How long do membrane key switches last?

How long do membrane key switches last?

The service life of a membrane keyboard key is about 3 million times. The material quality of membrane key switches is one of the important factors affecting their service life. High-quality materials have better wear resistance, corrosion resistance and insulation, and can withstand more presses. In addition, the frequency of use of membrane key switches will also affect their service life. If the membrane key switch is used frequently, the wear of its keys will be more serious, thus affecting its service life.

Yu An Electronics has now developed into one of the leading manufacturers of membrane switches. With our rich experience and growing market demand, we have transformed our business into a comprehensive one-stop service provider for tactile membrane switches.

What is the lifespan of a membrane keyboard key?

The service life of a membrane keyboard key is about 3 million times. The membrane keyboard generates contact signals through three layers of membranes. When the key is pressed, the membranes contact to form a path to complete the input. This structure is simple and affordable.

The main factors affecting the service life of a membrane keyboard include the frequency of use, ambient temperature and the use environment. High frequency of use, high temperature and humid environment will shorten the service life of the membrane keyboard.

In addition, the aging of the silicone inside the membrane keyboard will also cause problems such as changes in the feel of the keys, a slip in the rebound feel, or key jams.

In order to extend the service life of the membrane keyboard, it is recommended to avoid using it in a hot, humid or dusty environment, and pay attention to keeping the keyboard clean and maintained.

How long do key switches last?

The service life of a metal dome key switch can usually reach 1 million times. This switch has a short action stroke and is suitable for use in harsh environments. It is widely used in industrial controllers, lighting, communication equipment, medical equipment, marine equipment and other fields.

Factors affecting the life of a metal dome key switch include:

- Key force: Excessive key force will accelerate the wear of the switch and shorten its service life.

- Material quality: High-quality metal dome key switches use high-quality materials such as metal, ceramic, glass, etc. These materials have good wear resistance and high temperature resistance, which can improve the service life and stability of the key switch.

- Use environment: Extreme temperature conditions (such as high and low temperature environments) will reduce the service life of the switch.

In addition, the shelf life of metal dome key switches is under good storage conditions, and plastic parts such as ABS shells can remain unaffected for more than three years.

What type of keyboard lasts the longest?

Mechanical keyboard switches have the longest service life. Mechanical keyboards use mechanical switches, and their service life can usually reach 50 million keystrokes, which is much higher than the 20 million to 30 million keystrokes of ordinary keyboards.

The durability of mechanical keyboards is mainly due to the design of their mechanical switches. The keys of a mechanical keyboard are composed of keycaps, shafts and springs, and each key operates independently to provide good feedback. This independent key structure enables the mechanical keyboard to maintain high durability under continuous and repeated pressing.

In addition, the switches of mechanical keyboards use metal contact points, which are not easy to oxidize, and have strong signal transmission performance, which further extends the service life.

Why are membrane keyboards so cheap?

First of all, the material and production costs of membrane keyboards are low. The structure of membrane keyboards is relatively simple, and a layer of membrane is used as a key trigger device. This design reduces the complexity of production materials and processes, thereby reducing manufacturing costs.

In contrast, mechanical keyboards use independent mechanical switches as trigger devices for each key. These switches contain complex mechanical structures, and the manufacturing materials and processes are relatively complex, resulting in relatively high costs.

Secondly, the production process of membrane keyboards is relatively simple. The key triggering principle of membrane keyboards is achieved through the bending and contact of the membrane. This design makes the production process more efficient and further reduces costs. Each key of a mechanical keyboard is an independent mechanical switch, and the manufacturing process is more complex and the cost is correspondingly higher.

Can membrane keyboards get wet?

Membrane keyboards may get wet in a humid environment. The design of membrane keyboards usually has a certain waterproof function, but it is not completely waterproof.

The waterproof performance of membrane keyboards is mainly reflected in its structure. The membrane keyboard consists of upper and lower covers, keycaps, rubber caps and circuit boards. The design between the rubber caps and the circuit boards can effectively prevent liquid from entering. However, this waterproof function is mainly for a small amount of liquid splashing, rather than long-term immersion or the intrusion of a large amount of liquid.

The waterproof principle of membrane keyboards mainly depends on its structural design. When liquid splashes onto the keyboard, the liquid is usually blocked by the rubber cap and drained through the drainage hole, thus protecting the circuit board from damage.

What lasts longer, membrane or mechanical?

Mechanical keyboards are usually more durable than membrane keyboards.

