Customized LED Membrane Switch: Membrane Switch Design Guide

Customized LED Membrane Switch: Membrane Switch Design Guide

What is a customized LED membrane switch?

Customized LED membrane switch is a type of thin, flexible keypad that includes built-in light-emitting diodes (LEDs). These LEDs help users see button functions more clearly—especially in low-light or outdoor environments.

Unlike traditional keyboards, membrane switches do not use separate moving parts for each button. Instead, they rely on pressure pads layered within a sealed surface. When LED lights are added, the result is a clear, intuitive, and reliable interface tailored to your product needs.

Customization includes more than just color or size. It allows for personalized tactile feedback, lighting patterns, graphic overlays, and electrical layouts. Whether you need a single LED or full backlighting, a tailored solution is possible.

How does a membrane switch with LED enhance visibility?

Visibility is everything when using electronic devices in dark or high-glare environments. A membrane switch with LED offers pinpoint lighting that guides users instantly.

The LEDs are strategically placed beneath the graphic overlay. These can illuminate icons, symbols, or entire panels. This makes it easier to locate controls quickly and accurately.

You can choose:

- Selective LED lighting for specific buttons

- Edge lighting for visual elegance

- Full-panel illumination for critical equipment

LEDs improve not just the look—but the safety and usability of your product.

What are the benefits of a customized LED membrane switch?

There’s more to this switch than its glowing buttons. Let’s look at the real advantages.

- Better User Experience: Backlit buttons guide users in dark or fast-paced settings.

- Enhanced Brand Identity: Custom lighting colors and layouts reflect your brand’s style.

- Space-Saving Design: Thin profile allows for sleek, compact devices.

- Power Efficiency: LEDs consume minimal power.

- Increased Durability: Sealed construction resists moisture, dust, and contaminants.

- Flexible Customization: You decide the size, shape, tactile feel, and brightness.

- Improved Safety: Reduces user errors with clearly defined active buttons.

These benefits make the customized LED membrane switch a must-have in industries like medical, military, industrial controls, and consumer electronics.

Can a custom membrane keypad be waterproof?

Yes, absolutely. In fact, it’s one of the most important features in many applications.

Custom membrane keypad is designed with layers of flexible material, sealed to keep out water, dust, and chemicals. When properly manufactured, it can meet IP65, IP67, or even higher protection ratings.

Waterproof keypads are ideal for:

- Outdoor control systems

- Medical devices

- Food processing machines

- Marine electronics

And with proper venting and sealing, they won’t trap moisture or fog up.

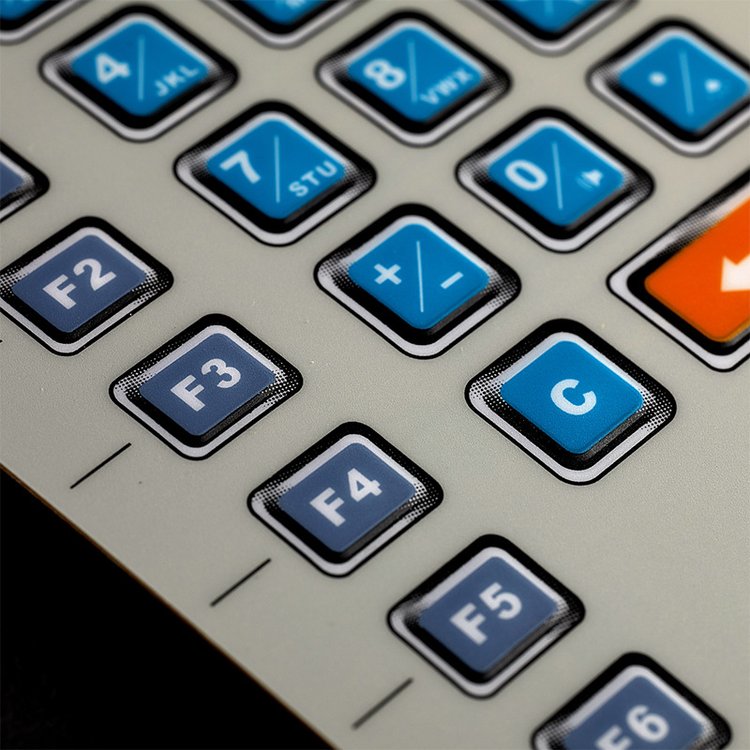

What makes a metal dome membrane switch different?

The metal dome membrane switch introduces tactile feedback into the user interface. While flat switches offer no physical response, metal domes deliver a satisfying “snap” when pressed.

Here’s what sets them apart:

- Higher tactile feedback: Perfect for applications requiring confirmation of input.

- Longer lifespan: Metal domes can endure over one million presses.

