Why Modern Control Panels Rely on Membrane Switch Technology

Why Modern Control Panels Rely on Membrane Switch Technology

You often choose membrane switch technology for control panels because it brings outstanding durability, flexible design, and easy customization. This technology improves how a panel looks, saves space, and gives you reliable tactile feedback. Many industries count on it for these reasons:

| Industry | Key Applications |

|---|---|

| Medical Equipment | Ultrasonic therapy device, ventilator, infusion pump keyboard |

| Industrial Equipment | CNC machine tool control panels, testing instruments, factory assembly line equipment control panels |

| Consumer Electronics | Coffee machine, remote control, microwave |

| Smart Home Devices | Smart thermostats, smart door locks, smart lighting control panels |

- Durability

- Customizability

- User confidence

- Withstands harsh conditions

Key Takeaways

- Membrane switch technology offers durability and reliability, making it ideal for harsh environments like medical and industrial settings.

- Customization is a key advantage; you can design control panels with unique shapes, colors, and graphics to fit specific needs.

- The sleek, low-profile design of membrane switches saves space and enhances the aesthetics of consumer electronics and smart home devices.

- Tactile feedback from membrane switches boosts user confidence, ensuring clear communication when buttons are pressed.

- Cost efficiency is a major benefit; membrane switches use fewer parts, reducing manufacturing costs and allowing for easy updates.

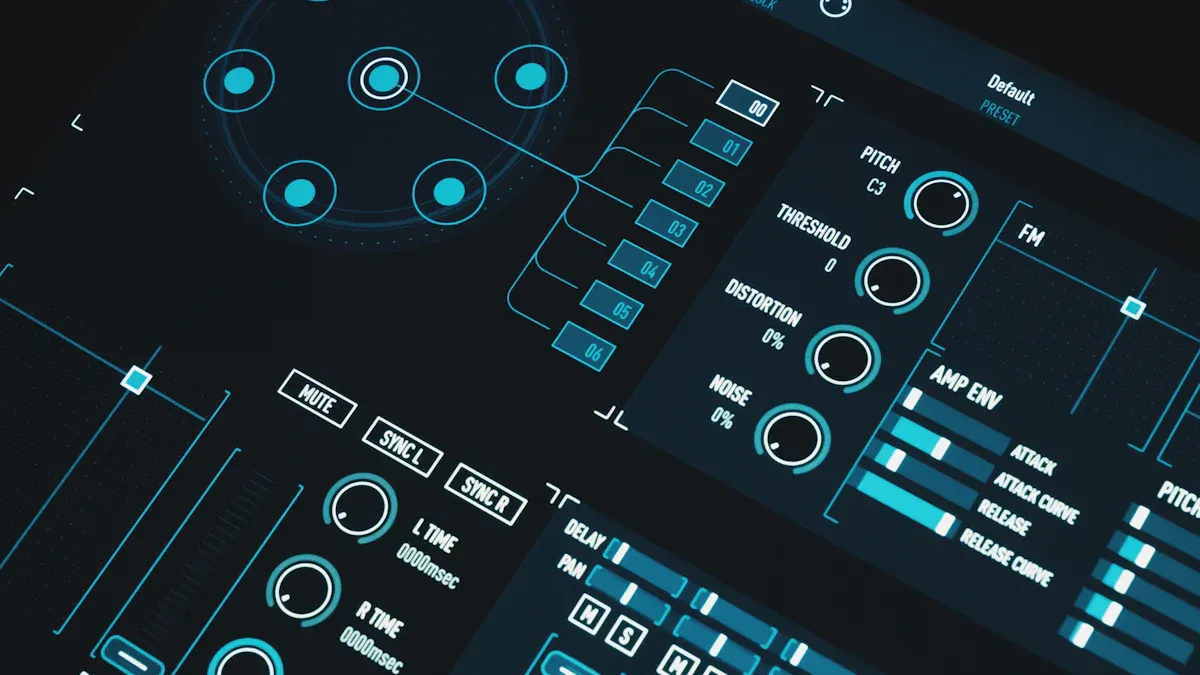

Membrane Switch Technology Overview

Structure and Function

You can understand membrane switch technology by looking at its layered structure. Each layer has a special job. The table below shows the main components and their roles:

| Component | Description |

|---|---|

| Graphic Overlay | Customizable with icons or branding, and wear-resistant. |

| Circuit Layer | Screen-printed with silver or carbon conductive traces. |

| Isolation Layer | Provides physical isolation when the button is not pressed. |

| Damper Layer | Typically made of stainless steel or plastic, creates a tactile ‘click.’ |

| Adhesive Layer | Provides panel mounting. |

When you press a button on a membrane switch, the process works in a few clear steps:

- You press the button, and the dome collapses to connect the circuit.

