Custom membrane switches – High Quality, Fast Delivery

Custom membrane switches – High Quality, Fast Delivery

What Are Membrane Switches?

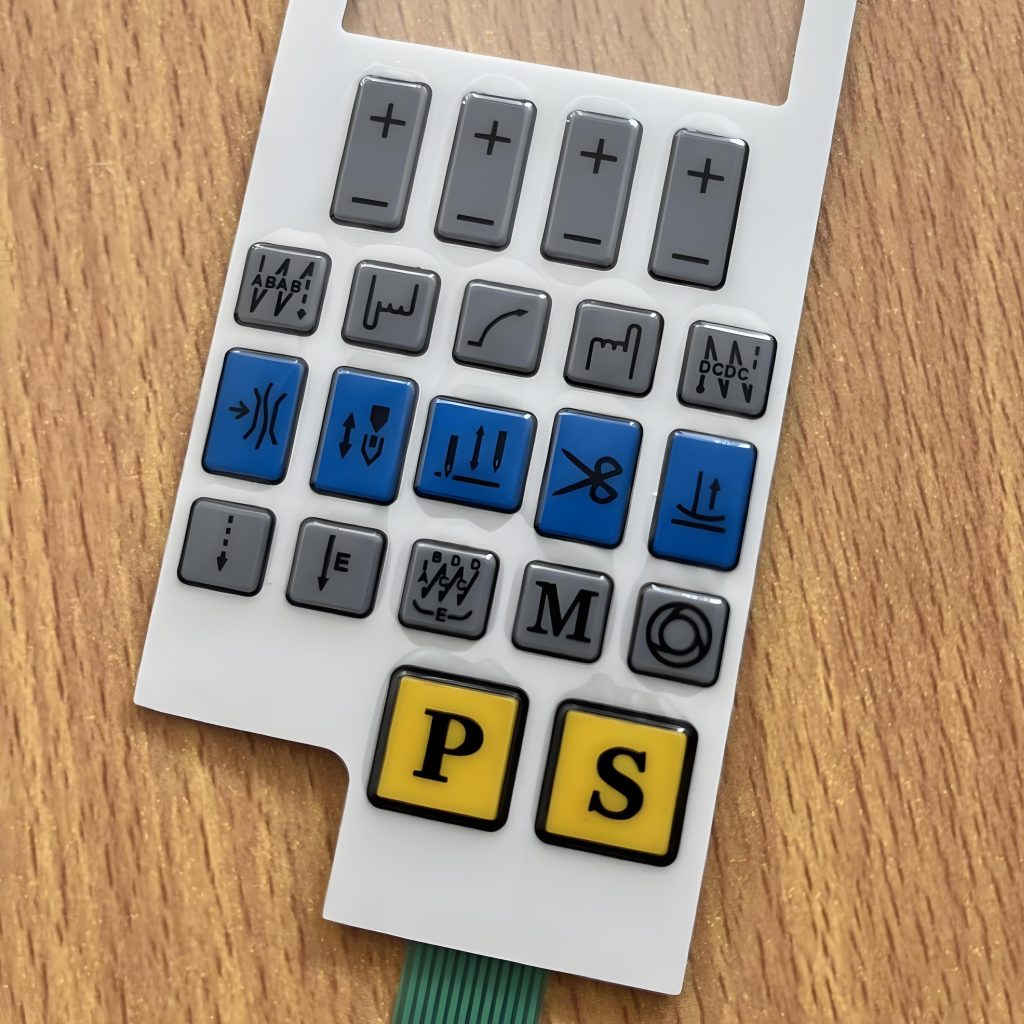

Membrane switches are thin, flexible interfaces used to send user commands to electronic devices. They replace bulky mechanical buttons with a smooth, sealed surface. These switches are found in medical instruments, control panels, consumer electronics, and industrial devices.

In structure, a membrane switch includes several layers. The top layer is a printed graphic overlay that displays symbols or text. Beneath it lies the circuit layer, usually made from polyester or polyimide. When a user presses a key, the contact completes an electrical circuit, sending a signal to the device’s main board.

