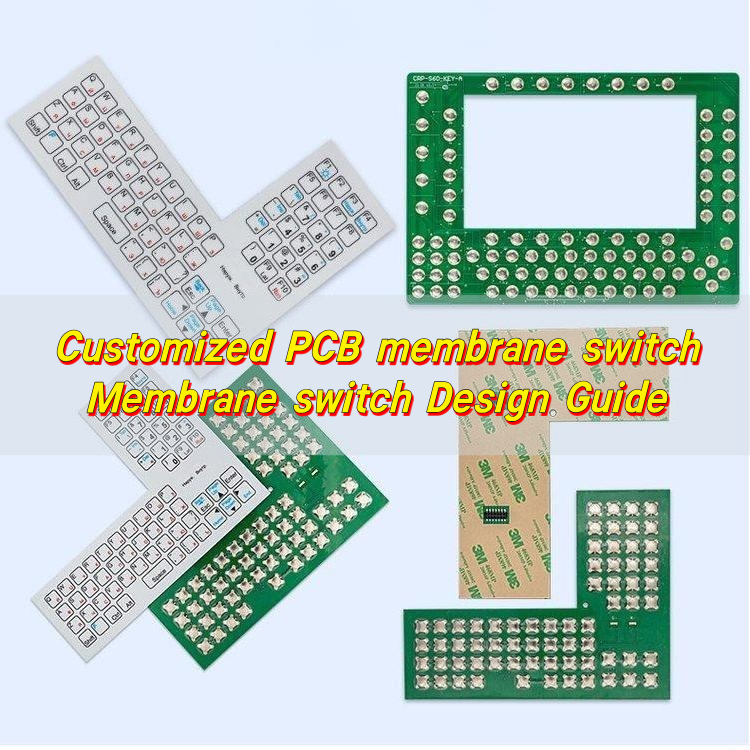

Customized PCB membrane switch, Membrane switch Design Guide

Customized PCB membrane switch, Membrane switch Design Guide

What is a customized PCB membrane switch?

