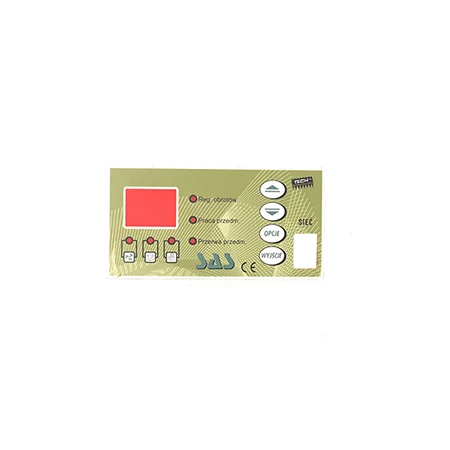

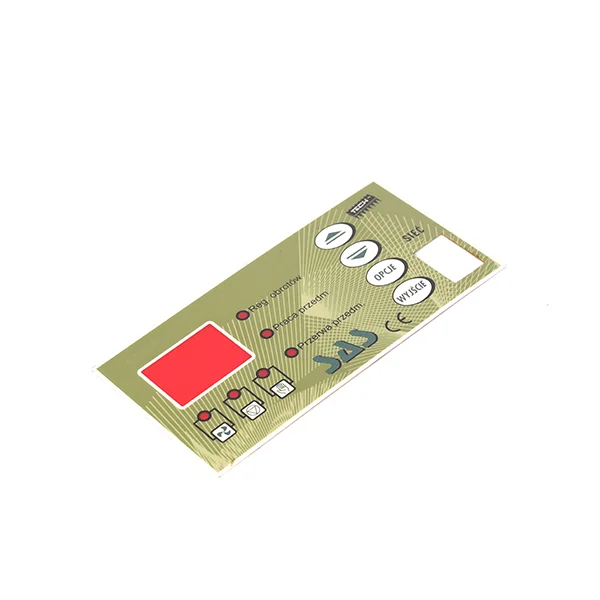

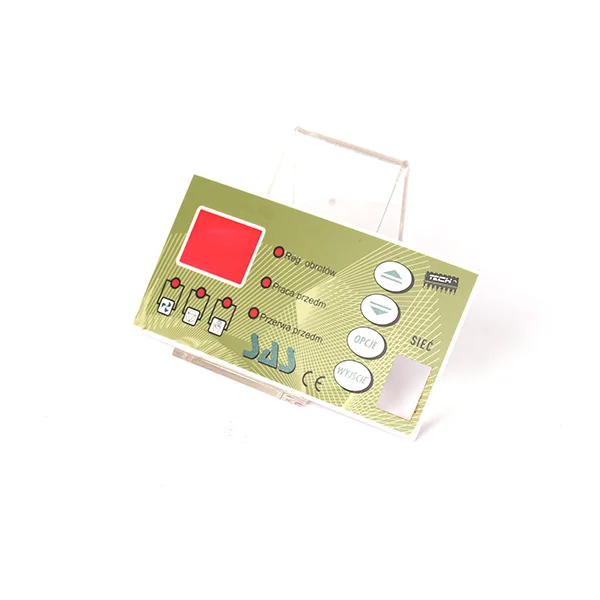

Graphic Overlay Keypad in Micro Pile Machine Case

Yu An Electronics is an integrated industry and trade company that specializing in the manufacturing of various tactile membrane switches, our products range from the simplest membrane switches such as PET membrane switch, FPC membrane switch and PCB membrane switch. Meanwhile, some special backlit lighting products also available in Yu An, for example: LED membrane switch, light guide film tactile membrane switches, fiber optical products. In addition, epoxy products and digital printed products also are the optional.

Our service:

