What is the internal structure of a membrane switch?

What is the internal structure of a membrane switch?

Membrane switches sound quite professional. In fact, they are commonly known as panel buttons. Membrane switches are used in the control panels of many devices. They are widely used in electronic communications, electronic measuring instruments, industrial control, medical equipment, automotive industry, smart toys, and household applications. Electrical appliances and other fields. Membrane switches are widely used in various industries due to their beautiful appearance, long service life, simple structure, easy installation, good hand feel, and small occupation area.

Introduction to membrane switches

The membrane switch is a multi-layer structure key switch composed of a certain elastic insulating material layer, which integrates the functions of keys, indicating components, and instrument panels. The action of the membrane switch is only realized by the vertical bounce of the elastic membrane. Although the elastic membrane has been pressed millions of times, the amplitude when pressed is very small, only 0.1-0.3MM. In addition, the material selection is reasonable, so the membrane material Being able to withstand a long life of millions of times without deformation determines the durability of the membrane switch.

1. Panel materials are mainly PVC, PC, PET

2. The membrane switch rebounds within 6 seconds when pressed.

3. The application scope is mainly various household appliances, medical products, and industrial machinery control panels.

4. Membrane switch panel: The appearance is digital printing technology, beautiful and has a strong sense of design.

The principle of membrane switch

Generally speaking, a common membrane switch is mainly composed of 6 layers of materials. In order from the outside to the inside, they are panel, surface glue, upper circuit, isolation layer, lower circuit, and bottom glue.

1. Panel: The panel mainly wraps the membrane switch. On the basis of properly arranging the buttons, it plays a necessary decorative role in the entire membrane switch through different colors, patterns, and button shapes. The main function of the panel layer is to have high transparency, high ink adhesion, high elasticity, and anti-folding properties.

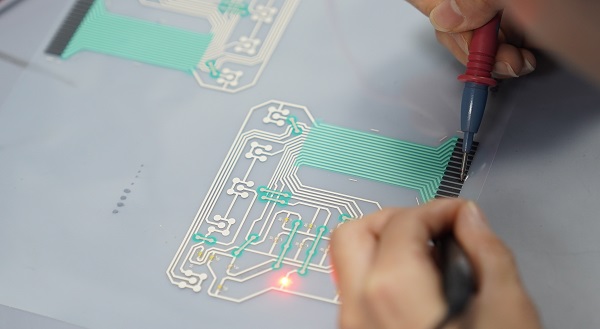

2. Upper circuit and lower circuit: The upper and lower circuits are the electrical components of the membrane switch. It can directly affect the performance of switching appliances. The upper and lower circuits are the two electric shock roles necessary for switch closure. A specific membrane switch is set based on the size of the PCB.

3. Top glue, isolation layer, and bottom glue: The materials of these three-layer structures are mainly assembled with 3M glue. They have different names due to their different positions in the switch structure. These glues can have different thicknesses depending on their respective layers. This is mainly determined by the thickness of the switch and the operating force of the button.

There are raised buttons in the PET button membrane switch buttons, and the upper line button points are convex to enhance the feel. The isolation layer is also a part of the membrane switch. The lower circuit is mainly assembled with the bottom of the panel. Below the key point of the panel is the metal dome array that contacts the lower circuit. When pressed, the current is transmitted to the lower circuit to transmit instructions. Pressure acts on the panel key points and at the same time on the metal dome, and conducts the circuit through the metal dome, which provides stable and consistent electronic and mechanical operation.

The membrane switch launched by Yu An Electronics brings innovation in user interface technology reliability and functionality. With their durable construction, customizable design options and seamless integrated functionality, our membrane switch products have the potential to enhance the industry’s user experience. If you have any good suggestions or needs, you are welcome to send us an email for consultation.