1. Durability comparison

- Mechanical keyboard: Each key of a mechanical keyboard has an independent switch, and this structure makes the durability of the mechanical keyboard very high. The service life of a mechanical keyboard is usually between 5-10 years, which is suitable for high-frequency use.

- Membrane keyboard: The membrane keyboard generates signals through the electrodes on the membrane trigger circuit. Its structure is relatively simple and the key life is short, generally around 5 million times. After long-term use, some keys may not work properly.

2. Usage scenarios and advantages and disadvantages

- Mechanical keyboard: Suitable for scenarios that require high-frequency typing or gaming, because its key feel is strong, the feedback is obvious, and it can provide a better user experience. The disadvantages of mechanical keyboards are that they are expensive, heavy, and inconvenient to carry.

- Membrane keyboard: Suitable for users who need lightness and affordable price. Because of its light weight, easy to carry, and low noise, it is suitable for use in a quiet office environment. The disadvantage of membrane keyboard is that it has a short service life and the feel may decrease after long-term use.

What are the pros and cons of membrane keyboards?

The advantages of membrane keyboards include:

- Cheap price: The price of membrane keyboards is generally low, cost-effective, and suitable for mass production.

- Portability: Membrane keyboards are small in size, thin in thickness, light in weight, and easy to carry.

- Durability: Membrane keyboards are made of materials such as silicone and rubber, which are resistant to oil and stains, acid and alkali, and shock, and are suitable for use in various environments.

- Waterproof and dustproof: The sealed structure of the membrane keyboard makes it waterproof and dustproof, suitable for use in various environments.

- Silent: The membrane keyboard does not make a loud sound when typing, which is suitable for an environment that needs to be kept quiet.

The disadvantages of membrane keyboards include:

- Short service life: Since there are no separate moving parts, the service life of the membrane keyboard is relatively short, and the commonly used keys are easily worn out, resulting in failure.

- Low tactile feedback: membrane keyboards lack mechanical devices, low tactile feedback, and error-free and blind typing are more difficult.

- Wear of keycaps: membrane keyboards usually use ABS materials for keycaps, which are easy to be oily and shiny after long-term use, affecting the appearance and feel of use.

- Insufficient personalization: membrane keyboards are mostly produced by assembly lines, suitable for mass production, but not suitable for high-end customization, and personalized options are limited.

In short, the service life of membrane key switches is affected by many factors such as material quality, design structure, use environment and manufacturing process, usually ranging from tens of thousands to hundreds of thousands of times. Proper use of membrane key switches, including avoiding excessive pressure, preventing harsh environments, regular cleaning, and avoiding long-term pressing, can effectively extend their service life.

As a company specializing in the manufacture of membrane key switches, Yu An Electronics has always been committed to providing high-quality membrane key switch products. Strictly control every link to ensure that our membrane key switches have excellent performance and long service life.