Because they combine durability with elegance, membrane switches have become a popular choice for compact designs. Their sealed surface also protects against dust, moisture, and cleaning agents. This makes them suitable for harsh or sterile environments where mechanical switches might fail.

What Is a Membrane Button?

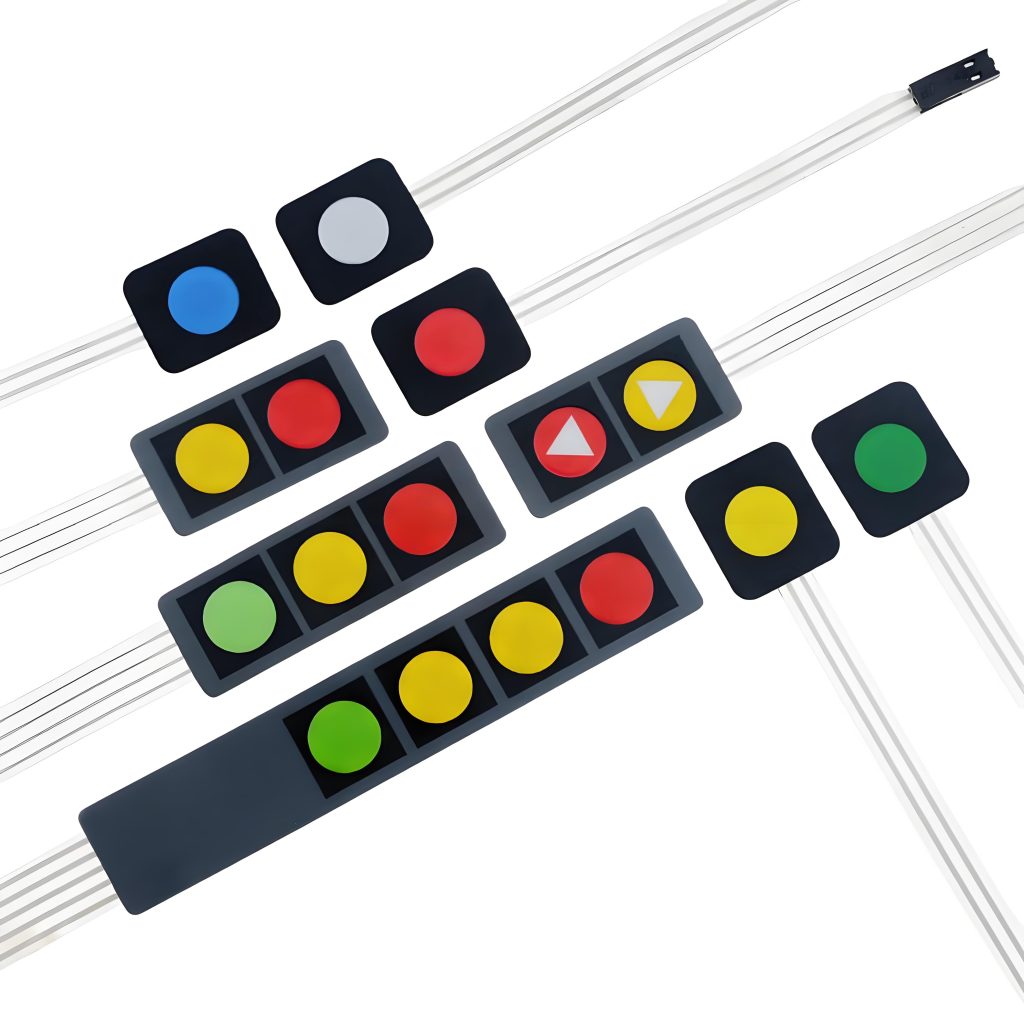

A membrane button is a single key within the switch assembly. Each button can be customized for shape, feel, and feedback. Some use tactile domes for a crisp “snap,” while others use flat designs for silent operation. The tactile feedback is especially important. It gives the user a physical response that confirms the button press.