Tags:

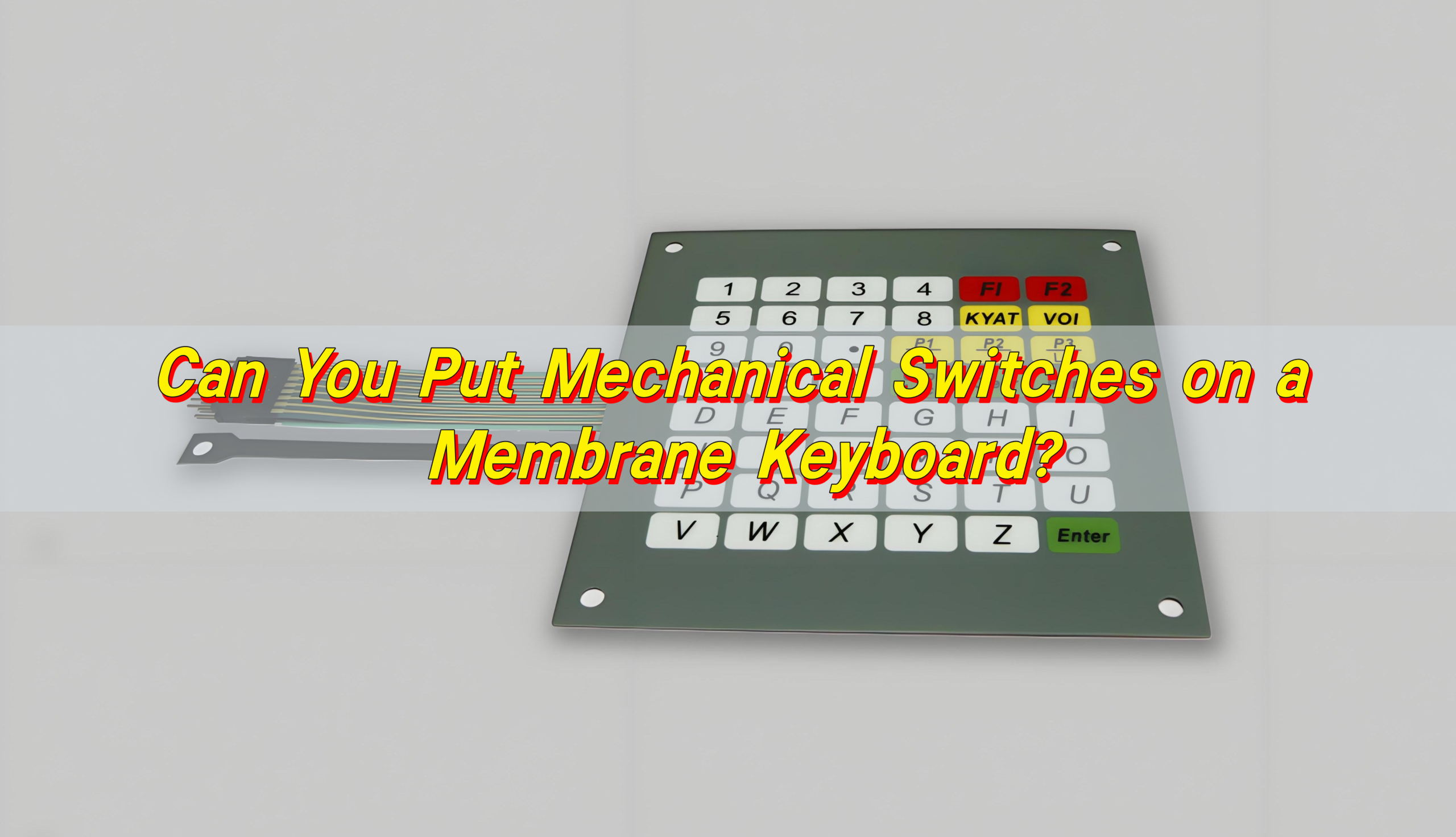

Can You Put Mechanical Switches on a Membrane Keyboard?

No, you can’t. Mechanical switches and membrane keyboards use completely different structures. Membrane boards rely on pressure pads, while mechanical ones use physical switch mechanisms. They’re not compatible. But there are still ways to improve the feel and sound of a membrane keyboard without full mechanical parts. What are membrane switches keyboard? Membrane switch keyboards ...

