What is an Elastomer Rubber Switch and How Does It Work

What is an Elastomer Rubber Switch and How Does It Work

You use an elastomer rubber switch when you want a button that feels soft. It also snaps back fast. This switch uses bendy materials like silicone rubber. You feel a clear click each time you press it. Many people pick this switch because it costs less than other kinds. You can find it in things you use every day. For example, it is in remote controls, electronic toys, and medical equipment.

| Application Type | Examples |

|---|---|

| Consumer Electronics | Remote controls, electronic toys, appliances |

| Industrial Devices | Industrial control equipment |

| Medical Devices | Medical equipment interfaces |

| Military Applications | Military control systems |

Key Takeaways

- Elastomer rubber switches feel soft and give a clear click. This makes them easy for people to use. – These switches are made from strong silicone rubber. They can handle heat, chemicals, and water. This helps them last a long time. – The switches work by bending a bendy layer. This layer connects or disconnects a circuit. It gives good feedback to the user. – Compression molding is used to make these switches. This keeps them strong and helps them keep their shape. – Elastomer rubber switches are great for things like remote controls and medical tools. They give comfort and work well for a long time.

Elastomer Rubber Switch Basics

Definition

An elastomer rubber switch is a button made with soft, bendy material. When you push the button, the rubber bends down. This lets the circuit underneath connect. That means you can turn things on or off or send signals. You see this switch in remote controls, toys, and medical devices. People like this switch because it gives a soft click and lasts a long time.

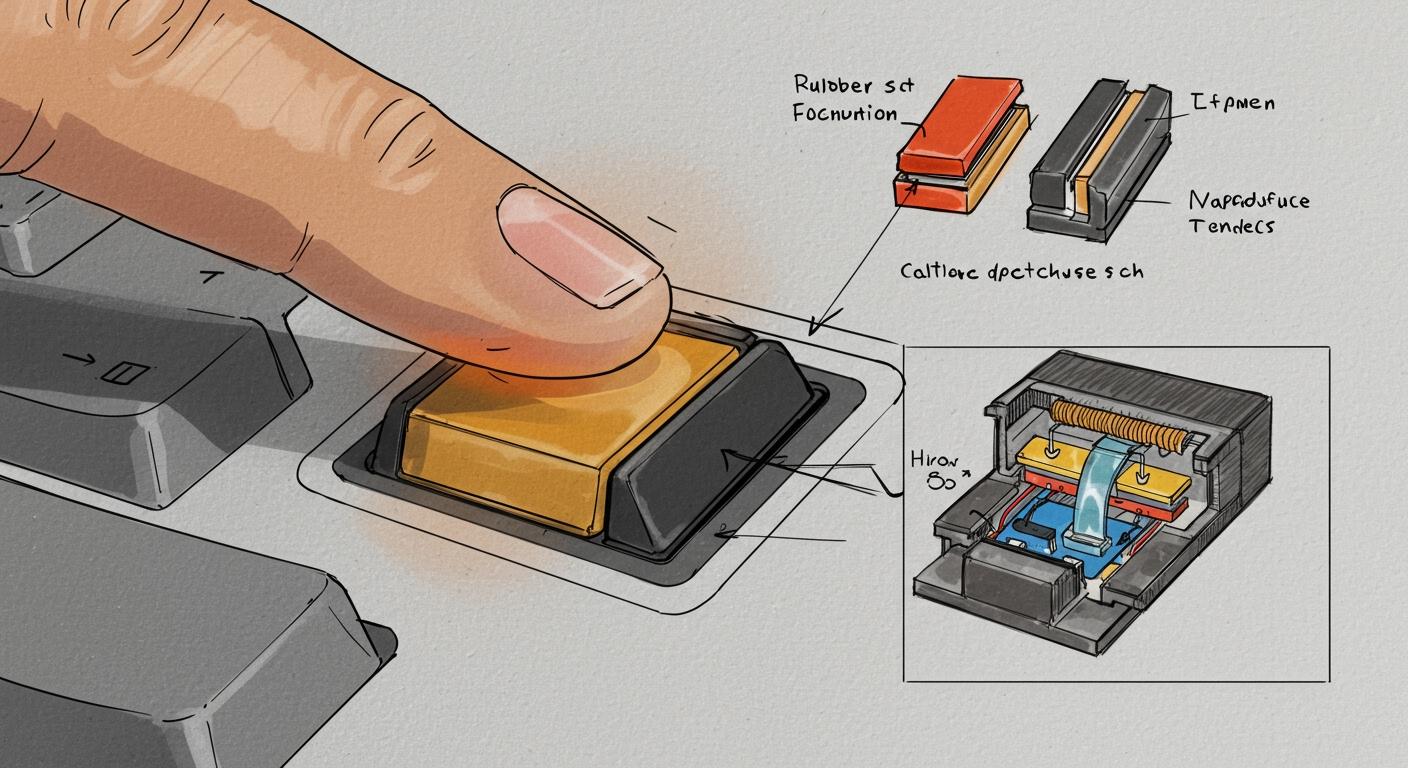

Key Components

Each elastomer rubber switch has important parts. These parts help the switch work well every time. Here is a table that shows the main parts and what they do:

