Which custom graphic overlay service is right for you

Which custom graphic overlay service is right for you

Selecting the right custom graphic overlay starts with your unique needs. You must weigh factors such as durability, usability, and industry standards. The table below highlights essential decision points to consider:

| Factor | Importance |

|---|---|

| Durability | Withstands heavy use and harsh environments |

| Usability | Enhances interaction with clear symbols |

| Visual Design | Guides attention to key functions |

| Compliance | Meets industry-specific standards |

Key Takeaways

- Identify your specific needs before choosing a custom graphic overlay. Consider factors like durability, usability, and compliance with industry standards.

- Select the right material and printing method based on your application. Polyester is ideal for harsh environments, while polycarbonate suits less demanding settings.

- Always request samples to test durability and adhesion. This step helps ensure your overlay performs well in real-world conditions.

Graphic Overlay

When you select a custom graphic overlay, you must consider the unique needs of your industry. Each application—industrial, medical, or consumer—demands specific features. The table below highlights key requirements for each sector:

| Application Type | Key Requirements |

|---|---|

| Industrial | Resistance to chemicals, durability for harsh conditions, simplified control panels |

| Medical | Sterilization capability, precise touch sensitivity, clear labeling |

| Consumer Electronics | Durability, user comfort, aesthetic appeal, features like backlighting and touch compatibility |

custom graphic overlay printing

You need a printing method that matches your environment. In industrial settings, overlays often face chemicals, heat, and abrasion. Providers like Maverick Label and Duratech offer overlays that resist wear and maintain clarity under UV exposure. Polyester overlays deliver high tear resistance and dimensional stability, making them ideal for heavy-duty use.

Tip: Always ask about adhesion and abrasion testing. Reliable providers test overlays in real-world conditions to ensure long-term performance.

Design Mark Overlays

Design mark overlays help you create intuitive interfaces. In medical devices, overlays must allow for easy cleaning and precise touch. Clear labeling supports safe and efficient operation. For consumer products, overlays should enhance user comfort and visual appeal.

Overlay Label

Environmental factors such as temperature and humidity can affect overlay performance. Choose materials that withstand high temperatures and resist moisture. Chemical exposure in industrial environments requires overlays with strong chemical resistance. A custom graphic overlay tailored to your application ensures durability and reliability.

Custom Graphic Overlay Options

Graphic Overlay Design

When you design a custom graphic overlay, you face several important choices. You must select the right material, printing method, and finish to match your application. Environmental factors, such as extreme temperatures, chemical exposure, and dust, often influence your decisions. You also need to consider how users will interact with the overlay. Embossing can provide tactile feedback, while backlighting improves visibility in low-light conditions.

Common design challenges include:

- Selecting materials for durability and usage conditions

- Adding features like embossing or tactile switches

- Choosing surface finishes for both aesthetics and protection

- Optimizing printing and cutting for manufacturability

- Picking adhesives that ensure long-term adhesion

Note: Always test overlays for abrasion, chemical resistance, and temperature cycling to guarantee performance in real-world conditions.

Graphic Overlay For Control Panels

Control panels require overlays that combine durability with clear labeling. You often see these overlays in manufacturing, military, and industrial settings. They must withstand frequent use and harsh environments. Polyester overlays work well for these applications because they resist chemicals and abrasion. Polycarbonate overlays offer easy customization and lower costs, making them suitable for less demanding environments.

Here is a comparison of common materials used for control panel overlays:

| Material Type | Characteristics | Applications |

|---|---|---|

| Polycarbonate | Easy to die cut, lower cost, optically clear, shows wear after 100,000 actuations | General use, less harsh environments |

| Polyester | Thinner, more resilient, shows no wear after 1,000,000 actuations, chemical resistant | Industrial, military applications |

| Control Panel Overlays | Custom designed for specific tasks, used in various industries like manufacturing and military | Human-machine interfaces |

You should also pay attention to adhesive selection. Acrylic adhesives work best for metal and low-energy plastics. Silicone adhesives suit high-temperature applications. Transfer tapes are ideal for flat surfaces, while double-sided foam tapes help with irregular surfaces.

