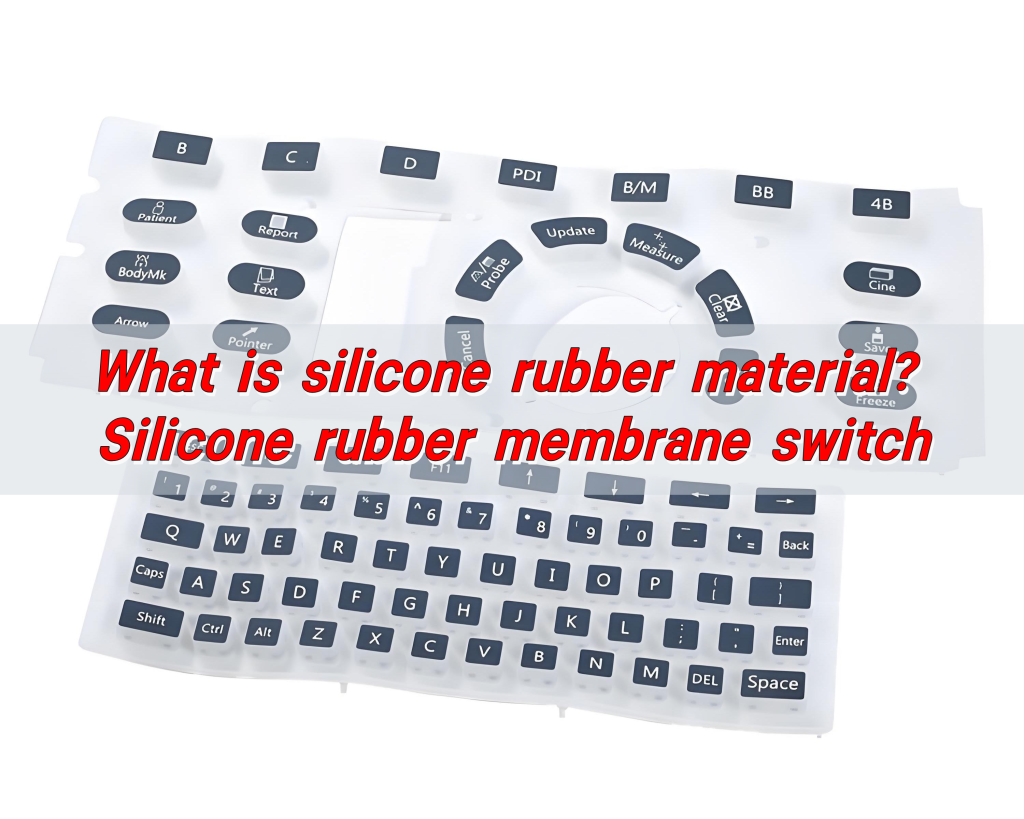

What is silicone rubber material? Silicone rubber membrane switch

What is silicone rubber material? Silicone rubber membrane switch

Silicone rubber material is a polymer elastomer with silicon-oxygen bonds as the main chain. It is temperature-resistant from -60℃ to 230℃, soft and insulating. The membrane switch made of it can be turned on instantly when pressed, rebounds neatly, is waterproof, dustproof and oil-resistant, making home appliances, automotive and medical panels thin and reliable.

What is silicone rubber material?

Silicone rubber is a synthetic elastomer made from silicon, oxygen, carbon, and hydrogen. Unlike most rubber types made from petroleum-based sources, silicone rubber is derived from silica (sand), giving it a unique chemical structure.

Its chemical backbone includes alternating silicon and oxygen atoms, giving it unmatched heat and cold resistance. This also makes it UV-resistant, non-toxic, and hypoallergenic. Because of its special composition, silicone rubber material can easily be molded into various forms—from thin membranes to thick buttons—perfect for electronic devices.

What are the main silicone rubber properties?

Silicone rubber properties stand out in nearly every category. Here’s why:

- Heat Resistance: It can endure temperatures from -60°C up to 230°C.

- Flexibility: It stays soft and elastic, even in icy conditions.

- Chemical Resistance: Silicone rubber doesn’t degrade easily when exposed to oils, solvents, or chemicals.

- Waterproof: Its structure makes it ideal for sealing applications. No wonder it’s used in kitchen appliances, medical gear, and waterproof switches.

- Electrically Insulating: Safe around circuits, it prevents accidental shocks and failures.