| Component | Function |

|---|---|

| Piezoresistive pattern | Changes resistance to control the circuit when pressed. |

| Dielectric elastomer actuator | Moves up and down to open or close the circuit. |

| Acrylic dielectric elastomer | Is the base and helps the switch move. |

| Inkjet-printed carbon black | Makes a path for electricity when you press the switch. |

| Conductive grease | Helps connect different parts of the switch better. |

| Top layer (dome/tactile layer) | Gives the button a soft, bouncy feel when pressed. |

| Graphic overlay | Shows symbols or words so you know what each button does. |

| Membrane layer | Holds patterns that finish the circuit when pressed. |

| Bottom layer (electronic circuit) | Has the main electronic parts that make the switch work. |

Tip: The top layer is the part you touch. It gives you a nice click and makes the switch easy to use.

Materials Used

Most elastomer rubber switches use silicone rubber. Silicone rubber is good because it can handle heat, sunlight, and chemicals. It keeps its shape and works in many places. Here are some important things about silicone rubber:

- Works in temperatures from -60°C to +200°C.

- Does not get damaged by sunlight or ozone.

- Does not react with most chemicals.

- Safe for food and medical devices.

- Keeps water out and stays flexible.

Silicone rubber comes in different types. LSR is good for making detailed shapes. HTV is strong and lasts a long time. VMQ is used for general things. FVMQ is used where there are lots of chemicals.

To make an elastomer rubber switch, you must mix the rubber well and cure it right. Good mixing helps the switch work the same every time. Proper curing keeps the rubber from breaking down too soon. Most switches use rubber with a hardness between 30 and 60 durometers. This makes the button feel just right—not too hard or too soft.

Note: Makers check that the materials are safe and good quality. They look at cost, how the switch fits in devices, and if it will last a long time.

How Elastomer Rubber Switches Work

Working Mechanism

When you press the switch, something simple happens. The button has soft rubber on top of a circuit. Under the button, there is a flex wall. This wall bends when you push down. It gives some resistance. You feel a gentle snap when it bends. The snap helps you know the switch is working.

The switch changes shape when you press it. The elastomer bends and moves. This connects or disconnects the circuit below. The shape change also affects electricity in the switch. A dielectric elastomer actuator uses voltage to move. This movement stretches or squeezes strips inside. The strips change resistance and control electricity.

Here is a table that shows how the switch works:

| Mechanism | Description |

|---|---|

| Dielectric elastomer actuators | Use voltage to move and change the circuit. |

| Resistance change | Stretching strips raises resistance and can break the circuit. |

| Voltage application | High voltage stretches strips and makes tiny cracks that stop electricity. |

When you press the switch, the shape change affects electricity. The actuator inside gets squeezed by voltage. This makes the film thinner and wider. It changes how electricity flows. The switch has a film between two electrodes. When you add voltage, charges gather at the electrodes. This squeezes the film and changes its area. That helps the switch work.

Tactile Feedback

You feel a soft click when you use the switch. This feeling comes from the soft materials. The flex wall bends and pushes back. It gives you feedback when you press the button. This feedback tells you the switch worked.

- Soft materials react to your touch and give a gentle click.

- Some switches have liquid metal inside. This helps the button move fast and return to shape.

- Joule heating can happen in the materials. When you press, the button can warm up a little. This changes how the material feels.

Tactile feedback is important. It helps you know the switch turned something on or off. The flex wall makes sure you feel a snap. You do not have to guess if the button worked.

Compression Molding

Manufacturers use compression molding to make these switches. This process shapes the rubber and gives it strength. Here are the main steps:

- Put uncured rubber into a heated mold.

- Get the machine and tools ready and clean.

- Measure the right amount of rubber for the mold.

- Put the rubber into the mold cavity.

- Close the mold and press hard. This shapes and cures the rubber.

- Open the mold and take out the finished part.

- Trim extra material and clean the part.

