What is a Membrane Switch Panel? A Complete Guide

What is a Membrane Switch Panel? A Complete Guide

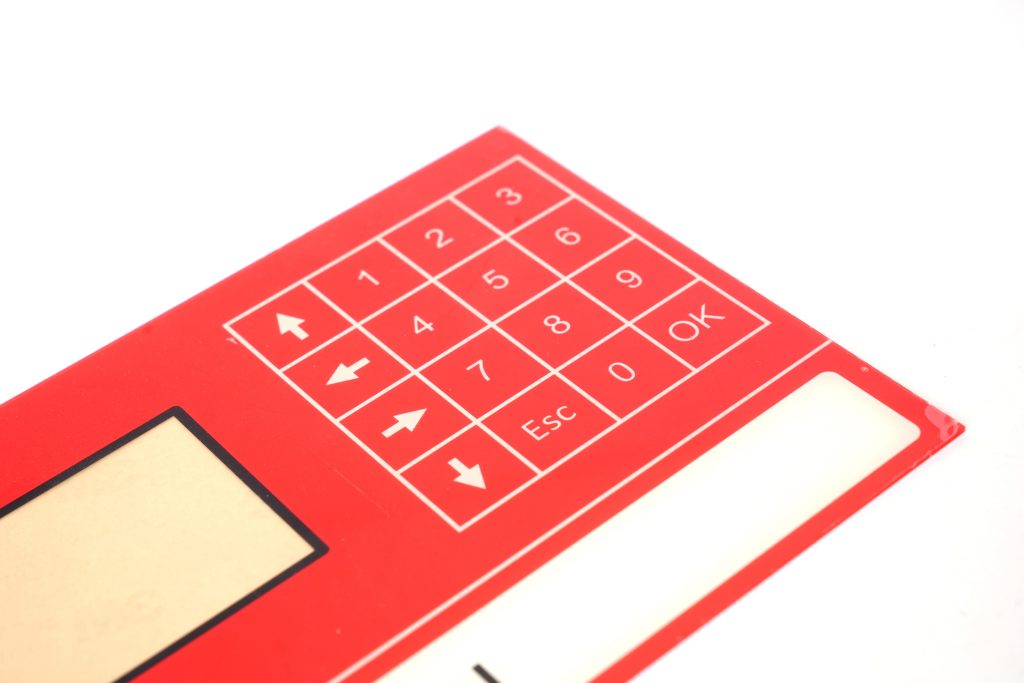

Membrane switch panel is a thin, beautiful electronic component that integrates key functions, indicator components and instrument panels. It consists of a panel, an upper circuit, an isolation layer and a lower circuit. When pressed, the upper circuit contacts and the lower circuit are connected. When released, the contact rebounds and the circuit is disconnected.

The membrane switch panel has good waterproof, dustproof, oil-proof and harmful gas erosion resistance, long service life and easy installation. It is widely used in electronic communications, medical equipment, industrial control and household appliances.

What is a Membrane Panel Switch?

Membrane panel switch is a type of user interface that allows users to send commands to an electronic device through a flexible, multi-layered switch. Unlike mechanical switches, which use moving parts to create a connection, membrane switches rely on pressure to activate a circuit.

These panels are made up of several layers, including:

- Graphic Overlay: The visible surface where the user interacts with buttons.

- Spacer Layer: Keeps the circuit open until pressure is applied.

- Circuit Layer: Conductive pathways that trigger commands when connected.

- Adhesive Layer: Bonds everything together securely.

Because of their design, membrane switches are thin, lightweight, and resistant to moisture, dust, and chemicals. Their simplicity and efficiency make them a top choice for various industries.

Membrane vs. Mechanical Switch: Which is Better?

When comparing membrane switches to mechanical switches, it’s important to consider the application. Both have their strengths, but membrane switch panels dominate many industries due to their durability and ease of maintenance.

Why Choose a Membrane Switch Panel?

- Longer Lifespan: No moving parts mean less wear and tear, resulting in millions of actuations before failure.

- Dust & Water Resistance: Their sealed design makes them perfect for harsh environments, unlike mechanical switches that can trap dirt and moisture.

- Compact & Lightweight: Ideal for space-saving applications such as medical devices and portable electronics.

- Customizable: Can be tailored with backlighting, embossing, and different tactile responses for a better user experience.

