Membrane switch panel manufacturer, Custom membrane switch panel

Membrane switch panel manufacturer, Custom membrane switch panel

What Is a Membrane Panel Switch?

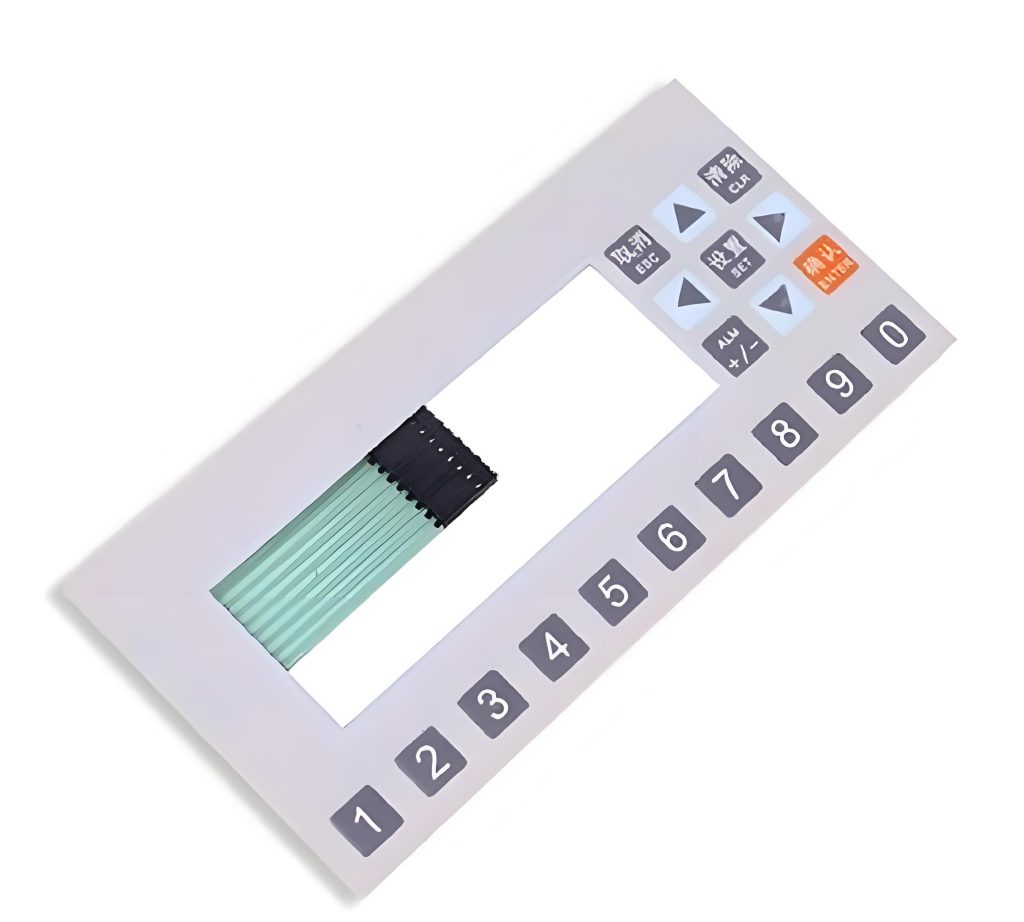

Membrane switch panel is a type of electrical switch used to turn a circuit on and off. Unlike mechanical switches that rely on moving parts, membrane switches consist of flexible layers that respond to touch. Each press connects conductive traces beneath the surface, sending a signal to the circuit below.

The structure looks simple from the outside — a flat, printed surface with labeled buttons. But beneath that layer lies a carefully engineered system of films, adhesives, and circuitry. The entire assembly is sealed, providing excellent resistance to dust, moisture, and chemicals.

That’s why membrane switch panels are often used in environments where reliability matters more than tactile feel — like medical monitoring devices, industrial control panels, and outdoor electronics.

What Are Membrane Switches Mainly Made Of?

A membrane switch typically consists of multiple layers, each playing a specific role in the function and feel of the switch.

- Graphic Overlay:

This is the top layer — what the user sees and touches. It’s usually made from polyester or polycarbonate films, printed with labels, colors, and symbols. It provides both protection and aesthetic design.

- Adhesive Spacer:

Below the overlay, the adhesive spacer separates the upper and lower circuits. It allows the top layer to flex when pressed and return to its original shape afterward.

- Circuit Layer:

This layer carries the printed conductive traces, often made using silver or carbon ink on a polyester substrate. For high-end designs, FPC membrane switches use flexible printed circuits to handle complex layouts or tight spaces.

- Backer or Support Layer:

The back layer provides structural support and sometimes includes adhesive for mounting the panel onto equipment.

- Optional Layers:

Depending on the application, there might be additional layers such as LED backlighting, EMI shielding, or tactile metal domes for a crisp button response.

Each layer must align perfectly during production. A minor misalignment can affect performance or shorten lifespan, which is why manufacturing precision is critical.