- Variety of sizes: Choose domes from 4mm to 20mm depending on your needs.

- Accurate actuation force: Ranges from 180g to 600g for customized feel.

These switches are common in high-performance electronics like remote controls, automotive panels, and industrial keypads.

How does membrane switch design affect performance?

Membrane switch design plays a direct role in device performance. A good design ensures quick response, reliable actuation, and extended lifespan.

Key design factors include:

- Layer structure: Every membrane switch has multiple layers—top graphic, spacer, circuit, and adhesive.

- Circuit design: You can choose from silver-printed circuits, copper flex, or PCB for different needs.

- Dome placement: Metal domes must sit precisely beneath the overlay graphics.

- LED location: LEDs should not interfere with dome response or circuit integrity.

- Embossing and spacing: Proper embossing makes buttons easier to press and identify.

In short, optimized design equals better performance. Poor layout can lead to premature device failure.

What to include in a membrane switch design guide?

If you are planning to design and develop a membrane switch, good design guidelines can save time, cost, and effort. Here are key elements to include:

- Application environment: Indoor, outdoor, high-heat, or humid?

- User interface: What’s the required tactile feel and LED layout?

- Graphics and overlays: Custom icons, text, logo printing, colors.

- Circuit type: Flexible printed circuit (FPC), PCB, or PET silver?

- Tactile elements: Choose between metal dome or polydome.

- Lighting plan: Position and type of LED lighting.

- Connector options: ZIF, male/female headers, or solder pads.

- Shielding: If needed, EMI or ESD protection.

- Assembly process: Mounting style and adhesive backing.

- Certifications: RoHS, REACH, ISO standards.

Each factor influences product reliability and end-user satisfaction.

Where is a membrane switch panel commonly used?

Membrane switch panel can be found in countless devices across industries:

- Medical equipment: Easy to clean and operate with gloves.

- Industrial machinery: Resistant to dust and oil.

- Consumer electronics: Slim, stylish interfaces with long life.

- Military gear: Rugged and ready for harsh conditions.

- Home appliances: Sleek controls for modern designs.

- Automotive panels: Custom LED lighting for safety and branding.

Their adaptability, combined with durability and aesthetic appeal, makes them the go-to choice for control interfaces.

Conclusion:

Customized LED membrane switches are revolutionizing control panel design. With the right membrane switch design, your product becomes easier to use, longer-lasting, and more visually appealing.

Want to create your own custom membrane switch panel? Get expert guidance and precision solutions from the team at Yu An Electronics.

Contact us at sales@best-membraneswitch.com

Membrane Switch with LED, Customized LED Membrane Switches

Our LED membrane switches provide bright, even backlighting, long lifespan and reliable performance for control panels in dark environments. What are LED membrane switches? LED membrane switches are advanced user interface panels that combine a flexible membrane circuit with integrated light sources. The structure looks simple from the outside. Inside, it is a layered system ...

Click Touch Membrane Switch, Premium Membrane Switch with Tactile Click Response

Our click touch membrane switch provides clear tactile click response, stable performance and long service life, ideal for control panels requiring obvious touch feedback. What is a click touch membrane switch? A click touch membrane switch is a pressure-activated interface designed to deliver a clear, physical response each time a key is pressed. Unlike flat ...

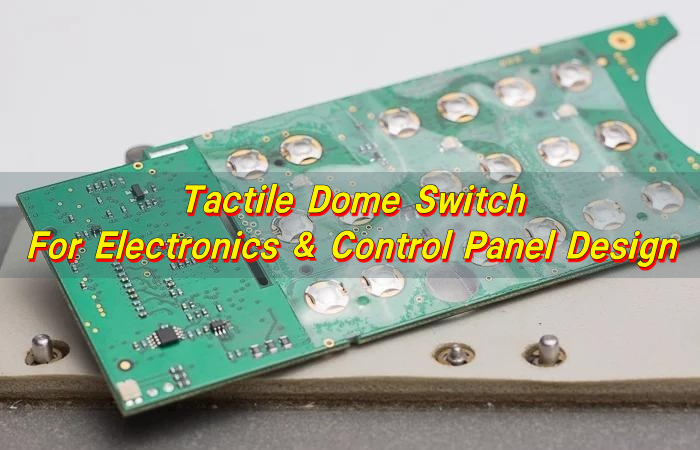

Tactile Dome Switch – For Electronics & Control Panel Design

Our tactile dome switch delivers crisp tactile feedback and reliable precision actuation, with industrial-grade durability for small device control panels. Custom sizes available for your design needs. What is a tactile dome switch? A tactile dome switch is a compact switching component used in electronic interfaces where clear feedback matters. It delivers a sharp, physical ...

Contact us online