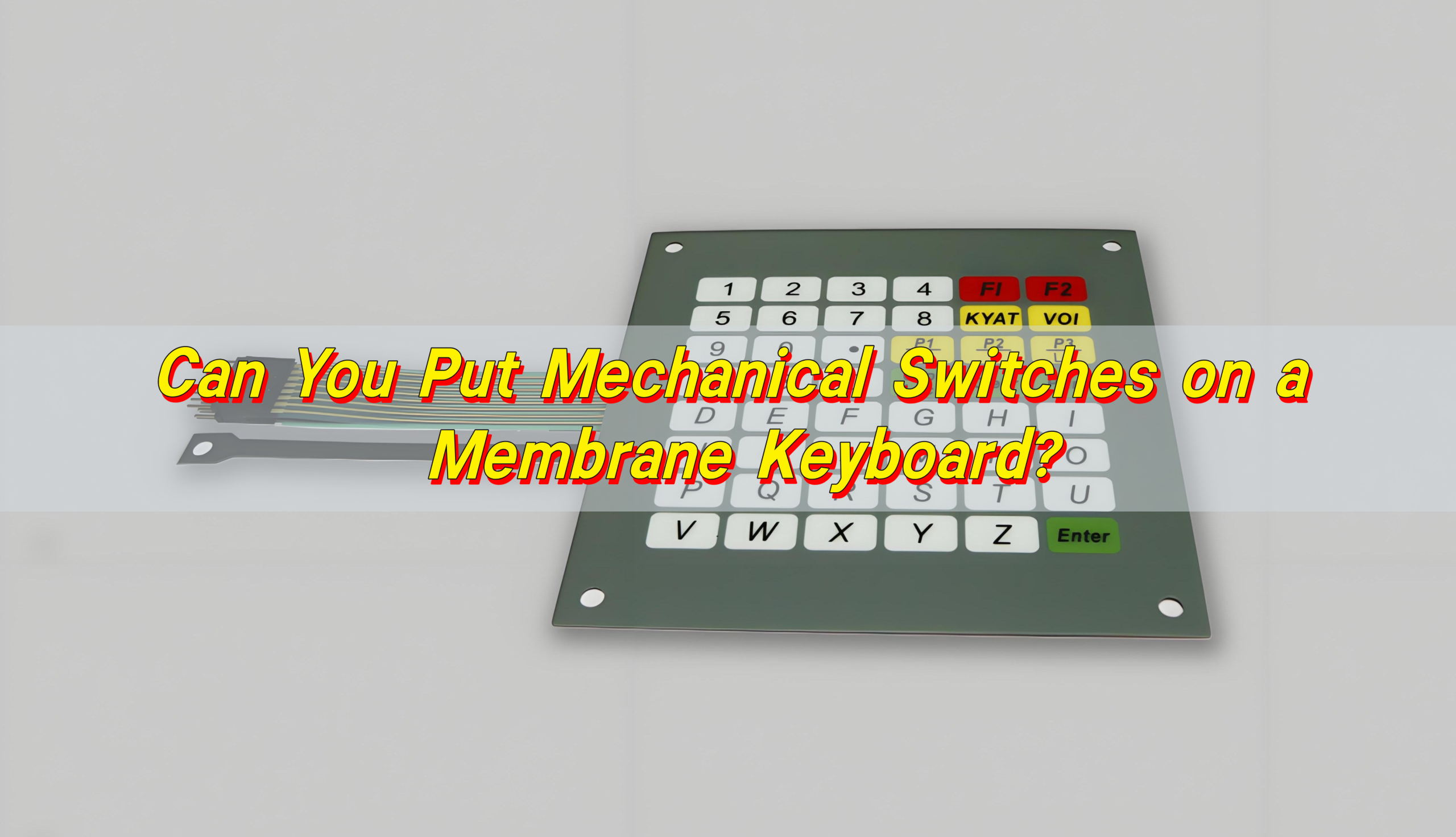

Can You Put Mechanical Switches on a Membrane Keyboard?

No, you can’t. Mechanical switches and membrane keyboards use completely different structures. Membrane boards rely on pressure pads, while mechanical ones use physical switch mechanisms. They’re not compatible. But there are still ways to improve the feel and sound of a membrane keyboard without full mechanical parts. What are membrane switches keyboard? Membrane switch keyboards ...

