Custom Membrane Keypads – Industrial Grade Custom Design

Custom Membrane Keypads – Industrial Grade Custom Design

Our custom membrane keypads are engineered with industrial-grade durability, waterproof & oil-resistant for control panels. Fully customizable sizes, layouts and symbols for your device needs.

What is a custom membrane keypad?

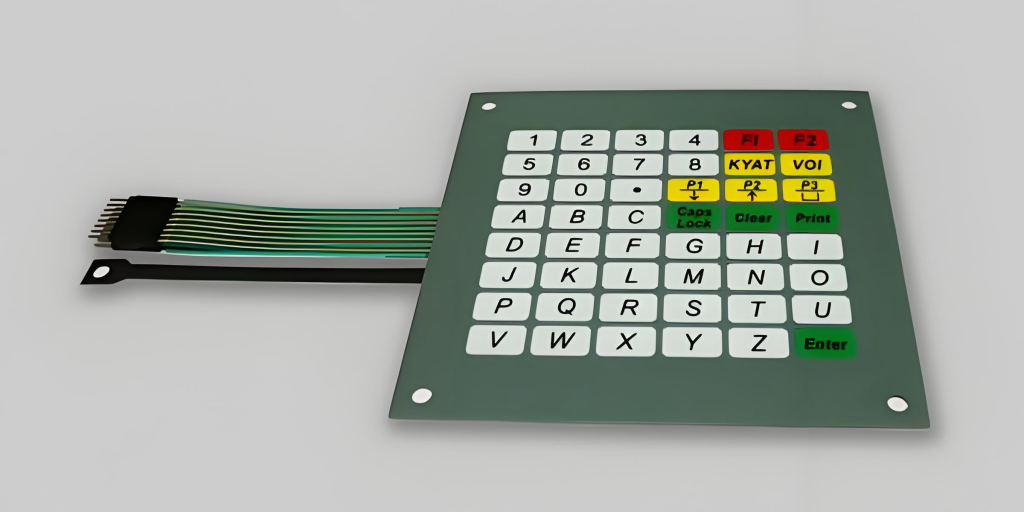

A custom membrane keypad is a low-profile input interface designed for a specific product, device, or operating environment. It combines printed circuits, tactile layers, and a protective overlay into one sealed structure. Unlike off-the-shelf keypads, this solution is tailored to match exact electrical, mechanical, and visual needs.

