Custom Membrane Keypad, Membrane Keyboard Manufacturer

Custom Membrane Keypad, Membrane Keyboard Manufacturer

In a world where the touch of a button can trigger something as simple as turning on your microwave or as critical as activating a medical defibrillator, the membrane keypad plays a quiet yet powerful role. These ultra-thin, often overlooked components are the unsung heroes of modern devices. But behind every reliable keypad is a manufacturer who understands more than just circuits—they understand the user.

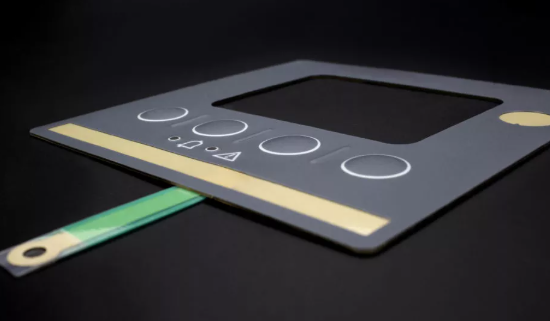

Yuan Electronics isn’t just a membrane keypad manufacturer; they’re a solution provider. From custom membrane keypads to rapid prototyping for new product launches, they deliver precision, quality, and trust. Whether you’re designing control panels for heavy-duty equipment or creating intuitive user interfaces for medical devices, Yuan tailors every keypad to your exact needs. Their engineering team collaborates closely with clients across the globe, delivering user-friendly and durable solutions that are built to last.

What Is a Membrane Keypad?

A membrane keypad is a type of human-machine interface (HMI) built using flexible materials layered together to form a flat, compact, and tactile input surface. Unlike mechanical keyboards, which rely on physical switches beneath each key, a membrane keypad uses pressure pads that complete a circuit when pressed. These keypads are known for their sleek profile, moisture resistance, and ability to withstand harsh environments—qualities that make them indispensable in industries like medical devices, consumer electronics, automotive controls, and industrial machinery.

Components on a Membrane Keypad

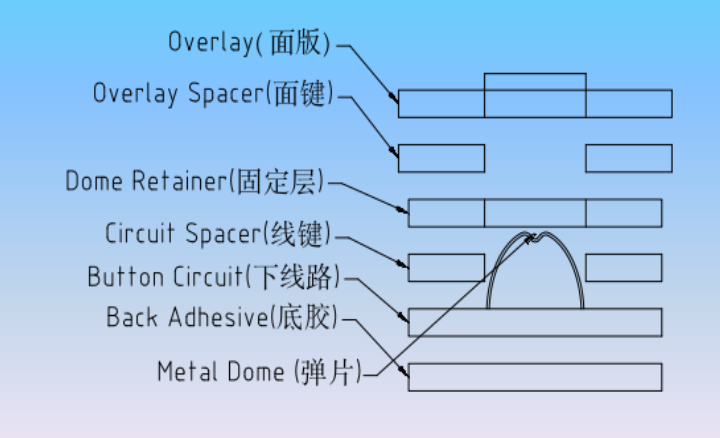

A membrane keypad is a compact, multi-layered user interface device composed of several functional components. Each layer plays a specific role in providing electrical connectivity, user interaction, tactile response, and mounting stability. A typical membrane switch may including:

- Graphic Overlay: The top layer with printed symbols or text. It’s what users see and touch.

- Graphic Adhesive: Bonds the overlay to the dome layer. Die-cut for flexible key response.

- Dome Retainer: Holds metal or poly domes that give tactile feedback when pressed.

- Spacer Adhesive: Separates the circuit layers. It prevents accidental touches and allows key movement.

- Circuitry: Printed conductive traces (silver, carbon, or copper) that send signals. Often made on PET film or FPC.

- Back Adhesive: Used to stick the keypad to a device surface. Usually made from strong industrial adhesive.

Its structure like below:

Optional features include backlighting, shielding layers, and waterproof seals, making these keypads highly adaptable.

Types of Keypad Membranes

Not all membrane keypads are created equal. Depending on the application, the construction and features can vary dramatically:

- Tactile Membrane Keypad: Includes domes beneath each key that “snap” when pressed, giving immediate feedback.

- Non-Tactile Membrane Keypad: Smooth and silent, perfect for low-noise environments or cost-sensitive projects.

- Flexible Membrane Keypad: Designed to bend and flex, great for wearables or curved surfaces.

- Rigid Membrane Keypad: Mounted on firm substrates like PCB or aluminum for added durability.

- Backlit Membrane Keypad: Integrates LEDs or EL panels to improve visibility in dim environments.

