Difference between mechanical and membrane keyboards

Difference between mechanical and membrane keyboards

What is a membrane keyboard?

Membrane keyboard is a type of keypad that uses a flexible printed circuit to register key presses. Unlike traditional keyboards with individual mechanical parts under each button, membrane keypads rely on pressure to push conductive layers together. This pressure causes an electrical contact that sends the signal.

This type of design makes membrane keypads slim, lightweight, and sealed. The surface is usually flat, and it has no individual moving components under the keys. Most membrane designs use a rubber dome or silicone sheet under the graphic overlay, which adds some tactile feel.

These are commonly used in devices like microwaves, washing machines, medical instruments, and industrial machines because of their low profile and ability to resist dust, moisture, and chemicals.

They’re also more affordable in large-scale production and easy to customize with LED backlighting, printed graphics, or waterproof sealing. However, the keystroke feeling is generally softer, and feedback is less crisp than mechanical types.

What is a mechanical keyboard?

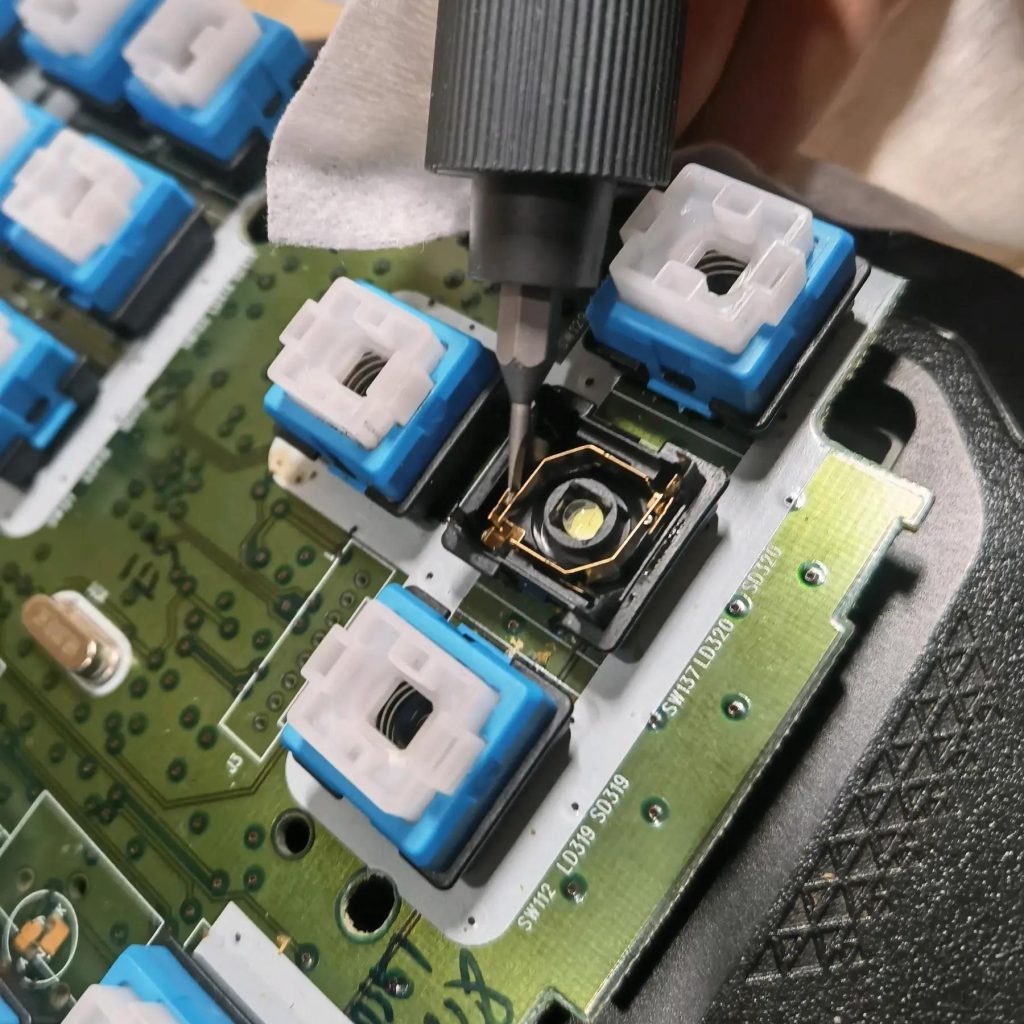

Mechanical keyboard, in this context, refers to a keypad with physical switches under each button. Each switch is made up of a housing, spring, and moving metal contact. When a button is pressed, the switch components move and register a signal through actual contact between metal parts.

These switches give a strong tactile feedback. The press feels distinct. Users can tell immediately if the input was successful. Because each key is an independent mechanism, the feedback, travel distance, and sound are more noticeable.

Mechanical keypads are widely used in high-precision applications, such as communication equipment, factory control panels, and military-grade devices. Their biggest strengths are long lifespan, clear tactile feel, and stable performance even in harsh environments.

Some common types of mechanical switches include tactile, linear, and clicky switches. Each one offers a different feel and sound. Unlike membrane designs, mechanical keyboards are more repairable, customizable, and reliable over long-term use.

What’s the difference between mechanical and membrane keyboard?

The most obvious difference is how the key press is registered.