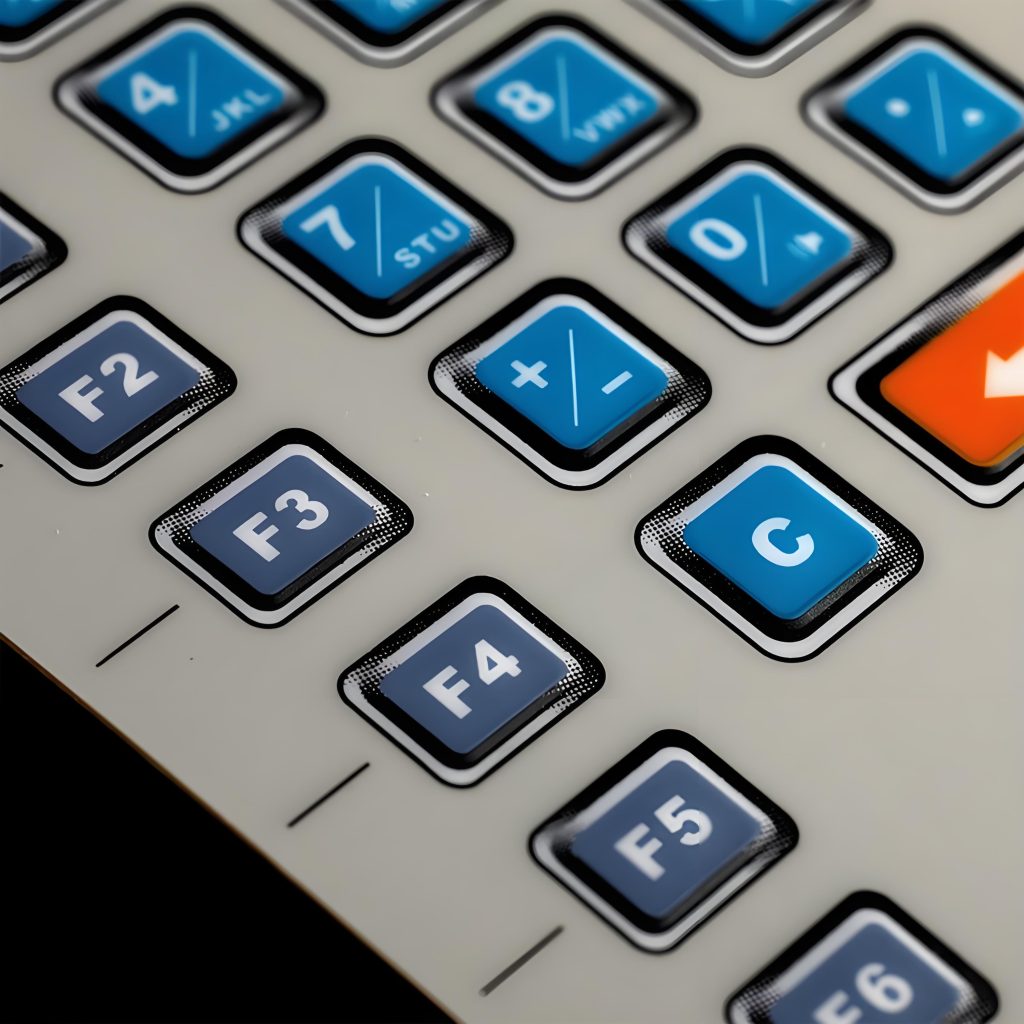

Most designs include several layers bonded together. The top layer is usually a graphic overlay. It carries symbols, text, and branding. Beneath it sits the spacer layer. This layer defines key travel and feel. Below that is the circuit layer, often printed with conductive ink. When a key is pressed, the circuit closes and sends a signal.

Custom membrane keypads differ from mechanical keys in many ways. They are thinner. They are quieter. They resist dust and moisture well. These traits make them suitable for industrial controls, medical equipment, and commercial devices.

Customization allows control over nearly every detail. Key size, layout, actuation force, and surface texture can all be adjusted. Backlighting, shielding, and embossing are also common options. This flexibility is why engineers often choose custom membrane switches keypads for demanding projects.

How to choose custom membrane keypads?

Choosing the right keypad starts with understanding how the device will be used. Environment matters. User behavior matters. Electrical needs matter.

Begin with the operating conditions. Temperature range is critical. Exposure to water, oil, or chemicals also matters. Outdoor equipment needs stronger overlays. Medical devices need smooth, cleanable surfaces.

User interaction is another key factor. Think about how often keys are pressed. Consider whether operators wear gloves. Decide if tactile feedback is required. Some users prefer a crisp snap. Others prefer a soft press.

Electrical requirements come next. Voltage and current levels guide circuit design. Interface type matters too. Common options include matrix circuits and tail connectors. Shielding may be needed to reduce noise.

Visual design also plays a role. Symbols must be clear. Contrast must be strong. Fonts should be easy to read. Backlighting may help in low-light settings.

Why use custom membrane keypads for devices?

Devices demand interfaces that are reliable and easy to use. Custom membrane keypads meet both needs. They combine durability with design freedom.

One strong advantage is sealing. The layered structure blocks dust and moisture. This protects internal electronics. It also extends service life. Many industrial failures start at the interface. A sealed keypad reduces that risk.

Another benefit is space efficiency. These keypads are thin. They fit compact housings. This helps designers reduce overall device size.

Cost control is also important. For medium to high volumes, membrane solutions are cost-effective. Tooling is simpler than mechanical alternatives. Assembly time is shorter.

Design consistency adds value. Graphics are printed directly. Labels do not peel off. Legends stay clear after years of use. This improves usability and brand perception.

Custom membrane keypads and keyboards also support integration. They can include LEDs, windows, and shielding layers. This reduces the need for extra components.

How to customize membrane keypads for your panel?

Customization follows a clear process. Each step builds on the last. Clear communication makes the process smooth.

First comes layout design. Engineers define key positions and sizes. Spacing must feel natural. Errors at this stage affect usability. Digital drawings help confirm details early.

Next is material selection. Overlay material affects feel and durability. Common choices include polyester and polycarbonate. Each has strengths. Texture can be added for grip.

Circuit design follows. Conductive inks form the signal paths. The layout must match the device interface. Tail length and connector type are defined here.

Feedback options are then considered. Tactile domes add a clear snap. Non-tactile designs offer silent operation. Actuation force can be tuned.

Additional features may be added. These include:

- LED indicators for status

- Shielding layers for EMI control

- Windows for displays

- Adhesive backing for mounting

Prototype samples validate the design. Testing checks fit, feel, and function. Adjustments are made before mass production.

Which custom membrane keypad fits your device?

Different devices require different solutions. There is no universal design. Matching the keypad to the device ensures good performance.

- Industrial equipment often needs strong overlays. High actuation life is important. Keys may be pressed thousands of times per day.

- Medical devices focus on hygiene. Smooth surfaces are common. Sharp edges are avoided. Cleaning agents must not damage graphics.

- Consumer electronics value appearance. Slim profiles matter. Backlighting improves user experience. Consistent feel across units is important.

- Transportation systems need vibration resistance. Keypads must stay responsive under motion. Adhesives must hold firmly.

