How to repair a membrane switch?

How to repair a membrane switch?

How to repair a membrane switch? To repair a membrane switch, you can first determine the type of fault, and judge it by observation, touch and multimeter detection. Then disassemble the membrane switch, check and determine the specific fault location and cause, and then repair it, such as repairing the conductive layer with conductive ink, repairing the isolation layer with insulating tape, and repairing the panel layer with double-sided tape. Finally, install and test the repair effect, and pay attention to daily maintenance.

What are the parts of a membrane switch?

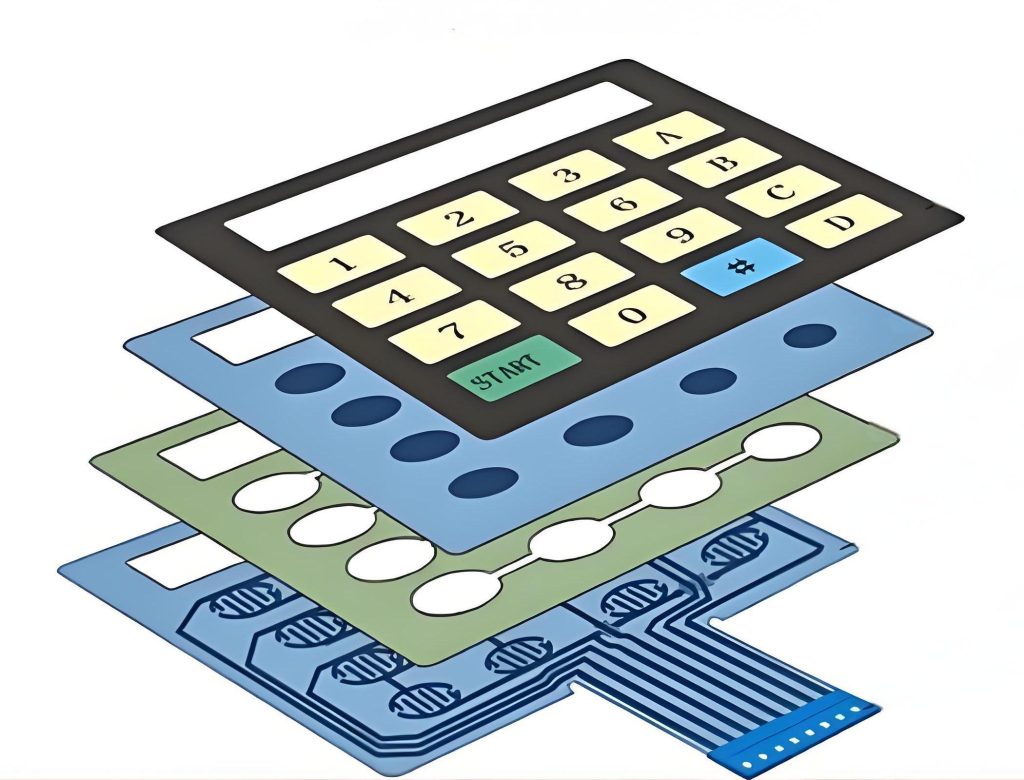

The membrane switch is mainly composed of the following parts:

- Panel: The panel is the “outer coat” of the membrane switch, which plays a decorative role through different colors, patterns and button shapes. The main materials of the panel include polycarbonate PC and polyester PET, which have high transparency, high ink adhesion, high elasticity and anti-folding characteristics.