Compression molding helps the switch in many ways:

- The process makes the rubber strong and stable.

- The switch keeps its shape and works well in tough places.

- Fewer defects mean the switch lasts longer.

- This method is cheap and works for many switches.

- The process can meet special needs, like handling chemicals or extreme heat.

You get a good switch because compression molding controls shape and quality. The switch works for many uses and always gives a soft click.

Advantages and Disadvantages

Benefits

Elastomer rubber switches have many good points. You feel a soft click when you press the button. This lets you know the switch is working. The switch is strong and lasts a long time. The rubber dome switch keeps out water, dust, and chemicals. It works where other switches might not.

Here is a table that compares rubber dome switches and membrane switches:

| Advantage | Rubber Dome Switch | Membrane Switches |

|---|---|---|

| Tactile Feedback | Superior tactile feedback | Limited tactile feedback |

| Durability | High durability and impact resistance | Less durable |

| Environmental Resistance | Excellent sealing against water, dust, chemicals | Limited environmental resistance |

| Application Suitability | Great for industrial, medical, and automotive uses | Best for thin, cost-effective devices |

Rubber dome switches work well in tough places. They keep out moisture and dust. The materials also block oils and chemicals. This makes them good for many devices.

Drawbacks

There are some bad points to rubber dome switches. The rubber can get weak over time. Heat, air, and chemicals can make it lose strength. Sometimes, bubbles or air pockets form inside. These can make the switch break sooner.

Common problems are:

- Bubbles and air pockets that make it weaker.

- Low strength from bad material or not enough curing.

- Warping if the switch is not cured right.

Here is a table that shows some ways the switch can fail:

| Failure Mode | Cause of Failure |

|---|---|

| Chain Scission | Long-term exposure to heat, oxygen, or chemicals |

| Oxidative Degradation | Environmental factors that weaken the rubber |

| Bubbles and Voids | Air pockets that lead to leaks or early failure |

| Insufficient Tensile Strength | Poor material choice or curing process |

| Warpage | Structural issues from improper curing |

You should check rubber dome switches often in harsh places. This helps you find problems before the switch stops working.

Comparison to Other Switch Types

Rubber Dome Switch vs. Elastomer Rubber Switch

You may wonder how these switches are different. Both use soft materials, but they feel different when pressed. A rubber dome switch gives a strong, clear click. The dome collapses fast when you push it. You feel a rounded bump and a quick snap. An elastomer rubber switch feels smoother and quieter. The flexible material absorbs sound, so it is not loud. You get a softer touch and less pushback.

Here is a table that shows how the feedback feels:

| Switch Type | Tactile Feedback Characteristics |

|---|---|

| Elastomer Rubber Switch | Softer and smoother feedback, quieter, absorbs sound because it is flexible. |

| Rubber Dome Switch | More clear and strong click, rounded bump, softer than many mechanical switches, quick collapse. |

| Membrane Switch | Usually less feedback, often feels flat and not very responsive. |

A rubber dome switch works well when you need a clear click. You find it in medical tools, factory controls, and keyboards. An elastomer rubber switch is best for devices needing a soft touch and quiet use.

Elastomer Rubber Switch vs. Membrane Switch

You see membrane switches in thin and cheap devices. A membrane switch uses flat layers and does not give much feedback. The button feels flat and not very responsive. You do not feel a strong click. Membrane switches are easy to make and fit in small spaces. You can make many membrane switches quickly and for less money.

An elastomer rubber switch is better when you want grip and strength. You get more feedback and a button that lasts longer. The flexible rubber does not wear out fast and feels nice to use.

Tip: Pick a membrane switch for simple controls and small spaces. Choose an elastomer rubber switch for a better feel and longer life.

Applications

You find rubber dome switches in many places. They work in medical gear, factory controls, automation, trains, planes, navigation, computer keyboards, and office tools. The rubber dome gives a strong click and lasts a long time.

An elastomer rubber switch is used in remote controls, toys, and devices needing a soft touch. It fits well in products that need quiet and comfort.

A membrane switch is good for devices where cost and space matter most. You see membrane switches in appliances, control panels, and gadgets with little room. The thin design helps them fit in tight spots.

- Membrane switches are best for:

- Cheap devices

- Products with little space

- Fast making needs

- Elastomer rubber switches work well for:

- Devices needing to last long

- Products needing grip and feedback

You should think about what you need before picking a switch. Each type is good for different uses.

