Custom Switch Manufacturer, Membrane Switch Manufacturers

Custom Switch Manufacturer, Membrane Switch Manufacturers

A trusted custom switch manufacturer delivers tailored membrane switches that match your product’s design, feel, and function. Whether it’s for medical, industrial, or consumer use, Yu An Electronics turn your ideas into durable, user-friendly solutions.

What is a custom membrane switch?

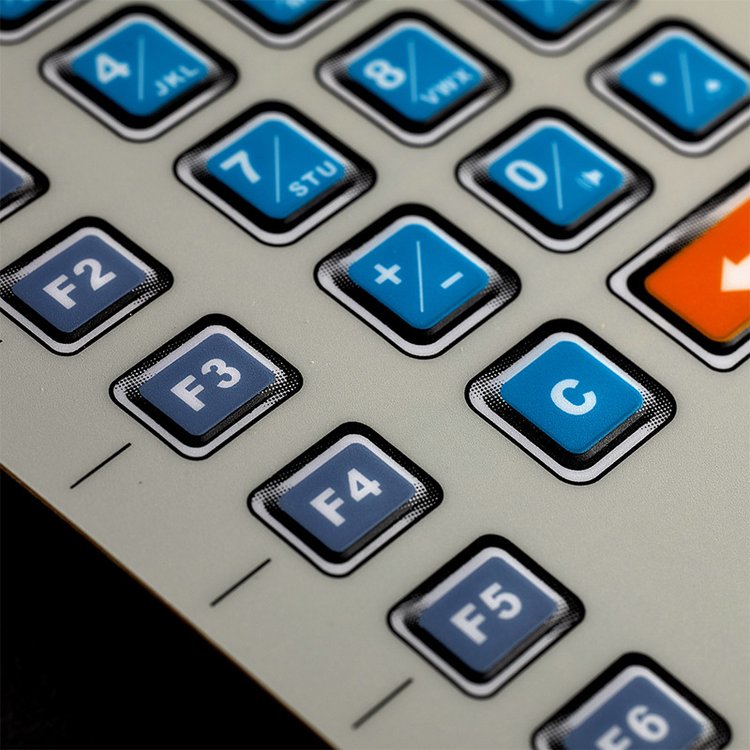

Custom membrane switch is a pressure-sensitive keypad made specifically for your product. Unlike standard keypads, it’s tailored to fit your design, function, and feel. These switches are created from multiple layers—usually polyester or polycarbonate—with conductive traces printed underneath.

When pressed, the switch completes a circuit and sends a signal to the device. What makes it custom is the flexibility in design. You choose the layout, material, feedback, icons, lighting, and shape. This is not just a switch—it’s a user experience element.

Whether it’s a consumer gadget, a medical instrument, or an industrial panel, a custom membrane switch gives you control over every detail.

Yu An Electronics offer options that help your design feel intuitive and high-end. Your layout can be curved or rectangular. The surface can be glossy, matte, or anti-glare.

Why choose a custom membrane keypad?

Custom membrane keypad is not just about aesthetics. It solves problems. It enhances function.

First, it fits your product exactly. No cutting. No modification. It’s made to match your enclosure, your dimensions, and your expectations.

Second, it improves user interaction. Whether you’re designing for gloves, wet conditions, or dark environments, a custom membrane keypad adapts. Add waterproof features, emboss buttons for better feel, or include LED lighting to guide users in low light.

Third, Custom membrane switch panel can feature your logo, your colors, and your tone. It builds identity into every touch.

Finally, it lasts. Quality membrane switch manufacturers test each product for reliability. Actuation cycles can reach over a million presses. It resists moisture, chemicals, and wear.

In the end, you’re not just building a keypad. You’re building trust, interaction, and satisfaction.

How to customize membrane switches?

Step one is defining your needs. What is the switch used for? Where is it used? Indoor or outdoor? Dry or wet?

Next, you choose your layout. Decide how many buttons you need, their location, and what functions they control. Round buttons, square keys, or sliders.

After layout, it’s time to pick the tactile feel. Some products need a strong click. Others need soft touch. That’s where metal domes or polyester domes come in.

