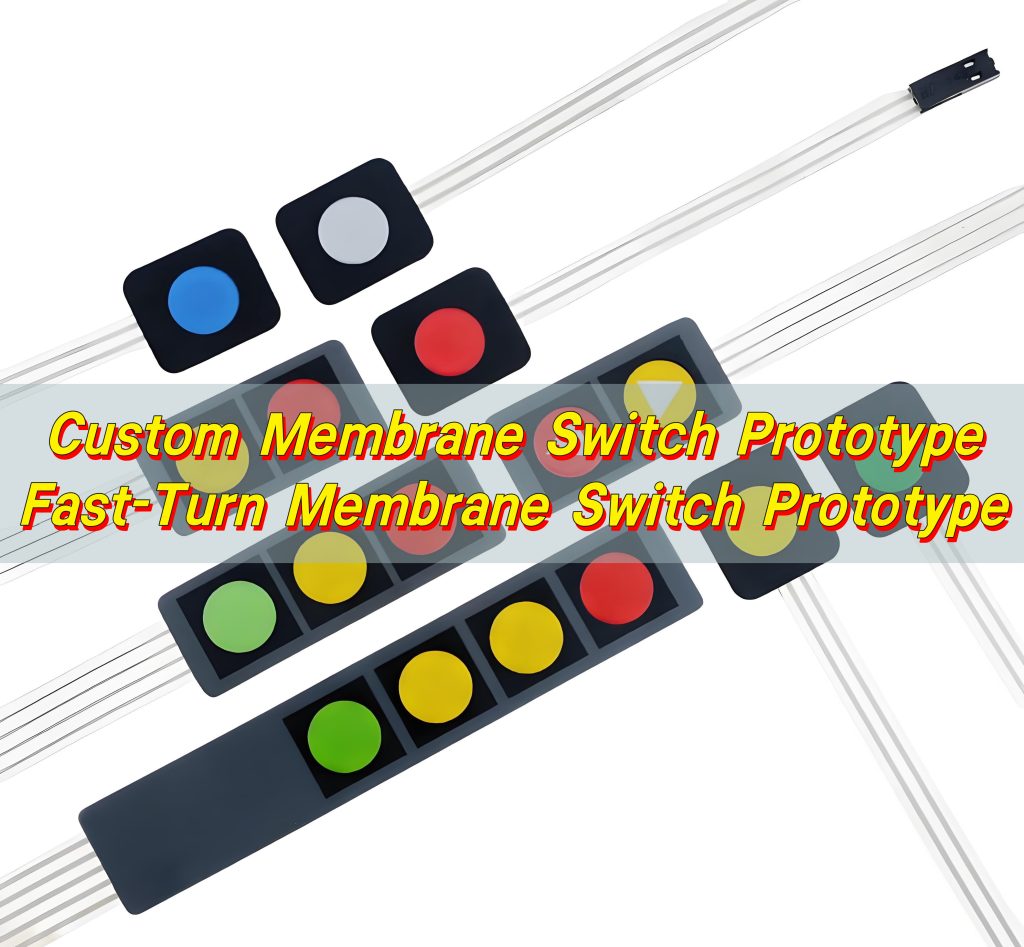

Custom Membrane Switch Prototype – Fast-Turn Membrane Switch Prototype

Custom Membrane Switch Prototype – Fast-Turn Membrane Switch Prototype

Our high-quality membrane switch can be customized into a reliable custom membrane switch prototype, tailored to your device’s size, layout and function for R&D testing and prototype verification.

What is a custom membrane switch prototype?

Custom membrane switch prototype is a low-volume, functional version of a membrane switch made for testing and validation. It reflects the intended design, layout, materials, and performance targets of the final product. Unlike a concept mockup, this prototype is built to be pressed, tested, and used.

The main purpose of a prototype membrane switch is learning. It shows how the switch responds under real conditions. It helps confirm whether the design matches the user’s expectations. It also reveals issues that may not appear in drawings or simulations.