Custom membrane buttons can be shaped and arranged to guide users. Raised keys help blind operation. Color coding improves clarity.

How to install custom membrane keypads?

Installation is usually simple. Good preparation ensures success. Most issues come from surface problems, not the keypad itself.

Start by cleaning the mounting surface. Remove dust, oil, and residue. A clean surface ensures strong adhesion. Allow the surface to dry fully.

Align the keypad carefully. Dry fitting helps. Once aligned, remove the liner gradually. Apply pressure evenly. Avoid trapping air.

Connector attachment follows. Ensure the tail is not bent sharply. Secure it according to the device design. Avoid stress on the circuit.

After installation, test all keys. Check response and lighting. Early testing catches issues before final assembly.

In many cases, no special tools are needed. Adhesive backing simplifies the process. This saves time during production.

How to maintain custom membrane keypads?

Maintenance needs are low. This is one reason these keypads are popular. Simple care keeps them working well.

Regular cleaning helps. Use mild cleaners when needed. Avoid harsh solvents unless the material supports them. Soft cloths protect the surface.

Inspect the keypad during routine service. Look for wear or lifting edges. Early signs help prevent larger issues.

Avoid excessive force. Keys are designed for specific loads. Pressing too hard does not improve response.

In harsh environments, check seals periodically. Ensure moisture has not entered the housing. Good enclosure design supports keypad life.

Custom membrane panel designs often include protective coatings. These coatings resist wear and fading. They reduce maintenance effort over time.

What makes durable custom membrane keypads?

Durability comes from design choices. Materials, structure, and process all matter. Each layer plays a role.

Overlay quality is critical. Strong films resist abrasion. Printed graphics must bond well. UV resistance prevents fading.

Circuit reliability matters too. Conductive inks must be consistent. Proper curing improves stability. Trace design reduces stress.

Adhesive selection affects longevity. The right adhesive matches the environment. Temperature and humidity influence performance.

