Membrane switch design guide, Membrane switch manufacturers

Membrane switch design guide, Membrane switch manufacturers

The membrane switch design guide mainly includes the structure and design points of membrane switches, covering a variety of types. Among them, metal dome membrane switches are widely used due to their excellent performance. Its design needs to consider the requirements of key feel, life and waterproof. The metal dome is installed under the key to enhance the touch and conduct electricity. When designing, pay attention to the dome position, line routing and pressure distribution to ensure stability and reliability.

What are the key elements in a membrane switch design guide?

membrane switch design guide includes the following core elements:

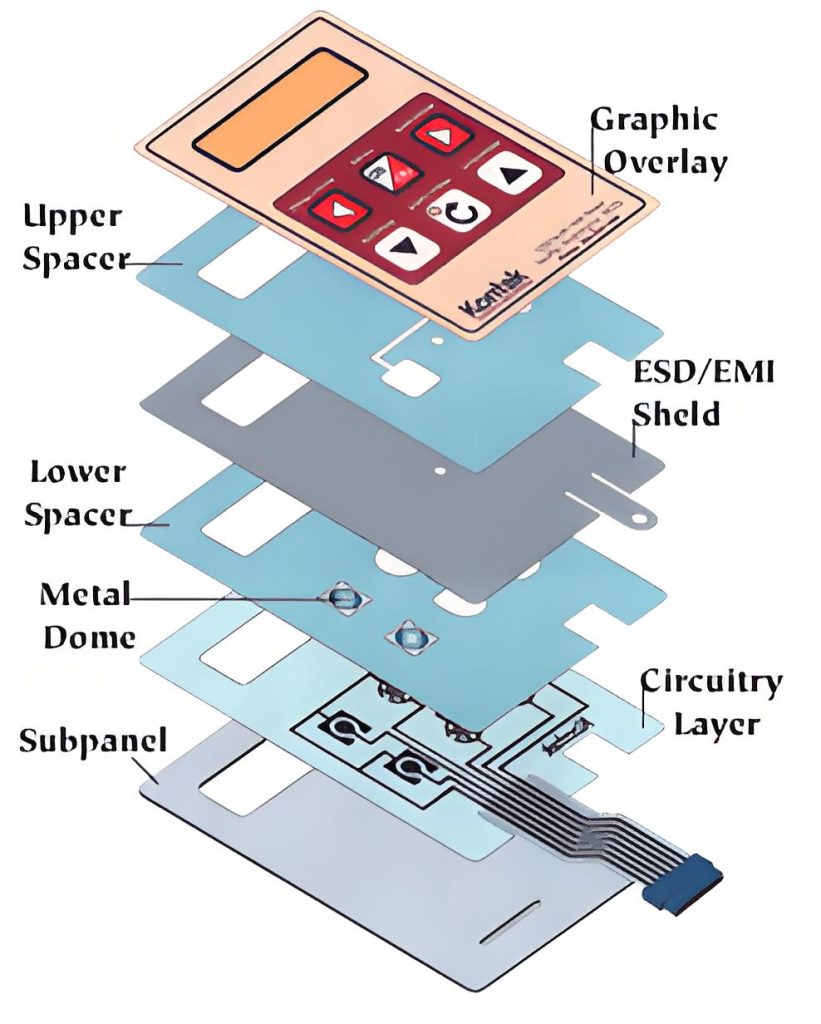

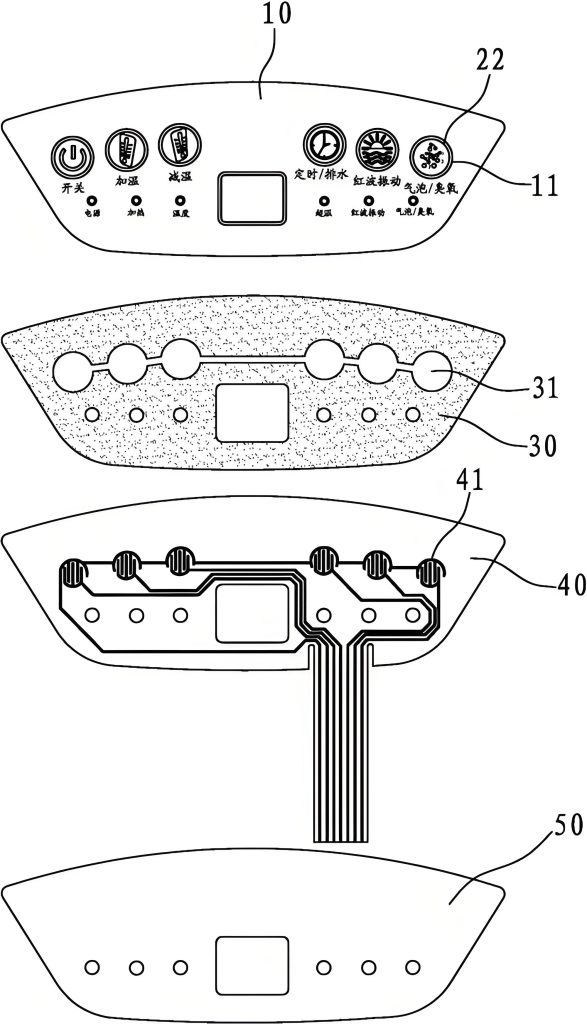

- 1. Layer Structure

Each switch is built from multiple layers—graphic overlay, spacer, dome layer, circuit layer, and adhesive. Every layer serves a unique function. Together, they deliver tactile response, circuit control, and durability.