Now design the top layer. This is the visible face. Add icons, texts, symbols, or graphics. You can use screen printing or digital printing based on color and durability needs.

For the circuit layer, choose between silver ink or FPC membrane switch. FPC is more durable and flexible. It’s perfect for complex circuits or tight spaces.

Once designed, you get a prototype. You test it. You feel it. Then it goes into production. Yu An Electronics guides you through each step.

How to design a membrane switch panel?

Start by sketching the layout. Map out the position of each button. Think of how users will interact with it. Too many buttons close together? Confusing. Too few? Limiting.

Keep the surface clear. Icons and text should be easy to read. Use contrast—dark text on light backgrounds, or light symbols on dark ones. Add braille or raised elements if needed.

Next, consider layers. A standard panel includes the graphic overlay, spacer, circuit, and adhesive. Each layer adds something: protection, spacing, or connectivity.

Decide on tactile feedback. Add metal domes for a crisp click. Use embossed buttons to guide finger position. Or choose non-tactile if silence is key.

If light matters, integrate LEDs. With a LED membrane switch, you can light up individual buttons or highlight important zones. That adds clarity and style.

Mounting is the final detail. Will you use adhesive backing? Screws? Clamps? The right choice ensures easy assembly and lasting performance.

A good membrane switch panel manufacturer helps you avoid guesswork. Yu An Electronics provide design files, 3D views, and guidance. That saves time and improves results.

How long does custom switch production take?

With an experienced custom switch manufacturer, you can get both. Here’s what to expect:

- – Design consultation and drafts: 1–2 days

- – Sample prototype: 3–7 working days

- – Mass production: 7–15 working days, depending on volume

Urgent orders? That’s possible too. Some membrane switch manufacturers offer expedited services. That includes faster tooling, quicker printing, and shorter lead times.

For clients who need rapid development, we offer a 48-hour sample turnaround and a 7-day production cycle.

What makes FPC membrane switches unique?

FPC membrane switches offer key advantages over traditional PET-based ones. They use flexible copper circuits instead of silver ink.

First is reliability. Copper doesn’t degrade as easily. It handles more bending and pressure.

Second is precision. FPC allows finer traces. That means smaller parts, tighter routing, and more functions in less space.

Third is heat resistance. FPC circuits can endure soldering and high temperatures better than silver ink.

Fourth is durability. FPC membrane switches last longer. They can handle up to five million actuations. They’re ideal for high-use applications—medical, industrial, automotive.

They also work well with SMT components. You can mount sensors, LEDs, resistors, or ICs directly on the circuit. That makes your switch smarter and more integrated.

In short, FPC isn’t just flexible—it’s powerful. It gives your product more life, more features, and more value.

How do LED membrane switches work?

Inside the layers, thin LEDs are embedded. These lights can be placed under each button or on the edge. When the switch is pressed—or even idle—the LED glows.

This improves usability. In dark areas, backlit buttons guide the user. In emergencies, flashing lights draw attention. It also adds a premium look.

You can choose from red, green, blue, or white LEDs. Some designs even offer RGB backlighting for full color control.

The LED power comes from your circuit or external source. The lighting can be always on, triggered by pressing, or controlled by software. Adding LEDs doesn’t make the switch bulky. The lights are thin. They fit inside the standard switch layers.

LED switches are great for medical devices, remote controls, and consumer electronics. They add both style and function.

Conclusion:

Custom membrane switches enhance product performance, durability, and user experience. From FPC to LED options, each design is built to match your exact needs.

At Yu An Electronics, we offer fast delivery, expert design, and reliable quality. Contact us at sales@best-membraneswitch.com to get started with your custom switch solution.

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

What is rubber dome keyboard? Rubber keyboard

Rubber keyboard is known for its soft feel, quiet operation, and reliable everyday performance. A rubber dome keyboard is a keyboard that uses a flexible rubber dome under each key to register input. When a key is pressed, the dome collapses and makes contact with the circuit below, sending a signal, then springs back when ...

Contact us online