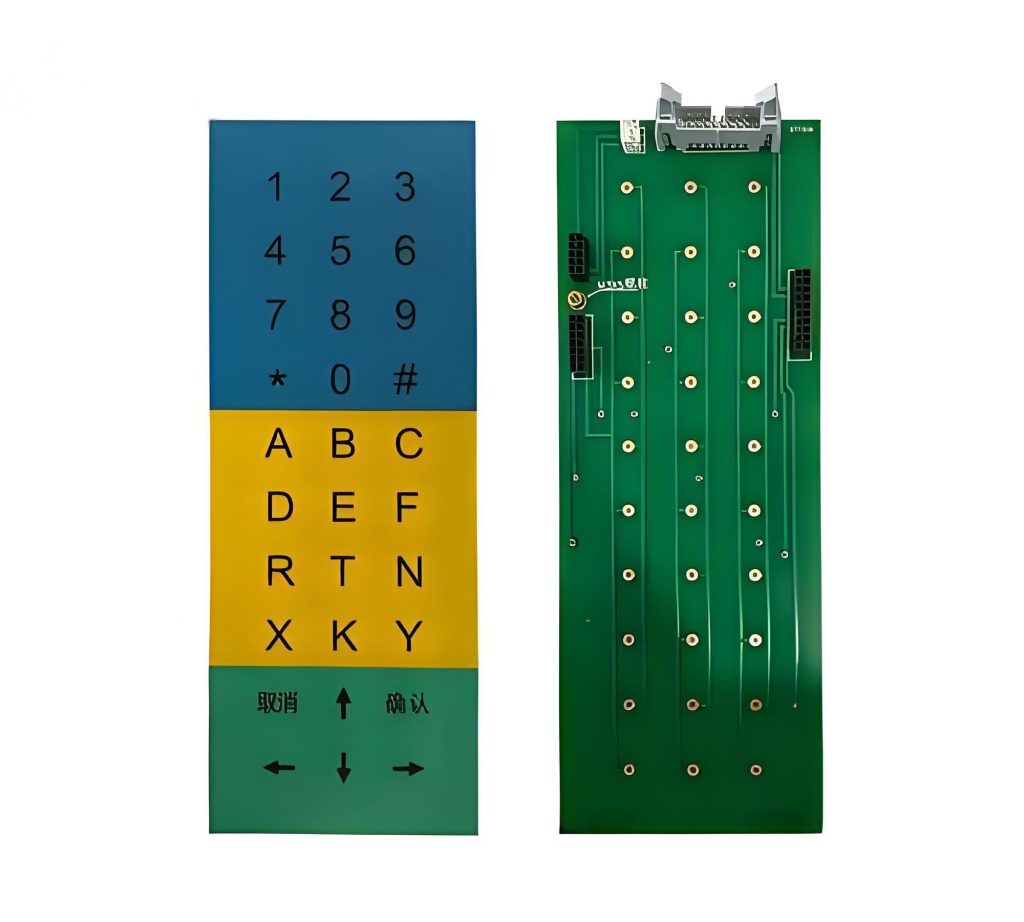

Customized PCB membrane switch is a user interface solution designed for a specific product or application. It combines a PCB with a thin, flexible membrane that contains printed circuits, tactile or non-tactile switches, and a graphic overlay.

Custom PCB design provides a stable foundation and ensures reliable electrical connections. The membrane switch layer acts as the operational surface, allowing the user to control the device with simple, low-force presses. The combination creates a compact, durable, and attractive interface that works well in industrial, medical, and consumer products.

Because it is customized, the design can include unique layouts, special graphics, backlighting, embossing, or even environmental sealing. This means the switch does more than function—it can enhance the product’s appearance and brand identity.

Why choose a PCB custom membrane switch keypad?

Choosing a PCB custom membrane switch keypad gives you more control over how your product operates and feels. Standard keypads might fit some applications, but a custom one ensures every detail supports your goals.

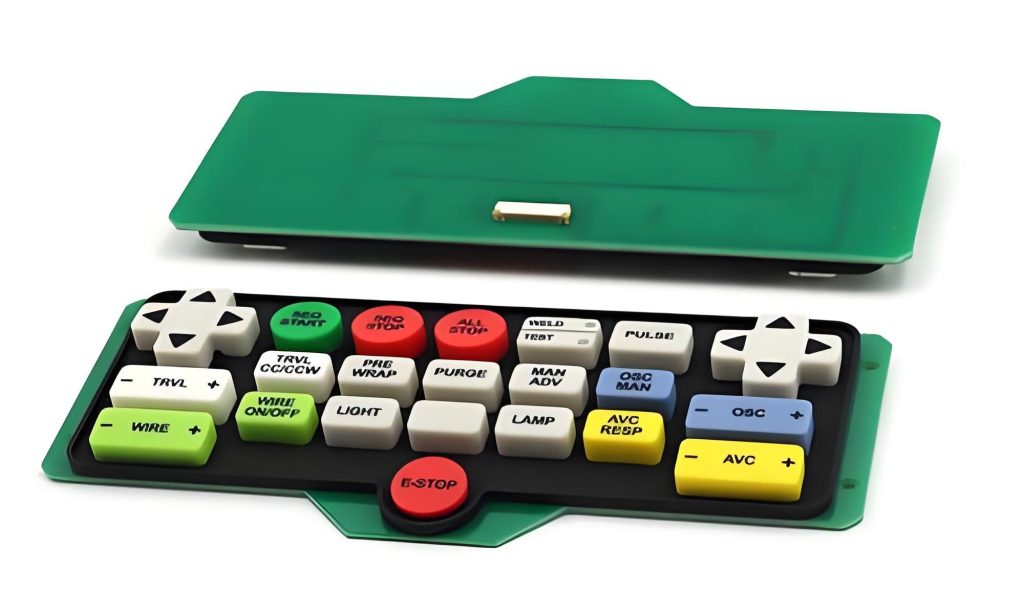

One of the biggest advantages is integration. A PCB custom membrane switch keypad can include multiple functions—buttons, LEDs, and even touch-sensitive zones—into a single unit. This saves space, reduces wiring, and improves assembly efficiency. In addition, the layers can be designed to resist dust, moisture, or chemicals, which extends product life in challenging environments.

From an appearance standpoint, a custom keypad creates a polished and cohesive design. The graphics, colors, and textures can align with your product’s style. Whether the goal is industrial toughness, medical precision, or consumer elegance, a PCB custom membrane switch keypad can deliver it.