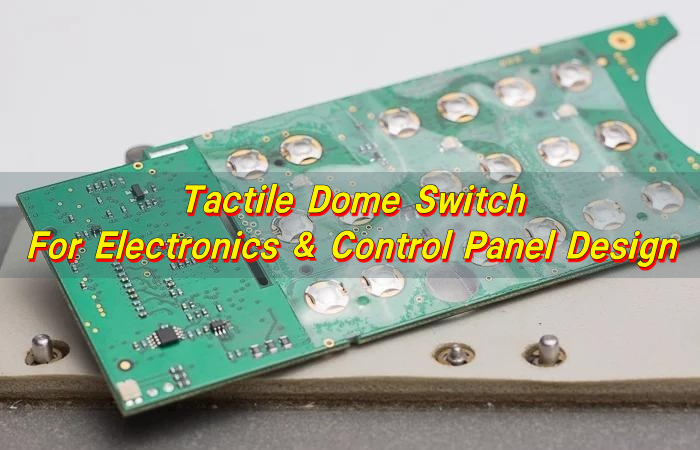

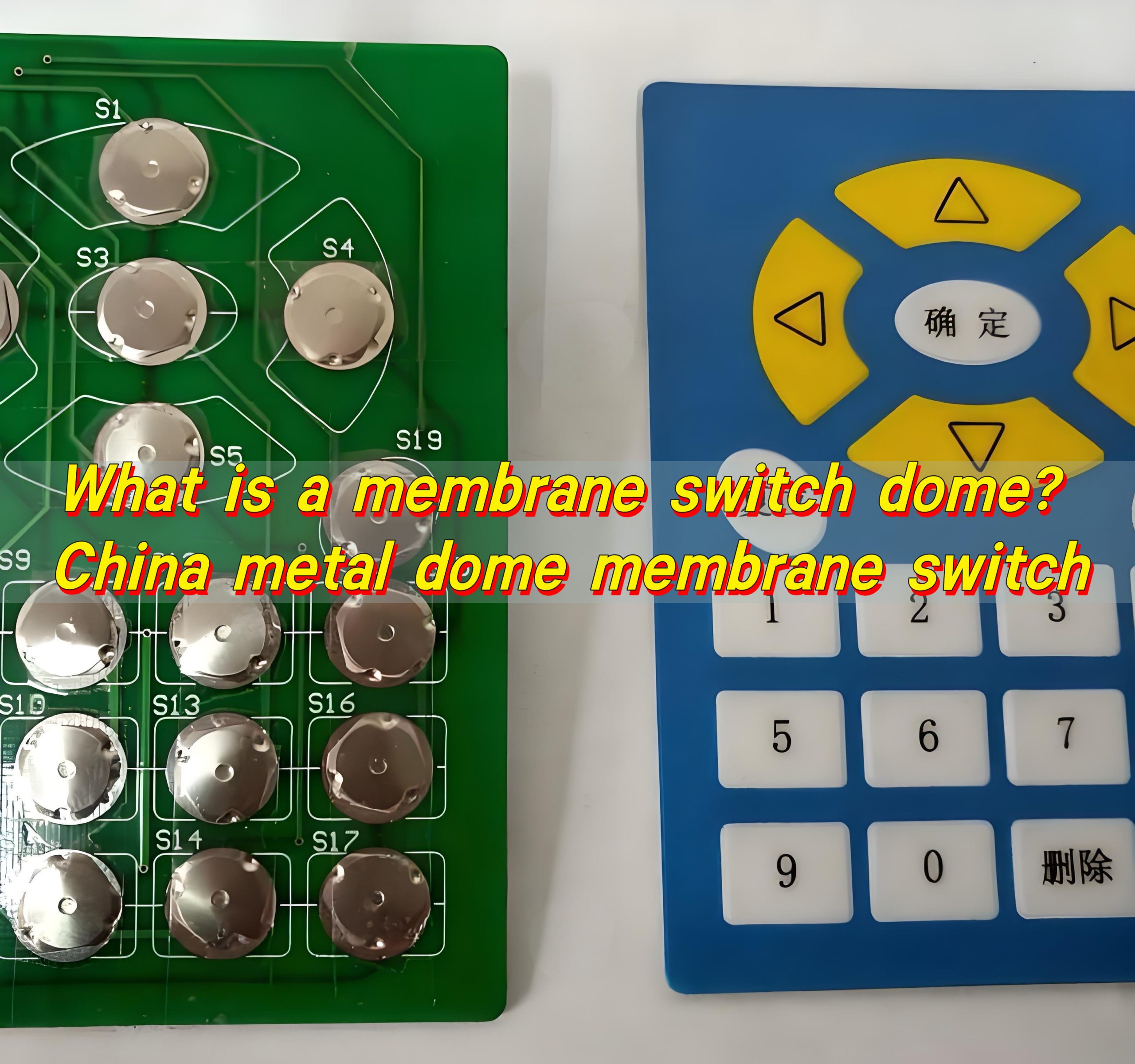

Tactile elements add complexity. Metal domes must be well-aligned. Proper support prevents collapse.

Testing validates durability. Life cycle tests simulate real use. Environmental tests expose weaknesses. Adjustments improve the final product.

Conclusion:

Custom membrane keypads offer a practical and flexible interface solution for many devices. They support compact design, reliable input, and clear graphics. Customization allows precise alignment with device needs and user behavior.

For technical support or project inquiries, contact the sales team at sales@best-membraneswitch.com

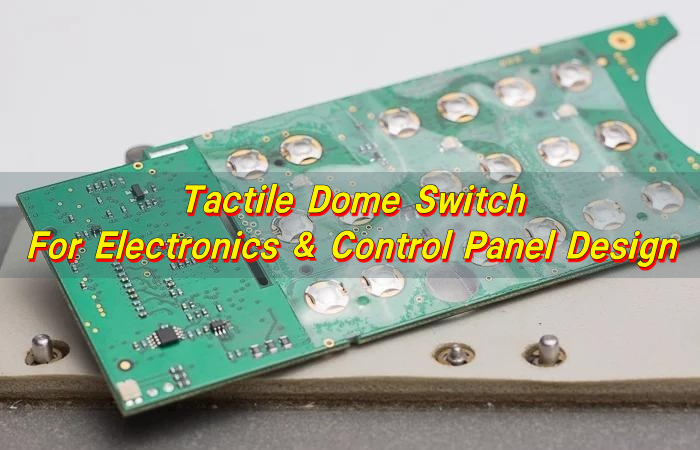

Tactile Dome Switch – For Electronics & Control Panel Design

Our tactile dome switch delivers crisp tactile feedback and reliable precision actuation, with industrial-grade durability for small device control panels. Custom sizes available for your design needs. What is a tactile dome switch? A tactile dome switch is a compact switching component used in electronic interfaces where clear feedback matters. It delivers a sharp, physical ...

What is a membrane switch dome? China metal dome membrane switch

A membrane switch dome is a small but powerful part of many modern input devices. You see it in factory control panels, medical tools, handheld devices, POS systems, and more. It looks simple, yet it shapes how a product feels, responds, and lasts over time. What Is a Dome Switch Membrane Keyboard? A dome switch ...

Membrane Switch Button Touch Control Panels – Crucial Benefits You Must Learn

The application of membrane switch touch control panels spreads across various industries. They are used for a wide range of purposes. These products feature an efficient interface, providing outstanding user-friendliness. Moreover, they exhibit remarkable durability. You can expect many advantages when relying on the finest membrane touch control panels. The performance and utility are two ...

Contact us online