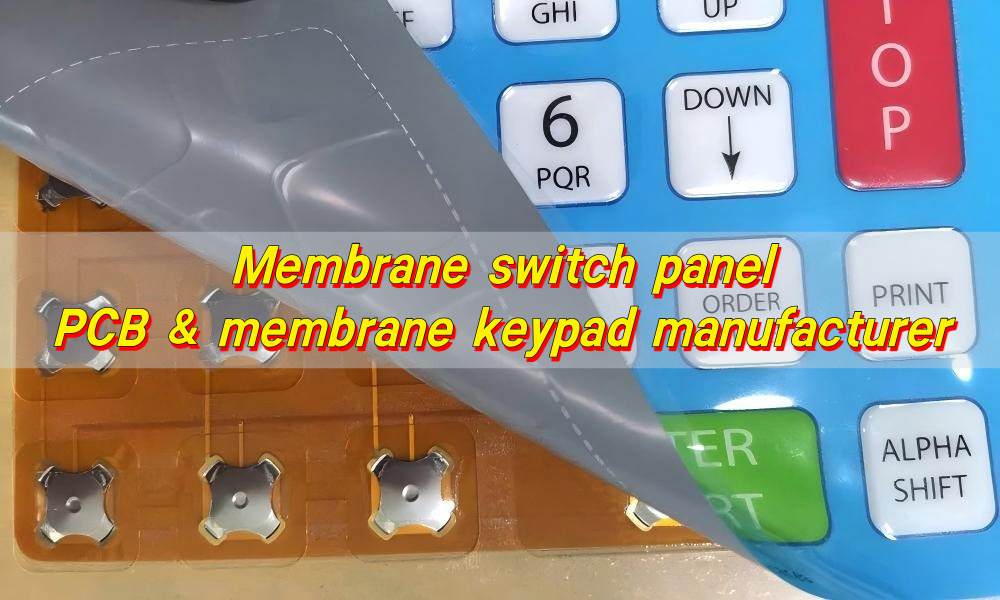

Membrane Switch Panel, PCB & Membrane Keypad Manufacturer

Membrane Switch Panel, PCB & Membrane Keypad Manufacturer

What Does a PCB & Membrane Keypad Manufacturer Do?

PCB & membrane keypad manufacturer specializes in designing and producing custom-built user interfaces that connect humans with machines. Our work involves the creation of membrane switches, membrane buttons, and PCB-based membrane keypads that fit specific device requirements.

Manufacturers use multilayer construction. The top layer has printed graphics, often protected by polyester or polycarbonate films. Beneath that lies a spacer layer, a printed circuit, and tactile elements like metal domes.

We also provide end-to-end support from concept to assembly, including prototyping, circuit integration, and mass production. Our work goes beyond simply manufacturing products; we solve design challenges and ensure seamless interaction between users and devices.

How Does a PCB Based Membrane Keypad Work?