- 2. Material Selection

From polyester to polycarbonate, choosing the right top layer material affects how it feels, resists wear, and handles environmental stress. A design guide helps select materials that match both usage and industry needs.

- 3. Tactile Feedback

Do you want a soft touch or a sharp click? Metal domes or non-tactile designs? Understanding membrane switch types helps you decide.

- 4. Circuit Design

Whether it’s printed with silver ink or made from copper flex, the circuit layer is the brain of the switch. Good design guides ensure circuit reliability, trace width clarity, and long-term electrical performance.

- 5. Graphic Layout

Looks matter. Your interface must be clean, intuitive, and aligned with your branding. Design guides offer layout suggestions to keep the look professional and user-friendly.

How does a membrane switch design guide help?

A membrane switch design guide gives structure to your ideas. It translates creative visions into functional realities.

For large OEMs, it saves time by streamlining the design phase. Fewer revisions, quicker production, and less stress across the board.

A reliable guide will help you match your switch design to real-world use. Whether it’s resistance to chemicals, extreme temperature performance, or flexible mounting options—every spec matters.

How can a design guide transform your membrane switch?

By applying tested design rules, you prevent wear issues, ensure smooth conductivity, and maximize ergonomic comfort. Small changes—like adjusting dome size or spacer thickness—can bring big boosts in performance.

What safety considerations are in the membrane switch design guide?

In any switch used for control—especially in medical, military, or industrial fields—safety isn’t optional.

Design guides prioritize safety with features such as:

- ESD shielding to protect circuits from electrostatic discharge

- Moisture seals to prevent short circuits in humid environments

- UV-resistant inks to avoid fading under sunlight exposure

- Fail-safe layouts, including redundant traces in mission-critical systems

Guides also help with choosing LED backlighting for better visibility in low light or emergency conditions. Every element that enhances safety makes the final product more trustworthy and compliant with industry standards.

What mistakes to avoid in membrane switch design?

Here are common errors that can be avoided:

- Ignoring environment exposure: If your switch goes outdoors, you need UV protection and waterproof layers.

- Choosing the wrong dome type: Not all dome switches feel the same. Some users prefer softer feedback; others need a sharp click.

- Overlooking circuit spacing: Incorrect trace width or spacing can cause failure or signal interference.

- Skipping testing: Rushing into mass production without testing can result in huge cost losses.

By following a solid design guide, these risks drop dramatically. You stay ahead of issues before they arise.

Which membrane switch type suits your needs?

Different industries need different solutions. That’s where the guide becomes even more useful.

1. Tactile Switches with Metal Domes

These offer that satisfying “click.” Ideal for medical devices or industrial controls where clear feedback matters.

2. Non-Tactile Switches

Smooth and silent, they’re great for settings where minimal noise is key—like labs or quiet workspaces.

3. Capacitive Membrane Switches

Modern and sleek, these react to finger touch without pressure. They’re popular in home appliances and sleek tech interfaces.

4. Flexible Circuit Switches

When your product needs to bend or fit in tight spaces, these are the go-to option.

5. Backlit Membrane Switches

Essential for night-time or low-light use. LED, EL, and fiber optic backlights are commonly integrated.

Design guides explain how each type performs and when to use them. That’s powerful knowledge.

How do manufacturers design membrane switches?

Leading membrane switch manufacturers follow a careful process:

- Concept Analysis: They listen to your goals, user needs, and application environment.

- Design Proposal: Using CAD tools and years of field experience, they draft a layout with layers, dimensions, and specs.

- Material Selection: Based on the guide, they suggest adhesives, overlays, dome types, and circuits.

- Prototype Creation: Before scaling, they build a working sample to verify feedback, conductivity, and appearance.

- Testing & Feedback Loop: A responsible manufacturer refines the prototype based on tests—ensuring it survives real-world use.

- Mass Production: Only after validation do they move to large-scale production with consistent quality.

Without a design guide, much of this process would involve guesswork. With it, every step becomes efficient, predictable, and optimized.

Why choose Yu An Electronics membrane switch manufacturer?

At Yu An Electronics, we’ve spent decades perfecting the art and science of membrane switches. From medical-grade switches to rugged industrial panels, we’ve done it all.

- Expert Design Support: Our team doesn’t just follow your drawings—we help improve them. We use our own membrane switch design guide to recommend better materials, smarter layouts, and enhanced tactile performance.

- Precision Prototyping: We bring your idea to life with exacting detail. No shortcuts. No delays. Just reliable samples you can test right away.

- Tight Quality Control: Every switch is tested for feel, durability, conductivity, and adhesion. You receive switches that just work—day after day, press after press.

- Full Customization: Whether you need embossed buttons, LED windows, unusual shapes, or multilayer circuits, we can create it.

- Customer-First Service: We respond fast, listen well, and solve problems before they happen. That’s what real partnerships feel like.

Working with Yu An Electronics means peace of mind. You get a product built right the first time—and every time after that.

Conclusion:

A well-structured membrane switch design guide unlocks this potential. It gives you the tools to design smart, avoid costly mistakes, and meet industry demands with confidence.

Yu An Electronics is here to help you do just that—with passion, precision, and proven performance. Contact us today at sales@best-membraneswitch.com

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

Contact us online