Membrane buttons can be printed with legends, icons, or backlighting. This helps operators identify controls in low-light environments. Some advanced versions even integrate LED indicators to show device status.

In short, the membrane button is the user’s first point of contact. A well-designed button can greatly improve usability and perception of quality.

How Is a Membrane Switch Made?

The production of a custom membrane switch is a detailed process that blends printing, cutting, and laminating. Every layer has its purpose, and precision is essential to maintain reliability.

- Design and Artwork Creation: Yu An Electronics‘s engineers start with a circuit design and overlay. These define the switch layout, color scheme, and connector positions.

- Printing the Overlay: The graphic overlay is printed using durable UV inks on polyester or polycarbonate. It can include transparent windows, embossing, and textures.

- Circuit Printing: The circuit is screen-printed using conductive silver ink or carbon ink. This layer is responsible for electrical performance.

- Dome and Spacer Assembly: If a tactile response is needed, metal or polyester domes are placed on the circuit. A spacer layer separates the top and bottom circuits until pressed.

- Final Lamination and Testing: Layers are aligned and laminated together under controlled pressure. The finished switch then goes through electrical and visual testing.

This entire process demands accuracy. Even a small alignment error can affect performance. That’s why experienced manufacturers like Yu An Electronics rely on automated printing and inspection systems to maintain consistency.

How Do Membrane Switches Work?

A membrane switch works on a simple principle: completing or breaking an electrical circuit. When a button is pressed, the top circuit layer bends down to touch the bottom layer.

When pressure is released, the layers separate, and the circuit opens again. This momentary action gives precise control without mechanical parts that wear out quickly.

Some switches include metal domes to enhance tactile feel. These domes deform when pressed, producing a satisfying click and returning instantly to their shape.

In addition, custom membrane keypads can integrate LEDs, resistors, or flexible connectors directly into the design. This saves space and simplifies assembly. Yu An Electronics engineers can also add shielding to protect against electromagnetic interference (EMI), which is critical for medical or aerospace equipment.

What Are the Characteristics of a Custom Membrane Switch?

Custom membrane switches stand out for their adaptability. Every design can be modified to fit the application’s mechanical, electrical, and aesthetic needs.

- Flexible Design Options: Choose layout, shape, color, and tactile type freely.

- Durable Materials: Polyester and polycarbonate overlays resist chemicals and abrasion.

- Precise Printing: Graphic overlays are printed in high resolution, keeping legends crisp and long-lasting.

- Backlighting Choices: Integration of LEDs or EL panels enhances visibility.

- Weather Resistance: Sealed layers protect circuits from humidity and dust.

- Compact Structure: Their thin design suits portable or space-limited products.

Each of these features can be adjusted according to customer requirements. Whether you need a custom membrane switch panel for industrial equipment or a compact membrane switch keyboard for handheld electronics, customization helps achieve the best user experience.

What Are the Advantages of a Custom Membrane Switch?

The advantages of custom membrane switches extend far beyond appearance. Making them the first choice for modern devices.

- 1. Long Service Life

Membrane switches can handle millions of actuations. Metal dome versions provide even higher endurance. The sealed design minimizes dust and moisture ingress.

- 2. Superior Hygiene

Because the surface is sealed, cleaning is simple. This is critical for hospital devices, laboratory tools, and food-processing controls where hygiene is essential.

- 3. Lightweight and Slim

Its design allows for compact control panels, a feature particularly important in wearable technology and portable instruments.

- 4. Aesthetic Flexibility

Custom colors, printed logos, and backlighting enhance product appearance. The design flexibility also supports brand consistency across different product lines.

- 5. Cost Efficiency

Compared with mechanical switches, membrane versions require fewer components and assembly steps. This keeps production costs reasonable, even for small batches.

- 6. Reliable Operation

No exposed metal contacts or moving parts means fewer points of failure. The switches maintain stable performance across temperature ranges.

- 7. Easy Integration

Flexible tail connectors simplify connection to PCBs or controllers. This reduces assembly time and improves system reliability.

