features, including shrouds or key-operated switches, protect your team. Compatibility with control systems ensures seamless integration. Certifications and standards guarantee compliance. Easy installation and maintenance save time and reduce costs. Manufacturer reputation signals reliability and durability.

| Criteria | Description |

|---|---|

| Type of Operation | Momentary or maintained pushbutton |

| Contact Configuration | Number and type of contacts (NO, NC) matching control logic |

| Current and Voltage Rating | Handles the circuit’s current and voltage requirements |

| Environmental Ratings | Resistance to temperature, humidity, dust, and water (IP ratings) |

| Size and Mounting | Physical size and mounting style suitable for the panel |

| Material and Build Quality | Robust materials for harsh environments |

| Actuation Force | Prevents accidental activation |

| Color and Labeling | Color-coded and labeled for safety and ease of use |

| Illumination | Illuminated for visibility in low-light conditions |

| Safety Features | Shrouds or key-operated switches for safety |

| Compatibility with Control Systems | Compatible with existing control logic and voltage levels |

| Certifications and Standards | Compliance with industrial standards |

| Ease of Installation and Maintenance | Easy to install and maintain with available replacement parts |

| Manufacturer Reputation | Reliable and durable products |

Tip: Always review your application’s requirements before selecting a switch. This step helps you avoid costly mistakes and ensures long-term reliability.

Compare Options

You need to compare different conductive panel switch models to find the best fit for your needs. Follow these steps:

- Check quality assurance processes, such as ISO certifications and product testing.

- Review the supplier’s product range to ensure all your switch needs are covered.

- Research the supplier’s reputation through reviews and testimonials.

- Confirm strong technical support for product selection and troubleshooting.

- Assess lead time and inventory availability for timely delivery.

- Compare pricing to ensure good value without sacrificing quality.

- Look for customization options to meet your unique specifications.

- Evaluate long-term reliability of both the supplier and their products.

- Review the return policy for fairness and transparency.

- Consider opportunities for strategic partnerships with the supplier.

Note: A thorough comparison helps you select a switch that meets your technical requirements and supports your business goals. Reliable suppliers and well-matched products reduce downtime and improve safety.

You need to focus on touch sensitivity, durability, response time, and customization when choosing conductive panel switches. Always check voltage and current ratings, material quality, and environmental resistance. Use this checklist for a smart selection:

- Align graphic overlays correctly.

- Choose durable, wear-resistant materials.

- Ensure clear feedback for users.

- Test switches in real-world conditions.

- Gather user feedback for improvements.

| Functionality | Description |

|---|---|

| On/Off Control | Turns devices on or off safely and efficiently. |

| Mode Selection | Lets you switch between different operational settings. |

Think about your specific application and environment. For expert advice, reach out to a trusted supplier or consult with an industry professional.

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online