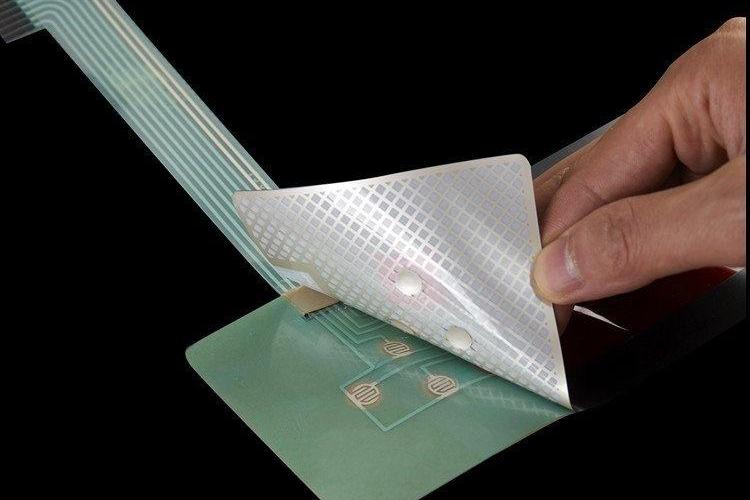

A membrane switch prototype usually includes multiple layers. These layers may include a graphic overlay, spacer, circuit layer, adhesive, and sometimes tactile elements. Each layer plays a role in how the switch looks and feels.

What makes a prototype “custom” is the freedom of design. Size, shape, button layout, colors, legends, and electrical paths can all be adjusted. This flexibility allows teams to tailor the switch to a specific device or application.

In many projects, more than one prototype is created. Early versions focus on layout and feel. Later versions focus on durability and performance. Each iteration brings the design closer to production readiness.

At Yu An Electronics, custom membrane switch prototypes are built using production-grade processes whenever possible. This ensures that test results are meaningful and reliable.

How to customize a membrane switch prototype?

Customizing a membrane switch prototype starts with clear requirements. These requirements guide every design choice. They define what the switch must do, where it will be used, and how users will interact with it.