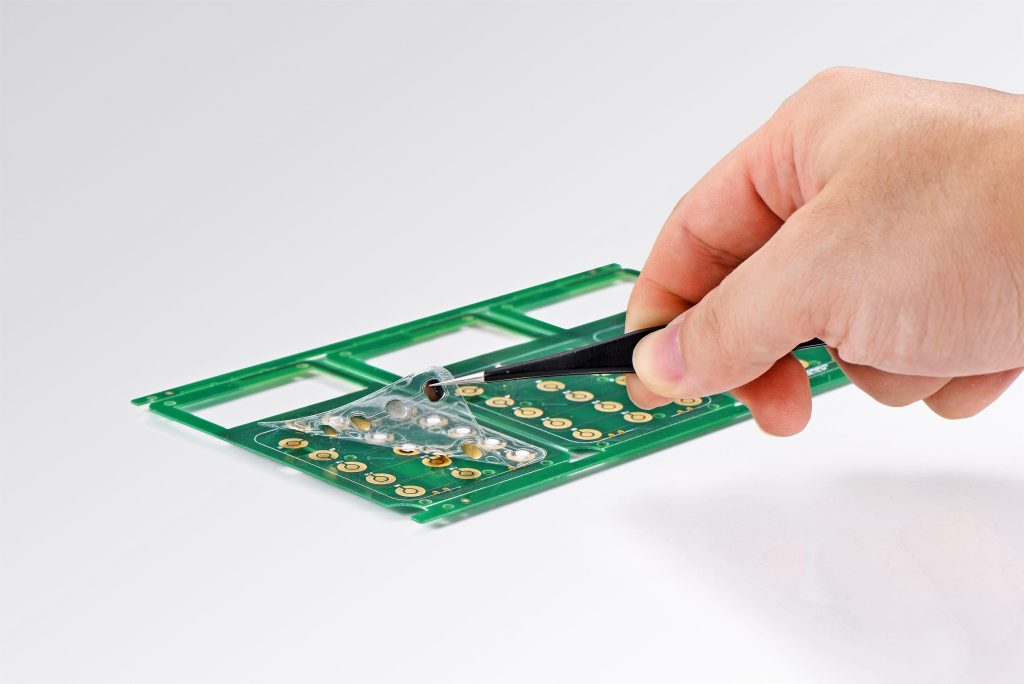

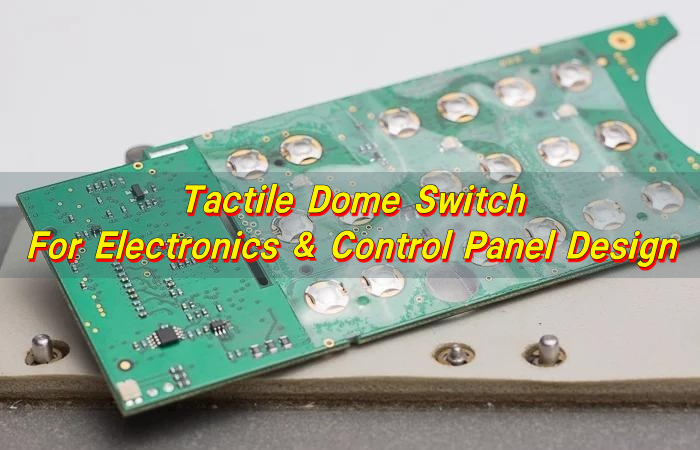

PCB based membrane keypad integrates the circuit layer directly onto a printed circuit board. This allows for more reliable electrical contact and stronger mechanical support.

When a user presses a key, a metal dome or conductive pad collapses, completing the circuit on the PCB. The electrical signal travels instantly to the controller or microprocessor, activating the intended function.

Unlike flexible membrane circuits, PCB-based keypads use rigid substrates. This improves durability, prevents warping, and enhances soldering reliability for LED indicators or electronic components.

The process is clean and efficient:

- The membrane layer provides the tactile surface and label graphics.

- The dome layer delivers the tactile feedback.

- The PCB layer ensures accurate electrical function.

Together, these layers form a responsive, long-lasting keypad that handles thousands, sometimes millions, of actuations with consistent performance.

Why Choose a PCB Membrane Keypad Over a Flexible Type?

When it comes to design selection, engineers often compare PCB membrane keypads with flexible types. Each has its place, but the PCB option stands out in several ways.

- First, rigidity. A PCB membrane keypad has a stable structure that resists bending and deformation. This makes it ideal for applications requiring steady performance over time.

- Second, reliability. The electrical traces are etched onto a solid board, not printed on a flexible film. This minimizes wear and ensures accurate signal transmission even under heavy use.

- Third, component integration. PCB keypads can include LEDs, resistors, or microchips directly on the board. That simplifies the circuit design and shortens the assembly process.

- Additionally, the PCB layer improves heat resistance, which is valuable in industrial or automotive environments. Flexible keypads can degrade faster under high temperature or humidity.

- Lastly, the tactile feel of a PCB membrane keypad often feels crisper and more controlled. Users can feel each press clearly—something that builds trust in every touch.

While flexible types are great for lightweight or portable devices, PCB-based versions deliver professional-grade stability for demanding products.

What Makes Membrane Switches Reliable in Harsh Use?

Reliability is the most critical factor in membrane switches. These components must perform perfectly even in dusty, humid, or high-temperature environments.

Quality membrane switch panel uses multiple sealing layers that prevent moisture and dust intrusion. PET films and adhesives form tight bonds to ensure no air gaps exist.