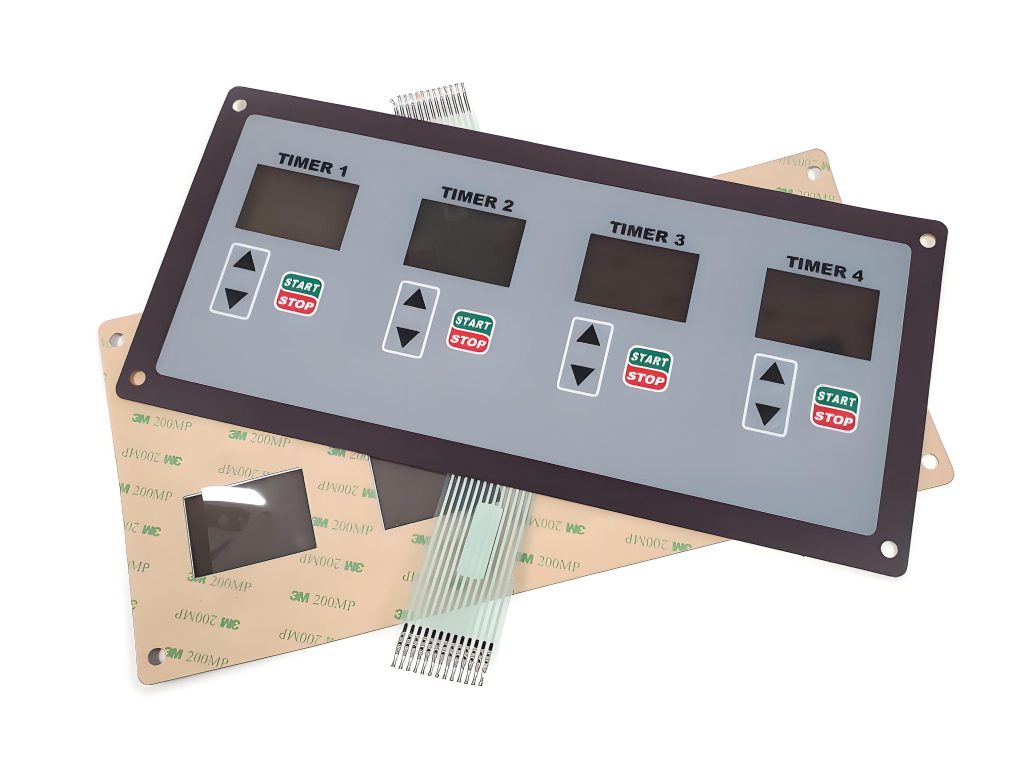

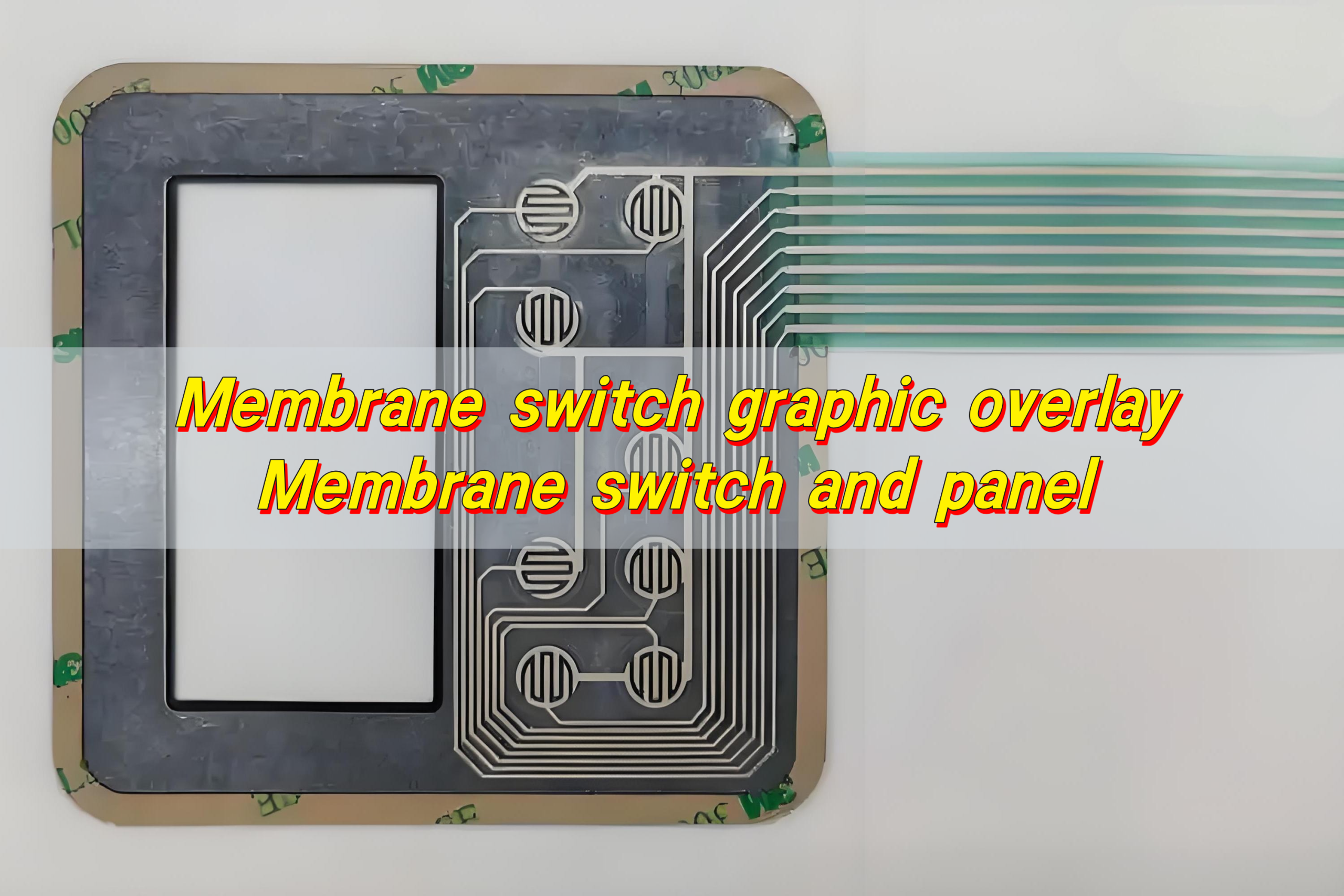

Membrane switch graphic overlay, Membrane switch and panel

Membrane switch graphic overlay is an outer film printed with button logos and patterns, usually made of PET or PC, which protects the internal circuit and provides an operating interface. It is closely integrated with the membrane switch panel, which is a multi-layer film structure containing a conductive layer and an insulating layer to achieve ...