- Custom Membrane Keypad: Tailored for specific branding, shapes, functionality, or even antimicrobial properties.

Yuan Electronics offers various membrane keypads and switches, if you are interested in it, welcome to visit our factory.

Functions of a Membrane Keypad

Membrane keypads serve as a communication bridge between users and machines. They send input signals to underlying circuits or control systems. These keypads can activate functions, adjust settings, or even navigate complex software interfaces. In medical devices, they control diagnostic instruments. In home appliances, they operate timers and temperature settings. In military gear, they’re embedded into control panels for navigation or communication systems.

Membrane keypads often include features like multi-layer switching, custom key mapping, and touch response calibration. Whether it’s controlling complex medical instruments or launching a coffee maker, the membrane keypad makes it seamless and intuitive.

How Do Membrane Keypads Work?

The working principle of membrane keypad is the same as metal dome. When a user presses a key, the top layer flexes and bridges a gap between two circuit paths—typically made from conductive ink. This action closes the circuit momentarily, sending a signal to the connected control system.

In tactile keypads, the embedded metal or poly domes compress to give feedback, then rebound to their original shape once released. In non-tactile keypads, there’s no physical sensation—but the function still executes flawlessly.

Membrane Keyboard vs. Mechanical Keyboard

| Feature | Membrane Keyboard | Mechanical Keyboard |

| Switch Mechanism | Uses pressure pads and conductive traces to register input. | Utilizes individual mechanical switches beneath each keycap. |

| Tactile Feedback | Generally soft, quiet, and less tactile; may feel “mushy.” | Offers crisp tactile or audible feedback, depending on switch type (e.g., Cherry MX). |

| Noise Level | Low noise—suitable for quiet environments like offices and medical labs. | Noisier—audible clicks especially on tactile and clicky switches. |

| Typing Speed & Accuracy | Moderate—can feel less responsive during high-speed typing. | High—precise actuation helps improve typing speed and reduce input errors. |

| Durability (Lifespan) | 5–10 million keystrokes per key on average. | 50–100 million keystrokes per key—much longer lifespan. |

| Repairability | Difficult to repair; individual keys can’t be replaced. | Easier to repair or customize; individual switches and keycaps are replaceable. |

| Key Rollover / Anti-Ghosting | Limited rollover—some keys may not register when pressed simultaneously. | High rollover—multiple simultaneous key presses are accurately detected. |

| Customization | Basic customization—typically limited to graphics or layout in custom builds. | Highly customizable—switch types, keycaps, and backlighting can be modified. |

| Portability & Size | Lightweight and slim; excellent for space-constrained designs. | Bulkier due to switch structure; less travel-friendly. |

| Price | Cost-effective—ideal for mass-market or embedded system applications. | More expensive due to complex components and build quality. |

| Use Case | Industrial controls, medical devices, home appliances, ATMs, POS terminals. | Gaming, programming, data entry, and professional typing setups. |

| Water/Spill Resistance | Often more water-resistant due to sealed design. | Less resistant; open design can allow spills to reach circuit level. |

| Maintenance | Minimal—usually just external cleaning. | Requires regular cleaning to remove dust and debris from under the keys. |

How to Make a Custom Membrane Keypad?

Creating a custom membrane keypad is a multi-step process that blends mechanical design, electronic functionality, and aesthetic appeal. Whether you’re designing for an industrial control panel, medical device, or consumer appliance, each keypad is uniquely engineered to meet specific user interface requirements. Design a membrane keyboard process including:

1. Define the Application Requirements

Consider the membrane switch specifications, like:

- Operating environment (temperature, humidity, exposure to chemicals)

- Number of keys and key layout

- Required tactile feedback (tactile or non-tactile)

- Backlighting or display integration (LED, EL, or fiber optics)

- Electrical interface (matrix, dome, or custom circuit)

- Labeling or graphics (symbols, icons, text)

2. Design the Graphic Overlay

The topmost layer—the graphic overlay—represents the user interface. It includes key labels and logos or branding. Usually made of polyester (PET) or polycarbonate (PC) for their durability and print quality.

3. Select the Tactile Layer (Optional)

If tactile feedback is needed, metal domes or formed polydomes are placed below each key. When pressed, the dome collapses, completing the circuit and providing a physical “click” to the user.

You can choose:

- Metal dome (for crisp, durable feedback)

- Polydome (integrated into polyester sheet, quieter, low-cost)

Tactile domes are mounted on a dome retainer layer for alignment and consistent actuation.