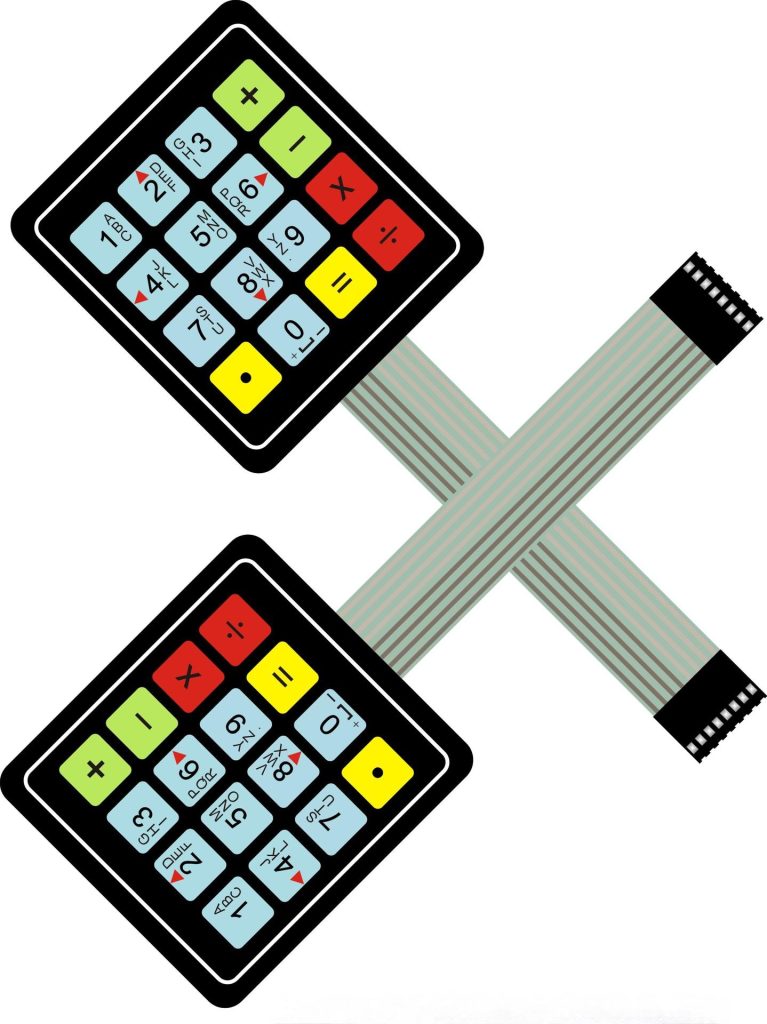

The customization process often begins with the interface layout. This includes button placement, spacing, and size. Good layout improves usability and reduces input errors. It also affects how the switch fits into the overall device design.

Next comes graphic design. This includes colors, symbols, text, and surface finish. The goal is clarity and consistency. A clean design helps users understand functions quickly. It also reinforces brand identity.

Electrical design is another key area. Circuit routing, contact type, and connector style must match the system requirements. Even in a prototype membrane switch, electrical accuracy matters.

Customization also involves tactile response. Some applications require a soft touch. Others need clear tactile feedback. Dome type, force level, and travel distance can all be adjusted during prototyping.

Common customization steps include:

- Defining the operating environment

- Choosing button shapes and sizes

- Selecting surface textures

- Adjusting actuation force

- Deciding on backlighting or indicators

Each step affects how the prototype performs. Small changes can have a big impact on user experience.

Yu An Electronics supports this customization process with direct engineering input. Customers are not limited to standard templates. Instead, designs are refined through discussion and technical review. This helps avoid issues later in production.

What materials are used in a prototype membrane switch?

Materials define how a membrane switch prototype feels, looks, and lasts. Choosing the right materials during prototyping helps ensure that test results reflect real-world performance.

The most visible material is the graphic overlay. This layer is what users touch. It is often made from polyester or polycarbonate. Polyester is known for durability and chemical resistance. Polycarbonate offers good clarity and flexibility.

Below the overlay sits the circuit layer. This layer carries electrical signals. It may use silver ink, carbon ink, or copper traces.

Spacer layers create separation between contacts. They control actuation distance and prevent accidental activation. Adhesives bond layers together and attach the switch to the device housing.

Tactile elements are often added to improve feedback. Metal domes or polyester domes are common choices. They provide a crisp response and consistent force.

Common materials used in a prototype membrane switch include:

- Polyester or polycarbonate overlays

- PET or flexible PCB circuits

- Silver or carbon conductive inks

- Pressure-sensitive adhesives

- Metal or plastic tactile domes

At Yu An Electronics, material choices for prototypes are discussed in detail with customers. The aim is to match production intent as closely as possible. This reduces surprises later.

Why is a membrane switch prototype important before production?

A membrane switch prototype acts as a safety net. It catches problems early, when they are easier and cheaper to fix. Skipping this step increases risk and uncertainty.

One major benefit is design validation. Drawings and simulations cannot fully predict how a switch will feel in use. A prototype allows hands-on evaluation. Users can test button spacing, force, and responsiveness.

Prototypes also help verify electrical performance. Signal reliability, contact resistance, and connector fit can all be tested. This reduces the chance of failures in the field.

Another important role of a prototype membrane switch is communication. It creates a shared reference point between teams.

From a cost perspective, prototyping saves money. Changes made during production are far more expensive. A small investment in prototyping often prevents large losses later.

Prototyping also supports compliance and quality planning. Test data gathered during this stage helps define acceptance criteria for production.

Key reasons why prototyping matters include:

- Reducing design risk

- Improving user experience

- Verifying electrical function

- Aligning teams and stakeholders

- Supporting smooth production ramp-up

At Yu An Electronics, prototypes are treated as learning tools. Feedback from each prototype cycle is documented and applied. This disciplined approach helps customers move into production with confidence.

What fits a custom membrane switch prototype?

A custom membrane switch prototype fits many types of devices and industries. Its flexibility makes it suitable for both simple and complex interfaces.