- Biocompatibility: Medical-grade silicone is safe for skin contact and even implants.

These silicone rubber material properties make it incredibly versatile. From flexible silicone rubber membrane switches to robust rubber keypads, it performs where other materials fail.

What are the disadvantages of silicone rubber?

Although silicone rubber has many advantages, it also has some minor problems.

- Tear Resistance: It’s not the strongest in resisting cuts or tears. However, proper reinforcement solves this in most designs.

- Compression Set: Over time, it may not return to its original shape if kept compressed too long.

- Cost: Compared to basic rubber types, silicone rubber material price is slightly higher.

Most of these limitations are manageable through improved designs or adding reinforcement layers. In most real-world uses, the benefits far outweigh the drawbacks.

What is the difference between silicone rubber and normal rubber?

Normal rubber (like natural or synthetic rubber) is great for general use. It’s cheaper and works fine for everyday products like tires or gloves. But it breaks down faster when exposed to heat, sun, or chemicals.

Silicone rubber, on the other hand, lasts longer. It doesn’t crack in the sun. It doesn’t melt under heat. It doesn’t break down when touched by grease or solvents. Its silicone rubber material composition is more stable and predictable, especially in demanding environments.

So, when performance matters—like in a rubber dome switch inside a medical device or a silicone rubber membrane switch in an outdoor control panel—silicone rubber wins.

Why is silicone rubber so expensive?

The silicone rubber material cost often raises eyebrows, especially when compared to standard rubber. Here’s why:

- Raw Materials: It’s made from highly purified silica, requiring a complex refining process.

- Production Process: Silicone rubber is manufactured under controlled conditions to ensure purity and reliability.

- Performance Grade: You’re not paying for just rubber. You’re paying for heat resistance, chemical resistance, and lifespan.

- Specialty Use: Many silicone rubber applications are for critical environments—medical, automotive, aerospace—where quality is non-negotiable.

Yes, the price is higher. But the durability it provides can eliminate replacements and failures, saving money in the long term.

How long does silicone rubber last?

Under normal conditions, silicone rubber can last 10–20 years or more. Even in outdoor environments exposed to sunlight, ozone, or rain, it holds strong. That’s why it’s trusted in automotive gaskets, medical implants, and rugged industrial switches.

Its resistance to wear and aging means fewer replacements. And in sensitive equipment like silicone rubber membrane switches, that reliability is gold.

Why choose silicone rubber for membrane switches?

Membrane switches need to be slim, flexible, and responsive. They also need to survive harsh use and environmental abuse.

Silicone rubber membrane switches combine soft-touch feedback with durable construction. They’re perfect for control panels, remote devices, and even medical equipment. Here’s why:

- Tactile Feedback: The rubber dome switch delivers a responsive, satisfying click.

- Water & Dust Resistance: Ideal for outdoor or industrial environments.

- Custom Designs: Buttons, colors, shapes—all easily customizable with silicone rubber.

- Long Life: Withstands thousands—often millions—of actuations.

When reliability and user experience matter, silicone rubber material gives you both.

What are the common silicone rubber uses?

Silicone rubber has found its way into almost every industry. Here are some key uses:

- Electronics: From silicone rubber membrane switches to rubber keypads in remote controls and calculators.

- Medical: Tubes, masks, and even implantable devices use biocompatible silicone.

- Automotive: Used in engine gaskets, sensors, and seals that face extreme temperatures.

- Aerospace: Insulation, seals, and padding that must survive wild temperature changes.

- Industrial: Rubber dome switches for heavy-use machinery controls.

Its ability to remain stable in demanding environments makes it irreplaceable in many applications.

Conclusion:

Silicone rubber material is more than just a component, its unique structure and flexibility make it an ideal choice for demanding applications, especially for silicone rubber membrane switches and rubber dome switches.

Whether you’re building next-gen electronics, robust control panels, or safe medical devices, silicone rubber offers a reliable, high-performance solution.

Need help with your silicone rubber components or membrane switches? Reach out today. Contact us at sales@best-membraneswitch.com to get expert advice.

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

What is rubber dome keyboard? Rubber keyboard

Rubber keyboard is known for its soft feel, quiet operation, and reliable everyday performance. A rubber dome keyboard is a keyboard that uses a flexible rubber dome under each key to register input. When a key is pressed, the dome collapses and makes contact with the circuit below, sending a signal, then springs back when ...

Contact us online