What are membrane keypads and how do they function?

What are membrane keypads and how do they function?

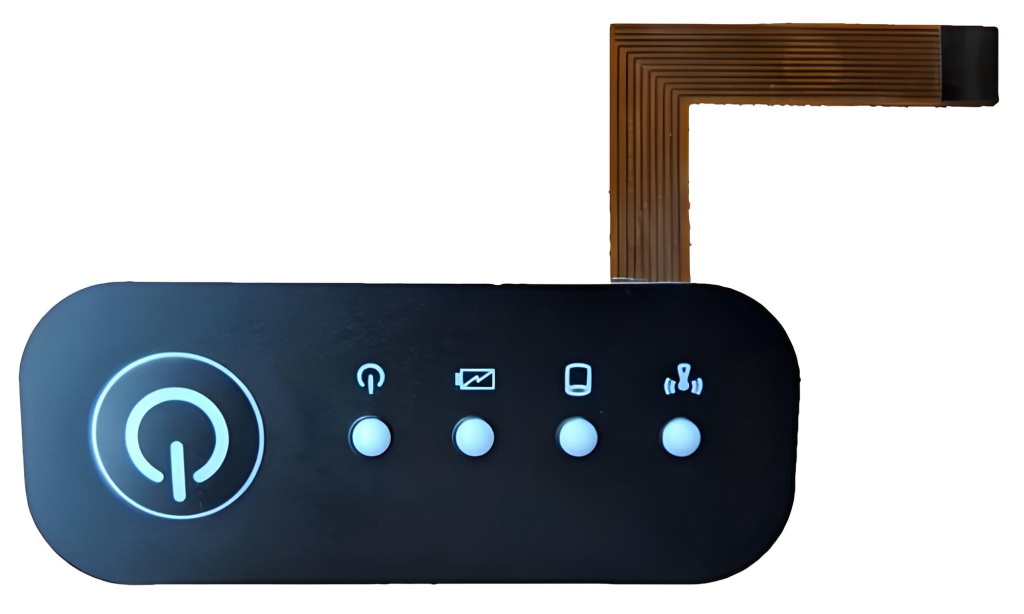

Membrane keypads are slim input interfaces built from layered plastic films with printed circuits. Instead of moving keys, they use pressure to bring conductive layers into contact, which makes them lightweight, sealed, and resistant to dust and moisture.

What is a membrane keypad?

Membrane keypad is a thin, sealed input interface used to send commands to electronic devices. It replaces bulky mechanical buttons with a flat surface that responds to pressure. When a user presses a key area, internal layers touch and close a circuit. The device then receives a signal and performs an action.

Early control panels relied on tall switches and exposed contacts. They worked, but they collected dust and moisture. They also wore out quickly in busy environments. The membrane approach solved many of these problems in one step.

Today, the membrane keypad appears in factories, hospitals, kitchens, and offices. It is quiet. It is lightweight. It is easy to clean. These features make it attractive for modern product design, where space, safety, and reliability matter.

Another reason for its popularity is flexibility. Designers can change colors, shapes, icons, and layouts without changing the main electronics.

Companies like Yu An Electronics focus on this balance between function and appearance. Our work with engineers to build reliable circuits. At the same time, our help product teams shape the surface so it feels natural to use.

It is also worth noting that a membrane keypad is not a single rigid part. It is a system made of layers. Each layer has a role, from protecting the circuit to guiding the user’s finger. Together, they form a durable interface that can survive millions of presses.

Where are membrane switch keypads commonly used?

You may not notice them, but membrane switch keypads are everywhere.

- They sit on the front panels of microwave ovens, washing machines, and coffee makers.

- They guide workers on industrial control panels.

- They appear on medical devices that demand strict hygiene.

- In factories, they control conveyors, mixers, and testing stations. Operators often wear gloves. A flat sealed surface makes cleaning easier and prevents grease from reaching the electronics.

- In healthcare, the stakes are higher. Nurses and technicians need buttons that respond every time. They also need surfaces that resist bacteria and strong cleaning chemicals.

- Consumer electronics also benefit. Remote controls, small instruments, and portable tools rely on thin keypads to save space. The design can be playful or serious. It can show icons, words, or both.

- Automotive applications use this technology too. Climate control panels and dashboard modules often include membrane layers under decorative films.

- Even in offices, printers and copiers use membrane designs. They reduce noise. They reduce failure points. They lower service costs.

The range keeps growing. Smart home devices, fitness equipment, and point-of-sale terminals all depend on similar structures. As electronics become smaller and more connected, thin input solutions gain value.

What is the basic structure of a membrane keypad?