Graphic Overlay Manufacturing

Manufacturing methods for custom graphic overlays include digital printing, screen printing, and sub-surface printing. Each method offers unique benefits:

| Feature | Digital Printing | Screen Printing |

|---|---|---|

| Cost | Cost-effective for small to medium runs, prototypes. | More economical for high volumes after setup costs. |

| Durability | Inks are thinner but durable with UV-cured finishes. | Thicker ink layers, excellent for heavy use outdoors. |

| Ideal Use | Best for complex graphics and small quantities. | Preferred for spot colors and textured finishes. |

Digital printing allows you to create overlays with unlimited color choices and intricate designs. Screen printing works better for high-volume orders and provides thicker, more durable ink layers. Sub-surface printing, where the graphics are printed beneath the surface, protects the design from wear and chemicals. Companies like Marking Systems Inc. specialize in this technique for maximum accuracy and longevity.

You can choose from a variety of finishes to enhance both function and appearance:

- Embossed buttons for tactile feedback

- Matte or glossy surfaces for different lighting conditions

- Textured or smooth finishes for grip or easy cleaning

- Backlighting options for improved visibility

Polyester and polycarbonate overlays come in gloss or matte finishes, with different texture levels to suit your needs. Armalex films offer extra durability and protection with a range of surface options.

Polycarbonate Overlays

Polycarbonate overlays remain popular due to their versatility and cost-effectiveness. They are easy to process and offer a wide range of textures and finishes. However, polycarbonate has limited chemical resistance and a shorter flex life compared to polyester. For applications that demand higher durability, such as industrial or military environments, polyester overlays provide superior chemical resistance and longer lifespan.

Here is a comparison of polycarbonate and polyester properties:

| Property | Polycarbonate (PC) | Polyester (PET) |

|---|---|---|

| Flex Life | Generally shorter lifespan than PET | Longer lifespan than PC |

| Abrasion Resistance | Available in various textures, some hard-coated options | Requires hard-coating for durability |

| Chemical Resistance | Limited chemical resistance | Superior chemical resistance |

| Flammability | Flame-resistant options available | Generally burns under suitable conditions |

| Appearance | Wider range of textures and finishes | More consistent gloss and texture |

| Ease of Production | Easier to process, lower costs | Harder to process, longer lead times |

For less demanding environments, polycarbonate overlays offer a balance of performance and affordability. In harsher settings, polyester overlays deliver the resilience you need.

Tip: Always match your overlay material and finish to your application’s environment and usage. This ensures your custom graphic overlay performs reliably and lasts longer.

Service Providers

Choosing the right service provider for your custom graphic overlay project can make a significant difference in quality, reliability, and overall satisfaction. You should evaluate providers based on their ability to handle complex designs, deliver consistent quality, and offer dependable support throughout the process. Companies like Specialty Printing, RSP, and Cole Graphic Solutions have built strong reputations for high-quality overlays and excellent customer service. JN White also stands out for its expertise in integrating graphic overlays into complex membrane switch assemblies.

Customization

You want a provider that offers a wide range of customization options. Leading companies allow you to select from materials like polycarbonate and polyester. You can request features such as clear or tinted windows, selective adhesives, and unique textures. Many providers offer back-lighting for enhanced visibility, dead-front effects for a clean appearance until activation, and embossed buttons for tactile feedback. Die cutting ensures overlays fit your equipment perfectly.

| Customization Option | Description |

|---|---|

| Materials | Polycarbonate, polyester, and specialty films |

| Features | Clear/tinted windows, selective adhesive, texture |

| Back-lighting | Improves overlay visibility |

| Dead-front | Clean look until illuminated |

| Embossed buttons | Tactile feedback for users |

| Die cutting | Precise shapes for custom applications |

Specialty Printing and JN White both provide extensive customization, including pressure-sensitive overlays, membrane switch overlays, and integration with rubber keypads or metal sub-panels.

Quality

Quality assurance should be a top priority when selecting a provider. High-quality overlays resist abrasion, UV radiation, and extreme temperatures. Providers use advanced printing techniques to meet exact color and graphic specifications. They select materials for durability and functionality in your specific application. Prototyping and sampling allow you to test overlays in real-world conditions before full production. Adhesive selection ensures overlays stay affixed under various conditions. Environmental sealing protects internal components from moisture and dust. Top providers comply with industry standards to guarantee safety and performance.

| Quality Assurance Measure | Description |

|---|---|

| Material Selection | Ensures the right materials for durability and function |

| Printing Techniques | Advanced methods for precise colors and graphics |

| Prototyping and Sampling | Real-world testing for durability and effectiveness |

| Adhesive Selection | High-performance adhesives for secure attachment |

| Environmental Sealing | Protects internal components from moisture |

| Compliance with Industry Standards | Meets regulatory requirements for safety and performance |

You should look for providers who engineer overlays to withstand harsh environments and who offer environmental sealing to protect your devices.

