PCB Surface Mount Tactile Membrane Switches, PCB membrane switch

PCB Surface Mount Tactile Membrane Switches, PCB membrane switch

What Are PCB Surface Mount Tactile Membrane Switches?

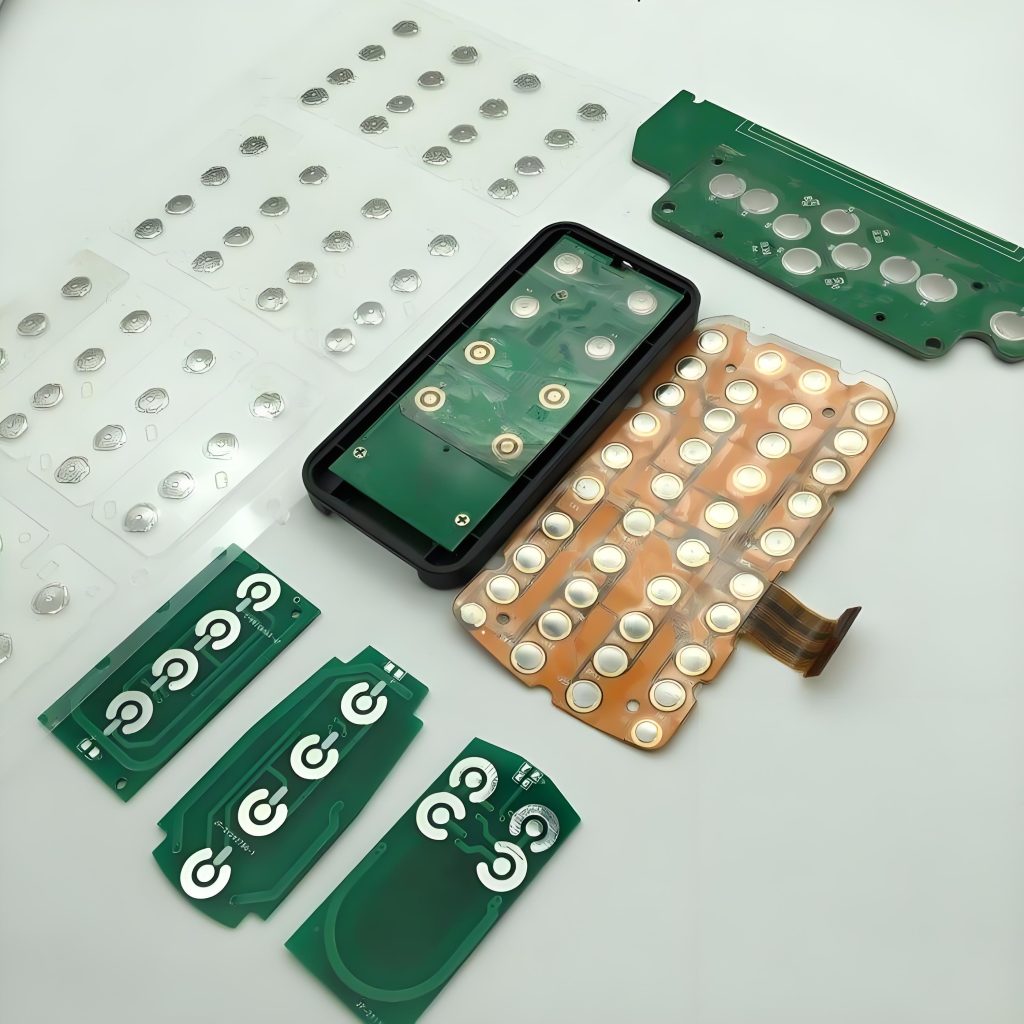

A PCB surface mount tactile membrane switch is a type of electronic switch mounted directly onto a printed circuit board. Unlike traditional mechanical switches, membrane switches are composed of flexible layers. These layers include a printed circuit, a spacer, and a top membrane layer with printed graphics.

The “tactile” aspect refers to the physical feedback users feel when pressing the switch. This click-like response ensures precise control, even in devices with small buttons.

The surface mount design allows these switches to attach directly to the PCB without additional hardware. This provides a stable electrical connection, reduces space usage, and simplifies assembly.

The flexibility of these switches makes them ideal for a wide range of electronics, from compact handheld devices to large industrial control panels.

How Do Tactile Membrane Switches Enhance Control Panels?