- This action completes the electrical path, which the control system reads as an input.

- You feel and hear a ‘click,’ which confirms your action.

This design makes membrane switch technology reliable and easy to use. You get clear feedback every time you press a button.

Comparison with Mechanical Switches

You might wonder how membrane switch technology compares to traditional mechanical switches. The main difference lies in their structure and materials. The table below highlights these differences:

| Switch Type | Layers and Materials |

|---|---|

| Membrane Switch | Three layers: top and bottom are thin, flexible pads with printed conductive traces; center is a spacer with holes for switches. |

| Mechanical Switch | Each key has its own switch, usually with keycaps, mechanical switches, a PCB, and a case. Types include linear, tactile, and clicky, each giving a unique feel. |

Tip: Membrane switch technology uses fewer moving parts, so you get a thinner, lighter, and more durable control panel. Mechanical switches often take up more space and can wear out faster.

You can see why many industries choose membrane switch technology for modern control panels. It offers a simple structure, reliable function, and a better fit for compact designs.

Advantages of Membrane Switches

Durability and Reliability

You want your control panels to last as long as possible, especially in demanding environments. Membrane switch technology stands out because it uses fewer moving parts than traditional mechanical switches. This design means less wear and tear over time. You can see the difference in average lifespan in the table below:

| Switch Type | Average Lifespan (keypresses) |

|---|---|

| Membrane Switches | 10 to 20 million |

| Mechanical Switches | 50 to 100 million |

Even though mechanical switches may last longer in terms of keypresses, membrane switch technology offers other important benefits. You get high reliability and fast response, which are crucial for critical applications. The table below highlights how these features help you in tough environments:

| Feature | Benefit |

|---|---|

| Fast response | Ensures quick interaction in critical applications |

| High reliability | Maintains performance in demanding environments |

You can trust membrane switch technology to keep working even when exposed to dust, moisture, or chemicals. This makes it a smart choice for medical devices, industrial equipment, and outdoor controls.

Design Flexibility and Customization

You often need control panels that fit unique shapes, sizes, or branding requirements. Membrane switch technology gives you unmatched design flexibility. You can choose from different colors, graphics, and layouts. You can add custom icons, company logos, or even backlighting for better visibility.

You can also select different materials for overlays, such as polyester or polycarbonate, to match your needs. If you want to add extra features like LED indicators or touch-sensitive areas, membrane switch technology makes it easy. This versatility helps you create control panels that stand out and meet your exact specifications.

Aesthetics and Space Efficiency

You want your devices to look modern and professional. Membrane switch technology helps you achieve a sleek, low-profile appearance. The thin layers allow you to design compact control panels that save space. This is especially useful for handheld devices, medical instruments, and consumer electronics.

You can use vibrant graphics and smooth surfaces to improve the overall look of your product. The flat design also makes cleaning easy, which is important in environments where hygiene matters. You get both style and function in one package.

Tactile Feedback and User Experience

You need to know when you have pressed a button, especially in critical situations. Membrane switch technology uses special features to give you clear tactile and audible feedback. For example:

- The dome contact feature provides a crisp tactile and audible response. You feel and hear a click, so you know the circuit has been activated.

This feedback boosts your confidence and reduces the chance of errors. You can operate equipment quickly and accurately, even if you are wearing gloves or working in low-light conditions.

Tip: Membrane switch technology improves user experience by combining reliable feedback with easy operation.

You can see why so many industries rely on membrane switch technology. It offers durability, flexibility, attractive design, and a satisfying user experience—all in a cost-effective package.

Applications in Custom Control Panels

Industrial and Medical Uses

You often see membrane switch technology in industrial and medical equipment. In factories, you use these switches on control panels for machines, testing devices, and assembly lines. The sealed surface keeps out dust, oil, and chemicals. This helps your equipment last longer and work safely. In hospitals, you find membrane switches on devices like ventilators and infusion pumps. The flat surface makes cleaning easy, which helps prevent the spread of germs. You can trust these switches to work even when you wear gloves or need to press buttons quickly.