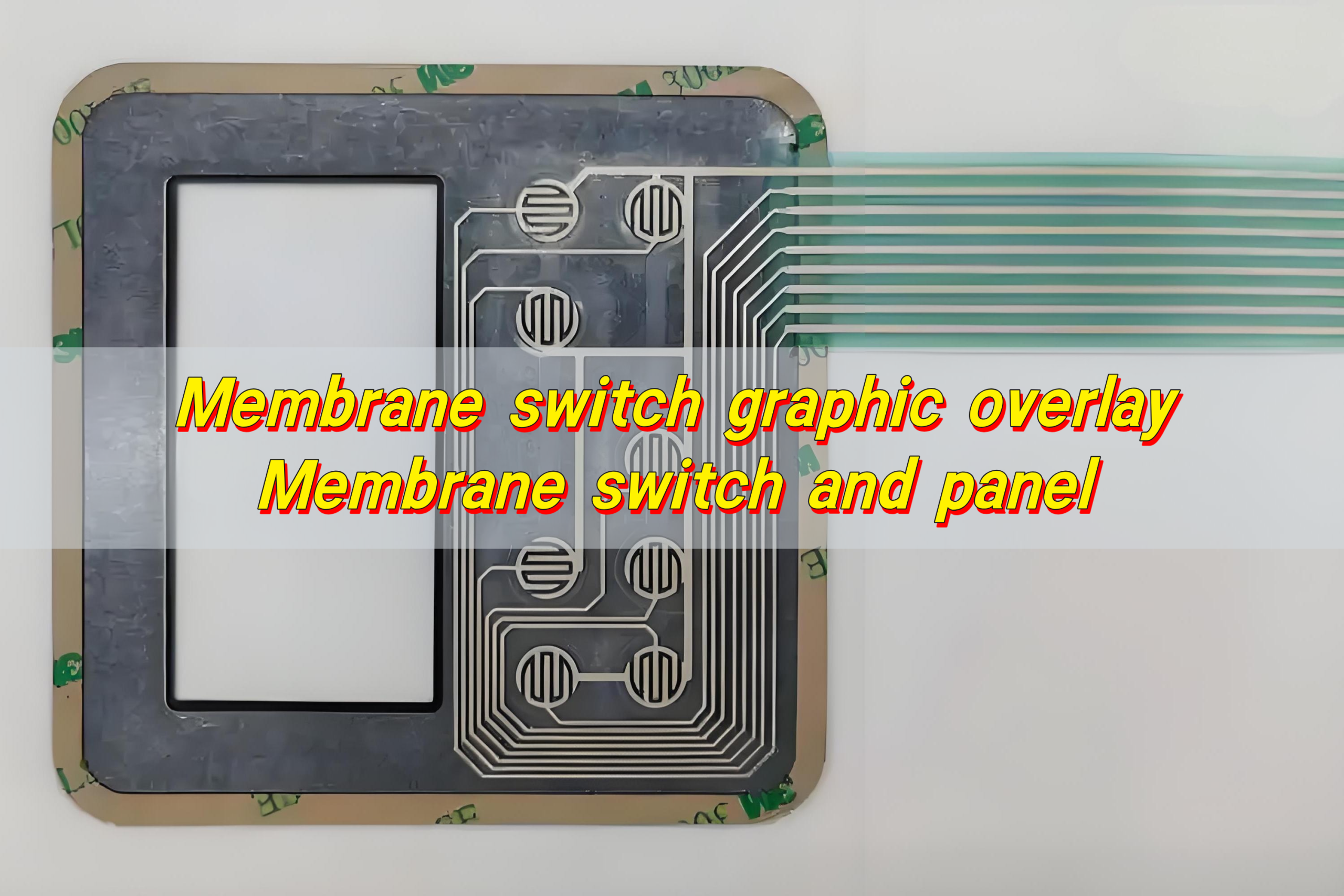

Membrane switch graphic overlay, Membrane switch and panel

Membrane switch graphic overlay is an outer film printed with button logos and patterns, usually made of PET or PC, which protects the internal circuit and provides an operating interface. It is closely integrated with the membrane switch panel, which is a multi-layer film structure containing a conductive layer and an insulating layer to achieve ...

What are membrane switches? Membrane switch design guide

Membrane switches are thin, flexible interfaces that activate a circuit when pressed. Built from multiple flat layers, they offer a clean look, strong durability, and precise control. Commonly used in medical devices, industrial panels, and consumer electronics, they’re known for being reliable, customizable, and space-saving. What is membrane switch design? Membrane switch design is the ...

Contact us online