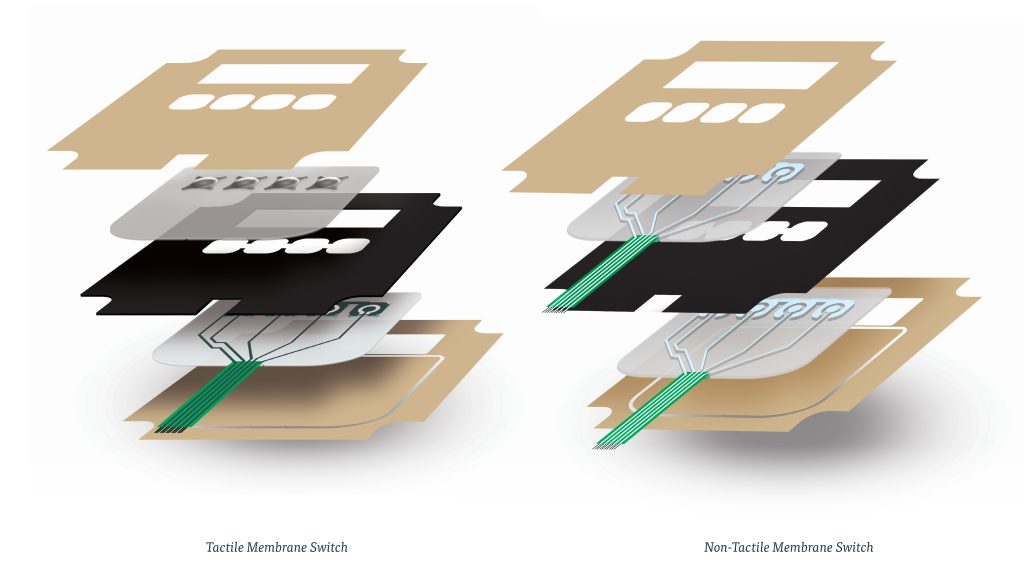

Membrane keypad looks simple from the outside. Inside, it is carefully layered. Each layer solves a specific problem. Together, they create a stable and responsive system.

- The top layer is the graphic overlay. It shows symbols, numbers, or words. It also protects the inner parts from wear. This layer is often made from polyester or polycarbonate. It must resist scratches and fading. It must also feel good under the finger.

- Below the overlay sits a spacer layer. This thin sheet has holes under each key area. These holes allow the top circuit layer to bend and touch the bottom circuit layer when pressed.

- Then come the circuit layers. They carry printed conductive traces. One layer holds rows. The other holds columns. When a key is pressed, the traces meet through the hole in the spacer. That contact closes the circuit.

- At the bottom, there is usually an adhesive layer. It bonds the keypad to the device housing. Some designs also include a rigid backing, such as aluminum or plastic, for extra support.

- Optional layers can be added. A metal dome layer gives tactile feedback. It creates a soft “click” feeling that many users prefer. A shield layer can reduce electrical noise. A waterproof layer can improve sealing for outdoor use.

Although the structure sounds complex, it follows a clear logic. Protect. Separate. Connect. Support. In the end, the structure is quiet proof of smart engineering. It hides complexity under a smooth surface.

Which factors are critical in membrane keypad design?

Good design decides whether users enjoy a product or avoid it. With membrane keypads, design goes beyond looks. It shapes comfort, accuracy, and trust.

- First comes layout. Keys must be easy to find. Important functions should stand out. Spacing matters, especially for gloved hands or fast operation.

- Next is tactile response. Some users like a soft press. Others want a clear click. Metal domes, embossed areas, or special films can change the feeling.

- Then there is durability. How many presses should the keypad survive? A home appliance may need one million. An industrial controller may need five million or more.

- Environmental resistance is another key factor. Will the product face water, oil, sunlight, or chemicals? Outdoor equipment needs UV resistance. Medical devices need strong chemical resistance.

- Graphics also play a role. Clear symbols reduce training time. High contrast colors improve visibility. Backlighting helps in dark environments.

- Electrical performance cannot be ignored. Trace width, spacing, and connector type affect signal stability. A small design mistake here can cause ghost signals or dead keys.

This is where experience matters. A skilled membrane keypad design team sees risks early. They suggest changes before production starts. That saves time and prevents expensive redesigns.

What materials are used in membrane switch keypad construction?

Materials define performance. They decide how long the keypad lasts, how it feels, and how it survives its environment.

- The graphic overlay often uses polyester. It resists scratches well. It also handles repeated pressing without cracking. Polycarbonate is another option. It is clear and strong, but it scratches more easily.

- Circuit layers use polyester films with printed silver or carbon ink traces. Silver offers low resistance. Carbon improves wear resistance at contact points.

- Spacer layers usually use polyester or adhesive films. Their thickness controls key travel.