4. Create the Circuit Layer

This layer contains the actual printed circuit, usually screen-printed with conductive silver or carbon ink on polyester sheets. It connects the keys to the device’s controller.

5. Incorporate a Spacer Layer

The spacer separates the circuit and overlay layers and provides a cavity for key travel. When a key is pressed, the top layer collapses into the cavity, allowing the contact points to touch and register a signal.

6. Add a Rear Adhesive Layer

This layer allows the membrane keypad to be affixed to the product housing. It must be compatible with the surface material (metal, plastic, glass) and withstand environmental stresses. Commonly used adhesive: 3M 467MP or 3M 468MP for industrial-grade bonding.

7. Choose Backlighting (Optional)

For visibility in low-light environments, backlighting is often added using:

- LEDs (for specific key areas)

- EL panels (for uniform backlight)

- Light guide films (for ultra-thin illumination)

This is sandwiched between circuit and overlay or in a separate layer depending on design. For detailed information, you are welcome to contact Yuan electronics.

8. Connect with Tail Termination

Circuit tails extend from the keypad to connect with your system via:

- ZIF (Zero Insertion Force) connectors

- FPC (Flexible Printed Circuit)

- Flat ribbon cables

Proper alignment, shielding, and tail orientation are critical for functionality and assembly.

9. Final Assembly and Testing

All layers are aligned and laminated using heat and pressure. Once assembled, the keypad undergoes:

- Electrical continuity testing

- Tactile force testing

- Peel strength validation

- Visual inspection for graphics and cutouts

Only fully verified keypads proceed to packaging.

10. Packaging and Integration

The final product is carefully packaged to prevent deformation during shipping and is ready for direct integration into your device or enclosure. Yuan Electronics offers full-service customization, from early-stage design to final production.

Can You Replace Keys on a Membrane Keyboard?

Unfortunately, membrane keypad replacement for individual keys isn’t straightforward. The keys are part of a continuous sheet rather than separate components. While you can’t swap out a single key like on a mechanical keyboard, you can sometimes fix responsiveness issues through cleaning or circuit repair.

If your device is critical or your keypad is heavily worn, reaching out to a membrane keypad repair specialist like Yuan Electronics is your safest bet.

How Many Years Does a Membrane Keyboard Last?

The average lifespan of a membrane keyboard is between 3 to 5 years under normal use. Industrial-grade versions—like those designed by Yuan—can last significantly longer, with rated lifespans exceeding 1 to 10 million actuations per key.

Why Do Membrane Keyboards Fail?

Common causes of membrane keypad failure include:

- Wear and Tear: Layers delaminate or conductive ink fades.

- Liquid Damage: Especially without waterproof sealing.

- Environmental Stress: UV exposure, chemicals, or extreme temperatures.

- Mechanical Abuse: Excessive pressure or sharp objects puncturing the overlay.

That’s why it’s important to choose a high-quality membrane keypad manufacturer that uses industrial-grade materials and tight quality control.

How Often Should You Get a New Keyboard?

If you’re seeing input lag, stuck keys, or missing functions, it might be time to upgrade. For average users, replacing a keyboard every 3 to 5 years is a good rule of thumb. Industrial users should follow a maintenance schedule and consider proactive replacement before key failures impact operations.

Best Membrane Keypad Manufacturer – Yuan Electronics

When it comes to quality, responsiveness, and customization, Yuan Electronics ranks among the best membrane keypad manufacturers in the global market. With more than 15 years of hands-on experience, Yuan specializes in:

- Custom membrane keypads for medical, industrial, and consumer products

- Waterproof, dustproof, and UV-resistant keypad membranes

- Embedded LED backlighting and tactile dome integration

- Rapid prototyping and low to high-volume manufacturing

- Expert membrane keypad repair and circuit design services

Yuan’s engineering team collaborates closely with you to ensure each keypad not only works flawlessly—but feels right, looks sharp, and lasts long.

FAQs

Q: Can I clean my membrane keypad with alcohol?

Yes, but use isopropyl alcohol and a lint-free cloth. Avoid soaking the surface to protect the circuit layers.

Q: Can I repair a non-working key?

In some cases, yes. You can open the housing and clean contact points, or consult experts in how to repair membrane keypad issues.

Q: Is it worth customizing a small batch?

Yes. Yuan Electronics offers low minimum order quantities for custom membrane keypad projects, ideal for startups or prototyping. Competitive price and free shipping fee!

Q: Are membrane keyboards waterproof?

Some are. Yuan Electronics manufactures waterproof membrane keypads sealed with protective films or silicone gaskets.

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online