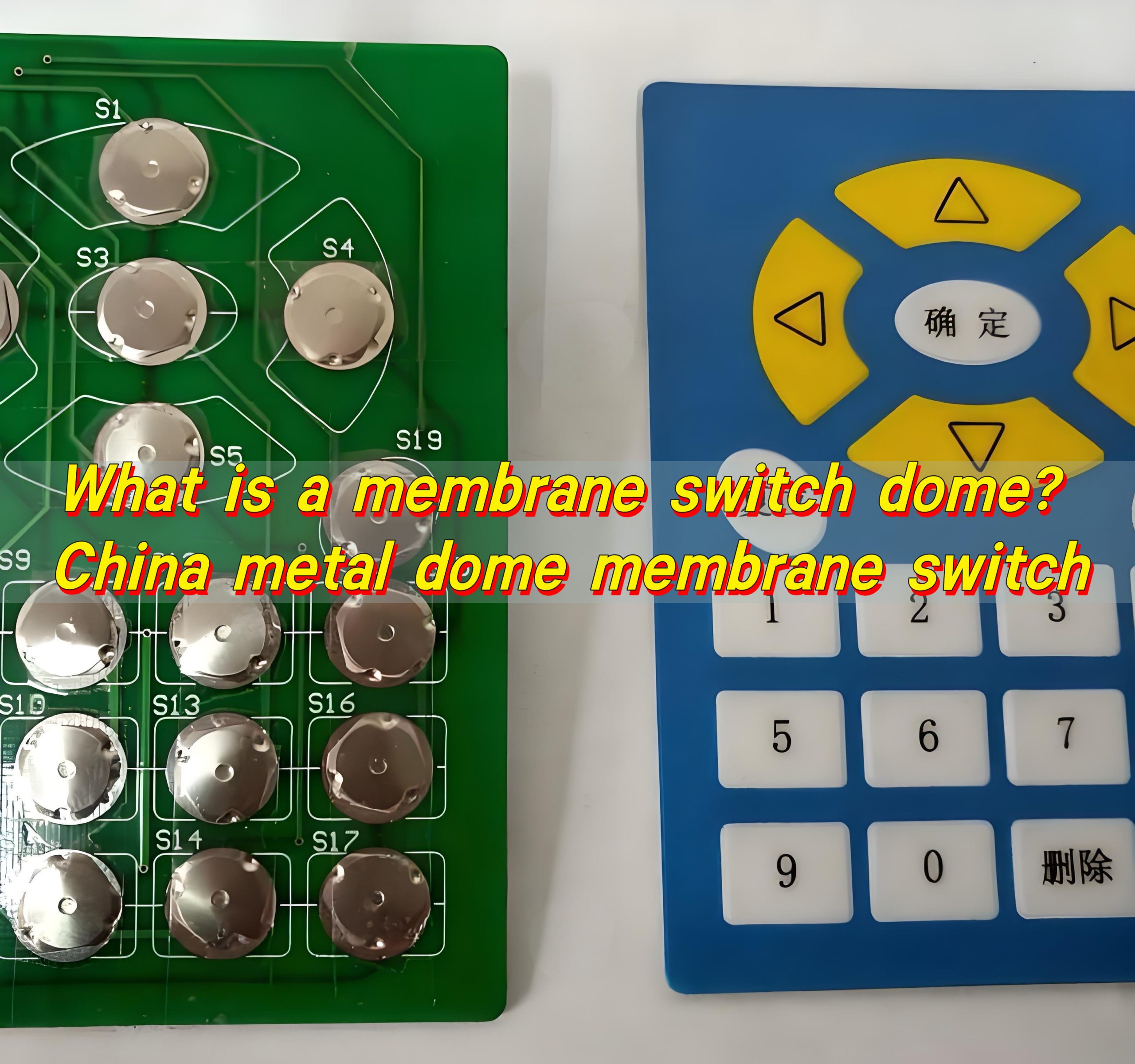

Tactile domes—often stainless steel or nickel-plated—provide consistent feedback and conductivity. They are tested to endure over one million cycles.

Conductive inks used on circuits are another factor. Silver or carbon inks maintain conductivity even after prolonged use. Combined with a PCB base, the circuit remains stable, and the connection stays accurate.

In short, membrane switches are designed for durability, precision, and reliability. They’re not fragile—they’re built for real-world environments.

How Are Membrane Switch Panels Made?

Creating a membrane switch panel is a detailed process involving design, material selection, and precision assembly.

- Design Phase – We’ll start with the circuit schematic and user interface layout.

- Material Selection – The top layer uses polyester or polycarbonate film for durability and clarity. Beneath it, spacer and circuit layers are made from PET or PCB materials.