Turnaround

Fast turnaround times help you keep projects on schedule. Most suppliers deliver custom graphic overlays within 3–7 days. Some, like Dongguan Tiantai, can expedite orders in as little as 72 hours. Quick prototyping and efficient production processes ensure you receive overlays when you need them.

| Supplier | Average Turnaround Time |

|---|---|

| Most suppliers | 3–7 days |

| Dongguan Tiantai | Expedites to 72 hours |

Tip: Ask about lead times for both prototypes and full production runs to avoid unexpected delays.

Support

Reliable support makes your experience smoother from design to delivery. You should choose providers who respond quickly to questions and offer guidance on material selection, design optimization, and adhesive choices. Customer reviews play a key role in establishing trust. Real feedback from other clients helps you set expectations and feel confident in your decision. Providers with high reorder rates and positive testimonials often deliver consistent results.

- Customer reviews build trust and provide authentic feedback.

- Testimonials help you understand the service process and reduce confusion.

- High reorder rates indicate strong customer satisfaction.

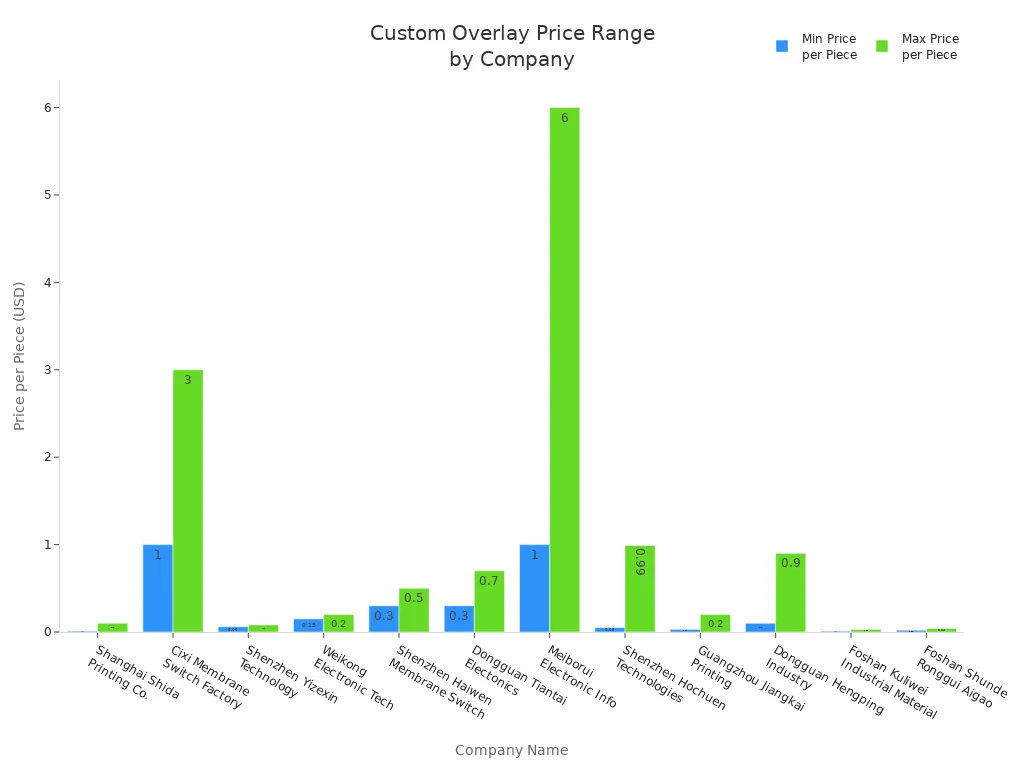

Pricing

Understanding pricing models helps you budget effectively. Most providers offer competitive rates for digital printing, membrane switches, embossed button panels, and custom labels. Minimum order quantities usually start at 100 pieces, with prices ranging from $0.5 to $3 per piece depending on complexity and features.

| Product Type | Price Range (USD) | Minimum Order |

|---|---|---|

| Digital Printing Graphic Overlay | $0.5 – $3 | 100 Pieces |

| Membrane Switches Graphic Overlays | $0.5 – $3 | 100 Pieces |

| Embossed Button Front Panel | $0.5 – $3 | 100 Pieces |

| Gradient Color Membrane Keypad | $0.5 – $3 | 100 Pieces |

| Rubber Keypad Buttons | $0.5 – $3 | 100 Pieces |

| Custom PC/PET Embossed Button Labels | $0.5 – $3 | 100 Pieces |

| Silicone Rubber Membrane Switch | $0.5 – $3 | 100 Pieces |

You should request detailed quotes and ask about volume discounts or additional fees for special features.