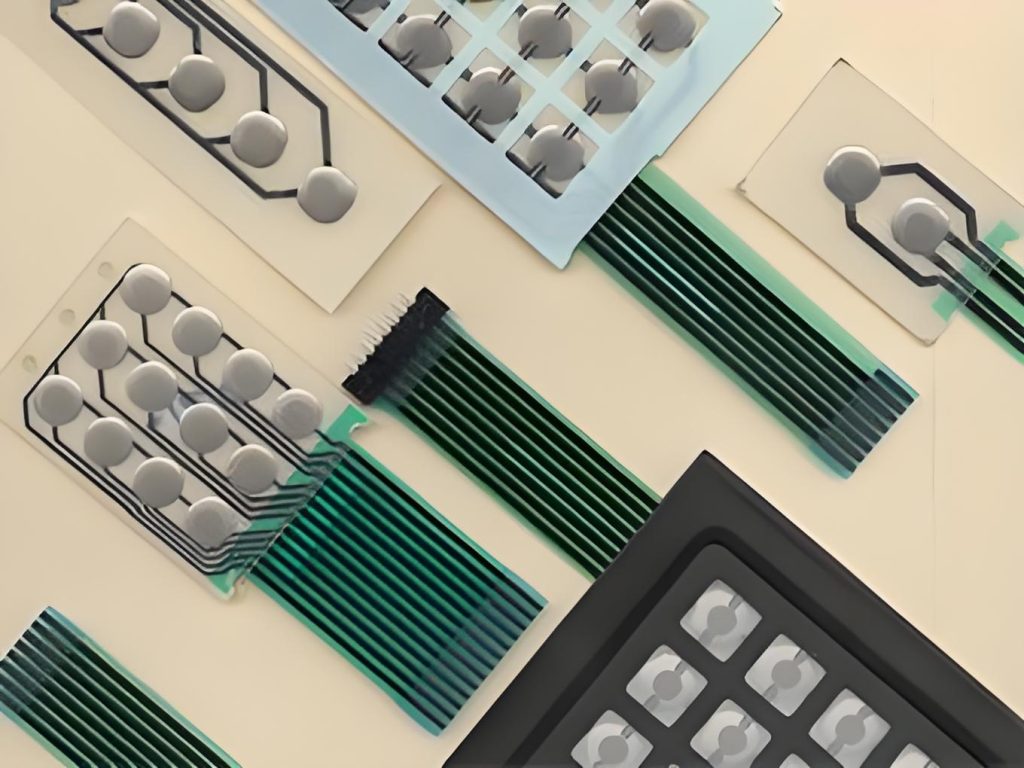

- Upper circuit: The upper circuit is one of the electrical components of the membrane switch, usually printed on the panel. The contacts of the upper circuit are deformed when pressed, and contact with the lower circuit for conduction. After release, the contacts rebound and disconnect the circuit.

- Isolation layer: The isolation layer is located between the upper circuit and the lower circuit, which plays an insulating and fixing role to prevent the upper and lower circuits from directly contacting each other and causing a short circuit.

- Lower circuit: The lower circuit is also an electrical component of the membrane switch, and cooperates with the upper circuit to complete the conduction and disconnection of the circuit.

Surface adhesive, isolation layer, bottom adhesive: These double-sided adhesive materials are used to fix and protect various components to ensure the structural stability and smooth operation of the membrane switch.

Working principle of membrane switch: When the membrane switch is pressed, the contact of the upper circuit deforms and contacts the plate of the lower circuit to conduct the circuit; after the finger is released, the contact rebounds and the circuit is disconnected. This structure makes the membrane switch have a reliable switching function.

How do you clean membrane switches?

- Clean the appearance of the membrane switch: First, you need to clean the appearance of the membrane switch. You can use a damp cloth to wipe it gently. Be careful not to use detergents containing chemicals to avoid damaging the surface.

- Remove the bottom centrifugal paper: Peel off the centrifugal paper at the bottom of the membrane switch from the edge by about 10mm, then stick it to the corresponding position, and slowly tear off the remaining centrifugal paper to ensure a tight fit.

- Avoid repeated operations: During the posting process, if you need to tear off the membrane switch that does not match the centrifugal paper, you should put it aside first to avoid sticking to other objects and affecting the posting effect.

Precautions for cleaning membrane switches

- Power-off operation: Before any cleaning operation, be sure to disconnect the power supply to prevent electric shock.

- Use appropriate detergents: Avoid using detergents containing chemicals to avoid damaging the surface.

- Gentle operation: During the posting process, avoid repeated operations, paste at one time, avoid tearing at too large an angle, and press it flat on the table when trying to press it, and avoid holding it in your hand and pressing it in the air.

How to repair a membrane switch?

The methods for repairing membrane switches mainly include the following:

- Replace the membrane switch: If the membrane switch fails due to external impact or long-term use, you need to replace it with a membrane switch of the same specification and model.

- Clean the membrane switch: If there is dirt or other substances on the surface of the membrane switch, you can use alcohol or diluted detergent to clean it.

- Remove static electricity: When electronic equipment is in an environment with static interference, the membrane switch may fail. At this time, you need to use anti-static gloves or tools to remove static electricity to restore the normal operation of the membrane switch.

- Calibrate the membrane switch: If the key distance of the membrane switch changes or the keyboard steel plate is deformed, the membrane switch may become less usable. Calibration can be used to adjust the usability and key position of the switch2.

