Translucent Silicone for Button – Custom Silicone Buttons

Translucent Silicone for Button – Custom Silicone Buttons

What is a translucent silicone?

Translucent silicone is a soft, flexible rubber that lets light pass through, but not fully like glass. It sits somewhere between transparent and opaque. This unique look makes it perfect for applications where backlighting is essential—like keypads that glow in the dark or indicator buttons on smart home panels.

More than looks, it performs. Translucent silicone rubber can handle temperature changes, moisture, dust, and repeated pressing. It doesn’t crack, fade, or lose shape easily. That’s why it’s used widely in buttons and switches today.

And yes—it’s safe. Translucent silicone is non-toxic, hypoallergenic, and often meets FDA or ROHS standards. For electronic products, especially wearables or handhelds, safety and feel matter just as much as functionality.

How are translucent buttons made?

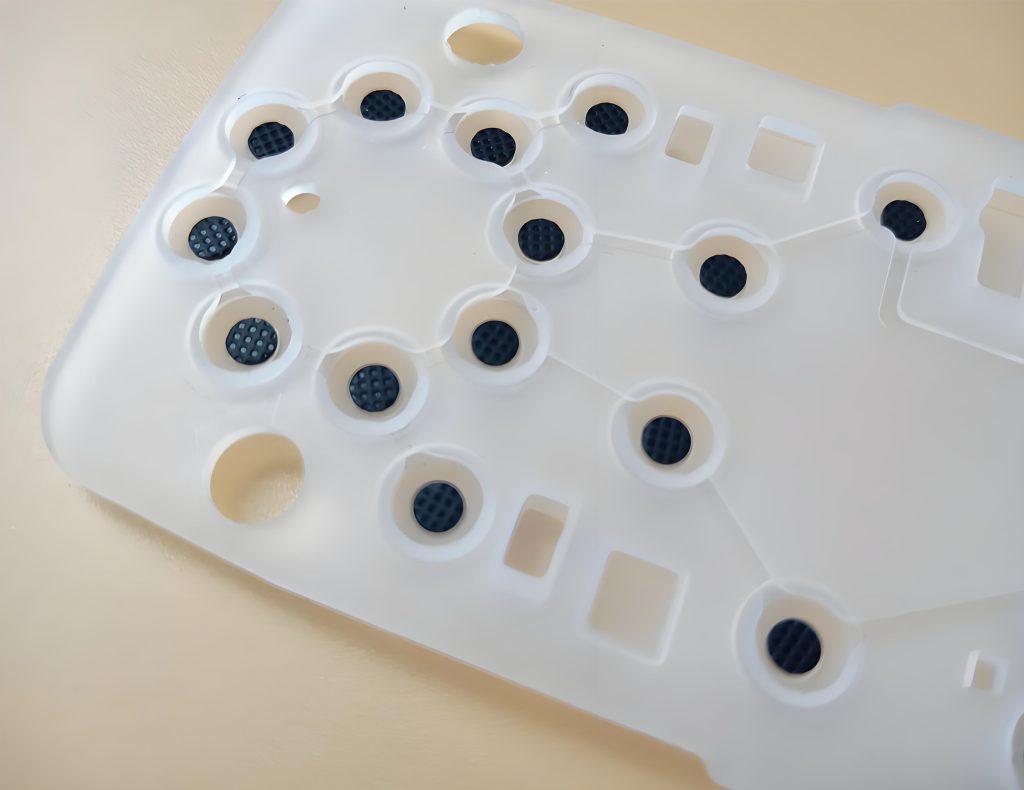

The making of translucent silicone buttons is a high-precision process that balances durability and design. It starts with raw silicone rubber, often in a translucent base form. Custom pigments can be added for colored translucency, but even then, the light still passes through.

The rubber is then molded using compression or injection molding. Molds are designed with the button shape, travel distance, and tactile feel in mind. These molds may include parts for a silicone membrane layer that adds protection and improves user experience.