What Does a Membrane Switch Do?

A membrane switch panel acts as the bridge between user and machine. When a button is pressed, it sends a signal to the device’s control board, executing a function like turning on a light, starting a motor, or adjusting settings.

Its key purpose is to simplify user interaction. Instead of bulky buttons or knobs, membrane switches provide a flat, easy-to-clean surface that responds to even gentle touches.

For instance, in a medical device, a membrane keypad might start a diagnostic cycle with a single press. In a microwave oven, it allows users to input time or temperature without needing physical dials.

How Good Are Membrane Switches?

Today, they are recognized for their excellent durability, lightweight structure, and versatility.

- One major advantage is their sealing capability. Since the surface is smooth and enclosed, dust and fluids cannot easily penetrate. This feature is crucial for medical, food-processing, or outdoor applications where hygiene and protection matter.

- Another strength is customization. Manufacturers can integrate backlighting, embossed keys, or transparent windows for display screens.

- Moreover, membrane control switch panels consume minimal power, making them ideal for battery-driven equipment. The thin, flexible profile allows them to be mounted on curved or compact surfaces where mechanical buttons would not fit.

In short, membrane switches are not just good — they’re exceptionally practical for designers aiming to combine reliability, affordability, and aesthetic appeal.

What Are the Disadvantages of Membrane Switches?

While membrane switches offer many advantages, they have some limitations. The most common concern is limited tactile feedback. Unlike mechanical keyboards where each key has a distinct click, membrane switches often feel softer.

However, this issue can be addressed through tactile domes or embossed surfaces that give a responsive “snap” when pressed. Another point is that repairing a damaged membrane panel can be difficult since it’s a sealed unit. But given their long service life and low failure rate, replacements are rarely needed.

Lastly, membrane switches might not suit heavy-duty machinery that requires high actuation force. For most electronic devices though, they deliver reliable performance with minimal drawbacks.

How Durable Is a Membrane Control Switch Panel?

Durability is where the membrane control switch panel truly stands out. These panels are engineered to withstand harsh environments, repetitive use, and extended service life.

Most high-quality panels can handle over one million actuations per key without failure. The materials used — such as polyester overlays and conductive silver inks — maintain stability even under stress, humidity, and heat.

In industries like aerospace, automotive, or industrial automation, membrane switches continue to operate flawlessly despite continuous operation. They resist corrosion, ultraviolet exposure, and cleaning agents.

Additionally, LED membrane switch panels offer illuminated feedback that enhances user visibility, especially in dim settings. The LEDs are long-lasting, low-heat, and energy-efficient, contributing to the overall longevity of the panel.

How Long Do Membrane Switches Last?

On average, a well-designed membrane switch can last anywhere between one to five million actuations, depending on materials and usage conditions. Lifespan depends on several factors:

- The type of overlay material and printing process.

- Environmental exposure, including humidity and temperature.

- The quality of adhesives and conductive inks.

- The presence of tactile domes that reduce strain on the circuit.

When properly designed and assembled, these panels maintain stable electrical performance for years. That’s why they’re widely used in mission-critical electronics, where reliability cannot be compromised.

Where Are Membrane Switches Used?

The versatility of membrane switches makes them suitable for a wide variety of industries.

- In medical technology, they’re used in monitors, analyzers, and patient care equipment, providing easy sterilization and safe operation.

- In industrial machinery, membrane panels serve as control interfaces for automation systems, sensors, and testing devices.

- In consumer electronics, such as microwave ovens, printers, and fitness equipment, they deliver intuitive operation while keeping production costs low.

- They are also common in aerospace, automotive, and military applications, where lightweight, compact, and dependable control systems are essential.

With custom membrane keypads, designers can integrate unique layouts, lighting effects, and tactile elements to match the product’s design goals.

What Is the Difference Between a Membrane Switch and a Mechanical Switch?

The primary difference between membrane switches and mechanical switches lies in their construction and tactile feel.

A mechanical switch uses moving components, springs, or levers to complete an electrical circuit. Each key press provides a noticeable click, which some users find satisfying.

On the other hand, a membrane switch relies on flexible layers that compress to make contact. The action is softer and quieter. While mechanical switches can wear out due to friction, membrane switches are sealed, reducing the risk of contamination or corrosion.

From a cost and design perspective, membrane switches are more compact, lightweight, and easier to customize. They’re also more resistant to environmental factors like moisture and dust.

Both technologies have their strengths, but membrane switches often win when space-saving, cleanliness, and long-term durability are top priorities.

Conclusion:

Membrane switch panels provide reliable and long-lasting control interfaces for countless applications. With the right materials and design, they can endure millions of actuations while maintaining visual appeal and performance.

From its layered structure to its long lifespan, the advantages of membrane switches far outweigh their limitations. They’re durable, customizable, and cost-effective, suitable for a wide range of industries.

If you’re developing new equipment or upgrading your existing interface, we can help you design a custom solution tailored to your needs. Reach out to us at sales@best-membraneswitch.com

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online