- Cost-Effective: Lower production costs compared to mechanical switches, making them the preferred choice for mass production.

Why Choose a Mechanical Switch?

- Tactile Feedback: Mechanical switches provide a satisfying “click”, making them ideal for gaming keyboards and industrial control systems.

- Higher Actuation Force: Reduces accidental presses, which is beneficial in specific applications.

For most modern applications, membrane switch panels win due to their superior durability, space efficiency, and lower maintenance needs.

How to Make a Membrane Panel Switch?

The manufacturing process of a membrane switch panel requires precision and expertise.

- Step 1: Design the Layout

Every membrane switch panel manufacturer starts with a detailed design. The button placement, circuit paths, and graphic overlay are planned to ensure smooth operation.

- Step 2: Printing the Circuit Layer

Conductive ink, usually silver or carbon-based, is screen-printed onto a flexible polyester film to create electrical pathways.

- Step 3: Adding the Spacer & Adhesive Layers

A spacer layer is added to keep the circuit open until the button is pressed. Industrial-strength adhesives hold the layers together.

- Step 4: Applying the Graphic Overlay

The top layer is printed with symbols, text, and branding. Embossing or coating can enhance durability and usability.

- Step 5: Testing & Assembly

Every switch panel is tested for electrical conductivity, durability, and responsiveness before being shipped to customers.

What are the Advantages of Membrane Switch Panels?

Membrane switches offer game-changing benefits in various industries. Their unique structure and functionality make them a preferred choice over traditional switch technologies.

- Unmatched Durability: Unlike mechanical switches that can break or wear down over time, membrane switch panels last longer due to their sealed, non-mechanical design.

- Superior Environmental Resistance: These panels are dust-proof, moisture-resistant, and chemical-resistant, making them perfect for medical, military, and industrial environments.

- Customization & Versatility: Membrane switches can be tailored to any application. Options include backlighting, antimicrobial coatings, different textures, and various tactile responses.

- Easy Maintenance: With a smooth, sealed surface, cleaning is simple, reducing downtime in hospitals, factories, and commercial settings.

Where are Membrane Switches Used?

Membrane switch panels have transformed multiple industries due to their versatility and reliability. Some common applications include:

- Medical Equipment: Used in hospital devices, diagnostic tools, and patient monitoring systems.

- Industrial Machinery: Found in control panels for heavy equipment, automation systems, and manufacturing processes.

- Consumer Electronics: Common in microwaves, remote controls, and security keypads.

- Military & Aerospace: Rugged designs withstand extreme conditions, vibrations, and high-pressure environments.

- Marine Applications: Water-resistant membrane switch panels ensure reliable operation in boats, submarines, and offshore installations.

Why Choose a Custom Membrane Switch Panel?

Custom membrane switch panel allows for:

- Branded Designs: Customize with logos, colors, and unique button layouts.

- Enhanced Functionality: Add LED backlighting, raised buttons, or anti-bacterial coatings.

- Perfect Fit: Ensures seamless integration into your product, improving ergonomics and aesthetics.

Why Use a Backlit Membrane Switch Panel?

Backlit membrane switch panels enhance visibility and usability. They are commonly used in low-light environments, such as:

- Medical Equipment: Ensures clear button visibility during emergency procedures.

- Automotive & Aerospace: Used in dashboards and aircraft cockpits.

- Industrial Machines: Operators can see controls even in dark environments.

Backlighting options include LEDs, fiber optics, and electroluminescent films, each offering energy-efficient illumination.

How to Repair a Membrane Switch Panel?

Although membrane switch panels are durable, occasional malfunctions may occur.

- Cleaning the Surface: Dust or debris can cause unresponsiveness. Use isopropyl alcohol to clean the panel.

- Checking for Damage: Look for signs of wear, cracks, or peeling.

- Conductive Ink Repair: If the circuit is broken, conductive silver ink can restore connectivity.

- Professional Repair: For complex issues, contact a membrane switch panel manufacturer for expert servicing.

Conclusion:

Membrane switch panel is an invaluable technology across many industries. It outshines mechanical switches with its durability, water resistance, and customizable features. Whether you need a custom switch panel, a backlit design, or a rugged solution for extreme environments, membrane switches deliver unmatched performance and reliability.

If you need a trusted membrane switch panel manufacturer, custom solutions, or expert guidance, contact sales@best-membraneswitch.com

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

Contact us online