Where are membrane switches used?

Membrane switches are widely used in many fields, including electronic communications, industrial control, medical equipment, automotive industry, smart toys, home appliances, etc.

- Electronic communications: Membrane switches are used in these fields to control various functions and provide stable and reliable switching operations.

- Industrial control: In industrial automation equipment, membrane switches are used to control the start and stop of various machines and equipment.

- Medical equipment: In medical equipment, membrane switches are used to operate various medical instruments to ensure the accuracy and safety of operation.

- Automotive industry: In automobiles, membrane switches are used to control audio, air conditioning and other equipment to provide a convenient operating experience.

- Smart toys: In these fields, membrane switches are used to control various functions of toys and home appliances.

How long do membrane switches last?

The service life of membrane switches is usually more than 1 million times. The life of a membrane switch depends mainly on its material quality, design rationality and manufacturing process level. High-quality materials, reasonable design and exquisite manufacturing process can significantly extend its service life.

Factors affecting the life of a membrane switch

- Material quality: The material quality of a membrane switch is one of the key factors that determine its life. High-quality substrate materials can provide good elasticity and durability, and the conductivity and corrosion resistance of conductive materials also directly affect the reliability and life of the switch.

- Design rationality: Design rationality includes key structure design, sealing design and layout design. Reasonable key structure design can reduce the possibility of mechanical wear and failure, sealing design prevents external contaminants from invading, and layout design reduces misoperation, all of which can extend the life of the switch.

- Manufacturing process level: The manufacturing process level is also an important factor affecting the life of a membrane switch. A high level of manufacturing process can ensure the accuracy and consistency of the switch and reduce defects and hidden dangers in the production process.

What is the advantage of membrane switch?

The advantages of membrane switches mainly include the following aspects:

- Long service life: The service life of a membrane switch can generally reach more than three years, and even in some cases more than fifty years.

- Good high temperature resistance: Since the film is a transparent material, it will not deform due to excessive temperature, thus extending the service life of the product.

- Strong wear resistance: The switching action of the membrane switch is only realized by the vertical bounce of the elastic film, and the creep amplitude is very small, which enables the film material to withstand millions of uses without deformation.

- Good sealing: The membrane switch adopts an integral structural seal, with good waterproof, dustproof, oil-proof, and anti-harmful gas erosion characteristics, suitable for use in various harsh environments.

- Light weight and small size: The membrane switch can be arranged and combined into a membrane keyboard in design. The sealed sheet structure composed of multiple layers of film has a smaller volume, lighter weight, and improved reliability.

- Low cost: The price of some membrane switches is very low. Compared with other multi-functional electronic products, the price advantage of membrane switches is very obvious.

- Excellent conductivity: The circuit of the switch can be printed with carbon paste, silver paste, copper platinum, etc. The conductive layer can be folded at will, and the resistance can be controlled at any required resistance value.

- Beautiful appearance: Modern perfect silk screen printing technology combined with perfect design can produce any desired pattern, rich colors, beautiful and generous.

In short, repairing a membrane switch requires certain skills and experience, but as long as you master the correct methods and steps, you can easily repair a membrane switch. When repairing a membrane switch, you need to pay attention to safety, operate carefully, keep it clean, and test the repair effect to ensure that the repaired membrane switch works properly.

Custom Switch Manufacturer, Membrane Switch Manufacturers

A trusted custom switch manufacturer delivers tailored membrane switches that match your product’s design, feel, and function. Whether it’s for medical, industrial, or consumer use, Yu An Electronics turn your ideas into durable, user-friendly solutions. What is a custom membrane switch? Custom membrane switch is a pressure-sensitive keypad made specifically for your product. Unlike standard ...

Custom Membrane Panel Switch, Membrane Switch Manufacturers

What is a switch panel? Switch panel is the control surface that allows someone to press, tap, or hold a button to activate a function. In older systems, this might have been a row of plastic buttons or toggles. But today, membrane switch panels have taken the lead. Unlike bulky mechanical panels, a membrane panel ...

What is a backlight membrane switch? LED membrane switch

Backlit membrane switch is a special membrane switch that realizes the backlight function by adding light guide film (LGF) into the structure of membrane switch. This light guide film can convert the point light source of LED lamp into a uniform surface light source, thus providing clear button identification and operation interface in low light ...

Contact us online