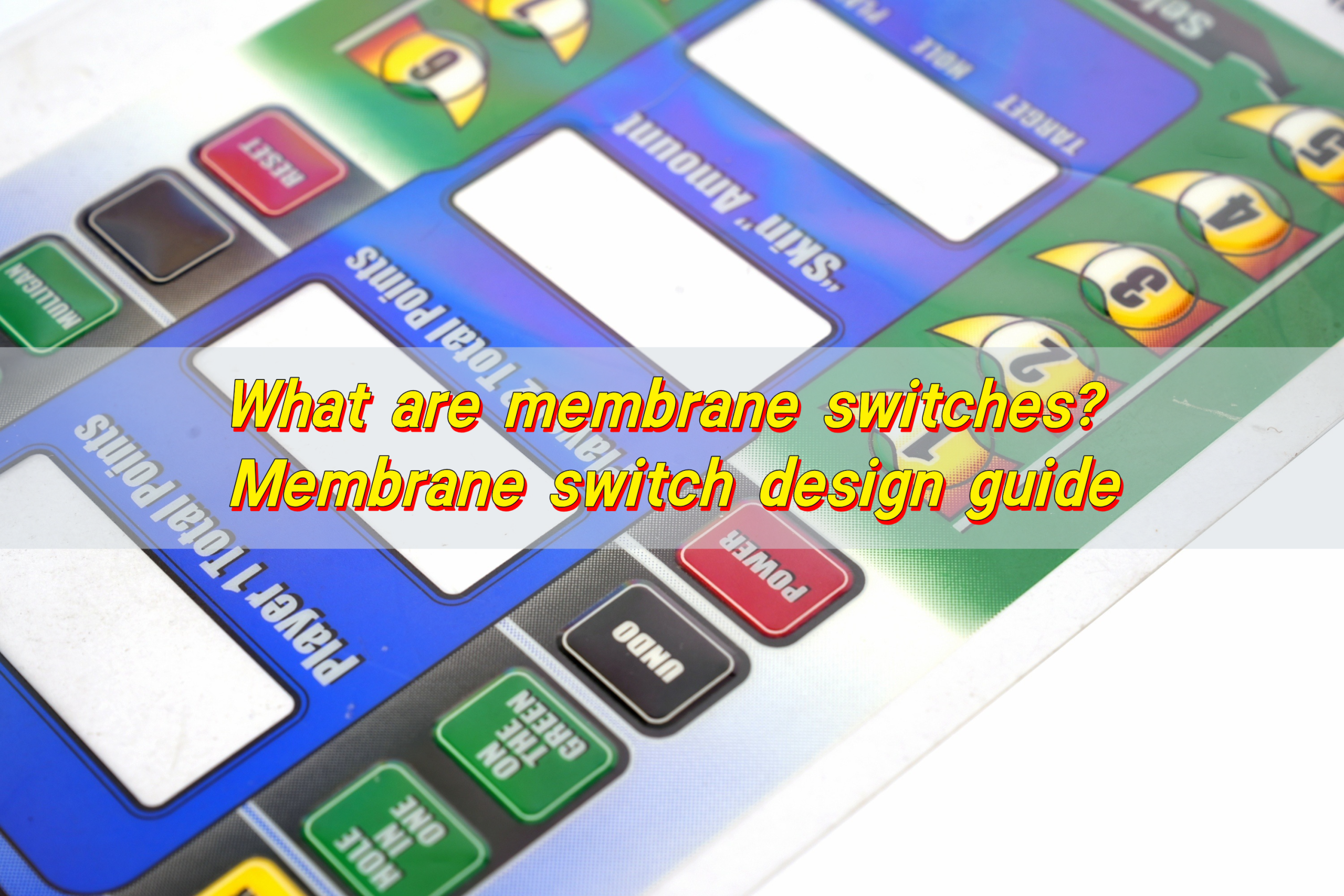

What are membrane switches? Membrane switch design guide

Membrane switches are thin, flexible interfaces that activate a circuit when pressed. Built from multiple flat layers, they offer a clean look, strong durability, and precise control. Commonly used in medical devices, industrial panels, and consumer electronics, they’re known for being reliable, customizable, and space-saving. What is membrane switch design? Membrane switch design is the ...

Contact us online