Membrane tactile push button, Tactile membrane switch push button

Membrane tactile push button, Tactile membrane switch push button

The membrane tactile push button has become a staple in modern electronics, combining slim design with reliable performance. Whether you see it in household appliances, medical equipment, or industrial machines, this button provides a simple yet precise way to trigger commands.

What is a membrane switch?

Membrane switch is a low-profile electrical switch created by layering flexible materials. It typically includes polyester or polycarbonate layers, conductive traces, and a printed circuit interface. Unlike mechanical switches that rely on bulky parts, membrane switches focus on thin and lightweight construction.

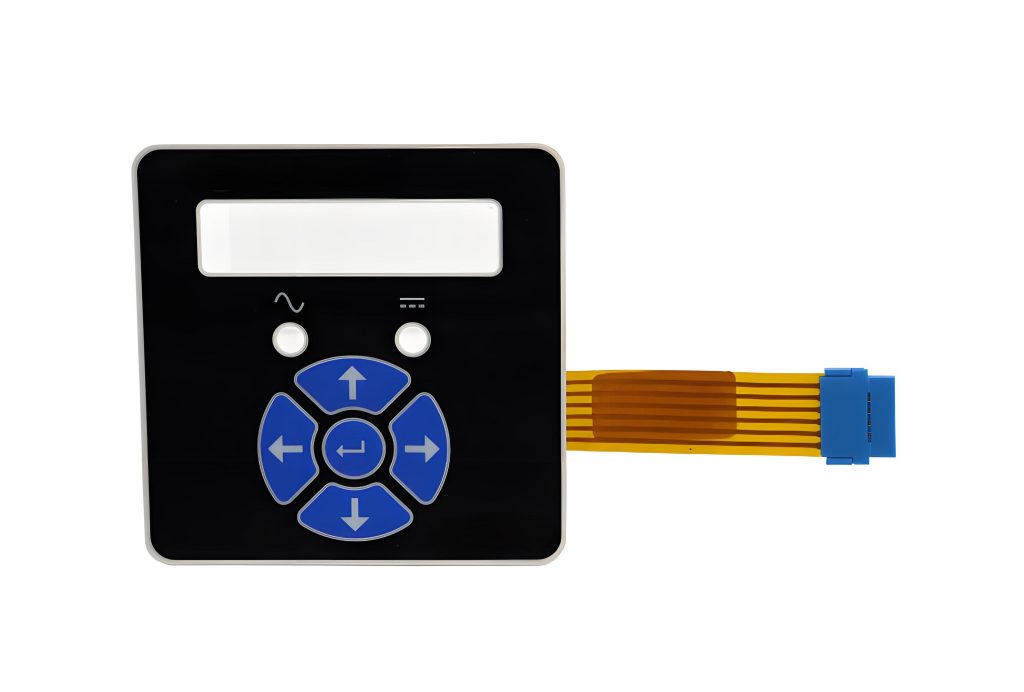

The most recognizable part of a membrane switch is the graphic overlay. This is the visible surface that users press. Beneath it are spacer layers, conductive circuits, and contact pads. When a user presses the overlay, the layers come together to close the circuit, sending the signal.

These switches are not only space-saving but also resistant to moisture, dust, and contaminants. That is why they are highly preferred in sectors where cleanliness and reliability matter.

What do membrane switches look like?

Membrane switches are usually flat and sleek in appearance. The front side often displays symbols, icons, or lettering to indicate the function of each button. Some versions integrate LEDs or backlighting to improve visibility in dim conditions.

Designs can vary depending on the product. For instance, a microwave oven panel has a full numeric keypad with icons, while a medical device may have simple navigation arrows. Tactile versions also include a dome-shaped structure beneath the overlay, which gives a noticeable feedback when pressed.

How does a membrane button work?

The function of a membrane tactile push button relies on layers working together. When you press the surface, the force pushes down a dome or spacer layer until it meets the conductive path. At that moment, the circuit closes, and the signal travels to the controller.

Tactile membrane switches go a step further by adding feedback. Users feel a “snap” when pressing the button, confirming the input. This is achieved through a dome switch, usually made of metal or polyester. The dome not only gives feedback but also improves the lifespan of the switch.

This simple yet effective mechanism is why these switches are found in such a wide range of devices, from everyday gadgets to advanced industrial systems.

What is a membrane switch used for?

Membrane switches have broad applications across industries.

- Medical equipment: Diagnostic machines, monitoring systems, and handheld devices.

- Home appliances: Ovens, washing machines, and refrigerators.

- Industrial control panels: Machinery operation, HVAC control, and factory automation.

- Consumer electronics: Remote controls, keyboards, and calculators.

- Military and aerospace equipment: Rugged devices needing sealed interfaces.

The versatility comes from their flexibility, thin profile, and customizable design, making them a practical choice for nearly any electronic product.

What is the difference between membrane and tactile switches?

Membrane switches are typically flat, soft, and silent. They may or may not include tactile feedback.

Tactile switches, often referred to as “tact switch smt smd,” are small mechanical components mounted on a PCB. They create a distinct click sound and feel when pressed.

The main difference lies in the structure and user experience. Membrane switches are slim and sealed, which protects against contamination. Tactile switches, meanwhile, deliver a sharper feedback that many users prefer in control applications.

For projects where space and sealing are critical, membrane switches shine. But if the goal is a crisp and mechanical feel, tactile switches might be the better choice.

What is the difference between tactile and membrane buttons controller?

Tactile button controller uses discrete tactile switches mounted on a circuit board. Each press activates a physical component, producing a direct response. These are common in gaming controllers and handheld electronics.

Membrane button controller integrates multiple buttons within a single layered structure. The surface is usually a flat sheet with printed graphics. Presses activate circuits hidden beneath.

The difference can be seen in thickness, response, and durability. Tactile controllers often feel sturdier and are easier to replace, while membrane controllers save space and allow flexible layouts.

What are the different types of tactile push buttons?

Tactile push buttons come in several variations, each suited for different uses:

- Standard tactile switches: Small, square, or rectangular switches mounted on PCBs.

- Low-profile tactile switches: Designed for slim devices where space is tight.

- Sealed tactile switches: Built with protective layers to resist moisture and dust.

- Illuminated tactile switches: Integrated with LEDs for visibility in dark conditions.

- Long-travel tactile switches: Provide a deeper press with more pronounced feedback.

Each type addresses specific requirements. For example, sealed versions are perfect for medical and outdoor equipment, while illuminated ones are ideal for dashboards and handheld devices.

What are the best tactile switches?

The “best” tactile switch depends on the application. For consumer electronics, reliability and compact size matter most. In industrial settings, sealed and rugged versions perform better. Gaming devices often prioritize switches with sharp feedback and long lifespans.

What are the disadvantages of touch switches?

While membrane and tactile switches both offer many advantages, they are not without limits. Touch switches that rely solely on capacitive sensing can sometimes trigger false inputs if exposed to water or dirt. Also, users may miss the physical feedback that tactile or membrane buttons provide.

That said, most of these challenges can be minimized with good design. Adding tactile domes, sealing against moisture, or combining technologies often resolves the issue.

Conclusion:

The membrane tactile push button is an essential component in modern interface design. It delivers a balance of durability, compactness, and usability that fits industries ranging from healthcare to consumer electronics.

If you are seeking a professional supplier for tactile membrane switch push buttons, Yu An Electronics is your trusted partner. With certifications including ISO9001, ISO13485, IATF16949, and AS9100D, we deliver top-quality solutions across medical, automotive, and aerospace industries.

For more details, or to discuss your project requirements, contact us at sales@best-membraneswitch.com

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

Contact us online