Note: Reliable providers validate samples for adhesion, UV resistance, and legibility. They maintain high on-time delivery rates and provide documentation for material traceability and certifications.

Selection Guide

Checklist

You can simplify your decision-making process by following a clear checklist. Use these steps to choose the right custom graphic overlay provider:

- Define your application and environment needs.

- Select materials and finishes that match your requirements.

- Request samples to test durability and adhesion.

- Review the provider’s manufacturing capabilities and quality assurance.

- Compare turnaround times and pricing.

- Check for customization options, such as embossing or backlighting.

- Read customer reviews and testimonials.

- Confirm compliance with industry standards and regulations.

Tip: Testing samples in real-world conditions helps you avoid costly mistakes later.

Questions

Before you commit to a provider, ask targeted questions to ensure they meet your needs:

- What is the main purpose of the graphic overlay in terms of user interaction?

- Does the graphic overlay comply with relevant safety regulations, such as NFPA 79?

- How does the design enhance user experience and safety?

- What are your manufacturing capabilities in printing and membrane switch technology?

- How do you ensure the quality and functionality of the overlays?

- Are the overlays compatible with my existing systems and applications?

These questions help you evaluate both technical expertise and customer support.

Red Flags

Stay alert for warning signs that may indicate an unreliable provider. The table below highlights common red flags and their descriptions:

| Red Flag | Description |

|---|---|

| Failure to meet WCAG criteria | Overlays may not address accessibility, leading to inadequate solutions for users with disabilities. |

| Performance Issues | Overlay scripts can slow down loading times and reduce responsiveness, harming user experience. |

| Security Risks | Third-party code may introduce vulnerabilities and expose your systems to attacks. |

| Interference with Assistive Tech | Overlays can conflict with assistive technologies, creating barriers for users with disabilities. |

Note: Reliable providers always address accessibility, performance, and security concerns up front.

Choosing the right custom graphic overlay service involves several key steps:

- Define your needs and environment.

- Match provider capabilities to your application.

- Use a checklist to compare options.

When you group overlays by geometry and rendering mode, you boost performance and reliability. Reach out to providers with your checklist to start your project confidently.

FAQ

What is the typical lifespan of a custom graphic overlay?

You can expect most overlays to last 3–7 years. Polyester overlays often last longer in harsh environments.

Can you request a prototype before full production?

Yes, most providers offer prototypes. You can test fit, durability, and design before placing a full order.

How do you choose between polycarbonate and polyester overlays?

| Polycarbonate | Polyester |

|---|---|

| Lower cost | Higher durability |

| Easy to cut | Chemical resistant |

You should match the material to your application’s needs.

Membrane Switch with LED, Customized LED Membrane Switches

Our LED membrane switches provide bright, even backlighting, long lifespan and reliable performance for control panels in dark environments. What are LED membrane switches? LED membrane switches are advanced user interface panels that combine a flexible membrane circuit with integrated light sources. The structure looks simple from the outside. Inside, it is a layered system ...

Click Touch Membrane Switch, Premium Membrane Switch with Tactile Click Response

Our click touch membrane switch provides clear tactile click response, stable performance and long service life, ideal for control panels requiring obvious touch feedback. What is a click touch membrane switch? A click touch membrane switch is a pressure-activated interface designed to deliver a clear, physical response each time a key is pressed. Unlike flat ...

Tactile Dome Switch – For Electronics & Control Panel Design

Our tactile dome switch delivers crisp tactile feedback and reliable precision actuation, with industrial-grade durability for small device control panels. Custom sizes available for your design needs. What is a tactile dome switch? A tactile dome switch is a compact switching component used in electronic interfaces where clear feedback matters. It delivers a sharp, physical ...

Contact us online