How to select a PCB custom membrane switch panel?

Selecting the right PCB custom membrane switch panel requires looking at several factors. First, think about where and how it will be used. Indoor equipment may not need the same sealing and material strength as outdoor devices or medical tools. If the environment is harsh, you may need materials that resist UV light, chemicals, or high humidity.

The next factor is performance. Decide whether you want tactile feedback, which gives users a clear click sensation, or non-tactile designs for silent operation. The actuation force—the amount of pressure needed to activate the switch—should also be considered for user comfort.

Appearance is another key element. Since the panel often includes a custom graphic overlay, you can choose colors, labels, and icons that make operation intuitive. Backlighting can improve usability in low-light settings, and embossing can help users find buttons by touch.

Finally, work with a professional membrane switch manufacturer, such as Yu An Electronics, who can help you select the right materials, circuits, and structures to balance performance and cost-effectiveness.

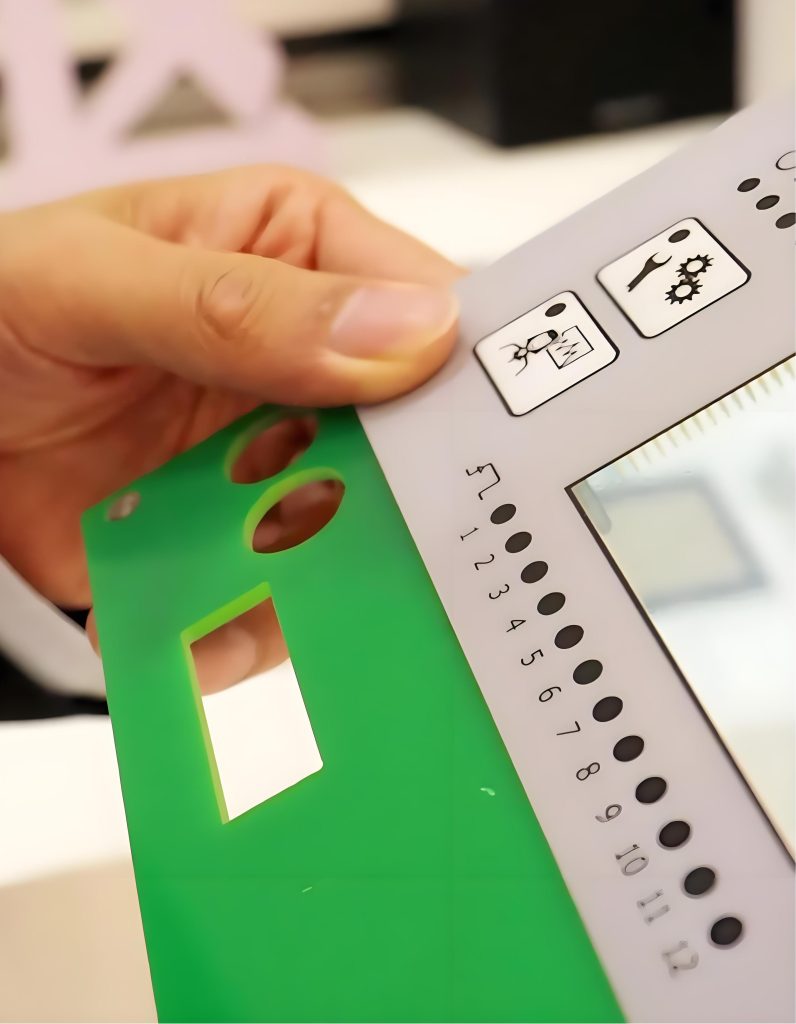

What is a custom graphic overlay?

Custom graphic overlay is the top layer of a membrane switch. It is the part users see and touch, so it plays a big role in both appearance and function. Made from materials like polyester or polycarbonate, it can be printed with detailed graphics, colors, and labels to match your product’s branding.

This layer is more than decoration. It protects the underlying circuitry from wear, moisture, and chemicals. Depending on the design, it can include transparent windows for displays, cut-outs for LEDs, or textures for better grip.

A good custom graphic overlay should be durable and easy to clean. It must also resist fading or cracking over time. Because it is customized, it can match the exact size, shape, and style you want. It can even be designed with anti-glare or anti-bacterial properties for specific applications.