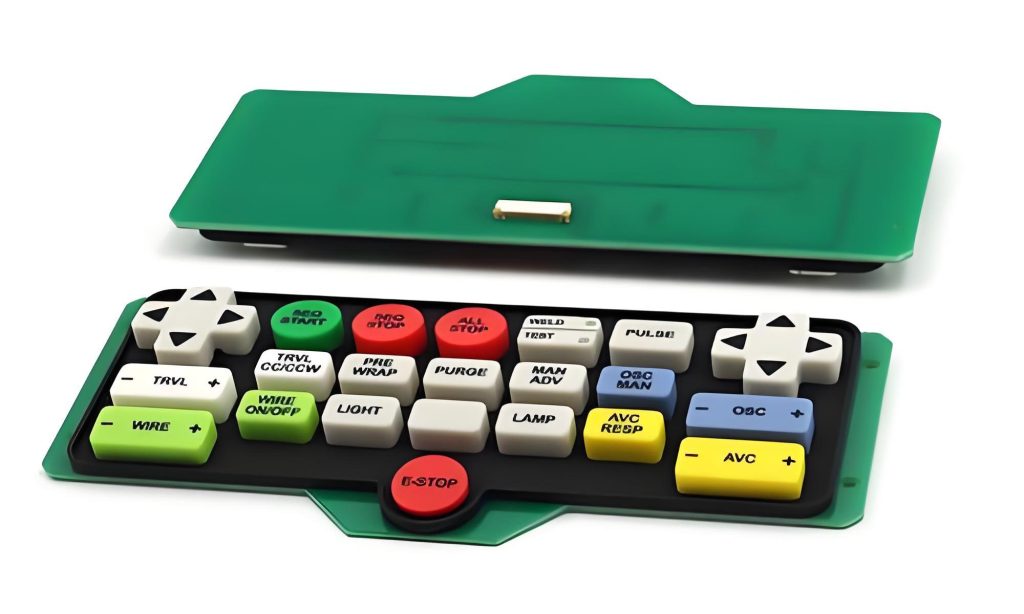

Control panels are the interface between humans and machines. Using tactile membrane switches can dramatically improve this experience.

First, these switches offer a precise, responsive feel. Users can operate them quickly without looking, thanks to the tactile feedback.

Next, they are resistant to dust, moisture, and spills when combined with proper sealing. This ensures reliable performance even in harsh environments, like manufacturing floors or outdoor equipment.

In addition, the graphics, colors, and layout of the membrane can be customized. This creates visually intuitive panels that improve user interaction.

Top Benefits of PCB Surface Mount Switches

Why choose PCB surface mount switches instead of traditional mechanical switches? The advantages are clear:

- Compact Design: The surface mount structure eliminates the need for bulky mounting hardware, freeing up valuable PCB real estate.

- Enhanced Durability: With fewer moving parts exposed, these switches are less prone to wear and tear.

- Customizable Tactile Feedback: The resistance and feel of the switch can be adjusted according to application requirements.

- Seamless Integration: Soldering directly onto the PCB simplifies the assembly process and ensures consistent electrical performance.

- Cost-Efficiency: Fewer components and reduced assembly steps can lower production costs significantly.

How PCB Surface Mount Boosts Switch Performance?

Surface mount technology not only simplifies assembly but also enhances electrical performance. By reducing the distance between the switch contacts and the PCB traces, signal integrity improves. This leads to faster response times and reduces the likelihood of signal errors.

Thermal performance also benefits. Since the switch is soldered directly to the board, heat dissipation is more efficient. This is particularly important in high-speed or high-power devices.

Moreover, surface mount switches offer improved resistance to mechanical stress. Vibrations or shocks are less likely to cause disconnection, ensuring longevity and reliability. For industries where uptime is critical, this reliability is invaluable.

Why Use a PCB Mount Switch in Compact Devices?

Compact devices demand components that save space without compromising functionality. PCB mount switches are perfect for this.

Handheld gadgets, remote controls, and wearable electronics particularly benefit from the small footprint. Even in devices as thin as 5mm, tactile feedback can be preserved, providing a satisfying user experience.

Additionally, these switches are lightweight. In applications like drones or portable medical equipment, every gram counts. PCB surface mount tactile membrane switches deliver performance without adding bulk.

Where Are PCB Mount Switches Commonly Used?

These switches have a wide range of applications. Their versatility makes them ideal for many industries:

- Consumer Electronics: Smartphones, remote controls, and gaming controllers rely on tactile feedback for intuitive operation.

- Medical Devices: Reliable tactile switches are crucial in diagnostic equipment, monitoring devices, and portable instruments.

- Industrial Equipment: Keypads and control panels in harsh environments require switches that resist dust, moisture, and mechanical stress.

- Automotive Systems: Dashboard controls, infotainment systems, and climate controls benefit from low-profile, reliable switches.

- Aerospace Applications: Compact and lightweight switches reduce overall system weight while maintaining durability in extreme conditions.

The common factor across these uses is the demand for reliability, longevity, and consistent tactile response.

How PCB Surface Mount Switches Cut Assembly Costs?