Membrane keyboards use pressure to bring two conductive layers together through a flexible surface. Mechanical keyboards use a spring-loaded switch to send a signal.

Mechanical keypads are known for their stronger tactile feedback. They offer better user experience in terms of click feel and press accuracy. Membrane designs are quieter and more compact, but the keypress feels softer and less defined.

In terms of construction, membranes are made with thin, layered materials and rubber domes, while mechanical keyboards are built with solid mechanical switches for each button. This leads to a big difference in performance and longevity.

Mechanical keyboards are more durable, more responsive, and more satisfying for repeated input. Membrane keyboards are more affordable, more resistant to external conditions, and easier to integrate into waterproof or dustproof designs.

Are mechanical keyboards better than membranes?

Mechanical keyboards offer more advantages when it comes to long-term performance. They feel more responsive, and the keys usually last much longer. They are also easier to maintain or replace key by key.

But that doesn’t mean membrane keyboards are bad. In environments where cost, size, and sealing matter more than feedback and lifespan, membrane keyboards are better. They are often the right choice for low-usage panels or devices that need simple, sealed interfaces.

So, mechanical is better for performance. Membrane is better for simplicity. Each has a different focus.

Does a membrane last longer than mechanical?

No. Mechanical switches usually last much longer than membrane types. A mechanical key can survive 30 to 50 million presses, sometimes even more. Membrane keyboards, especially with rubber domes, usually reach around 1 to 10 million presses.

This means if your device will be used heavily every day, mechanical switches are the better long-term solution. They hold up better under pressure and keep their feel even after years of use.

Membrane switches are still durable in many cases. For light or moderate use, they may last long enough. But for continuous or industrial operation, mechanical switches clearly last longer.

What is the disadvantage of a membrane keyboard?

Membrane keyboards have several disadvantages compared to mechanical ones.

First, the feedback is weaker. The press feels softer, and sometimes users can’t tell if the key actually registered.

Second, the lifespan is shorter. The flexible material wears out faster, especially if used often. The rubber domes also lose elasticity over time, which causes keys to feel uneven.

Third, membranes are less responsive. There’s a slight delay between pressing the key and the circuit registering it. In some situations, this delay can affect performance.

Finally, once a membrane switch is damaged, it’s hard to repair. You usually have to replace the entire layer or keypad, rather than a single switch.

Despite these points, membranes still have value. They’re quiet, cheap, easy to seal, and useful for basic input tasks.

What is the lifespan of a membrane keyboard?

On average, a membrane keyboard lasts 1 to 5 million actuations per key. This can vary based on material quality, usage intensity, and environment.

Rubber dome types tend to break down sooner, especially if pressed with strong force or used in hot and humid conditions. Over time, the domes can crack or lose their bounce. The adhesive layers may also weaken.

That said, high-quality membrane keyboards that are used gently in controlled settings can last longer. Some custom-made designs reach up to 10 million presses, but that’s rare.

Compared to mechanical types, this is a much shorter lifespan. Mechanical switches, even budget ones, often survive ten times more presses.

What is the difference between membrane rubber dome and mechanical keyboards?

Rubber dome keypads are a form of membrane keyboards. They consist of a layer of silicone rubber with a metal dome underneath each critical area. When pressed, the dome collapses and pushes a conductive contact to close the circuit.

This adds a light tactile feel and makes the press more responsive than pure flat membrane sheets. Still, it’s softer and less defined than a mechanical click.

Mechanical keyboards use real switches. Each key has its own mechanical components and springs. The press feels crisp, the bounce is strong, and the signal is faster.

Here’s a comparison:

- Rubber dome: Soft, quiet, sealed, cheap, low travel, average lifespan

- Mechanical switch: Firm, loud or tactile, longer travel, more expensive, higher durability

Rubber domes are good when low noise and basic input are needed. Mechanical switches are better for critical systems and high-usage environments.

Conclusion:

The difference between mechanical and membrane keyboards lies in their construction, performance, and durability. Membrane keypads are compact, cost-effective, and good for sealed applications. Mechanical keypads are more tactile, longer-lasting, and suited for heavy-duty tasks.

When deciding between them, think about what your users need. Consider cost, feedback, environment, and expected use. The right choice depends on the situation.

If you’re unsure which type fits your project, we’re here to help. We specialize in both membrane rubber domes and mechanical dome arrays. Contact us at sales@best-membraneswitch.com

Capacitive Touch Switch – Reliable for Smart Device Control

Need professional capacitive touch switch solutions? We provide durable, customizable touch switches for all electronic control panels with stable performance. What is capacitive switching? Capacitive switching is a control method based on the electrical behavior of the human body. When a finger approaches or touches a sensing area, it changes the local electric field. The ...

Mechanical keyboard vs membrane: What’s the Difference?

When engineers and product teams compare mechanical keyboard vs membrane, they are usually deciding how users will interact with a device through a group of buttons. This decision affects reliability, feel, service life, sealing, and long-term maintenance. In industrial electronics, medical equipment, and embedded systems, the choice between a membrane keyboard and a mechanical keyboard ...

Silicone Rubber Keypad Manufacturer, Custom Membrane Switches

What is a silicone rubber keypad? Silicone rubber keypad is a flexible input component made from molded silicone elastomer. It allows users to press keys to send commands to an electronic device. Each key is formed as part of a single rubber sheet or pad. When pressed, the key makes contact with a circuit below ...

Contact us online