Note: Many hospitals choose membrane switches because they are easy to disinfect and can handle frequent use.

Consumer Electronics

You interact with membrane switches every day in your home. Coffee makers, microwaves, and remote controls use these switches for their buttons. The thin design lets you enjoy sleek, modern devices that fit well in your kitchen or living room. You get clear feedback when you press a button, so you know your command went through. Smart home devices, like thermostats and lighting panels, also use membrane switches. This technology helps you control your environment with just a gentle touch.

- You benefit from easy-to-clean surfaces.

- You enjoy reliable performance in your daily gadgets.

- You get stylish products that save space.

Custom Keypads and Panels

You may need a control panel that fits a unique shape or matches your brand. Membrane switch technology gives you many ways to customize keypads and panels for special equipment. You can choose special shapes, colors, and printed graphics to match your needs. The table below shows some common customization options:

| Customization Options | Description |

|---|---|

| Special Shapes | Membrane switches can be designed in unique shapes to fit specific equipment requirements. |

| Color Options | Various colors can be selected for the membrane switch to match the design of the equipment. |

| Printing | Custom printing options are available for graphics and labels on the membrane switch. |

You can create a control panel that stands out and works perfectly for your application. Many companies use these custom options to improve branding and make their equipment easier to use.

Tip: Custom membrane switches help you solve real-world challenges by fitting your exact needs.

Advanced Features and Integration

Electronic Integration

You can easily connect membrane switch technology with modern electronics. These switches support integration with microcontrollers, LEDs, and display modules. You can add features like backlighting, touch sensors, or even sound alerts. This makes your control panels smarter and more interactive. Many manufacturers design these switches to work with flexible printed circuits, which helps you save space and reduce wiring. You can also program the switches to perform multiple functions, giving you more control over your devices.

Human Factors and Ergonomics

You want your control panels to be comfortable and accessible for everyone. Membrane switches help you achieve this goal. Designers create different layouts and key sizes to fit various user needs. For example, some panels use large, easy-to-press keys for people who have trouble with small buttons. Others use smaller keys for users with limited movement. The table below shows how different designs improve accessibility:

| Keyboard Type | Description |

|---|---|

| Expanded Membrane | Large squares replace keys, making it easier for users to target large areas. |

| Small Membrane | Pocket calculator-size keys help users with limited limb movement. |

| Activation Pressure | Requires almost a pound of pressure, which helps prevent accidental presses for users with poor dexterity. |

| Programmable Keys | Up to 128 programmable keys allow for custom setups. |

| Emulates Mouse Control | Lets users control a mouse cursor with keystrokes, adding more accessibility options. |

You can see how these features make devices easier to use for people with physical limitations. This focus on ergonomics helps everyone operate equipment with confidence.

Scalability and Cost Efficiency

You can scale membrane switch designs for both small and large production runs. The simple layered structure keeps manufacturing costs low. You save money on materials and assembly because the switches use fewer parts. When you need to update graphics or layouts, you can do so without changing the entire panel. This flexibility helps you respond quickly to new requirements or branding changes. Many industries choose membrane switch technology because it offers reliable performance at a reasonable price.

Tip: You can reduce waste and speed up production by choosing membrane switches for your next project.

You see membrane switch technology in many control panels because it solves real problems. You get:

- Strong durability for tough environments

- Flexible designs for custom needs

- Modern looks that fit any device

- Clear tactile feedback for confident use

- Cost savings for your business

Consider membrane switch technology for your next control panel project. You will improve reliability and user experience.

FAQ

What makes membrane switches better for harsh environments?

You get strong protection from dust, moisture, and chemicals. The sealed surface keeps out harmful elements.

Tip: You can clean membrane switches easily, which helps them last longer in tough settings.

Can you customize the look of a membrane switch panel?

Yes, you can choose colors, shapes, and graphics. You can add your logo or special icons.

- Custom printing

- Unique shapes

- Backlighting options

How do you know if you pressed a membrane switch button?

You feel a clear tactile response. Many designs give you a crisp “click” sound.

This feedback helps you avoid mistakes and boosts your confidence.

Are membrane switches expensive to produce?

No, you save money with membrane switches. The simple design uses fewer parts.

You can order small or large batches without high costs. This makes them a smart choice for many projects.

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online