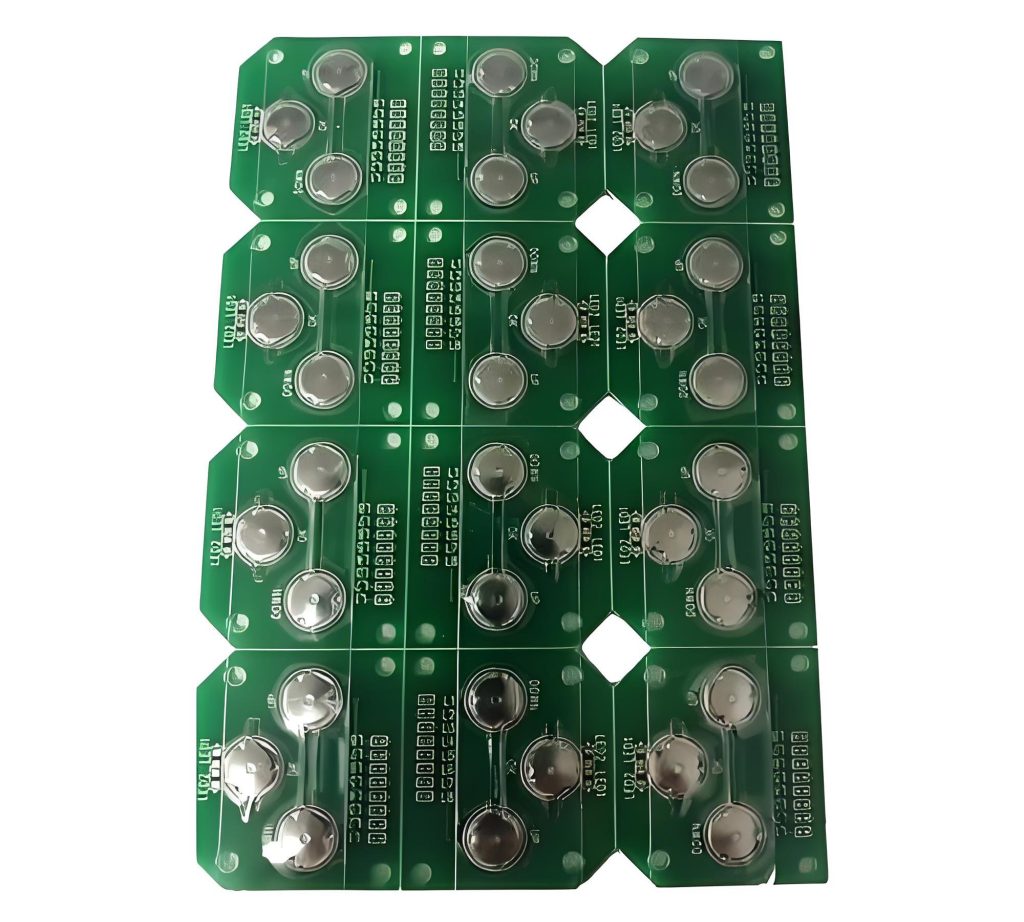

Cost savings arise naturally when using PCB surface mount tactile membrane switches. Here’s why:

- Fewer Components: Since the switch mounts directly on the PCB, additional brackets or connectors are unnecessary.

- Simplified Soldering: Surface mount assembly is faster and compatible with automated pick-and-place machines.

- Reduced Labor: Fewer assembly steps mean lower labor costs.

- Lower Defect Rates: Direct PCB attachment reduces misalignment and connection errors, minimizing rework.

- Smaller PCB Size: Compact designs reduce material costs per board.

Over the lifetime of production, these factors can result in substantial cost efficiency without compromising product quality.

Can You Easily Mount Tactile Membrane Switches on PCBs?

Yes, the mounting process is straightforward. PCB surface mount tactile membrane switches are designed for seamless integration. The key steps include:

- PCB Design: Ensure the switch footprint aligns with the board layout.

- Soldering: Most switches are compatible with standard SMT processes.

- Testing: After assembly, electrical continuity and tactile response should be verified.

Modern automated assembly lines handle surface mount switches efficiently, allowing high-volume production with consistent quality. Even smaller production runs can benefit, thanks to standardized footprints.

Which PCB Surface Mount Type Suits Industrial Designs Best?

Industrial applications often require switches with enhanced durability and high tactile reliability. Multi-layer membrane switches with reinforced top layers excel in these conditions.

Choosing the right type involves:

- Actuation Force: Devices with heavy use may need stiffer tactile feedback.

- Sealing Level: IP-rated designs prevent dust and moisture ingress.

- Temperature Tolerance: Industrial machinery often operates in extreme conditions, requiring heat-resistant membranes.

- Longevity: Switches rated for millions of cycles ensure minimal maintenance.

When properly selected, these switches maintain consistent performance even under challenging industrial conditions.

How to Maintain a Tactile Membrane Switch for Longevity?

Maintenance is simple but crucial to extend switch life. Key practices include:

- Clean Regularly: Wipe the surface with a soft, dry cloth to prevent dust buildup.

- Avoid Excessive Force: Pressing beyond the rated actuation force can reduce lifespan.

- Monitor Environmental Conditions: Keep devices within recommended temperature and humidity ranges.

- Inspect Connections: Ensure solder joints remain secure over time.

- Replace When Necessary: A worn switch should be replaced promptly to maintain functionality.

Routine care ensures the tactile feedback remains consistent and the device continues performing optimally.

Conclusion:

PCB surface-mount tactile membrane switches enhance user experience, improve control panel functionality, and reduce assembly costs. Whether in consumer electronics, industrial equipment, medical devices, or automotive systems, these switches deliver performance that meets stringent requirements.

Reach out today to explore our range of switches and learn how we can support your next project. Contact: sales@best-membraneswitch.com

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online