- Adhesives matter more than many expect. Poor adhesive leads to peeling or bubbles. Industrial designs use pressure-sensitive adhesives that stay stable under heat and humidity.

- Metal domes, when used, are often stainless steel. They provide tactile feedback and long life. Different shapes change the force needed to press a key.

- For backlighting, designers add light guide films and LEDs. These materials spread light evenly across symbols. This improves visibility and gives a modern look.

- Protective coatings may cover the overlay. Anti-glare coatings reduce reflections. Hard coatings resist scratches. Anti-microbial coatings support medical use.

Manufacturers like Yu An Electronics maintain strict material standards. They test batches. They track suppliers. Consistency matters. A small change in film quality can affect millions of presses over time.

What is the correct membrane keypad HS code for export?

When products cross borders, classification matters. The HS code decides taxes, paperwork, and delivery speed. A mistake can cause delays or extra fees.

For membrane keypads, the most common classification falls under HS code 8537.10 or 8536.50, depending on design and function. Many exporters use 8537.10, which covers control panels for electric control or distribution.

However, classification can vary by country and by product details. If the keypad includes electronic control circuits, it may fall under one code. If it acts mainly as a switch component, it may fall under another.

Some customs offices classify membrane switch keypad products under 8536.50, which covers electrical switches. Others consider them part of a control panel assembly.

Experienced manufacturers often support customers with this step. We prepare documents. We suggest commonly accepted codes. This saves time and stress. Yu An Electronics assists international clients with export details. Our logistics team understands how small errors can slow projects.

What determines the cost of a custom membrane keypad?

Cost never comes from one source. It grows from many small choices.

- Design complexity is the first factor. A simple numeric pad costs less than a panel with icons, windows, and backlighting.

- Material selection follows. Polyester overlays cost more than basic films. Hard coatings and special adhesives add value and cost. Metal domes add tactile quality but also add parts.

- Size and shape influence price. Larger panels use more material. Unusual shapes waste more film during cutting.

- Print quality also matters. Multiple colors, fine lines, and gradients require better printing processes.

- Quantity changes everything. High volumes spread tooling costs. Small batches carry higher unit prices.

- Testing requirements add another layer. Some clients ask for life cycle tests, chemical resistance tests, or temperature tests.

- Packaging and shipping also play a role. Protective packaging prevents damage but increases cost slightly.

Reliable membrane keypad manufacturer explains these factors clearly. Transparency builds trust. It also helps customers make smart trade-offs.

How do you select a reliable membrane keypad manufacturer?

Choosing a partner is as important as choosing a design. The right supplier supports growth. The wrong one creates delays and stress.

- Start with experience. Years in the field matter. They show stability and learning. A company that has seen many projects handles surprises better.

- Next, check technical capability. Ask about design support, prototyping, and testing. A good manufacturer offers guidance, not just production.

- Quality systems also matter. Certifications like ISO indicate structured processes. They reduce risk.

- Communication style reveals much. Fast, clear replies show respect for your project.

- Look at their client base. Diverse industries suggest flexible skills. Medical, industrial, and consumer projects require different standards.

- Ask about materials and suppliers. Stable supply chains protect schedules.

- Visit the factory if possible. Seeing production lines builds confidence.

Yu An Electronics has built its reputation through steady quality and open communication. We invest in testing equipment. We train engineers to work closely with customers. We value long-term cooperation more than quick sales.

Conclusion:

Membrane keypads offer a thin, reliable way to connect people and machines. They appear in homes, factories, hospitals, and vehicles. Their layered structure supports durability and flexible design. Careful material choices and thoughtful design shape performance and user comfort.

For project inquiries or technical discussion, contact: sales@best-membraneswitch.com

Backlit Membrane Switches – High-Quality Backlit Keypads

We provide reliable backlit membrane switches with long service life, stable backlight, and customizable design to fit your device control panel. What are backlit membrane switches? Backlit membrane switches are low-profile control interfaces that combine printed circuitry with integrated lighting. They allow users to see and operate equipment in low-light or dark environments. A backlit ...

Membrane Switch with LED, Customized LED Membrane Switches

Our LED membrane switches provide bright, even backlighting, long lifespan and reliable performance for control panels in dark environments. What are LED membrane switches? LED membrane switches are advanced user interface panels that combine a flexible membrane circuit with integrated light sources. The structure looks simple from the outside. Inside, it is a layered system ...

Click Touch Membrane Switch, Premium Membrane Switch with Tactile Click Response

Our click touch membrane switch provides clear tactile click response, stable performance and long service life, ideal for control panels requiring obvious touch feedback. What is a click touch membrane switch? A click touch membrane switch is a pressure-activated interface designed to deliver a clear, physical response each time a key is pressed. Unlike flat ...

Contact us online