If lighting is part of the design, the button base may include an LED source below it. The translucent silicone helps the light shine through evenly, giving it a glow that’s easy on the eyes. This is especially useful for small push button switches or control panels used at night.

After molding, buttons go through curing, trimming, and testing to make sure they meet the spec. Some even get printed legends or conductive pads underneath for circuit contact.

How do silicone buttons work?

Silicone buttons are more than just soft rubber caps. They’re engineered parts designed for precise response. Underneath every silicone button pad, there’s typically a conductive contact point. When you press the button, it bends the silicone dome downward. This dome snaps onto a circuit below, completing the signal.

Once pressure is released, the soft tactile button springs back into shape, ready for the next use. It’s a clean, quiet, and fast mechanism. Unlike mechanical switches that click loudly, silicone membrane buttons are more subtle, yet still responsive.

That’s why they’re used in thousands of devices. From remote controls and microwave panels to industrial equipment and medical tools, silicone buttons for electronics offer both comfort and reliability.

What is a silicone membrane switch?

Silicone membrane switch is a low-profile interface that uses layers of silicone to activate circuits. It’s thinner than mechanical keyboards but more durable than traditional overlays.

When paired with translucent buttons, the membrane switch becomes even more advanced. Light can pass through, legends can be illuminated, and designs can be made cleaner and sleeker. Plus, the sealed surface protects the electronics beneath from moisture, dust, and oils.

They’re also incredibly customizable. Need a small button switch with bright backlighting and clear icons? Silicone membrane switches have you covered.

What is translucent rubber?

Translucent rubber refers to any rubber-like material that allows light through but is not fully see-through. In electronics, translucent silicone rubber is the most common type. It blends the flexibility of traditional rubber with light diffusion qualities.

The “translucent” effect isn’t just for style. It helps improve visual clarity, especially in dark environments. Think of a glowing power button on your speaker or a light-up keypad on a vending machine.

Besides good looks, it resists yellowing and degradation better than many plastics. It doesn’t absorb water, is UV-resistant, and stays soft for years. That’s a big reason why buttons and switches in outdoor or medical devices use it.

What is RTV silicone vs silicone?

RTV stands for “Room Temperature Vulcanizing.” This type of silicone cures at room temperature and is often used in sealing, bonding, or small part casting.

In button making, RTV silicone can be used for quick prototypes or low-volume custom jobs. However, for mass production, cured silicone rubber sheets or injection-grade silicone are more common. These are more consistent in quality and offer better performance under stress.

So, while all RTV is silicone, not all silicone is RTV. For silicone buttons, especially those with silicone membrane button designs, industrial-grade silicone offers better tactile performance and long-term durability.

What are the uses of a silicone keypad?

They appear anywhere a human needs to interact with a machine. This includes:

- Medical devices: Easy to disinfect, soft touch, and durable.

- Consumer electronics: Remote controls, game pads, calculators.

- Industrial panels: Control systems for machines or safety equipment.

- Automotive systems: Dashboard controls, push button toggle switch units, seat adjusters.

- Wearables: Smartwatches, fitness trackers, and more.

You can choose smooth, matte, or glossy finishes. You can also decide on translucent buttons for backlighting or branding.

And they’re easy to integrate. A silicone button pad can sit over a PCB and seal the surface against moisture. No need for separate buttons, gaskets, or covers.

Why use translucent silicone rubber in electronics?

It is a rare material that combines form and function: its light-diffusing properties lend elegance to user interfaces, its softness enhances comfort, its chemical resistance extends device life, and its flexibility enables endless customization.

It turns static buttons into interactive, glowing controls. And it does so without adding mechanical complexity or design bulk.

It’s also energy efficient. Because the silicone spreads light smoothly, fewer LEDs are needed for the same visual impact.

Conclusion:

Whether you’re designing a smart home device, an industrial controller, or wearable tech, custom silicone buttons made from translucent silicone can elevate your product.

Its soft touch, long lifespan, and visual appeal make it a smart investment. And with custom molding, you’re not limited—you’re empowered.

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online