- 8. Custom Feedback

Yu An Electronics can adjust the haptic intensity or travel distance based on user preference. This helps achieve a perfect balance between comfort and control.

These benefits have made custom membrane keypads a favored solution for industries seeking precision and durability without sacrificing design aesthetics.

What Are the Application Areas of a Custom Membrane Switch?

Custom membrane switches are versatile. They can be found in numerous fields where control accuracy and longevity matter.

- Medical Devices: Equipment such as diagnostic machines, patient monitors, and sterilizers use membrane panels for their smooth, cleanable surfaces.

- Industrial Control Systems: Factories rely on durable switches to run machinery. A custom membrane switch panel can withstand oil, vibration, and temperature changes, maintaining stable function for years.

- Consumer Electronics: Appliances, remote controllers, and smart home devices use membrane keyboards for intuitive operation.

- Aerospace and Defense: Metal dome membrane switches offer tactile precision and EMI shielding for secure communication systems.

- Automotive and Transportation: From dashboards to control consoles, membrane switches perform well under vibration and temperature variations.

- Instrumentation and Measurement: Test equipment and data loggers use custom membrane keyboards for accurate input.

A well-engineered custom membrane switch enhances usability, reliability, and brand value.

Why Choose Our Custom Membrane Switch?

Selecting the right manufacturer makes all the difference. Yu An Electronics stands as a professional membrane switch manufacturer trusted by global clients for precision, quality, and fast delivery.

- Quality You Can Count On

Yu An Electronics follows international quality systems including ISO9001, ISO13485, IATF16949, and AS9100D. These certifications reflect our dedication to quality control in every process. Each switch undergoes electrical testing, visual inspection, and adhesion verification before shipment.

- Tailored Engineering

Our team provides complete design support — from artwork creation to final lamination. We help you choose materials, tactile domes, adhesives, and circuits that match your product’s environment. Customization isn’t limited to color or shape; we consider every functional detail.

- Fast Turnaround

With streamlined production lines and a mature supply chain, we deliver prototypes and mass orders quickly without compromising quality.

- Cost-Effective Solutions

By controlling both design and fabrication in-house, we reduce unnecessary costs. Our team helps optimize your layout to save space and simplify wiring.

- Reliable Communication

From concept to shipment, our engineers stay connected with your team. We believe good communication shortens development time and prevents misunderstandings.

- Traceability and Technology

Our manufacturing system integrates MES tracking to monitor every production step. This transparency provides complete traceability, ensuring consistency across all orders.

When you need a custom membrane keyboard or a metal dome membrane switch that meets tight specifications, Yu An Electronics delivers results you can rely on — with high quality and fast delivery as our promise.

Conclusion:

Custom membrane switches have reshaped how users interact with electronic devices. Their slim, sealed design combines aesthetics, functionality, and reliability. From medical tools to industrial machines, they perform under pressure, literally and figuratively.

For companies seeking custom membrane switch panels or keypads, collaboration with a skilled manufacturer is vital. Yu An Electronics brings advanced equipment, quality systems, and responsive service to every project. We don’t just manufacture switches — we help you build smarter interfaces that last.

If you’re ready to enhance your products with a custom membrane switch, our team is here to assist. Contact us today at sales@best-membraneswitch.com

FAQs

- 1. How long do membrane switches last?

A well-made membrane switch can last over one million cycles. Metal dome types often exceed five million presses due to their robust design.

- 2. Can membrane switches be waterproof?

Yes. With proper sealing and materials, membrane switches can resist moisture, dust, and even light water sprays.

- 3. What materials are used for overlays?

Common overlays include polyester and polycarbonate. Both provide durability, chemical resistance, and excellent print quality.

- 4. Can you integrate LEDs into a membrane switch?

Absolutely. LEDs can be embedded for backlighting or status indication, improving visibility and design appeal.

- 5. How fast can I receive my custom membrane switch?

At Yu An Electronics, prototype delivery typically takes 5–7 days, while mass production follows soon after depending on order quantity.

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

Contact us online