PET, FPC, PCB, LED, LGF, Fiber optical membrane switches available

Waterproof, UV protection design, EDS design, ITO film anti-static

Assemble LED, sensors, resistors

Fiber optical backlit, EL backlit, LGF backlit design

-

PC:0.175mm, 0.25mm, 0.375mm, 0.5mm, 1.0mm, 1.5mm, 2.0mm

-

PET thickness:0.13 mm, 0.15 mm, 0.18 mm, 0.188 mm, 0.2 mm, 0.25 mm, 0.28 mm

-

TPU:0.2mm, 0.3mm

-

PMMA0.5mm, 1.0mm, 1.5mm, 2.0mm:0.5mm, 1.0mm, 1.5mm, 2.0mm

| Basic Parameters of Tactile Membrane Switch | |

| Max. Panel size | 600*800mm |

| Max. Panel size (with emboss) | 400*500mm |

| Paste | silver paste, carbon paste |

| Ink color | red, black, blue, white, yellow, green, purple, etc |

| Trace width | 0.15-0.20mm |

| LED spec. | 0402, 0603, 0805, 1210 |

| Wire length | Per customer requirements |

| Waterproof class | IP65 |

| Connector | female pin, male pin |

| Metal dome types | triangle, for-legs, circle |

| Trip force (metal dome) | 280g, 340g, 450g |

| Travel (metal dome) | 0.35-0.71 |

| Diameter (metal dome) | 8.4mm, 10mm, 12.2mm |

| Surface treatment (metal dome) | gold plating, nickle plating, stainless |

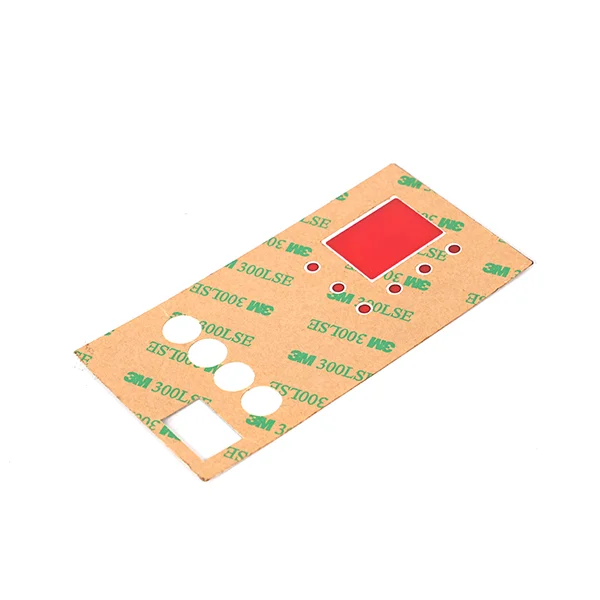

| Back adhesive | DSMS, 3M, SOKEN |

| Citcuit board option | FPC, PCB, Aluminum |

| Panel material | PET, PC, TPU, PMMA |

What are Advantages of Digital Printed Membrane Switches?

Different with screen printing method, digital printed technology offers some additional benefits, which including:

- High-tech printing techniques

- Beautiful and gradient colors

- Cost-efficient (prototype and small orders)

- High precision and detail

- Quick turnaround (prototype and small orders)

- Customization

Customer Background:

Terra Foundations, a key player in the foundation engineering industry, specializes in manufacturing cutting-edge micro pile machines. Their operational model involves assembling components sourced from various suppliers to create high-performance micro pile machines. With a strategic focus on revitalizing their brand image, Terra Foundations aimed to redesign the control interface overlay, envisioning a sleek gradient color scheme transitioning from vibrant chartreuse to pale lime green. Despite extensive inquiries with current suppliers, none could achieve the desired gradient effect through traditional screen printing methods. Following a recommendation from an industry peer, Terra Foundations approached our company for a solution.

Project Challenge:

The primary challenge revolved around the limitations of traditional screen printing methods, which proved incapable of delivering the desired gradient color for the micro pile machine overlay. Identifying digital printing technology as the most viable alternative, we faced the task of overcoming industry-wide difficulties in seamlessly blending colors to meet Terra Foundations’ precise design requirements.

Our Solutions:

Through close collaboration with our engineering team and a series of meticulous tests, we innovatively devised a method to achieve a flawless transition of the gradient color from vibrant chartreuse to pale lime green. The successful sample production that followed garnered high praise from Terra Foundations’ team, expressing utmost satisfaction with the visually striking gradient colors on the micro pile machine overlay.

Customer Feedback:

We expedited the production process when got the approval from customers and delivering the finished product within 2 weeks to Terra Foundations. The incoming inspections and functionality tests conducted by the Terra Foundations team were not only prompt but also thorough, confirming that all digital printed membrane switches featured consistent colors and adhered precisely to the design specifications without any deviations. This positive outcome not only solidified Terra Foundations’ satisfaction but also translated into several subsequent orders. Some initial sample orders seamlessly transitioned into mass production, underscoring the success of our collaboration in meeting Terra Foundations’ unique design aspirations for their micro pile machine control interfaces. This accomplishment showcases the prowess of digital printed membrane switches in addressing the specific aesthetic needs of Terra Foundations’ products.

Contact us online