By combining style with function, a custom graphic overlay makes your membrane switch more engaging to use and visually appealing.

How to design a custom membrane switch panel?

Designing a custom membrane switch panel starts with understanding the product’s needs. Begin by defining the number of buttons, their placement, and the type of feedback you want. Tactile domes can give a clear click, while flat designs can offer a sleek, silent feel.

Next, select the right materials for each layer. The graphic overlay must be tough but attractive. The spacer layer needs to create the right separation between contacts. The PCB must provide stable and precise electrical paths. Each material choice will affect durability, appearance, and cost.

Electrical layout is equally important. The traces must be designed for efficient current flow and minimal interference. If the panel includes LEDs, they should be placed for even illumination without glare.

Finally, test early and often. Prototypes allow you to check feel, performance, and appearance before mass production.

Carefully designed custom membrane switch panel will look great, feel right, and perform reliably for years.

How to avoid membrane switch design mistakes?

Some membrane switch design mistakes can affect performance or increase costs. The most common is not matching the design to the environment. A switch that works well indoors might fail outdoors if it’s not sealed against moisture and dust.

Another mistake is overlooking the user experience. Buttons that are too small, too hard to press, or poorly labeled can frustrate users.

Material selection errors can also cause problems. Using the wrong overlay material may lead to fading, cracking, or poor tactile feedback. Always choose materials that match the intended application.

Skipping prototypes is another risk. Without testing, small flaws can become big problems in production.

By working with a skilled manufacturer, you can avoid these issues. Yu An Electronics will guide you through material selection, layout optimization, and functional testing. This ensures your membrane switch design is both effective and cost-efficient.

How long do custom membrane switches last?

The lifespan of a custom membrane switch depends on its design, materials, and environment. A well-made switch can last millions of actuations without loss of performance. Factors like tactile dome quality, overlay durability, and proper sealing all play a role.

For example, a tactile metal dome can be rated for over one million presses. In contrast, non-tactile designs may last even longer because they have fewer moving parts. Environmental protection is also key—switches used outdoors or in industrial settings need extra sealing to prevent damage from moisture or dust.

Proper maintenance extends life as well. Keeping the switch clean and free from abrasive particles will reduce wear.

Where are customized PCB membrane switches used?

Customized PCB membrane switches are used in many industries. In medical devices, they offer a clean, sealed interface that is easy to disinfect. In industrial control panels, they provide durability and resistance to harsh conditions.

Consumer electronics use them for sleek designs with minimal moving parts. In automotive applications, they can control infotainment systems, climate settings, and other functions. Even household appliances benefit from them, combining simple operation with stylish graphics.

Because they are customizable, these switches can be adapted to almost any product. The ability to integrate multiple functions into one interface makes them a space-saving and cost-effective choice.

Their flexibility in design and materials allows them to match the demands of different markets. From rugged outdoor equipment to elegant home devices, customized PCB membrane switches offer a reliable and attractive control solution.

Conclusion:

Customized PCB membrane switch combines function, style, and durability into one efficient interface. Choose Yu An Electronics, your custom design can last for years, look great, and perform flawlessly.

Want us to customize your PCB membrane switch? Contact us at sales@best-membraneswitch.com

Backlit Membrane Switches – High-Quality Backlit Keypads

We provide reliable backlit membrane switches with long service life, stable backlight, and customizable design to fit your device control panel. What are backlit membrane switches? Backlit membrane switches are low-profile control interfaces that combine printed circuitry with integrated lighting. They allow users to see and operate equipment in low-light or dark environments. A backlit ...

Membrane Switch with LED, Customized LED Membrane Switches

Our LED membrane switches provide bright, even backlighting, long lifespan and reliable performance for control panels in dark environments. What are LED membrane switches? LED membrane switches are advanced user interface panels that combine a flexible membrane circuit with integrated light sources. The structure looks simple from the outside. Inside, it is a layered system ...

Click Touch Membrane Switch, Premium Membrane Switch with Tactile Click Response

Our click touch membrane switch provides clear tactile click response, stable performance and long service life, ideal for control panels requiring obvious touch feedback. What is a click touch membrane switch? A click touch membrane switch is a pressure-activated interface designed to deliver a clear, physical response each time a key is pressed. Unlike flat ...

Contact us online