- Printing and Circuit Formation – Silver, carbon, or copper inks are screen-printed on the circuit layer to create conductive pathways.

- Dome Placement – Metal domes or other tactile elements are placed precisely where keypress feedback is required.

- Lamination – Layers are bonded together with pressure-sensitive adhesives to form a single panel.

- Testing – Each switch is tested for electrical continuity, tactile response, and environmental resistance.

Some panels include LED indicators, backlight films, or EMI shielding. Others integrate connectors for direct attachment to PCBs.

Which Materials Improve Membrane Buttons’ Durability?

The materials used in membrane buttons directly determine their lifespan and performance.

- Polyester (PET) is a top choice. It provides excellent flexibility, resistance to wear, and long-term stability.

- Polycarbonate (PC) is another strong material, valued for its hardness and clear printing quality.

- Metal domes, typically stainless steel, provide tactile feedback and conductivity.

- Conductive inks—like silver or carbon—deliver low resistance and steady performance. Combined with precise curing temperatures, they ensure long-term circuit integrity.

- Protective coatings, UV films, and adhesive quality also matter. The better the adhesive, the longer the keypad can resist peeling, moisture, and vibration.

Together, these materials turn a keypad membrane into a robust component capable of functioning flawlessly even in demanding environments.

How Long Can a Quality Keypad Membrane Last?

Quality keypad membrane can last from one to five million actuations per key, depending on its design and materials.

Metal dome keypads often surpass this lifespan, maintaining stable tactile response even after years of use. The reason lies in their mechanical structure and the resilience of stainless steel domes.

Environmental factors also play a role. Panels designed with UV protection and sealed adhesives can last longer in outdoor or industrial applications.

In many cases, a well-designed PCB membrane keypad remains functional for more than ten years. That reliability saves costs in the long run and ensures every press feels consistent, even after years of use.

What’s the Difference Between Membrane Switches and Membrane Buttons?

Though often used interchangeably, membrane switches and membrane buttons are not exactly the same.

Membrane switch is the entire electrical system that includes layers, circuits, adhesives, and tactile elements. It’s responsible for sending electrical signals when pressed. Membrane button, on the other hand, is one key or part of that switch.

In simple terms: every membrane button is part of a membrane switch, but not every switch focuses on buttons alone. Some use sliders or pressure zones.

How to Select the Right PCB & Membrane Keypad Manufacturer?

Choosing the right PCB & membrane keypad manufacturer is a vital decision. The right partner ensures your design becomes a reliable, production-ready solution. Here’s what to look for:

- 1. Experience and Specialization: Look for manufacturers with a proven record in custom keypads and membrane switch panels..

- 2. Quality Certifications: Check for ISO9001:2015 and RoHS compliance.

- 3. Engineering Support: Professional manufacturer doesn’t just follow instructions—they help optimize designs for production efficiency and performance.

- 4. Material Control: They should use premium films, adhesives, inks, and metal domes.

- 5. Prototyping and Testing: Reliable companies offer prototyping and full testing before mass production.

- 6. Fast Delivery and Competitive Cost: Lead times and cost control are crucial.

- 7. After-Sales Support: Strong after-sales system ensures technical issues or updates are handled quickly.

For more information or custom solutions, contact sales@best-membraneswitch.com

Tactile Dome Switch – For Electronics & Control Panel Design

Our tactile dome switch delivers crisp tactile feedback and reliable precision actuation, with industrial-grade durability for small device control panels. Custom sizes available for your design needs. What is a tactile dome switch? A tactile dome switch is a compact switching component used in electronic interfaces where clear feedback matters. It delivers a sharp, physical ...

Custom Membrane Keypads – Industrial Grade Custom Design

Our custom membrane keypads are engineered with industrial-grade durability, waterproof & oil-resistant for control panels. Fully customizable sizes, layouts and symbols for your device needs. What is a custom membrane keypad? A custom membrane keypad is a low-profile input interface designed for a specific product, device, or operating environment. It combines printed circuits, tactile layers, ...

What is a membrane switch dome? China metal dome membrane switch

A membrane switch dome is a small but powerful part of many modern input devices. You see it in factory control panels, medical tools, handheld devices, POS systems, and more. It looks simple, yet it shapes how a product feels, responds, and lasts over time. What Is a Dome Switch Membrane Keyboard? A dome switch ...

Contact us online