Industrial equipment often uses membrane switches for control panels. Prototypes help confirm durability and readability in harsh environments. Factors like dust, moisture, and repeated use can be evaluated.

Medical devices rely on clear and reliable interfaces. A prototype allows testing with gloves, cleaning agents, and frequent operation. It also supports ergonomic evaluation.

Consumer electronics benefit from prototyping as well. User expectations are high. Button feel and visual design must be right. A prototype helps refine these details.

Other applications include automotive controls, communication devices, and laboratory equipment. In each case, the prototype helps match the interface to the application.

A prototype membrane switch fits projects that require:

- Custom layouts

- Low-profile interfaces

- Sealed surfaces

- Clear visual communication

- Consistent tactile response

Even low-volume or niche products benefit from prototyping. The insights gained often lead to better design choices.

Yu An Electronics works with customers across many sectors. This broad experience helps identify potential issues early. It also allows best practices to be applied across projects.

What are the benefits of custom membrane switch prototype?

The benefits of a custom membrane switch prototype extend beyond testing. They influence the entire development process in positive ways.

One clear benefit is speed. Fast-turn prototypes allow teams to evaluate designs quickly. This shortens development cycles and helps products reach market sooner.

Another benefit is clarity. Seeing and using a real switch removes guesswork. Decisions become easier when based on direct experience rather than assumptions.

Prototypes also support creativity. Designers can try new layouts or features without committing to full production. This encourages innovation.

From a quality perspective, prototypes help set standards. They define what “good” looks and feels like. Production can then aim to match this reference.

Additional benefits include:

- Better user feedback

- Lower production risk

- Improved cross-team communication

- More accurate cost estimates

- Stronger supplier relationships

At Yu An Electronics, customers often report that prototyping improves confidence. Teams feel more prepared when entering production. This confidence translates into smoother launches.

What can be tested with a custom membrane switch prototype?

A custom membrane switch prototype allows for comprehensive testing. It provides a realistic platform for evaluating both functional and experiential aspects.

Tactile performance is one of the first things tested. Actuation force, snap feel, and return behavior are evaluated. These factors directly affect user satisfaction.

Visual clarity is also tested. Text size, contrast, and icon placement can be reviewed under different lighting conditions. This helps ensure readability.

Electrical testing is critical. Contact resistance, signal stability, and connector performance are measured. Any inconsistencies can be addressed early.

Environmental testing may also be performed. Temperature exposure, humidity, and surface wear can be evaluated depending on the application.

Common test areas include:

- Button life cycle testing

- Force and travel measurement

- Electrical continuity

- Surface wear resistance

- Adhesion strength

At Yu An Electronics, testing feedback is integrated into design revisions. This iterative process leads to better outcomes.

How to choose a custom membrane switch manufacturer for prototypes?

Choosing the right custom membrane switch manufacturer is critical for successful prototyping. Not all suppliers approach prototypes with the same level of care.

Experience matters. A manufacturer with deep knowledge of membrane switches understands common pitfalls. This helps avoid delays and redesigns.

Engineering support is another key factor. Prototyping often involves questions and adjustments.

Material availability also affects prototype quality. A manufacturer who uses production-grade materials can deliver more realistic results.

Speed is important, but it should not come at the expense of accuracy. Fast-turn prototypes should still reflect final intent.

When evaluating a manufacturer, consider the following:

- Technical experience with custom designs

- Ability to support low-volume builds

- Clear communication and documentation

- Consistent quality control

- Proven track record in prototyping

Yu An Electronics combines these qualities. With years of experience in membrane switches and related components, the company supports both prototypes and production. Customers benefit from a seamless transition between stages.

Conclusion:

Custom membrane switch prototype plays a vital role in modern product development. It transforms ideas into testable interfaces and reduces uncertainty before production. Through careful customization, realistic materials, and thorough testing, prototypes provide valuable insights that improve final designs.

For more information or to discuss your custom membrane switch prototype needs, contact: sales@best-membraneswitch.com

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online