Do you understand the membrane switch manufacturing process?

Do you understand the membrane switch manufacturing process?

The membrane switch is a control system that integrates key functions, indicating components, and instrument panels. It is beautiful, lightweight, has excellent conductive properties, and has the characteristics of waterproof, dustproof, and anti-static interference. It is widely used in electronic communications, medical equipment, industrial control, Instrumentation, automotive industry, smart home and other fields. The following is a brief introduction to the membrane switch production process.

Membrane switch digital printing technology

In the previous printing of membrane switch panels, most of them were done by silk screen printing. Compared with current digital printing, silk screen printing technology is more complicated, the panel style is ordinary, and it lacks technical design style. The current digital printing technology can well display the content you want to express on the panel, and you can design specific patterns and company logos according to your needs. Just adjust the required ink to change the color and brightness in the membrane switch. Accurate expression of hue.

Membrane switch assembly

The main thing is to drill holes for the buttons on the membrane switch and determine the hole positions. First determine the hole positions according to the drawings, and then design a specific mold for mass production. When producing molds, make sure there are no skews or inaccurate positions.

The key position in the membrane switch is usually assembled with a metal dome. When the product has high requirements for the stability of the resistance and key sensitivity, a gold-plated dome can be used. Before assembling the dome, you need to place the dome on the PET film in a good position. Use tweezers to pick up the dome and place it at the key position on the circuit to ensure that the position is centered and will not affect the later use of the membrane switch.

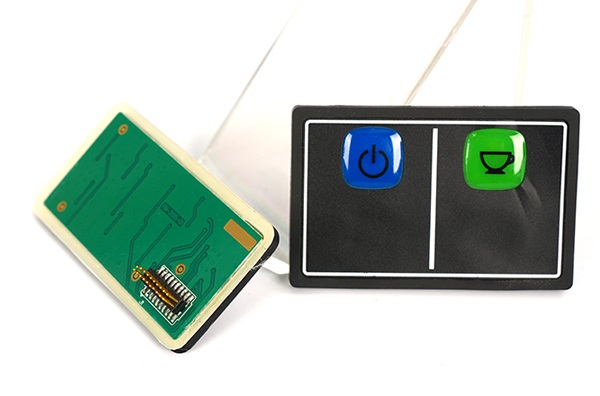

According to customer needs, we can also provide circuit board production and assembly, combine the PCB with the metal dome, and assemble the energized membrane switch panel. The film layer between the metal dome array and the PCB is connected through 3M glue, which has good sealing and adsorption effects. Prevent bacteria from entering the membrane switch during use and affecting the product life.

Membrane switch detection

First, inspect the appearance to see if there are obvious dry defects on the outside. The main purpose is to check whether the pattern on the membrane switch panel is misprinted, deinked, or scratched, and whether the button bump position is offset.

The second step is functional testing, which requires a 100% full inspection of the function of the membrane switch, and no open circuit, short circuit, poor insulation, etc.; products with LED lights must not have leakage. At the same time, check whether the resistance value of the membrane switch button is in compliance with the regulations and whether the current is stable.

Finally, there is performance testing. Life span testing is the main concern of customers. The metal dome produced by Best Technology has been measured to be able to reach 5 million normal presses and still has a rebound effect. However, the life span test needs to be based on the conditions such as no deformation or damage on the surface of the membrane switch, and no damage to the structural layer. However, in actual applications, there will be a span of time and the impact of environmental changes on the product. Most life tests are measured under ideal conditions.

Based on the above introduction, I believe you have already understood our membrane switch panels. If your products have applications for membrane switch products, you are welcome to inquire and we will provide professional answers and help to your needs.

What is a Custom Capacitive Switch? A custom capacitive switch senses touch through capacitance changes. When you touch a capacitive switch, the electricity stored in your body interacts with conductive material in the switch. The switch senses the resulting change in capacitance and reacts according to its programming. Capacitive touch technologies are becoming increasingly popular, and ...

We know, quality is the core of a product, so we always proceed many inspections and measurement of membrane switch to make sure the high quality and reliability. Below are some generally methods and inspect items in Yu An electronics, from this you can know how we guarantee the quality of the membrane keypads. 1. Shape ...

Membrane switch is a thin PET sheet with contacts, often be used as a switch in PCB, FPC and other circuit boards, and plays an important role in the touch switch between the user and the control device. The contact on the film key is located on the conductive part of the PCB board (mostly ...

Tags:

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Custom Membrane Switches Manufacturers, Custom membrane switch panel

What Are Custom Membrane Switches? Custom membrane switches are thin, flexible, and highly adaptable electronic interfaces. They replace bulky mechanical keys and provide a lighter and more controlled input experience. These switches allow you to customize every part of the interface. You can choose the look, feel, shape, features, and layout. You can adjust the ...

Contact us online