Now you know how an elastomer rubber switch works and why it is special. The switch has a silicone button, elastic webbing, and a spot that lets electricity flow. When you press the button, the webbing bends and connects the circuit. This gives you a clear signal that the button was pressed. These switches are used in many things like remote controls and medical tools. They are comfy to use and last a long time.

| Key Point | Description |

|---|---|

| Basic Structure | Has a silicone button, key mat, elastic webbing, button travel, and a spot for electricity to pass. |

| Functionality | Pressing the button bends the webbing and makes the electric spot touch the PCB, so the button press is counted. |

| Actuation Factors | How hard it pushes back, the weight, how hard the material is, webbing thickness, and coatings all change how it works. |

New designs let you change the switch to fit what you need. You can even add it to screens and sensors more easily now. If you want to learn more about switches, look at these links:

| Title | Description |

|---|---|

| How Does a Switch Work? | Find out how switches connect things and help networks work. |

| Demystifying Ethernet Switches: Key Concepts | Learn the difference between managed and unmanaged switches. |

| Further Reading | Evolutionary trends in pluggable optical modules, How to Build a Miniature Network Monitor Device, The 10 Most Important Products of the Decade |

Tip: Try using an elastomer rubber switch in your next project if you want something that feels good and works well.

FAQ

What makes a silicone rubber keypad switch different from other switches?

Silicone rubber keypad switches feel soft when you press them. They give strong feedback, so you know you pressed a button. The flexible material lasts a long time. These switches work in many devices because they keep out water and dust.

How do you clean a keypad without damaging it?

Use a soft cloth with mild soap to clean your keypad. Do not use strong chemicals. Wipe the surface gently. Let the keypad dry before you use it again.

Why do keypads feel different on each device?

Each keypad is made to fit its device. Some need a firm press, others feel soft. The shape, thickness, and material change how the keypad feels.

Can you replace a keypad if it stops working?

Most keypads can be replaced. Look at your device’s manual for help. Many keypads snap in and out. You might need a small tool to take out the old one and put in a new one.

Where do you find silicone rubber keypad switches in everyday life?

You see these switches in remote controls, toys, and medical devices. They help you use machines easily. You also find them in home appliances and industrial equipment.

Tip: If your keypad feels sticky or slow, try cleaning it before you get a new one.

| Device Type | Example Use of Keypad |

|---|---|

| Remote Control | TV channel selection |

| Medical Equipment | Patient monitoring controls |

| Toys | Game input buttons |

| Industrial Machine | Operation panels |

| Home Appliance | Microwave oven controls |

Membrane Switch with LED, Customized LED Membrane Switches

Our LED membrane switches provide bright, even backlighting, long lifespan and reliable performance for control panels in dark environments. What are LED membrane switches? LED membrane switches are advanced user interface panels that combine a flexible membrane circuit with integrated light sources. The structure looks simple from the outside. Inside, it is a layered system ...

Click Touch Membrane Switch, Premium Membrane Switch with Tactile Click Response

Our click touch membrane switch provides clear tactile click response, stable performance and long service life, ideal for control panels requiring obvious touch feedback. What is a click touch membrane switch? A click touch membrane switch is a pressure-activated interface designed to deliver a clear, physical response each time a key is pressed. Unlike flat ...

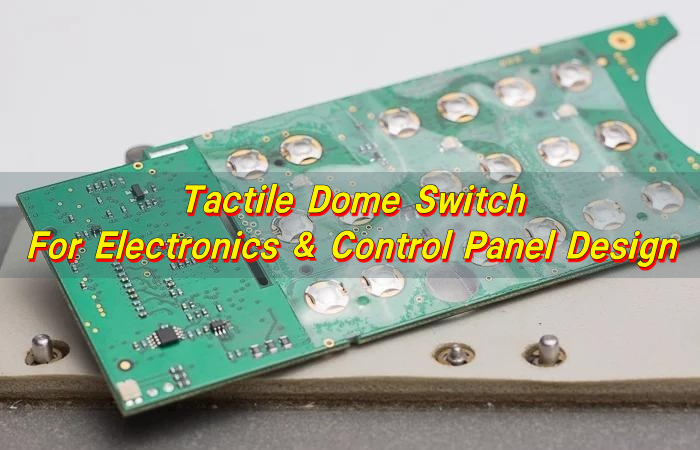

Tactile Dome Switch – For Electronics & Control Panel Design

Our tactile dome switch delivers crisp tactile feedback and reliable precision actuation, with industrial-grade durability for small device control panels. Custom sizes available for your design needs. What is a tactile dome switch? A tactile dome switch is a compact switching component used in electronic interfaces where clear feedback matters. It delivers a sharp, physical ...

Contact us online